Titanium CNC Machining – Precision Titanium Parts Supplier

Updated : Oct. 24, 2025Titanium alloys are known for their low weight, high strength, and excellent corrosion resistance. They are key materials in aerospace, medical devices, energy and chemical industries, and high-performance industrial applications.

As a professional supplier of titanium alloy products, Chalco not only offers a wide range of titanium raw materials but also possesses comprehensive CNC precision machining capabilities, enabling the direct delivery of high-quality finished titanium alloy parts. By combining raw materials with advanced CNC machining techniques, we achieve an integrated supply chain from material to parts, ensuring consistent quality, reliable precision, and on-time delivery. We provide trusted titanium alloy CNC products to customers worldwide.

Chalcotitanium Titanium Alloy CNC Machining: From Technical Challenges to Capability Breakthroughs

Titanium alloys are widely used in aerospace, medical, and energy fields due to their excellent properties. However, they are considered a typical "difficult-to-machine" material in CNC precision machining. Their low thermal conductivity, low elastic modulus, and strong tool affinity often bring the following challenges:

- Cutting temperature is too high → tool wear is accelerated, affecting processing efficiency;

- The tool is easy to stick → the surface quality is reduced and dimensional stability is poor;

- Difficult chip removal → easily leads to a discontinuous cutting process and even deformation of the workpiece;

- Thin-walled parts and parts with complex curved surfaces are more prone to vibration and precision deviation during machining.

Facing these challenges, Chalcotitanium has developed mature solutions based on advanced equipment and rich experience:

- Optimize tools and processes: Use high-performance tools and coatings, combined with reasonable cutting parameters and path planning, to effectively reduce tool wear;

- Efficient cooling: Apply high-pressure cooling and special cutting fluid to control cutting temperature and extend tool life;

- Stable clamping and five-axis machining: High-rigidity fixtures and five-axis linkage equipment ensure the dimensional accuracy and surface quality of complex curved and thin-walled parts;

- Accumulated experience: We have accumulated mature processes and successful cases in the processing of large-size parts, thin-walled parts, and precision structural parts, and are able to stably deliver high-quality products.

Alloy Expertise & Material Capability

We can provide the industry's most comprehensive range of commercially pure titanium and titanium-based alloy CNC machining materials, covering a variety of fields such as aviation, energy, medical, chemical, and marine engineering. The following are some typical alloys:

-

Grade 1 / CP4

High ductility and good formability, suitable for chemical and medical equipment.

-

Grade 2 / CP3

Good balance of strength and corrosion resistance, widely used in aviation, automobiles, and seawater desalination.

-

Grade 3 / CP2

Higher strength than Grades 1 and 2, suitable for applications requiring higher mechanical properties.

-

Grade 4 / CP1

The strongest commercially pure titanium, combining high strength and corrosion resistance.

-

Grade 7

The addition of palladium provides outstanding weldability and acid corrosion resistance.

-

Grade 11 / Ti-0.15Pd

Maintains excellent corrosion resistance in a variety of chemical environments.

-

Grade 5 / Ti-6Al-4V

The most commonly used α+β alloy, representing high strength, low weight, and corrosion resistance.

-

Grade 23 / Ti-6Al-4V ELI

Low-interstitial version with improved toughness and biocompatibility for medical implants.

-

Grade 6 / Ti-5Al-2.5Sn

Good weldability and formability, used in aviation.

-

Grade 9 / Ti-3Al-2.5V

High strength and good corrosion resistance, often used in pipes and high-temperature environments.

-

Grade 12 / Ti-0.3Mo-0.8Ni

Excellent performance in oxidizing and mildly reducing environments.

-

Ti-6-6-2

High strength and good corrosion resistance, used in aircraft engines.

-

Ti-6-2-4-2

Heat-treatment strengthened, often used in fuselages and rocket engine casings.

-

Ti-6-2-4-6

Suitable for high-strength marine and aircraft engine applications.

-

Ti-8-1-1

Outstanding high-temperature creep resistance, often used in jet engine components.

Don't see the titanium alloy you need?

Contact our titanium alloy CNC machining experts and we can customize your alloy selection and machining plan.

