Unveiling the Real Price of Titanium and Steel

Updated : Jun. 23, 2025When the buyer compared the two quotes she was stunned. Titanium alloy Ti-6Al-4V came in at \$45 per kilogram while 304 stainless steel was only \$1.30 per kilogram.

Raw Material Costs

Over seventy percent of titanium's price comes from extracting and refining the ore. The Kroll process alone consumes about forty kilowatt-hours of electricity and more than a kilogram of magnesium chloride for each kilogram of sponge titanium.

By contrast, melting steel in an electric-arc furnace adds less than fifty cents in power costs.

Energy and Remelting

Titanium requires a second melting stage in a vacuum-arc furnace. That step adds roughly a dollar in electricity and about eight dollars in equipment depreciation per kilogram. Steel usually goes through a single furnace cycle, and its energy costs barely register by comparison.

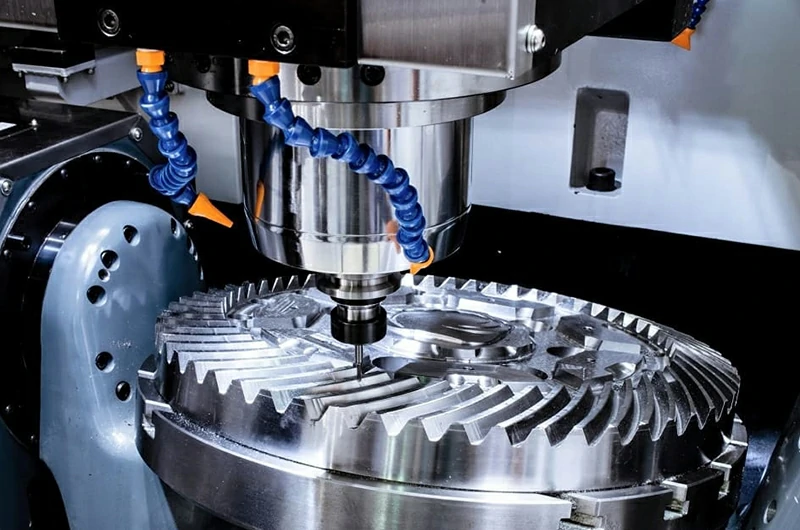

Machining Expenses

Cutting titanium takes twice as long and wears out tools twice as fast. To remove one kilogram of titanium, a machinist spends about twenty minutes at fifty dollars per hour. Removing the same amount of steel takes ten minutes at thirty dollars per hour.

Maintenance and Recycling

Steel structures need recoating every five years to ward off rust. The repainting bill can run into dollars per square meter. Titanium forms its own protective oxide layer and rarely needs extra upkeep. When it finally reaches end of life, recycling titanium costs more but recovers nearly all of the metal.

A Racing Chassis Example

On a racing chassis, titanium parts start at eighty dollars per kilogram for material and machining. Steel parts begin around ten dollars. Factor in a decade of maintenance and the fuel savings from a lighter frame, and titanium's net cost can fall while steel's net cost rises.

Choosing the Right Material

If you build short-run, high-performance parts like prototypes or medical implants, titanium often pays back quickly.

When you need large volumes on a tight budget—think construction beams or machinery housings—steel remains the cost-effective choice.

Blending both in hybrid designs can capture strength where it's needed and savings where it isn't.