Bolt Torque Chart

Updated : Aug. 22, 2025The torque data below is provided for engineering reference only.

In actual assembly, torque-tension can be affected by many factors, such as operator technique, thread surface finish, and lubrication condition.

For the safest and most accurate torque values, perform trial tightening and verification under your actual working conditions. All final responsibility and risk rest with the user.

Metric bolt torque chart

This chart provides the recommended maximum torque values for threaded products, but it is for reference only.

| Thread Size | Torque for Standard Threads in [N m] | ||||||

|---|---|---|---|---|---|---|---|

| Bolt Grade | 3.6 | 4.6 | 5.6 | 6.8 | 8.8 | 10.9 | 12.9 |

| M2 | 0,1 | 0,13 | 0,16 | 0,26 | 0,35 | 0,49 | 0,59 |

| M2,5 | 0,2 | 0,27 | 0,34 | 0,54 | 0,72 | 1,01 | 1,21 |

| M3 | 0,35 | 0,48 | 0,60 | 0,96 | 1,28 | 1,80 | 2,16 |

| M4 | 0,81 | 1,12 | 1,39 | 2,23 | 2,97 | 4,18 | 5,02 |

| M5 | 0,6 | 2,26 | 2,83 | 4,52 | 6,03 | 8,48 | 10,18 |

| M6 | 2,8 | 3,84 | 4,80 | 7,69 | 10,25 | 14,41 | 17,29 |

| M7 | 5,13 | 6,42 | 10,27 | 13,70 | 19,25 | 23,10 | |

| M8 | 9,35 | 11,69 | 18,70 | 24,93 | 35,06 | 42,07 | |

| M10 | 18 | 23 | 37 | 49 | 70 | 83 | |

| M12 | 32 | 40 | 65 | 86 | 121 | 146 | |

| M14 | 52 | 65 | 104 | 138 | 194 | 233 | |

| M16 | 81 | 101 | 161 | 215 | 302 | 363 | |

| M18 | 112 | 139 | 222 | 296 | 417 | 500 | |

| M20 | 157 | 197 | 315 | 420 | 590 | 709 | |

| M22 | 215 | 269 | 430 | 574 | 807 | 968 | |

| M24 | 272 | 340 | 544 | 726 | 1020 | 1224 | |

| M27 | 400 | 500 | 800 | 1067 | 1500 | 1800 | |

| M30 | 542 | 677 | 1083 | 1445 | 2032 | 2438 | |

| M33 | 739 | 923 | 1477 | 1969 | 2770 | 3323 | |

| M36 | 948 | 1185 | 1896 | 2528 | 3555 | 4266 | |

| M39 | 1229 | 1536 | 2457 | 3276 | 4607 | 5529 | |

| M42 | 1519 | 1899 | 3038 | 4050 | 5696 | 6835 | |

| M45 | 1898 | 2373 | 3796 | 5062 | 7118 | 8541 | |

| M48 | 2282 | 2853 | 4565 | 6086 | 8559 | 10271 | |

| M52 | 2954 | 3692 | 5907 | 7876 | 11076 | 13292 | |

| M56 | 3672 | 4591 | 7345 | 9793 | 13772 | 16526 | |

| M60 | 4582 | 5728 | 9164 | 12219 | 17183 | 20619 | |

| M64 | 5536 | 6920 | 11071 | 14762 | 20759 | 24911 | |

| M68 | 6720 | 8400 | 13440 | 17919 | 25199 | 30239 | |

Screws made of aluminum, stainless steel, and titanium each have different performance characteristics due to their material properties.

