Titanium 3D Printing: Benefits, Technologies & Applications

Updated : Jun. 24, 2025When titanium meets 3D printing, strength, corrosion resistance, and design freedom come together—making rockets, implants, racing parts, and electronics lighter, stronger, and more personalized.

This guide explains why titanium fits 3D printing, highlights key technologies, and shows where it's used—helping you see if it suits your next high-performance project.

Why titanium fits 3D printing

Traditional machining is challenging

- Titanium's low thermal conductivity leads to fast tool wear and low efficiency in CNC machining.

- Conventional methods waste a lot of material, and titanium is expensive—raising production costs.

3D printing reduces material waste and boosts efficiency, making it a smarter way to produce titanium parts.

Outstanding material properties

- Its high strength-to-weight ratio makes it ideal for lightweight, high-strength components.

- Excellent biocompatibility supports its use in implants and medical devices.

- Superior corrosion resistance ensures long-term stability in seawater and chemical environments.

- Titanium resists fatigue and cracking, even under intense use.

- It remains structurally stable at high temperatures, offering strong thermal performance.

Ideal for complex geometries

Titanium's ductility allows 3D printing of complex shapes hard to make by traditional methods. It also enables internal channels and lattices through topology optimization, boosting performance.

| Sector | Properties | Applications |

| Aerospace | Corrosion resistance High strength-to-weight ratio Heat resistance | Airframe and wing structures, compressor blades, rotors, and other turbine engine parts |

| Medical | Excellent strength Biocompatibility (non-toxic, non-allergenic) | Orthopedic devices like spinal, hip, and knee implants |

| Automotive & Racing | Corrosion resistance High strength-to-weight ratio Heat resistance | Brake calipers, brackets, rims, and uprights |

Benefits of titanium 3D printing

In aerospace, titanium 3D printing helps reduce the buy-to-fly ratio—a term describing the weight of raw material purchased versus the final part's weight.

With traditional methods, titanium parts may have a buy-to-fly ratio of 12:1 to 25:1. That means up to 90% of the expensive material is cut away and wasted.

Titanium 3D printing lowers this ratio to around 3:1 to 12:1, using only the material needed for the part and generating minimal waste from support structures.

For costly materials like titanium, this reduction leads to significant savings and greater efficiency.

Titanium 3D printing applications

Aerospace

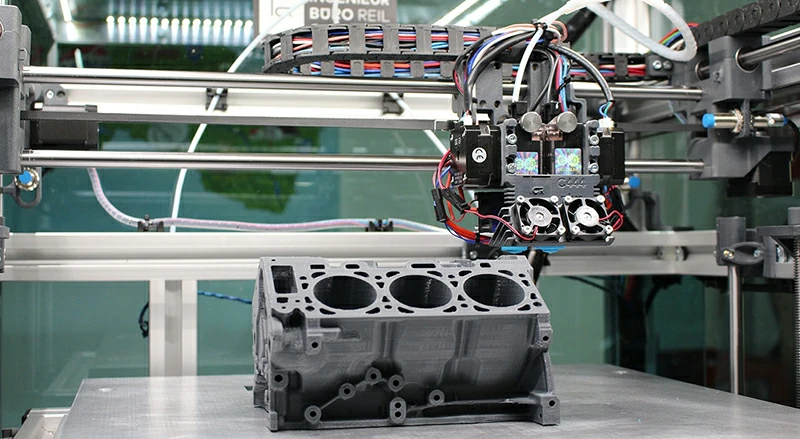

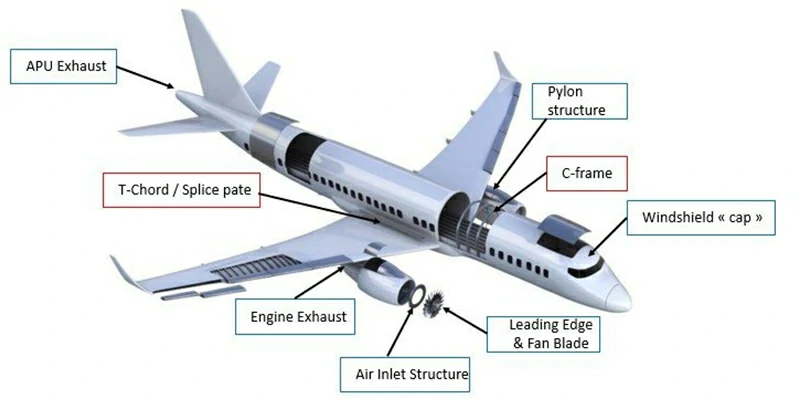

For aerospace companies, 3D printing titanium helps reduce the weight of high-load structures. It's ideal for jet engines, gas turbines, and various airframe components.

