Laser Welding Titanium

Updated : Aug. 12, 2025Titanium plays a vital role in the aerospace, medical device, marine equipment, and chemical industries due to its exceptional strength, lightweight, and excellent corrosion resistance. Laser welding, an advanced process for high-precision titanium joining, is widely adopted due to its minimal heat-affected zone and high weld quality.

Why Is Titanium Alloy Welding Particularly Suitable for Laser Welding?

Titanium is strong, lightweight, and corrosion-resistant, but it is susceptible to oxidation and deformation during welding, requiring tight process control. Compared to traditional methods, laser welding offers superior heat input control, defect reduction, and weld quality, making it an ideal choice for titanium alloys.

Why Is Titanium Alloy Difficult to Weld?

- High Melting Point (~1,668 °C): Requires higher energy input than most metals.

- Low Thermal Conductivity: Heat concentrates in the weld zone, increasing risks of local overheating, distortion, and cracking.

- Reactivity at High Temperature: Titanium readily reacts with oxygen and nitrogen, forming brittle oxides that degrade weld integrity.

Limitations of Traditional Welding Methods

Conventional processes (e.g., TIG/MIG) often struggle to precisely control heat input and to fully isolate the weld pool from air when working with titanium alloys. Inadequate handling can lead to oxidation, porosity, and cracking—defects that compromise appearance and structural performance.

Common Problems in Titanium Welding

- Oxidation/Discoloration: Blue/yellow hues indicate oxide formation and embrittlement from insufficient shielding.

- Deformation: Concentrated heat in thin sections can cause warping and dimensional loss.

- Porosity: Moisture or contaminants introduce pores that reduce joint strength.

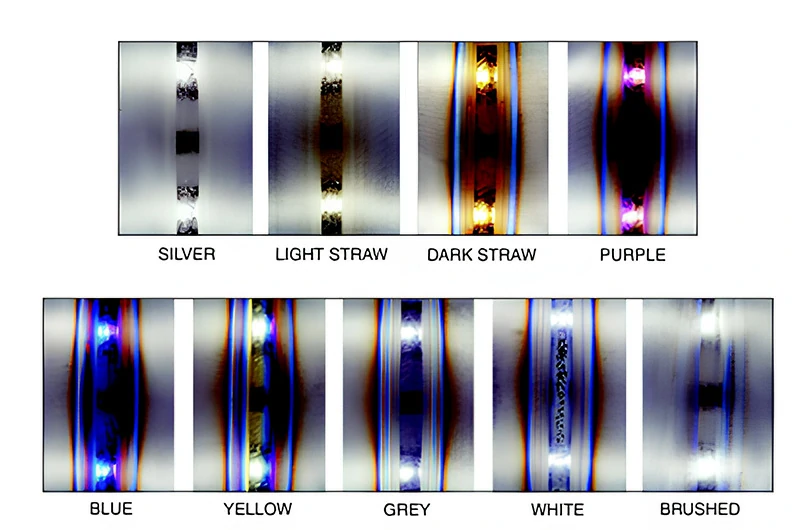

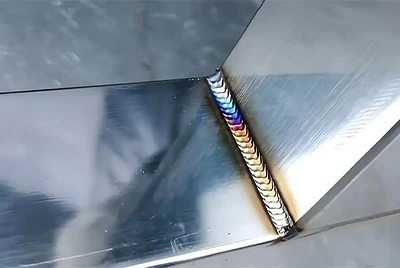

Judging Titanium Weld Quality by Color

Weld color reflects oxidation level and shielding effectiveness. Because titanium oxidizes readily at high temperature, surface color is a fast, visual quality indicator.

| Weld color | Representative meaning | Welding quality judgment |

|---|---|---|

| silver | No oxidation, very ideal weld state | Excellent, qualified |

| Light to dark yellow | Slight oxidation contamination, usually still within acceptable range | Qualified, acceptable |

| Purple | Moderate oxidative contamination, common in inadequately protected areas | Usually unqualified |

| Dark blue to light blue | Severe contamination indicates that the welding area has been exposed to the air for too long | Unqualified, should be reworked |

| Off-white | Extremely oxidized, the welded structure has been severely damaged | Waste, completely scrapped |

In its most severely oxidized state, a titanium weld appears white—unlike the black oxides common on other metals. This indicates excessive temperature and inadequate shielding and is unacceptable. A silver weld, by contrast, indicates minimal oxidation and top quality; however, silver and off-white can be misidentified, so careful inspection is important. In the heat-affected zone (HAZ), poor welds often show purple to dark blue discoloration, a clear sign of oxidation and overheat.

