Brazing of Titanium and Titanium Alloys

Updated : Jul. 9, 2025Titanium brazing is an advanced process that can achieve lightweight, high sealing and corrosion-resistant connections. It is widely used in aerospace, medical equipment, heat exchange equipment and precision instruments. Compared with welding, brazing shows higher flexibility in complex structures, thin-walled parts or dissimilar materials. However, the characteristics of titanium itself also bring many process challenges.

Challenges of brazing titanium

Titanium is extremely sensitive to oxygen and nitrogen, and will quickly form a dense oxide film when the temperature rises. This film will seriously hinder the wetting and flow of the brazing material, thereby affecting the strength and sealing of the joint. Therefore, brazing titanium must be carried out in an environment with extremely low oxygen content, usually requiring a vacuum degree of less than 10 ⁻⁴ Pa, or using high-purity argon with a purity greater than 99.999% as a protective atmosphere.

In addition to its high chemical activity, titanium has low thermal conductivity and a high melting point, which makes it difficult to evenly distribute heat input. During brazing, local overheating can easily lead to grain coarsening, structural transformation, and even joint cracking, especially when dealing with α+β titanium alloys such as Ti-6Al-4V.

Common brazing processes

Vacuum brazing

Vacuum brazing is considered to be the most mature and reliable process for titanium alloy brazing. It is particularly suitable for components with complex structures, high strength and high sealing requirements, such as aerospace heat exchangers, hydraulic system pipelines, engine cooling components, etc.

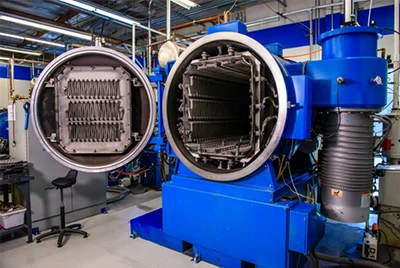

The process is usually carried out in a vacuum furnace, and the vacuum degree in the furnace must be controlled at 10 ⁻⁴ Pa or lower to completely isolate oxygen and moisture. The brazing temperature is usually set between 880°C and 950°C, and is optimized and adjusted according to the composition of the brazing material used and the size of the joint. In a vacuum environment, the oxide film on the titanium surface is naturally removed, and the brazing material can achieve complete wetting and diffusion without the use of flux.

The advantage of vacuum brazing is that it can obtain a uniform, inclusion-free joint structure, and no additional cleaning treatment is required on the surface after welding. It is particularly suitable for products with extremely high requirements for cleanliness and mechanical properties. However, its equipment investment is large, the heating cycle is long, and the process control precision is high. It is more suitable for mass production and key parts processing.

Induction brazing vs flame brazing

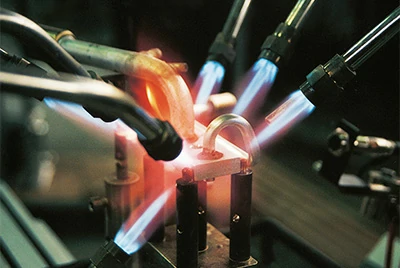

Induction brazing and flame brazing are two common low-cost titanium joining solutions when vacuum furnaces are not available or when only small batches of parts are processed. These processes rely on localized heating and the use of specialized fluxes to break through the oxidation barrier on the titanium surface.

TiBF-19 is the most common titanium-specific flux, with good chemical activity and wettability. It can work with brazing materials at 760°C to 815°C, allowing titanium materials to be brazed in air. Induction heating has the advantages of high heating efficiency and small heat-affected zone, while flame heating is easy to operate manually and has strong flexibility.

However, since this type of process operates in an open environment, it cannot completely block oxygen contact in the air, so it is easy to produce defects such as oxidation inclusions and pores. This makes it more suitable for non-load-bearing components, instrument prototypes or experimental samples with lower structural requirements, but not recommended for long-term service or load-bearing components.

Active brazing

When the connection objects include non-metallic materials such as ceramics, glass, quartz, etc., the traditional brazing process is not competent due to insufficient wettability. At this time, active metal brazing (Active Brazing Alloy, referred to as ABA) is required.

active brazing technology is to use brazing materials containing active elements such as titanium and zirconium, which react chemically with the ceramic surface at high temperatures to form stable compounds, thereby achieving wetting and firm connection. Common brazing materials include Ti-Zr-Ni-Cu alloys, etc., and the typical brazing temperature range is 850°C to 930°C.