Liebherr-Aerospace & Transportation SAS, a major aerospace supplier, began mass-producing 3D printed titanium nose landing gear brackets for the Airbus A350 XWB earlier this year.

By using titanium 3D printing, Liebherr reduced the bracket’s weight by 29% and increased its stiffness.

Contact us now

Boeing has also made a big bet on titanium 3D printing. Since 2015, it has partnered with Norwegian metal 3D printing company Norsk Titanium to produce large titanium structural parts for the 787 Dreamliner.

In 2017, Boeing used Norsk's proprietary Rapid Plasma Deposition (RPD) technology to create an unnamed titanium part, which was certified by the U.S. Federal Aviation Administration (FAA).

3D printed and machined parts by Norsk Titanium

Boeing uses Norsk’s proprietary Rapid Plasma Deposition (RPD) technology to produce titanium components.

Contact us now

Medical

In the medical field, 3D printed titanium implants are widely used in spinal, hip, knee, and limb surgeries. They enable large-scale personalized customization and significantly improve patient outcomes.

Osseus Fusion Systems, a U.S.-based company, develops such devices. Its 3D printed titanium spinal implant, the Aries-L interbody fusion device, features a proprietary multiplanar grid and optimized micro-surface topology that promote faster bone integration.

Titanium spinal implants by Osseus

Osseus uses titanium 3D printing to manufacture its interbody fusion devices.

Contact us now

As more medical manufacturers adopt additive manufacturing in production, the number of FDA-approved titanium-based 3D printed surgical implants continues to grow.

In 2023, ChoiceSpine received FDA approval for its Blackhawk Ti, a 3D printed titanium cervical interbody spacer system.

Contact us now

Automotive and motorsports

While 3D printing offers clear advantages, the consumer auto market is highly cost-sensitive, limiting the use of this expensive material in most vehicles.

One of the most notable uses of titanium 3D printing in the automotive world is Bugatti's development of brake calipers for its Chiron supercar.

Bugatti's titanium brake caliper

Bugatti's titanium brake caliper

Measuring 41 x 21 x 13.6 cm, the caliper was 3D printed using SLM technology in just 45 hours.

Contact us now

Last year, the company successfully tested the caliper, proving it could meet extreme strength, stiffness, and temperature demands.

U.S. wheel manufacturer HRE is another company benefiting from titanium 3D printing.

HRE's 3D printed titanium wheel

HRE used Laser Powder Bed Fusion (LPBF) technology to 3D print a complex-shaped wheel hub, achieving a 19% weight reduction in the process.

Contact us now

Bicycles and consumer products

3D printed titanium is widely used in high-performance bicycles—for frames, cranks, and brake levers—offering the strength of aluminum, the lightness of carbon fiber, and better sustainability.

Bicycle manufacturer Ribble launched the Allroad Ti, featuring a 3D printed titanium frame.

Contact us now

Earlier this year, Silca launched its latest line of 3D printed products, including a range of titanium derailleur hangers.

Contact us nowVerve Cycling partnered with Metron Additive Engineering to redesign its crankset using 3D printing, reducing weight and enhancing customization.

Contact us now

Futai Technology 3D printed golf club head

It offers golfers greater distance, improved shot stability, and increased forgiveness.

Contact us nowManufacturing

Semiconductor manufacturer ASML turned to titanium 3D printing for entirely different reasons. Its titanium wafer carrier trays are now 3D printed instead of forged, saving 64% in raw material and speeding up delivery.

Metal additive manufacturing company Norsk Titanium used a Directed Energy Deposition (DED) platform to print an 80 kg (about 176 lbs) near-net-shape Ti64 preform for semiconductor wafer production.

Precision products & electronics

3D printing enables the creation of ultra-thin, complex, and highly precise titanium parts—making it ideal for watch cases, such as those by Panerai and Holthinrichs.

In 2023, smartphone brand Honor launched the Magic V2 foldable phone, featuring a 3D printed titanium hinge cover that is lighter than its previous aluminum version, yet 150% stronger.

3D printed titanium hinge cover

According to Honor, it's the key to the product's smooth and durable folding performance.