- Aluminum screws strength grade: 5.6

- V2A stainless steel screws: 6.8

- Titanium screws: 8.8

ASTM A307

| Bolt Size | TPI | Proof Load (lbs) | Clamp Load (lbs) | Tightening Torque (ft lbs) | ||

|---|---|---|---|---|---|---|

| Galv+Waxed | Galv | Plain | ||||

| 1⁄4 | 20 | 1,053 | 790 | 2 | 4 | 3 |

| 5⁄16 | 18 | 1,735 | 1,302 | 3 | 8 | 7 |

| 3⁄8 | 16 | 2,567 | 1,925 | 6 | 15 | 12 |

| 7⁄16 | 14 | 3,521 | 2,640 | 10 | 24 | 19 |

| 1⁄2 | 13 | 4,700 | 3,525 | 15 | 37 | 29 |

| 9⁄16 | 12 | 6,028 | 4,521 | 21 | 53 | 42 |

| 5⁄8 | 11 | 7,485 | 5,614 | 29 | 73 | 58 |

| 3⁄4 | 10 | 11,062 | 8,297 | 52 | 130 | 104 |

| 7⁄8 | 9 | 15,301 | 11,476 | 84 | 209 | 167 |

| 1 | 8 | 20,071 | 15,053 | 125 | 314 | 251 |

| 1 1⁄8 | 7 | 25,271 | 18,953 | 178 | 444 | 355 |

| 1 1⁄4 | 7 | 32,093 | 24,070 | 251 | 627 | 501 |

| 1 3⁄8 | 6 | 38,254 | 28,690 | 329 | 822 | 657 |

| 1 1⁄2 | 6 | 46,534 | 34,900 | 436 | 1,091 | 873 |

| 1 3⁄4 | 5 | 62,928 | 47,196 | 688 | 1,721 | 1,377 |

| 2 | 4 1⁄2 | 82,800 | 62,100 | 1,035 | 2,588 | 2,070 |

| 2 1⁄4 | 4 1⁄2 | 107,640 | 80,730 | 1,514 | 3,784 | 3,027 |

| 2 1⁄2 | 4 | 132,480 | 99,360 | 2,070 | 5,125 | 4,140 |

| 2 3⁄4 | 4 | 163,282 | 122,461 | 2,806 | 7,016 | 5,613 |

| 3 | 4 | 197,726 | 148,295 | 3,707 | 9,268 | 7,415 |

| 3 1⁄4 | 4 | 235,152 | 176,364 | 4,777 | 11,941 | 9,553 |

| 3 1⁄2 | 4 | 275,890 | 206,917 | 6,035 | 15,088 | 12,070 |

| 3 3⁄4 | 4 | 319,939 | 239,954 | 7,499 | 18,746 | 14,997 |

| 4 | 4 | 366,970 | 275,227 | 9,174 | 22,936 | 18,348 |

SAE Grade 2

| Bolt Size | TPI | Proof Load (lbs) | Clamp Load (lbs) | Tightening Torque (ft lbs) | ||

