Bolt Thread Selection Guide

Updated : Aug. 21, 2025Titanium Bolt Threads Guide

In today's global supply chain, choosing the right titanium bolt thread size and type is critical to ensuring interchangeability and long-term reliability.

We help you quickly identify the right titanium bolt threads in both metric (ISO) and imperial (UTS) standards to boost assembly efficiency and reduce maintenance costs.

Importance of Bolt Threads

Threads are the defining feature of a fastener. Their dimensions and quality directly determine how well a bolt and nut fit, how forces are distributed, and how reliable the connection will be.

- Standardized threads let bolts and nuts from different manufacturers fit perfectly, preventing assembly failures.

- Precise thread angles and pitches spread the load evenly along the flanks, reducing localized stress and fatigue.

- High-quality thread engagement forms a tighter seal, cutting leakage risk and improving vibration resistance with lock washers or thread-locking compounds.

- Accurate threads reduce assembly resistance, minimize torque variation, and speed up production.

- Strict tolerance control (e.g., above 6H/6g class) lowers wear and extends the fastener's service life.

Bolt Size Chart

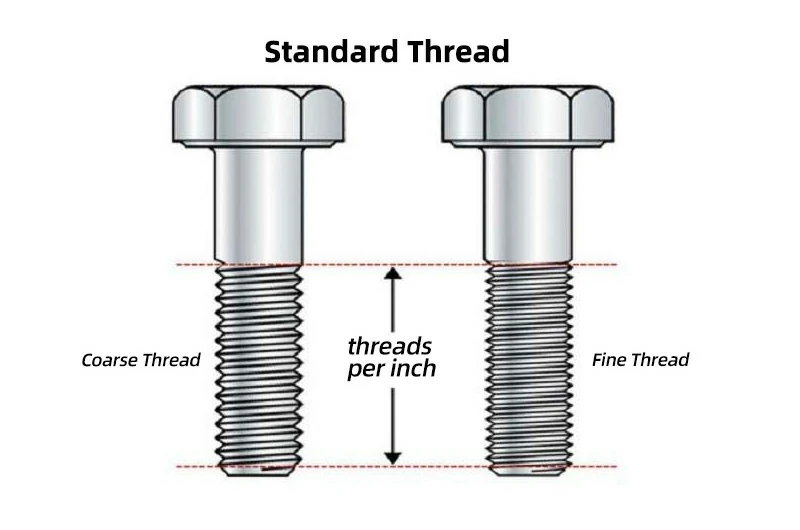

A bolt's thread is defined by its diameter and pitch, with imperial sizes expressed in threads per inch (TPI). The most common types fall into three main series.

- Coarse threads (UNC/UNRC): Strong resistance to cross-threading, durability in harsh environments, quick assembly.

- Fine threads (UNF/UNRF): Higher tensile strength, suitable for precision connections, require longer engagement.

- 8-thread series (8 UN): For large bolts ≥ 1″, meeting ASTM standards with high strength and durability.

Imperial Bolt Thread Sizes

Imperial threads (UNC/UNF) are commonly used in the North American market, especially in the oil, manufacturing, and heavy machinery industries.

| Size | Nominal (Major) | Coarse Thread (UNC) | Fine Thread (UNF) | ||||

|---|---|---|---|---|---|---|---|

| Diameter [in] | Threads Per Inch | Tensile Stress Area [in2] | Minor Area [in2] | Threads Per Inch | Tensile Stress Area [in2] | Minor Area [in2] | |