Contact us now

What are the main titanium 3D printing technologies?

Laser powder bed fusion (LPBF / SLM / DMLS)

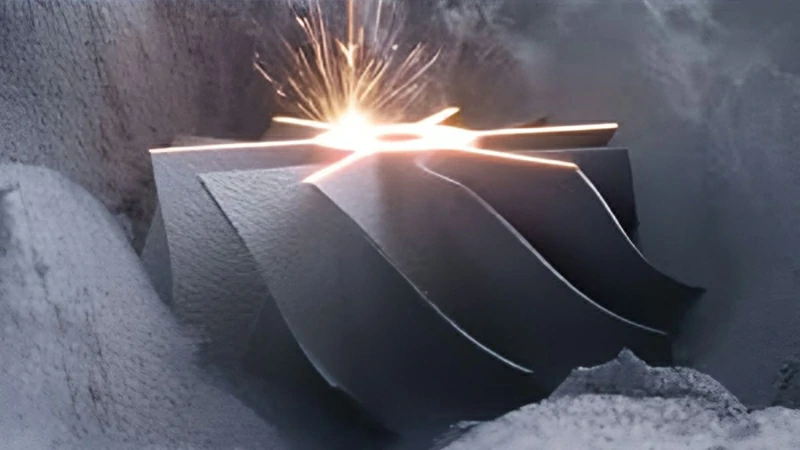

Laser powder bed fusion (SLM/DMLS/LPBF) uses a high-power laser in an inert gas environment to selectively melt layers of spherical titanium powder, which solidify rapidly.

It's ideal for small to medium-sized complex parts with tight tolerances, such as orthopedic implants and aerospace components.

SLM, DMLS, and LPBF are brand-specific terms for essentially the same laser-based powder bed fusion technology.

Electron beam powder bed fusion (EBM / EB PBF)

Electron beam powder bed fusion (EBM) melts titanium powder layer by layer using an electron beam in a vacuum environment. The process maintains a high-temperature build platform to reduce residual stress and prevent oxidation.

It's suitable for large implants and aerospace parts that require low internal stress and excellent material quality.

Directed energy deposition (DED)

Directed energy deposition (DED) uses a laser, electron beam, or arc as a heat source to melt titanium powder or wire directly in a molten pool, depositing material track by track.

It offers high deposition rates and is ideal for producing or repairing large parts up to one meter in size. Wire feedstock can be used to lower material costs.

Key DED variants include Electron Beam Additive Manufacturing (EBAM), Laser Metal Deposition (LMD/LENS), and Wire Arc Additive Manufacturing (WAAM).

Binder jetting

Binder jetting sprays a liquid binder onto layers of titanium powder to form a "green part,” which is later sintered to achieve full density.

This method allows fast printing and batch production of simpler geometric parts, making it suitable for medium-volume manufacturing.

Lithography-based metal manufacturing (LMM)

LMM builds green parts by curing photosensitive resin mixed with titanium powder layer by layer using light.

The resin is then removed through sintering, densifying the final part. LMM enables micron-level resolution and is ideal for producing highly detailed, small-scale parts such as microchannels and MEMS devices.

High-deposition-rate processes (RPD, Cold Spray, etc.)

Rapid Plasma Deposition (RPD) and Cold Spray are high-deposition-rate additive manufacturing techniques for large titanium parts. RPD uses a plasma beam to melt titanium wire for efficient buildup—perfect for structural aerospace parts like beams and landing gear.

Cold Spray, on the other hand, propels solid metal particles at supersonic speeds to bond at room temperature, with virtually no heat-affected zone. It's often used for in-field repairs or thick-wall builds.

These processes are highly efficient for producing parts over one meter in size, though they usually require post-machining for surface precision.

Post-processing techniques for 3D printed titanium alloys

After printing, post-processing is essential to achieve the required mechanical properties and surface finish. Below are the most common post-processing methods for titanium alloys.

Heat treatment

Heat treatment significantly improves mechanical properties like strength, toughness, and fatigue resistance. It's often applied to high-stress structural components.

For example, Ti-6Al-4V (Ti64) can reach a yield strength over 950 MPa after heat treatment, and even above 1000 MPa with HIP, while maintaining 9–15% elongation and excellent structural stability.

Hot isostatic pressing (HIP)

HIP combines high temperature and pressure to eliminate internal porosity from the 3D printing process, improving density and internal strength.