Active brazing still has strict requirements on the atmosphere. It is generally carried out under the protection of high vacuum or high-purity inert gas (such as argon) to prevent the active elements in the brazing material from reacting with oxygen. At the same time, details such as the thermal stress matching of the metal-ceramic interface and the control of the thickness of the reaction layer must also be strictly designed to ensure the airtightness and long-term stability of the joint.

The active brazing process is widely used in the combination of optical device housings, infrared windows, sensor ceramic housings and titanium bases, and is an important technical means to achieve titanium precision packaging.

Brazing filler metal classification

Titanium brazing filler metals can be roughly divided into five categories according to the basic components in their chemical composition: silver-based, titanium-based, aluminum-based, palladium-based , and zirconium-based .

The following table shows common brazing filler metals and their applicable temperature ranges:

| Brazing filler metal | Brazing temperature range (°C) |

| Silver Base | 720–950 |

| Titanium base | 850–1020 |

| Aluminum base | 600–750 |

| Palladium-based | 1050–1150 |

| Zirconium-based | 790–950 |

Silver-based solder

Silver-based solder has a low melting point, good fluidity and strong wettability, and is suitable for joining dissimilar metals such as titanium and copper, brass, and stainless steel. Its brazing temperature range is 720°C to 950°C, and it is a commonly used solder suitable for low heat input environments.

This type of solder is particularly suitable for the quick connection process of heat-sensitive parts, small instrument components or medical-grade titanium accessories. It needs to be used with special flux, such as TiBF-19, to improve the wetting effect of the titanium surface. It is not suitable for long-term use in high temperature or highly corrosive environments.

Titanium-based brazing filler metal

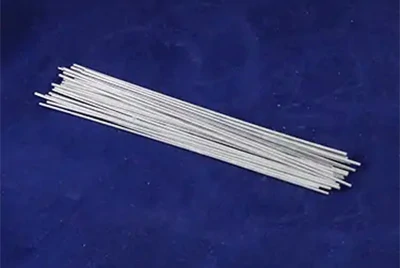

Titanium-based brazing filler metals are designed for high-performance connections between titanium alloys or between titanium and similar alloys, with a brazing temperature range of 850°C to 1020°C. Typical alloy systems such as Ti-Cu-Ni have high melting points, high strength, and good diffusion bonding properties.

Titanium-based brazing filler metals are widely used in aerospace, high-strength heat exchangers, hydraulic pipelines and other occasions. They are the preferred materials to ensure that the brazing seam strength is close to that of the parent material, and are resistant to high temperatures and corrosion. They are usually required to be used in a vacuum or high-purity argon environment, do not require flux, and can achieve clean and high-strength connections.

Aluminum-based brazing filler metal

Aluminum-based brazing filler metals are low-temperature brazing filler metals with a brazing temperature range of 600°C to 750°C. They are suitable for low-temperature connection of titanium and aluminum alloys or certain light metal parts.

Although aluminum has poor wettability on the titanium surface, aluminum-based brazing filler metals can still be used as auxiliary connecting materials for titanium structures in some composite materials or temporary packaging structures. It should be noted that aluminum-based brazing filler metals easily react with titanium to form brittle phases and are not recommended for use in stress-bearing components or long-term service situations.

Palladium-based solder

Palladium-based solder has the highest brazing temperature, usually 1050°C to 1150°C. It has strong wetting ability and corrosion resistance, and is suitable for high-temperature sealing, high vacuum systems and precious metal connection occasions.

This type of solder is used in connection environments that require extremely high reliability and long life, such as high-temperature aerospace components, nuclear power components, and expensive sensor packaging. Since palladium itself is expensive, this type of solder is usually only used in critical structures.

Zirconium-based brazing filler metal

The brazing temperature range of zirconium-based brazing filler metal is 790°C to 950°C, and it has good adaptability in the connection between titanium and stainless steel, zirconium alloy or ceramic.

Zirconium and titanium are similar in crystal structure and thermal expansion coefficient, which can effectively alleviate the thermal stress problem in the connection of dissimilar metals. This type of brazing material performs well in nuclear power equipment, chemical pipeline systems or highly corrosive working conditions and has certain development potential.

Brazing flux

At high temperatures, the surface of titanium is easily oxidized, and a hard oxide film will quickly form. This film is like a wall that prevents the solder from adhering and flowing, making it impossible for the metals to be firmly connected. To solve this problem, we usually need to add flux during brazing. The role of the flux is to "clean" this oxide film so that the solder can flow smoothly into the joint to complete wetting and connection.