|---|---|---|---|---|---|---|

| Galv+Waxed | Galv | Plain | ||||

| 1⁄4 | 20 | 1,750 | 1,313 | 3 | 7 | 5 |

| 5⁄16 | 18 | 2,900 | 2,175 | 6 | 14 | 11 |

| 3⁄8 | 16 | 4,250 | 3,188 | 10 | 25 | 20 |

| 7⁄16 | 14 | 5,850 | 4,388 | 16 | 40 | 32 |

| 1⁄2 | 13 | 7,800 | 5,850 | 24 | 61 | 49 |

| 9⁄16 | 12 | 10,000 | 7,500 | 35 | 88 | 70 |

| 5⁄8 | 11 | 12,400 | 9,300 | 48 | 121 | 97 |

| 3⁄4 | 10 | 18,400 | 13,800 | 86 | 216 | 173 |

| 7⁄8 | 9 | 15,200 | 11,400 | 83 | 208 | 166 |

| 1 | 8 | 20,000 | 15,000 | 125 | 313 | 250 |

| 11⁄8 | 7 | 25,200 | 18,900 | 177 | 443 | 354 |

| 11⁄4 | 7 | 32,000 | 24,000 | 250 | 625 | 500 |

| 13⁄8 | 6 | 38,100 | 28,575 | 327 | 819 | 655 |

| 11⁄2 | 6 | 46,400 | 34,800 | 435 | 1,088 | 870 |

ASTM A325

| Bolt Size | TPI | Tension | Tightening Torque Range (ft lbs) (Min - Max) | ||

|---|---|---|---|---|---|

| Min | Max | Galv+Waxed | Plain | ||

| 1⁄2 | 13 | 12,000 | 14,000 | 50 - 58 | 100 - 117 |

| 5⁄8 | 11 | 19,000 | 23,000 | 99 - 120 | 198 - 240 |

| 3⁄4 | 10 | 28,000 | 34,000 | 175 - 213 | 350 - 425 |

| 7⁄8 | 9 | 39,000 | 47,000 | 284 - 343 | 569 - 685 |

| 1 | 8 | 51,000 | 61,000 | 425 - 508 | 850 - 1,017 |

| 11⁄8 | 7 | 64,000 | 77,000 | 600 - 722 | 1,200 - 1,444 |

| 11⁄4 | 7 | 81,000 | 98,000 | 844 - 1,021 | 1,687 - 2,042 |

| 13⁄8 | 6 | 97,000 | 117,000 | 1,111 - 1,341 | 2,223 - 2,681 |

| 11⁄2 | 6 | 118,000 | 143,000 | 1,475 - 1,788 | 2,950 - 3,575 |

| 5⁄8 | 11 | 19,000 | 23,000 | 99 - 120 | 198 - 240 |

ASTM A449 / SAE Grade 5

| Bolt Size | TPI | Proof Load (lbs) | Clamp Load (lbs) | Tightening Torque (ft lbs) | ||

|---|---|---|---|---|---|---|

| Galv+Waxed | Galv | Plain | ||||

| 1⁄4 | 20 | 2,700 | 2,025 | 4 | 11 | 8 |

| 5⁄16 | 18 | 4,450 | 3,338 | 9 | 22 | 17 |

| 3⁄8 | 16 | 6,600 | 4,950 | 15 | 39 | 31 |

| 7⁄16 | 14 | 9,050 | 6,788 | 25 | 62 | 49 |

| 1⁄2 | 13 | 12,050 | 9,038 | 38 | 94 | 75 |

| 9⁄16 | 12 | 15,450 | 11,588 | 54 | 136 | 109 |

| 5⁄8 | 11 | 19,200 | 14,400 | 75 | 188 | 150 |

| 3⁄4 | 10 | 28,400 | 21,300 | 133 | 333 | 266 |

| 7⁄8 | 9 | 39,250 | 29,438 | 215 | 537 | 429 |

| 1 | 8 | 51,500 | 38,625 | 322 | 805 | 644 |

| 11⁄8 | 7 | 56,450 | 42,338 | 397 | 992 | 794 |

| 11⁄4 | 7 | 71,700 | 53,775 | 560 | 1,400 | 1,120 |

| 13⁄8 | 6 | 85,450 | 64,088 | 734 | 1,836 | 1,469 |

| 11⁄2 | 6 | 104,000 | 78,000 | 975 | 2,438 | 1,950 |

| 13⁄4 | 5 | 104,500 | 78,375 | 1,143 | 2,857 | 2,286 |

| 2 | 41⁄2 | 137,500 | 103,125 | 1,719 | 4,297 | 3,438 |

| 21⁄4 | 41⁄2 | 178,750 | 134,063 | 2,514 | 6,284 | 5,027 |

| 21⁄2 | 4 | 220,000 | 165,000 | 3,438 | 8,594 | 6,875 |

| 23⁄4 | 4 | 271,150 | 203,363 | 4,660 | 11,651 | 9,321 |

| 3 | 4 | 328,350 | 246,263 | 6,157 | 15,391 | 12,313 |

SAE J429 grade 5 bolts do not exceed 1-1/2" diameter.