The process typically runs at around 1000°C in a vacuum or argon atmosphere for about an hour.

HIP-treated titanium parts can reach near-forging density (about 99.5%) with significantly improved elongation and toughness.

CNC precision machining

While 3D printing offers design freedom, high-precision features—like mating surfaces, threaded holes, and sealing grooves—still require CNC machining to meet tight tolerances.

Surface finishing techniques

- Polishing: Creates a mirror-like finish, common in medical devices and premium decorative parts.

- Tumbling: Removes burrs in batch production, leaving a uniform matte surface.

- Sandblasting and honing: Improve coating adhesion or achieve fine textures.

These treatments enhance the feel, corrosion resistance, and functional adaptability of titanium parts.

Overview of titanium alloys for 3D printing

When selecting an alloy, it's important to consider factors such as load, temperature, corrosion environment, and biocompatibility. This ensures you maximize both the design freedom and material advantages that additive manufacturing offers.

| Alloy | Key characteristics | Main applications |

| Ti‑6Al‑4V (Grade 5) | Most widely used α+β titanium alloy; excellent strength-to-weight ratio and corrosion resistance | Aerospace structures, performance parts, general medical devices |

| Ti‑6Al‑4V ELI (Grade 23) | Extra-low interstitial version of Grade 5; excellent biocompatibility | Orthopedic implants, dental implants, custom prosthetics |

| Ti‑5Al‑5V‑5Mo‑3Cr (Ti‑5553) | High-strength β-titanium with excellent creep resistance and toughness | Landing gear, engine cases, high-load military structures |

| Ti‑6Al‑2Sn‑4Zr‑2Mo (Ti‑6242) | Outstanding high-temperature performance while maintaining strength | Hot sections of jet engines, racing engine components |

| Ti‑3Al‑2.5V (Grade 9) | Medium strength with good weldability and corrosion resistance | Chemical and oil & gas piping, bicycle frames |

| β21S (Ti‑15Mo‑3Nb‑3Al‑0.2Si) | Advanced β-titanium; high strength, creep and oxidation resistance | Jet engines, orthodontic brackets, orthopedic fasteners |

| TA15 (Ti‑6Al‑2Zr‑1Mo‑1V) | Near-α titanium with high specific strength and thermal stability | High-temperature load-bearing frames, aircraft skin reinforcements |

3D printer for titanium

Laser powder bed fusion (LPBF / SLM / DMLS)

- EOS:M 290,M 400‑4

- GE Additive / Colibrium Additive:M2 Series 5,M Line

- Nikon SLM Solutions:NXG X12,NXG 600

- 3D Systems:DMP Flex 350,Factory 500

- Velo3D:Sapphire,Sapphire XC

- TRUMPF:TruPrint 2000,3000,5000

- Renishaw:RenAM 500 series

- AddUp:FormUp 350

Electron beam powder bed fusion (EBM / EB PBF)

GE Additive Arcam:Q10 Plus,Q20 Plus,Spectra H

Directed energy deposition (DED)

- Sciaky: EBAM 110, EBAM 300 (electron beam + titanium wire)

- MELD Manufacturing: MELD L-Series (solid-state friction deposition using titanium rods or bars)

Binder jetting

- Desktop Metal: Production System P-50, X Series

- Desktop Metal P-1: Requires "Reactive Safety Kit" to support reactive materials like titanium and aluminum

- Markforged: PX100

Metal fused filament fabrication (Metal FFF / BMD)

Desktop Metal: Studio System 2 (BMD technology with dedicated Ti-6Al-4V filament)

Cold spray – solid-state high-speed deposition technology

Spee3D:WarpSPEE3D

Titanium 3D printer cost

Cost is a key factor many companies must evaluate before adopting titanium 3D printing.

High initial investment

- Industrial-grade titanium 3D printers typically range from $250,000 to $1,000,000.

- High-purity, spherical titanium alloy powder costs around $300–600 per kilogram.

- Many businesses choose to work with 3D printing service providers. The final printing cost is often several times the material cost, depending on part complexity and post-processing needs.

Why it's still worth the investment

- Lightweight, high-strength materials reduce aircraft weight, saving fuel and extending range—resulting in long-term operational cost savings.

- Titanium's biocompatibility and the design flexibility of 3D printing enable implants that better fit individual patients, improving surgical outcomes and reducing the need for revision surgeries.