Fluoroborate type flux

At present, the most commonly used titanium flux in the industry is fluorine borate type flux. For example, TiBF-19 is a representative product in this category. This flux is usually in the form of white powder and contains ingredients such as potassium fluoride and borate. At high temperatures, it can actively decompose the oxide film on the surface of titanium, and at the same time form a protective film in the heated area to prevent new oxygen from contacting the titanium surface, thereby helping the brazing material to flow smoothly and adhere to the base material.

This type of flux is mostly used in local heating processes such as flame brazing and induction brazing, and is particularly suitable for small parts, prototype samples or on-site repairs. Its operating temperature range is approximately between 750°C and 900°C. However, it will leave residue after use and needs to be thoroughly cleaned with hot water or chemical solutions after welding, otherwise it will corrode or contaminate the joint.

Active brazing system

In a vacuum furnace or under the protection of high-purity argon, we can also avoid adding external flux. This is because some brazing materials themselves contain "active elements", such as titanium or zirconium. These elements can directly react with the titanium surface at high temperatures to remove the oxide film and help the brazing material wet the base material well, which constitutes the so-called "active brazing system".

This method is cleaner, has no residue, and does not require cleaning after welding. It is particularly suitable for products with high requirements for cleanliness and sealing, such as aviation heat exchangers, precision medical equipment, and titanium ceramic packaging. Although this brazing method has high equipment requirements, the welding quality is more reliable and suitable for high-end industries.

Halogen flux

In the early days of titanium brazing, some fluxes containing zinc chloride were used. They have strong film removal ability, but also bring great side effects. This type of flux is easy to remain after welding, is highly corrosive to titanium, and is not easy to clean. Therefore, it has been basically eliminated in modern industry. Now it is only occasionally used in laboratory research or special circumstances.

How to choose titanium brazing flux correctly?

When designing the brazing process for titanium alloys, choosing the right flux often directly determines whether the welding can be successful. Different process environments, types of brazing materials, and connection objects have different requirements for the type and performance of the flux. The following is a reference table for selecting flux for titanium brazing .

Usage scenarios Recommended flux type Applicable instructions

Vacuum brazing + active brazing filler metal (such as BTi-5) No flux required The solder contains active elements, the interface reacts spontaneously, the surface is clean and no residue

Flame brazing in air TiBF-19 fluoride borate type flux Need to remove the oxide film, suitable for maintenance, small parts, experimental process

Induction brazing (non-vacuum) TiBF-19, TiFlux-A Wettability depends on flux, pay attention to post-soldering residue cleaning

Vacuum brazing + silver-based solder Little or no flux Wetting needs to be tested, and surface roughening can reduce flux dependence

Titanium and ceramic/glass brazing No flux (active solder) required Use active metal brazing systems such as Ti-Zr-Ni alloys

Medical/Aviation and other scenarios requiring no residue No flux or fully cleanable flux It is recommended to use vacuum brazing and active brazing filler metal, or strengthen the residual cleaning process.

Key process parameters of titanium brazing

In titanium brazing, the control of joint gap is very critical. The generally recommended overlap gap range is 0.025 to 0.1 mm, which can ensure that the brazing material can enter the joint smoothly through capillary action, but will not hinder the flow due to being too tight, or form defects such as pores and voids due to being too large.

The soaking time during brazing should not be ignored. Generally, it should be kept between 5 and 15 minutes to ensure that the brazing material is fully diffused and wetted at the joint, while also preventing the base material from growing in size due to long-term high temperature, which affects the mechanical properties.

The heating rate should be controlled within 10°C per minute. Titanium alloy has low thermal conductivity. If the temperature rises too quickly, the heat cannot diffuse evenly, which can easily cause thermal stress in the welding area and even cause warping, cracks or structural changes.

Protective atmosphere is also indispensable. There are two commonly used methods. One is a high vacuum environment, usually the vacuum degree must reach below 10 ⁻⁴ Pa; the other is to use ultra-high purity argon protection, the purity must reach 99.999%. Both methods can effectively prevent the oxidation reaction of titanium during heating.

Common defects in brazing

One of the most common problems in titanium brazing is oxide inclusions. This is usually caused by decreased flux activity or substandard vacuum. If the brazing material has poor wettability, black oxide inclusions are likely to appear in the weld, affecting the strength of the connection.

Another common problem is that the solder fails to fill the joint smoothly. This phenomenon of insufficient capillary action is often because the joint gap is designed to be too large, or there is oil, oxide scale, etc. on the surface that has not been cleaned, which hinders the flow of solder.

