Stay updated on the latest trends, innovations, and practical knowledge in the titanium industry, covering application areas and technological advancements.

Complete guide to titanium eyewear. Compare Pure Titanium (Gr1-Gr4), Beta Titanium, and Memory Metal (Ni-Ti). Lightweight, hypoallergenic & sweat-proof frames.

Deciding between CP Gr2 and Ti-6Al-4V? Gr5 offers 3x higher strength (895 MPa) while Gr2 excels in corrosion resistance & forming. See full property chart.

Compare Titanium (Gr1) and Stainless Steel (SS304) exhaust systems. Analysis of 40% weight reduction, heat dissipation, and the unique metallic exhaust note.

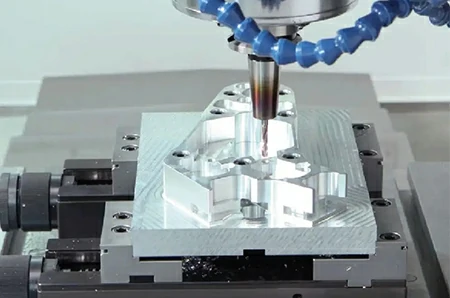

Chalcotitanium provides precision CNC machining of titanium alloys, including turning, milling, five-axis machining, and EDM, with tolerances of ±0.01 mm and Ra 0.8–1.6 μm. We offer polishing, anodizing, and electroplating, serving aerospace, medical, and energy industries.

Chalco Titanium specializes in titanium to stainless steel welding, offering 6 methods, applications, and high-performance clad solutions.

Titanium tube welding challenges, defects, and processes—covering preparation, key parameters, inspection, and ASTM B338/B862 products.

Titanium resists high-velocity seawater erosion & pitting. Learn about temperature limits (>80°C) for Crevice Corrosion and when to upgrade to Gr7 or Gr12.

Why choose Titanium over Platinum? 1/4 the weight (4.5 g/cm³) and superior hardness (Mohs 6). Discover the cost-effective choice for corrosion resistance.

Bolt torque chart—quickly look up the right tightening torque for any bolt size and grade.

Our user-friendly Thread Chart delivers comprehensive specifications for both Metric and Imperial screw sizes.

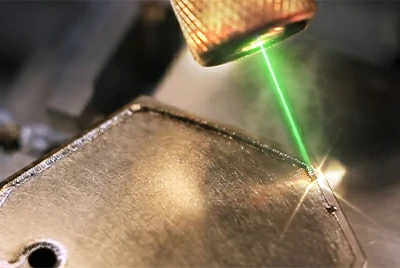

Comprehensive analysis of the key processes of laser welding titanium, from gas shielding, weld color judgment to welding mode selection, suitable for high-standard industries such as aviation, medical, and marine engineering.

Sourcing CP Ti? Check latest FOB/CIF prices ($7.8-$12.5/kg) for Plate & Sheet. ASTM B265 compliant materials for Desalination & Medical implants.