| #0 | 0.06 | - | - | - | 80 | 0.0018 | 0.0015 |

| #2 | 0.086 | 56 | 0.0037 | 0.0031 | 64 | 0.0039 | 0.0034 |

| #4 | 0.112 | 40 | 0.006 | 0.005 | 48 | 0.0066 | 0.0057 |

| #5 | 0.125 | 40 | 0.008 | 0.0067 | 44 | 0.0083 | 0.0072 |

| #6 | 0.138 | 32 | 0.0091 | 0.0075 | 40 | 0.0102 | 0.0087 |

| #8 | 0.164 | 32 | 0.014 | 0.012 | 36 | 0.0147 | 0.0129 |

| #10 | 0.19 | 24 | 0.0175 | 0.0145 | 32 | 0.02 | 0.0175 |

| 1/4" | 0.25 | 20 | 0.0318 | 0.0269 | 28 | 0.0364 | 0.0326 |

| 5/16" | 0.3125 | 18 | 0.0524 | 0.0454 | 24 | 0.058 | 0.0524 |

| 3/8" | 0.375 | 16 | 0.0775 | 0.0678 | 24 | 0.0878 | 0.0809 |

| 7/16" | 0.4375 | 14 | 0.1063 | 0.0933 | 20 | 0.1187 | 0.109 |

| 1/2" | 0.5 | 13 | 0.1419 | 0.1257 | 20 | 0.1599 | 0.1486 |

| 9/16" | 0.5625 | 12 | 0.182 | 0.162 | 18 | 0.203 | 0.189 |

| 5/8" | 0.625 | 11 | 0.226 | 0.202 | 18 | 0.256 | 0.24 |

| 3/4" | 0.75 | 10 | 0.334 | 0.302 | 16 | 0.373 | 0.351 |

| 7/8" | 0.875 | 9 | 0.462 | 0.419 | 14 | 0.509 | 0.48 |

| 1" | 1 | 8 | 0.606 | 0.551 | 12 | 0.663 | 0.625 |

| 1-1/8" | 1.125 | 7 | 0.763 | 0.693 | 12 | 0.856 | 0.812 |

| 1-1/4" | 1.25 | 7 | 0.969 | 0.89 | 12 | 1.073 | 1.024 |

| 1-3/8" | 1.375 | 6 | 1.155 | 1.054 | 12 | 1.315 | 1.26 |

| 1-1/2" | 1.5 | 6 | 1.405 | 1.294 | 12 | 1.581 | 1.521 |

| 1-3/4" | 1.75 | 5 | 1.9 | 1.74 | - | - | - |

| 2" | 2 | 4.5 | 2.5 | 2.3 | - | - | - |

Metric Bolt Thread Sizes

Both coarse and fine thread dimensions follow the ASME B1.13M standard. According to ASME B1.13M, coarse threads should be used as the first choice whenever possible. Quick Quote

| Nominal (Major) | Coarse Pitch | Fine Pitch | ||||

|---|---|---|---|---|---|---|

| Diameter [mm] | Pitch | Tensile Stress | Minor | Pitch | Tensile Stress | Minor |