When dealing with dissimilar metal connections, special attention should be paid to the formation of brittle intermetallic compounds. For example, between titanium and iron, excessive diffusion can easily form a Ti-Fe brittle phase, and when connecting titanium and aluminum at high temperatures, there is also a risk of a Ti-Al brittle phase. Reasonable control of the insulation time and temperature is the key to preventing this problem.

Quality inspection and control methods

After brazing, quality inspection is required to ensure reliable joint performance. Non-destructive testing methods such as X-ray, ultrasonic or dye penetration can be used to quickly identify defects such as pores, cracks, inclusions, etc. without destroying the product.

When it is necessary to confirm the strength of the joint, engineers will also conduct destructive tests. Shear strength and peel strength tests can reflect the firmness of the connection, while metallographic microscopic analysis can observe the organizational structure of the brazing seam to determine whether the wetting is sufficient, whether there is a brittle phase or discontinuity.

Typical industry applications of titanium brazing

In the aviation field, titanium lightweight heat exchangers are one of the important applications of brazing technology. Such products are usually complex in structure and consist of multiple channels. Vacuum brazing can ensure that each channel is firmly connected and leak-free, meeting the dual requirements of high strength and lightweight.

Contact us now

In medical devices, the biocompatibility of titanium is widely used. For example, Grade 5 titanium alloy is used to manufacture endoscope housings and their connecting parts. Brazing technology can achieve a connection method with precise structure, beautiful welds, and no impact on the service life of the device.

Contact us nowTitanium is becoming increasingly popular in jewelry manufacturing and repair due to its unique color and lightweight texture. Induction brazing can achieve seamless connection of precision parts while preserving the metal surface texture and improving the appearance of the finished product.

Contact us now

Titanium brazing products Chalco can provide

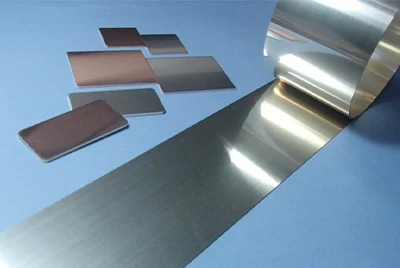

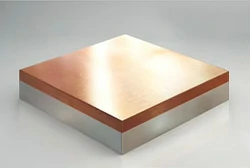

Titanium steel brazed composite plate is a bimetallic material that firmly combines industrial pure titanium with carbon steel or stainless steel through a brazing process. It combines the corrosion resistance of titanium with the mechanical strength of steel and is widely used in the lining structure of chemical storage tanks, pressure vessels and heat exchangers.

Titanium-copper brazing composite plate is made of a layer of titanium and a layer of copper diffused and connected by high-temperature brazing. It has both the corrosion resistance of titanium and the high conductivity of copper. It is often used in conductive parts in electroplating, electrolysis, and chlor-alkali industries, such as cathode plates, conductive rails, electrode support plates, etc. It is an ideal solution to replace titanium mesh welding components.

Titanium-aluminum brazed composite plates effectively combine titanium layers with aluminum substrates through a precisely controlled brazing process, creating a lightweight, corrosion-resistant composite material with excellent thermal conductivity. This product is suitable for aerospace heat sinks, battery thermal management panels, new energy heat exchangers and other occasions with high requirements on weight and heat dissipation efficiency.

Titanium-nickel brazed pipe is a composite structure pipe made of pure titanium and nickel or nickel alloy through brazing process. It has both the inertness of titanium and the anti-oxidation property of nickel, and is particularly suitable for use in high temperature, strong corrosion or special electrochemical environments such as condensers, evaporators, and electrolytic pipelines to improve pipeline life and electrochemical stability.

Titanium -stainless steel brazed transition joint is a structural connector developed to solve the problem of direct welding between titanium and steel. It is usually used to firmly combine titanium, stainless steel and intermediate metals (such as copper and niobium) through brazing, and is used in reactors, heat exchangers, piping systems and other dissimilar metal transition parts to achieve reliable connection and long-term service performance.

As a professional titanium material supplier, Chalco not only provides a variety of high-quality brazed composite plates, pipes and dissimilar metal joints such as titanium steel, titanium copper and titanium aluminum, but also meets the diverse needs of different customers for material specifications, structural forms and connection strength.

Chalco also has mature brazing processing and technical service capabilities. We can provide customers with a variety of process options such as vacuum brazing, induction brazing, active brazing, etc., and support small batch customization, dissimilar metal transition parts development, complex structural parts assembly and other engineering solutions.

Whether you need standardized brazing raw materials or are looking for high-airtightness, high-strength, mass-producible titanium brazing structural products, Chalco can provide you with one-stop support for the entire process from raw material selection, process design to product delivery.