Advantages of Laser Welding Titanium Alloys

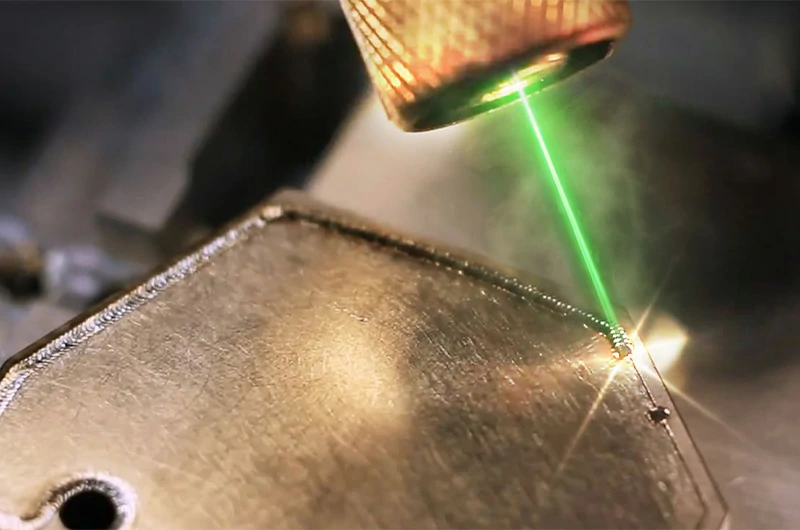

Precision Welding and Fine Heat Control

Laser beams can be tightly focused for accurate weld placement—ideal for thin-walled parts, complex geometries, and small components. Controlled heat input avoids burn-through and misalignment, improving consistency.

Laser welding concentrates heat and effectively reduces weld defects

the overall heat required for laser welding is lower than with conventional TIG welding.

For materials like titanium alloys, the less heat input, the less likely problems will occur during welding. Properly controlling heat input can effectively reduce excessive weld oxidation, lower internal residual stresses, and prevent excessive grain growth in the weld zone, thereby improving weld quality and service life.

Welding thin-walled titanium alloys does not affect strength

Titanium alloys are widely used in thin-walled structures, particularly in the aviation and medical industries. Laser welding can achieve high-quality welds without compromising the material's strength. The weld strength approaches that of the parent material, and the post-weld properties remain stable.

Less Post-Weld Processing

Clean, narrow welds and low heat input can reduce or eliminate grinding, cleaning, and heat treatment—saving time and shortening lead times.

High Speed and Productivity

Laser welding can be up to about four times faster than TIG, supporting medium- to high-volume production and automated lines while maintaining weld quality.