| [mm] | Area [mm2] | Area [mm2] | [mm] | Area [mm2] | Area [mm2] | |

| 1.6 | 0.35 | 1.27 | 1.076 | - | - | - |

| 2 | 0.4 | 2.073 | 1.789 | - | - | - |

| 2.5 | 0.45 | 3.391 | 2.98 | - | - | - |

| 3 | 0.5 | 5.031 | 4.473 | - | - | - |

| 3.5 | 0.6 | 6.775 | 6 | - | - | - |

| 4 | 0.7 | 8.779 | 7.75 | - | - | - |

| 5 | 0.8 | 14.18 | 12.68 | - | - | - |

| 6 | 1 | 20.12 | 17.89 | - | - | - |

| 8 | 1.25 | 36.61 | 32.84 | 1 | 39.17 | 36.03 |

| 10 | 1.5 | 57.99 | 52.29 | 1.25 | 61.2 | 56.3 |

| 12 | 1.75 | 84.27 | 76.25 | 1.25 | 92.07 | 86.04 |

| 14 | 2 | 115.4 | 104.7 | 1.5 | 124.5 | 116.1 |

| 16 | 2 | 156.7 | 144.1 | 1.5 | 167.2 | 157.5 |

| 20 | 2.5 | 244.8 | 225.2 | 1.5 | 271.5 | 259 |

| 24 | 3 | 352.5 | 324.3 | 2 | 384.4 | 364.6 |

| 30 | 3.5 | 560.6 | 519 | 2 | 621.2 | 596 |

| 36 | 4 | 816.7 | 759.3 | 2 | 914.5 | 883.8 |

| 42 | 4.5 | 1121 | 1045 | 2 | 1264 | 1228 |

| 48 | 5 | 1473 | 1377 | 2 | 1671 | 1629 |

| 56 | 5.5 | 2030 | 1905 | 2 | 2301 | 2252 |

| 64 | 6 | 2676 | 2520 | 2 | 3031 | 2975 |

| 72 | 6 | 3460 | 3282 | 2 | 3862 | 3799 |

| 80 | 6 | 4344 | 4144 | 1.5 | 4851 | 4798 |

| 90 | 6 | 5591 | 5364 | 2 | 6099 | 6020 |

| 100 | 6 | 6995 | 6740 | 2 | 7562 | 7473 |

| 110 | - | - | - | 2 | 9182 | 9084 |

Characteristics of Different Thread Pitches

Coarse threads (UNC/UNRC)

- Large pitch with greater travel per turn, ideal for heavy loads and fast assembly.

- Excellent resistance to damage and stripping, suitable for high-vibration or dirty environments.

- Lower risk of seizing, ensuring smoother tightening.

Fine threads (UNF/UNRF)

- Small pitch with shorter travel per turn, allowing precise adjustments.

- Deeper thread roots with a larger tensile stress area for higher tensile strength.

- Strong resistance to loosening under vibration, making them suitable for dynamic conditions.

- Require longer engagement length and have a slightly higher risk of seizing.

Special threads

- Round root threads (UNRC/UNRF) are compatible with standard coarse and fine threads, effectively reducing stress concentration.

- Enhanced root threads (UNJ) have a larger root radius, designed for high-reliability applications such as aerospace, and must be paired with internal J-nuts.

Understanding thread tolerances and classes

Thread tolerance defines the allowable variation in thread dimensions, including diameter and pitch.

The wider the tolerance range, the greater the difference between the actual and theoretical dimensions; the tighter the tolerance, the stricter the machining requirements.

Three-class system (Classes 1–3)

- Class 1 – Widest tolerance range.

- Class 2 – Standard recommendation for most general applications.

- Class 3 – Highest precision for fine, high-accuracy fits.

Letter designation for internal and external threads

- A – External threads (bolt, screw, stud), written as 1A, 2A, 3A.

- B – Internal threads (nut, threaded hole), written as 1B, 2B, 3B.

Characteristics of each class

- 1A/1B – Widest tolerance, smoothest assembly, ideal for quick assembly and disassembly.

- 2A/2B – Excellent interchangeability with a balance of accuracy and ease of assembly; industry standard.

- 3A/3B – Tightest tolerance, closest fit, for high-precision, zero-clearance applications.

How to ensure the correct thread pitch

Several factors must be considered when selecting the right thread pitch for your application.

Understand pitch systems

Metric and imperial screws both use pitch as a defining feature. Metric pitch is measured in millimeters, while imperial thread pitch is expressed in threads per inch (TPI).

The two can be approximately converted based on 2.54 cm per inch. However, mixing metric and imperial measurements in specifications can cause part mismatches.