Chalcotitanium CNC Products & Applications

Chalcotitanium has complete titanium alloy CNC precision machining capabilities, covering a variety of needs from conventional parts to complex structural parts:

- Process types: CNC turning, CNC milling, five-axis machining, drilling and boring, threading, electrical discharge machining (EDM)

- Size range: Maximum workpiece size up to XXX mm

- Precision level: Conventional tolerance can be controlled within ±0.01 mm

- Surface roughness: Ra 0.8–1.6 μm

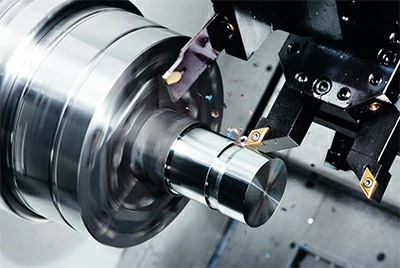

Turned Parts / CNC Turning

Typical parts: shafts, rings, valve cores

Application industries: aircraft engines, energy equipment

Features: high precision, stable dimensions, suitable for mass production

Milled Parts (CNC Milling)

Typical parts: housings, brackets, protective parts

Application industries: medical devices, consumer electronics

Features: balanced appearance and structural strength, with stable surface quality

5-Axis Complex Parts (5-Axis CNC Machining)

Typical parts: aviation structural parts, medical implants

Application industries: aerospace, medical

Features: high precision and consistency for complex curved surfaces and thin-walled structures

Fasteners (Threading & CNC Turning-Milling)

Typical parts: bolts, nuts, washers

Application industries: aviation, automobile, sports equipment

Features: reliable connection, high assembly precision, and support for mass customization

Custom Parts (Multi-Process CNC + EDM)

Typical parts: special structural parts, deep grooves, fine holes, complex internal cavities

Application industries: covering the needs of all industries

Post-Machining & Surface Finishing

High-quality surface treatment of titanium alloy parts is crucial. Due to titanium's low thermal conductivity and high chemical activity, improper machining can easily result in burrs, tool marks, and surface defects, impacting appearance and even performance safety, particularly in the aerospace and medical fields. Therefore, CNC molding often requires further finishing and surface treatment. This is achieved by controlling feed rates, speeds, and cutting depths, combined with grinding and polishing processes, to ensure both smoothness and performance.

Polishing

Remove minor defects and improve smoothness and aesthetics.

Sandblasting

Improve surface texture and even roughness, which is beneficial for subsequent coating.

Anodizing

Enhanced corrosion resistance, can be colored and decorated.

Electroplating

Improve wear resistance, corrosion resistance, appearance or electrical conductivity (including chrome/nickel plating).

Chemical Cleaning & Passivation

Remove surface residue and improve corrosion resistance.

PVD Coating (Physical Vapor Deposition)

Provides wear resistance, high temperature resistance and functional protection.

Quality Assurance & Inspection

In titanium CNC machining, quality control is central to the reliability of the finished product. Chalcotitanium uses a rigorous testing and certification system to ensure that every part meets customer requirements and international standards.

Compliance with international standards

Our products comply with ASTM, AMS, ISO 9001, AS9100D, and other standards for aviation, medical, and energy industries. Full traceable test reports are provided, with routine dimensional, hardness, and metallographic checks, plus optional NDT such as ultrasonic, penetrant, and X-ray.

Process Monitoring

From the entry of raw materials to CNC processing, heat treatment, surface treatment, and final packaging, each link has strict quality control records.

The precision testing equipment

The precision testing equipment is equipped with high-end testing devices such as three-coordinate measuring machines (CMMs), optical projectors, and roughness meters to ensure the detection accuracy of complex geometries and small-tolerance parts.

Through this complete quality and testing system, we not only ensure the consistency and reliability of parts, but also provide solid protection for our customers' aerospace certification and medical regulatory compliance.

Why Choose Us

Choosing the right titanium alloy CNC machining supplier means that the product can be more efficient and reliable from design to delivery. The advantages of Chalcotitanium are:

Integrated service: From material supply → precision CNC machining → post-processing → testing → finished product delivery, we provide a complete solution without the need for customers to coordinate with multiple parties.

Source manufacturer: has independent production and processing capabilities and can quickly complete parts manufacturing according to drawings.

Flexible support: When faced with tight delivery deadlines, inventory demands, or technical difficulties, we can leverage the collaboration between our subsidiaries and long-term partners to provide more flexible support.

Customization capability: supports small-batch trial production, large-batch production, and OEM/ODM personalized processing.

Global delivery experience: Our products have been exported to customers in the aviation, medical, energy and other industries, meeting international certifications and stringent requirements.

With these advantages, we are not only a supplier of titanium alloy materials, but also a trustworthy partner for CNC machining finished products.

Upload your drawings or contact our engineering team to get a customized solution today.