ASTM A193 B7 / ASTM A320 L7 / ASTM A354 BC

| Bolt Size | TPI | Proof Load (lbs) | Clamp Load (lbs) | Tightening Torque (ft lbs) | ||

|---|---|---|---|---|---|---|

| Galv+Waxed | Galv | Plain | ||||

| 1⁄4 | 20 | 3,350 | 2,513 | 5 | 13 | 10 |

| 5⁄16 | 18 | 5,500 | 4,125 | 11 | 27 | 21 |

| 3⁄8 | 16 | 8,150 | 6,113 | 19 | 48 | 38 |

| 7⁄16 | 14 | 11,150 | 8,363 | 30 | 76 | 61 |

| 1⁄2 | 13 | 14,900 | 11,175 | 47 | 116 | 93 |

| 9⁄16 | 12 | 19,100 | 14,325 | 67 | 168 | 134 |

| 5⁄8 | 11 | 23,750 | 17,813 | 93 | 232 | 186 |

| 3⁄4 | 10 | 35,050 | 26,288 | 164 | 411 | 329 |

| 7⁄8 | 9 | 48,500 | 36,375 | 265 | 663 | 530 |

| 1 | 8 | 63,650 | 47,738 | 398 | 995 | 796 |

| 1 1⁄8 | 7 | 80,100 | 60,075 | 563 | 1,408 | 1,126 |

| 1 1⁄8 | 8 | 82,934 | 62,201 | 583 | 1,458 | 1,166 |

| 1 1⁄4 | 7 | 101,750 | 76,313 | 795 | 1,987 | 1,590 |

| 1 1⁄4 | 8 | 105,006 | 78,754 | 820 | 2,051 | 1,641 |

| 1 3⁄8 | 6 | 121,300 | 90,975 | 1,042 | 2,606 | 2,085 |

| 1 3⁄8 | 8 | 129,492 | 97,119 | 1,113 | 2,782 | 2,226 |

| 1 1⁄2 | 6 | 147,550 | 110,663 | 1,383 | 3,458 | 2,767 |

| 1 1⁄2 | 8 | 156,687 | 117,515 | 1,469 | 3,672 | 2,938 |

| 1 3⁄4 | 5 | 199,500 | 149,625 | 2,182 | 5,455 | 4,364 |

| 1 3⁄4 | 8 | 218,400 | 163,800 | - | - | 4,778 |

| 2 | 41⁄2 | 262,500 | 196,875 | 3,281 | 8,203 | 6,563 |

| 2 | 8 | 290,850 | 218,138 | - | - | 7,271 |

| 2 1⁄4 | 41⁄2 | 341,250 | 255,938 | 4,799 | 11,997 | 9,598 |

| 2 1⁄4 | 8 | 373,801 | 280,351 | - | - | 10,513 |

| 2 1⁄2 | 4 | 420,000 | 315,000 | 6,563 | 16,406 | 13,125 |

| 2 1⁄2 | 8 | 466,200 | 349,650 | - | - | 14,569 |

| 2 3⁄4 | 4 | 468,500 | 351,263 | 8,050 | 20,124 | 16,100 |

| 2 3⁄4 | 8 | 515,851 | 386,888 | - | - | 17,732 |

| 3 | 4 | 567,150 | 425,363 | 10,634 | 26,585 | 21,268 |

| 3 | 8 | 618,451 | 463,838 | - | - | 23,192 |

| 3 1⁄4 | 4 | 674,500 | 505,875 | 13,701 | 34,252 | 27,402 |

| 3 1⁄4 | 8 | 730,550 | 547,913 | - | - | 29,679 |

| 3 1⁄2 | 4 | 791,350 | 593,513 | 17,311 | 43,277 | 34,622 |

| 3 1⁄2 | 8 | 851,201 | 638,401 | - | - | 37,240 |

| 3 3⁄4 | 4 | 917700 | 688275 | 21,509 | 53,771 | 43,017 |

| 3 3⁄4 | 8 | 982,300 | 736,725 | - | - | 46,045 |