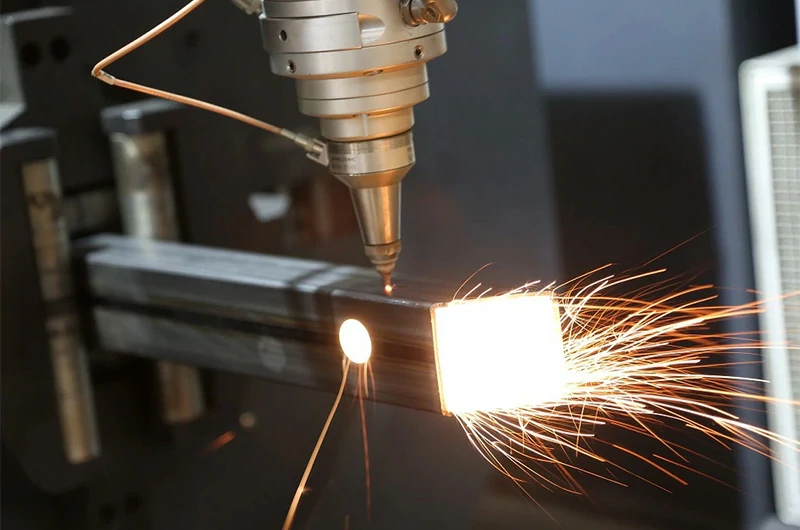

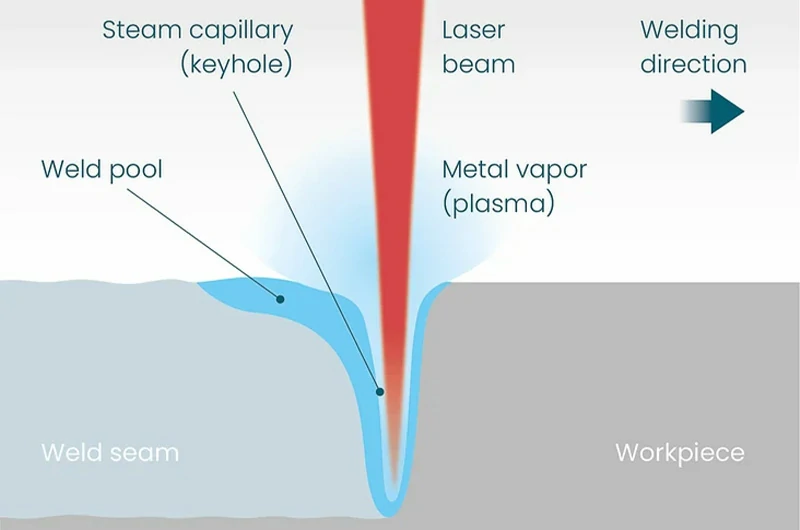

Deep penetration welding , reducing filler metal and risk of deformation

Laser welding has excellent penetration ability and can achieve a higher weld depth-to-width ratio than traditional arc welding. This means that at the same weld depth, the laser weld width is smaller and the structure is more compact.

Narrow welds have another important benefit: less filler metal is required. More filler metal generates greater internal stress during cooling, which can easily cause weld cracking or structural deformation. Laser welding reduces this risk by requiring less filler material, resulting in more stable and reliable welded structures.

Laser Type and Welding Mode Selection

Fiber laser

Fiber lasers are one of the most commonly used and widely used laser types. They feature high electro-optical conversion efficiency (typically >30%), excellent beam quality, and strong focusing capabilities. They are well-suited for welding titanium alloy sheets with thicknesses ranging from 0.5–6 mm, and are particularly well-suited for high-speed, continuous welding.

Recommended applications: automated production lines, aviation structural parts, and medical equipment welding.

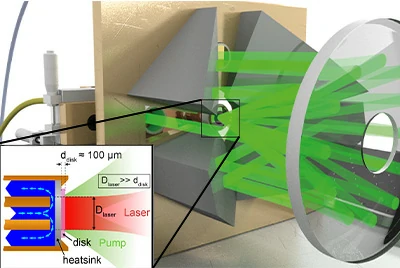

Disk laser

The Disk laser boasts higher laser power output and a wider beam cross-section, making it ideal for titanium alloy welding applications requiring high penetration depth. While maintaining high focusing performance, it also provides more stable weld formation, making it better suited for deep-penetration welding of complex structures and thicker plates (>6 mm).

Recommended applications: thick-walled structural parts, pressure vessels, aviation main load-bearing parts and other key welding parts.

Nd:YAG laser (solid-state laser)

Nd:YAG lasers, with a wavelength of 1064 nm, are suitable for spot welding, small-part welding, and detailed welding, and are compatible with fiber optic transmission. They are widely used in industries such as microelectronics and medical devices, where weld size and precision are extremely demanding. However, their relatively low photoelectric conversion efficiency and power output have led them to be gradually replaced by fiber lasers.

Recommended applications: precision parts, medical implants, sensor housings and other micro-welding fields.

CO₂ lasers

CO₂ lasers , with a wavelength of 10.6 μm, are suitable for cutting and welding thicker metals. However, due to the low initial absorption rate of titanium, surface preheating is often required to improve welding stability. Compared with other laser types, CO₂ laser equipment is larger and has higher maintenance costs, so its application in titanium alloy welding is currently limited.

Recommended applications: Cost-sensitive thick plate welding applications where the equipment is already equipped with a CO₂ laser system. However, it is not recommended as a first choice for new projects.

Welding mode selection recommendations

- Continuous laser welding is suitable for welding structural parts that require high strength and full penetration. Its fast weld formation speed and high aspect ratio make it the standard mode for welding medium and thick titanium alloy plates.

- Pulsed laser welding is suitable for thin-plate welding where thermal effects must be strictly controlled. It is also commonly used for precision spot welding, corner repair welding, and packaging processes. It can effectively reduce heat input and avoid weld penetration or edge burns.

Reference for Typical Welding Conditions

| Welding requirements | Recommended laser types | Recommended welding mode |

|---|---|---|

| 1–6 mm thin-walled structural parts | fiber laser | Continuous laser |

| >6 mm thick plate/deep penetration welding | Disk Laser | Continuous laser |

| Precision micro parts | Nd:YAG / Fiber Laser | pulsed laser |

| High-efficiency batch welding | fiber laser | Continuous laser |

| Extremely sensitive to thermal influences | Nd:YAG / Pulsed Fiber | pulsed laser |

Titanium Welding Shielding Gas

Shielding gas is essential. Titanium reacts with oxygen and nitrogen at high temperatures, causing oxidation, discoloration, brittleness, and failure.