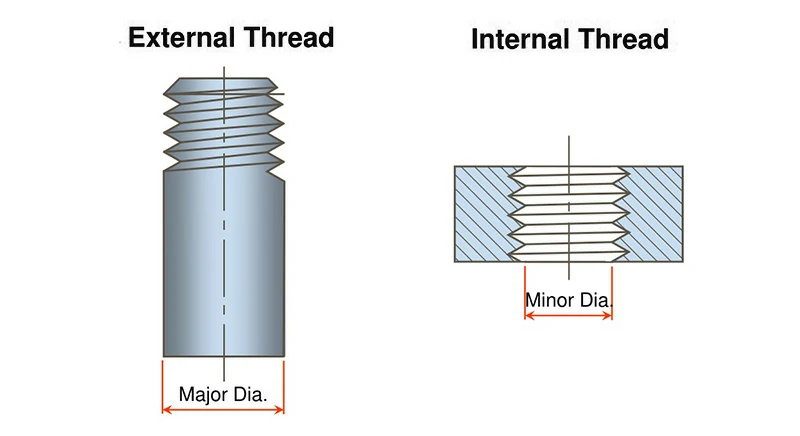

Differentiate external and internal threads

- External threads are found on screws and bolts, while internal threads are inside nuts or tapped holes.

- Matching the pitch between internal and external parts is essential for smooth installation and secure fit.

Measure and calculate pitch

- Use a ruler, caliper, or dedicated thread pitch gauge to measure the distance between thread peaks.

- A pitch gauge offers the most reliable and precise comparison.

- Pitch can also be calculated with the formula P = L / n, where P is the pitch, L is the thread length, and n is the number of threads.

Select the right pitch

- Decide whether you need standard, fine, or custom pitch.

- Standard pitch is typically the default, so if your requirement differs, specify it clearly.

- We also offer custom pitch production to meet specialized needs.

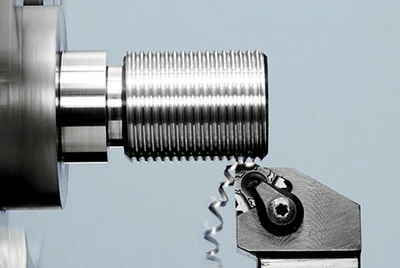

Machined Threads vs. Rolled Threads

| Feature | Machined threads (cut) | Rolled threads |

|---|---|---|

| Forming method | Material is removed with a cutting tool to create the thread profile | Cold-formed by pressing the blank between dies with the desired pitch |

| Root shape | Sharp with a small root radius | Smooth with a larger root radius |

| Material strength | Cutting may disrupt surface grain, leaving strength unchanged or slightly reduced | Cold working strengthens the surface, improving strength and fatigue resistance |

| Suitable materials | Works for both heat-treated and non-heat-treated parts; final strength depends on material properties after heat treatment | Best suited for non-heat-treated parts for maximum strength gain; heat-treated part strength depends on heat treatment conditions |

| Production cost | Uses standard lathes or milling machines; relatively high cost and slower speed | Uses dedicated thread rolling machines; high efficiency and ideal for mass production |

| Accuracy & tolerance | Capable of high precision and tight tolerances, but slower | Accuracy depends on die quality; excellent consistency in batches but limited by die precision |

We Offer One-Stop Fastener Solutions

We provide end-to-end services, from thread design and material selection to surface treatment and custom sizing.

- Full metric and imperial ranges to precisely match your project requirements

- Stock titanium grades and special alloys available

- Rolled and machined (cut) threads to meet different strength and precision needs

- Anodizing, PVD, and plating for various operating environments

- Strict inspection of thread tolerances and classes to ensure interchangeability and durability

Whether for mass production or small-batch prototypes, we deliver efficient, reliable, and fully integrated fastener solutions.

Titanium Bolts

Titanium Screws

Titanium Nuts

Titanium Washers

Titanium Threaded Rods

Titanium Rivets

Frequently Asked Questions (FAQ)

What if I know the bolt diameter but not the pitch?

Use a thread gauge or measure length L and thread count n, then calculate P = L / n.

Can metric bolts fit imperial nuts?

No, thread profiles differ and cause poor fit.

Can I order a custom pitch?

Yes, we produce custom pitches with extra lead time.

What is the MOQ and sample policy?

MOQ is 10 m. Samples in as fast as 2 weeks.

How are cables packaged and delivered?

Vacuum-sealed, sterile-packed, export-grade cartons. Standard sizes in stock, custom orders 2–4 weeks.