| 4 | 4 | 1052600 | 789450 | 26,315 | 65,788 | 52,630 |

| 4 | 8 | 1,121,950 | 841,463 | - | - | 56,098 |

ASTM A490

| Bolt Size | TPI | Tension | Tightening Torque Range (ft lbs) (Min - Max) | ||

|---|---|---|---|---|---|

| Min | Max | Plain | Lubricated | ||

| 1⁄2 | 13 | 15,000 | 18,000 | 125 - 150 | 63 - 75 |

| 5⁄8 | 11 | 24,000 | 29,000 | 250 - 302 | 125 - 151 |

| 3⁄4 | 10 | 35,000 | 42,000 | 438 - 525 | 219 - 263 |

| 7⁄8 | 9 | 49,000 | 59,000 | 715 - 860 | 357 - 430 |

| 1 | 8 | 64,000 | 77,000 | 1,067 - 1,283 | 533 - 642 |

| 1 1⁄8 | 7 | 80,000 | 96,000 | 1,500 - 1,800 | 750 - 900 |

| 1 1⁄4 | 7 | 102,000 | 122,000 | 2,125 - 2,542 | 1,063 - 1,271 |

| 1 3⁄8 | 6 | 121,000 | 145,000 | 2,773 - 3,323 | 1,386 - 1,661 |

| 1 1⁄2 | 6 | 148,000 | 178,000 | 3,700 - 4,450 | 1,850 - 2,225 |

ASTM A354-BD / SAE Grade 8

| Bolt Size | TPI | Proof Load (lbs) | Clamp Load (lbs) | Tightening Torque (ft lbs) | |

|---|---|---|---|---|---|

| Plain | Lubricated | ||||

| 1⁄4 | 20 | 3,800 | 2,850 | 12 | 6 |

| 5⁄16 | 18 | 6,300 | 4,725 | 25 | 12 |

| 3⁄8 | 16 | 9,300 | 6,975 | 44 | 22 |

| 7⁄16 | 14 | 12,750 | 9,563 | 70 | 35 |

| 1⁄2 | 13 | 17,050 | 12,788 | 107 | 53 |

| 9⁄16 | 12 | 21,850 | 16,388 | 154 | 77 |

| 5⁄8 | 11 | 27,100 | 20,325 | 212 | 106 |

| 3⁄4 | 10 | 40,100 | 30,075 | 376 | 188 |

| 7⁄8 | 9 | 55,450 | 41,588 | 606 | 303 |

| 1 | 8 | 72,700 | 54,525 | 909 | 454 |

| 1 1⁄8 | 7 | 91,550 | 68,663 | 1,287 | 644 |

| 1 1⁄4 | 7 | 120,000 | 90,000 | 1,875 | 938 |

| 1 3⁄8 | 6 | 138,600 | 103,950 | 2,382 | 1,191 |

| 1 1⁄2 | 6 | 168,600 | 126,450 | 3,161 | 1,581 |

| 1 3⁄4 | 5 | 228,000 | 171,000 | 4,988 | 2,494 |

| 2 | 4 1⁄2 | 300,000 | 225,000 | 7,500 | 3,750 |

| 2 1⁄4 | 4 1⁄2 | 390,000 | 292,500 | 10,969 | 5,484 |

| 2 1⁄2 | 4 | 480,000 | 360,000 | 15,000 | 7,500 |

| 2 3⁄4 | 4 | 517,650 | 388,238 | 17,794 | 8,897 |

| 3 | 4 | 626,850 | 470,138 | 23,507 | 11,753 |

| 3 1⁄4 | 4 | 745,500 | 559,125 | 30,286 | 15,143 |

| 3 1⁄2 | 4 | 874,650 | 655,988 | 38,266 | 19,133 |

| 3 3⁄4 | 4 | 1,014,300 | 760,725 | 47,545 | 23,773 |

| 4 | 4 | 1,163,400 | 872,550 | 58,100 | 29,085 |

SAE J429 grade 8 bolts do not exceed 1-1/2″ diameter.