- Argon: Most common and cost-effective; heavier than air, covers the weld area well.

- Helium: Expensive and harder to control, but enables higher temperature and deeper penetration for special cases.

- Argon–Helium Mix: Balances coverage and penetration for specific process needs.

Note: Shield the entire weld and HAZ. Use enclosed tooling or dedicated gas-coverage devices when possible.

Welding Preparation and Joint Design

Cleaning Before Welding

- Use non-chlorinated solvents (e.g., alcohol, acetone) to remove oils. Avoid chlorinated cleaners that release toxic gases when heated.

- After solvent cleaning, use a new or freshly cleaned stainless steel brush to remove oxide film.

- Do not use contaminated or old brushes that may embed residues into the surface.

- Weld as soon as possible after cleaning; if delayed, store parts in sealed containers with dry argon or nitrogen.

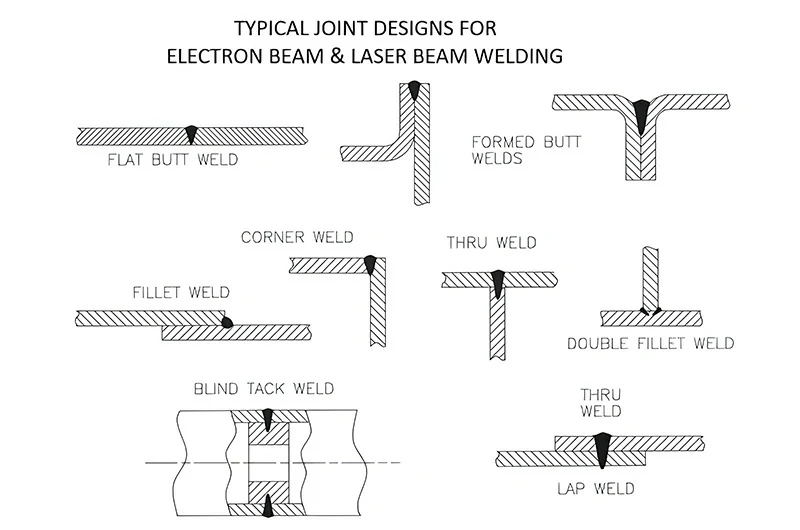

Fixture Usage and Connector Type Selection

Laser welding requires very tight joint-gap control. Use precise fixturing and computer-controlled beam/path control to align the beam with the seam.

| Connector Type | Technical requirements |

|---|---|

| Butt Weld | Assembly clearance ≤ 15% of material thickness; shear edges are acceptable but must be straight and vertical; misalignment or unevenness ≤ 25% of material thickness. |

| Lap Weld | The gap will seriously affect the penetration depth and welding speed; especially for titanium alloy round welding, any gap is unacceptable without full coverage of inert gas. |

| Fillet Weld | The seam edges need to be kept square and high assembly precision is key. |

Weld joint types chart:

Typical Applications of Titanium Laser Welding

The precision, speed, and ability to handle the unique challenges of titanium alloys make laser welding a valuable tool for a wide range of industries. The following industries stand to benefit greatly from this technology:

Aerospace

Titanium is widely used in aerospace engines, turbine blades , casings, exhaust systems, and spacecraft structures due to its lightweight, high-strength, and corrosion-resistant properties. Laser welding enables precise welding of thin-walled, complex structures with minimal deformation and high strength, ensuring component stability and reliability under the extreme conditions of flight.

medical devices

Titanium has excellent biocompatibility and is commonly used in implants, surgical instruments , orthopedic stents, etc. Laser welding can achieve high-quality, low-heat-impact welds, avoid residual contamination, and ensure the long-term safe use of products in the human body.

Automobile manufacturing

In high-performance cars and racing cars, titanium alloys are often used in exhaust systems and lightweight structural components . Laser welding can create clean, strong welds without damaging the material's properties. Its high welding speed makes it suitable for high-volume and efficient production.

Ocean and chemical industry

Titanium's resistance to salt corrosion makes it very suitable for ship components, offshore structures , chloride-resistant pipes, etc. Laser welding in such applications can ensure dense and corrosion-resistant welds and adapt to complex marine environments.

High-end consumer goods and niche industries

for titanium-cased watches , eyeglass frames, bicycle frames, and high-end sports equipment. The technology is also used in demanding niche applications such as military and electronics.