- Titanium alloys offer excellent high-temperature fatigue resistance, making them ideal for critical parts in jet engines, missile structures, and racing components.

Titanium 3D printing isn't just a manufacturing method—it's a driving force for performance gains and design freedom.

For industries with demanding environments, custom requirements, or strict lightweight goals, the value delivered in material performance, structural optimization, and operational efficiency far outweighs the initial cost.

Challenges of 3D printing: the technical barriers behind high performance

Lack of unified standards and certification

Currently, standards for combining titanium with additive manufacturing are still underdeveloped. This poses a barrier in high-risk industries like aerospace and medical.

For example, Boeing partnered with Oerlikon as early as 2018 to work on standardizing titanium 3D printing, aiming to meet FAA (Federal Aviation Administration) and DoD (Department of Defense) flight safety requirements.

High cost of titanium powder

Titanium powder for 3D printing must have high purity, excellent sphericity, and uniform particle size distribution. Producing it requires high energy and strict control, keeping prices high—typically around $300–600 per kilogram.

Complex temperature control and heat management

With a melting point of 1668°C, titanium demands precise thermal control during printing.

Improper heat input can cause internal stress, warping, or cracking, which can severely compromise structural integrity and service life—especially critical for aerospace and implant applications.

Difficulties in achieving uniform sintering and density

The mechanical performance of titanium parts relies heavily on the uniformity and density achieved during sintering or melting.

Porosity, inclusions, or microstructural inconsistencies can lead to stress concentrations and potential failure points, particularly when printing complex geometries.

Challenges in support structure design and removal

Titanium 3D printing often requires strong, intricate support structures to prevent collapse or distortion under high temperatures.

After printing, these supports must be removed with precision, without damaging the part—an added complexity in the overall process.

Overview of titanium and titanium alloy powder suppliers

Chalco Titanium

A leading titanium supplier in China, Chalco Titanium is actively expanding its titanium alloy powder business for additive manufacturing.

It offers both industrial-grade and aerospace-grade titanium materials, supports customized alloy development, and provides cost-effective bulk supply—serving aerospace, medical, and automotive markets worldwide.Quick Quote

Carpenter Technology

Offers medical- and aerospace-grade Ti-6Al-4V ELI (Grade 23) alloy powders with a well-established certification system. Widely serves manufacturers of medical implants, orthopedic, and dental devices.

IperionX

A U.S.-based supplier focused on sustainable titanium recycling. Develops eco-friendly titanium powders for 3D printing, promoting low-carbon additive manufacturing solutions.

Sandvik / Osprey

Provides certified Osprey Ti-6Al-4V Grade 5 and Grade 23 powders with consistent batch control. Widely used in aerospace and medical applications.

AP&C (Colibrium Additive, part of GE Additive)

A globally recognized leader in titanium powder atomization. Its products support both laser and electron beam additive manufacturing processes.

Titanium 3D printing service

For most businesses or individual users, purchasing a high-cost metal 3D printer to produce titanium parts isn't practical. Fortunately, there are now many mature third-party titanium 3D printing services available to deliver high-quality metal parts quickly and efficiently.

When choosing a printing service, it's important to confirm the type of titanium alloy offered (such as Ti-6Al-4V or commercially pure titanium). Some specialized grades, like CP-Ti or ELI versions, may require custom orders or additional lead time.

For example, on the globally recognized on-demand manufacturing platform Craftcloud, users can simply upload a CAD file, select titanium as the material, and receive instant quotes from various manufacturing partners. Users can then choose a provider based on price, lead time, or location.

Today, leading equipment manufacturers like 3D Systems, EOS, and SLM Solutions, as well as powder suppliers like Sandvik and Carpenter Additive, also offer custom titanium printing services. These services are widely used in high-demand industries such as medical, aerospace, automotive, and tooling.

Frequently asked questions about titanium 3D printing

How strong is 3D printed titanium?

Its strength can match forged parts, making it suitable for high-load structural components.

What materials cannot be 3D printed?

Some highly reactive metals and composite materials are still challenging for commercial 3D printing and not yet widely used.

What is titanium 3D printer filament?

It's a polymer filament infused with titanium powder, used in metal FDM-type printers.

How does titanium 3D printing work?

It uses a laser or electron beam to melt titanium powder or wire layer by layer to form a part.

What is 3D printing titanium powder?

It's high-purity, spherical titanium alloy powder specially made for additive manufacturing.