Terminology explanation

Proof load

This is the "pass” value obtained in a tensile test of a complete bolt (including the threads and head) in a laboratory setting. If the bolt reaches this load without permanent elongation, deformation, or fracture, it is considered qualified.

If a specific bolt standard does not list an official proof load, it can be estimated at approximately 92 % of its minimum yield strength.

Clamp load

To maintain a safety margin, we typically set the target clamp load at 75 % of the proof load. This ensures that, after tightening, the bolt remains well below its limit and is less likely to break.

Note: The 75 % value is a general guideline. Certain designs or engineers may specify a different percentage.

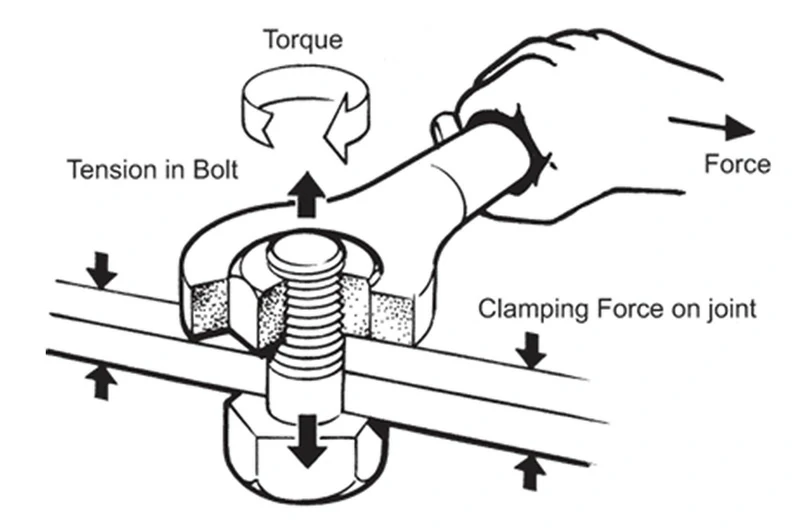

Torque

Torque is the rotational force applied to make an object turn, measured in newton-meters (N·m).

The basic formula: M = F × l

- M = torque (N·m)

- F = force applied to the wrench (N)

- l = lever arm length (m)

People also ask - FAQ

What is the difference between tension and torque?

Torque is the rotational force applied...

How should the torque chart be used for anchor bolts?

Chemical or mechanical anchors drilled into concrete...

What should I pay attention to in torque calculations?

- K-factor selection: waxed bolts ≈ 0.10, plain black bolts ≈ 0.20, hot-dip galvanized ≈ 0.25.

- Wrench calibration: check every 5 000 uses or every 6 months.

- Temperature effect: above 150 °C, yield strength decreases, so reduce target tension.

- Multi-bolt connections: use a staged tightening sequence (30 % → 70 % → 100 %) with a crisscross pattern.

One-stop service

In addition, we offer a one-stop supply of aluminum, titanium, stainless steel, and copper fasteners, covering a full range of bolts, nuts, screws, and rivets. We meet diverse needs from lightweight designs to high-strength and corrosion-resistant applications.

Titanium Bolts

Titanium Screws

Titanium Nuts

Titanium Washers

Titanium Threaded Rods

Titanium Rivets

Titanium Threaded Inserts

Instead of comparing prices over and over, talk directly with our experts—get the right bolt the first time and keep your project on schedule with zero stress.

Why choose us?

As industry experts specializing in fastener solutions, we stand by three core commitments:

- Engineering-grade quality – traceable raw materials, 100 % inspection before shipping, with ASTM / ISO / EN certification reports.

- Fast delivery – standard stock ships within 3 days, custom specifications in 1–2 weeks.

- One-stop technical support – torque calculation, selection advice, and sample testing, all handled directly by our engineers.