Titanium Corrosion Resistance in Water and Seawater

Updated : Sep. 23, 2025Why do conventional metals fail so quickly?

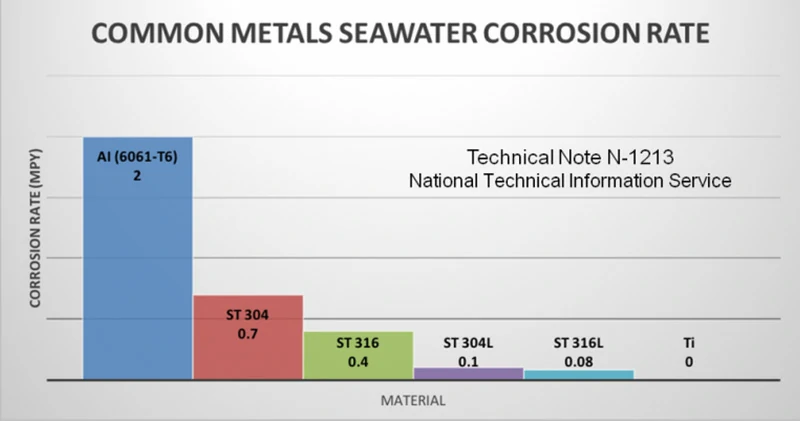

Coastal power plants and desalination systems typically experience shutdowns every 5–7 years due to corrosion of 316L stainless steel or Cu-Ni alloys. Maintenance costs may reach 25% of initial investment. Titanium, immune to seawater below 260 °C, is the key to minimizing downtime and maintenance.

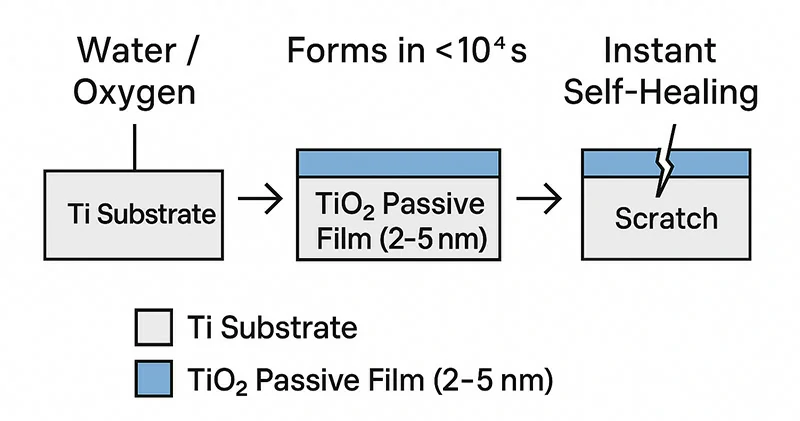

How does titanium "self-heal"?

When titanium contacts oxygen in water, it instantly forms a 2–5 nm thick TiO₂ passive film within less than 10⁻⁴ seconds. Even when scratched, the film self-repairs immediately.

As temperature rises, the oxide film thickens—reaching ~20 nm at 250 °C—while maintaining its dense structure and excellent chlorine resistance.

Commercially pure titanium (Gr 2) has a pitting resistance threshold of ~82 °C; palladium-alloyed titanium (Gr 7) increases this to ~150 °C.

In contrast, Cr₂O₃ or Al₂O₃ films on stainless steel tend to rupture under 300 mV SCE conditions, while TiO₂ remains stable and intact. Even after scratches, titanium "regrows" its protective layer in water, continuously resisting corrosion.

Experimental & field performance in water/seawater systems

In seawater corrosion environments, the application of titanium materials must strictly adhere to the latest international standards to ensure material reliability and safety.

| Application Environment | Grade | Temperature / Flow Rate | Corrosion Rate (mm/y) | Field Performance |

|---|---|---|---|---|

| Saturated Steam / Condensate | Gr 2 | 315 °C | < 0.001 | Zero corrosion in 2 years |

| Circulating Seawater | Gr 2 | 260 °C | < 0.0001 | No replacement in 16 years |

| High-Chloride Seawater (70–150 ppm Cl⁻) | Gr 7 | 150 °C | < 0.002 | Intact after 5 years |

| High-Velocity Erosion Test | Gr 2 | 36.6 m/s | < 0.005 | Minor wear after 18 months |

| SRB Microbial Corrosion | Gr 2 | Static · 35 °C | None | Verified over 12 months |

Key environmental factors affecting titanium's corrosion resistance

Gr 2 retains near-immunity up to 82 °C. Palladium-alloyed grades (Gr 7, Gr 11) increase pitting resistance up to ~150 °C.

In high Cl⁻ and high-temperature settings, Gr 12 is recommended, compliant with NACE MR0175.

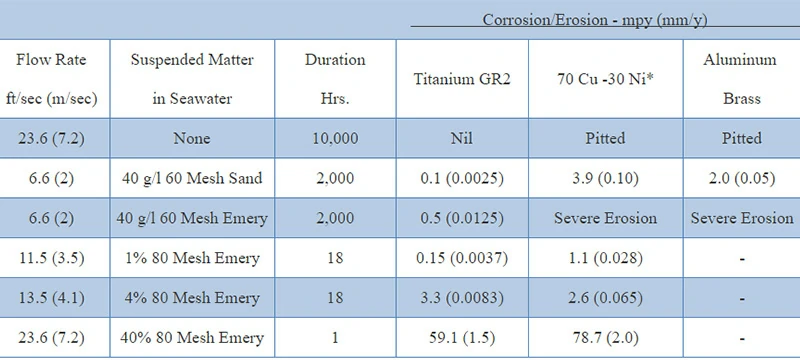

Titanium resists biofouling in flow speeds of 2–3 m/s and withstands erosion up to 36 m/s.

TiO₂ passive film remains stable across pH 1–12. Dissolved oxygen should be ≥ 1 ppm to prevent passivation failure.

Seawater performance comparison: titanium vs common metals (25 °C)

| Parameter | Ti Gr 2 | 316L SS | Cu-Ni 90/10 | Aluminum Brass |

|---|---|---|---|---|

| Uniform corrosion (mm/y) | < 0.0001 | 0.02–0.05 | 0.002 | 0.02 |

| Pitting threshold (°C) | 82 | 25–30 | 30 | 25 |

| Microbial corrosion risk | None | Medium–High | Medium | High |

| Safe flow velocity (m/s) | ≥ 30 | 6–9 | 4 | 4 |

| Tube replacement in 20 yrs | 0 | 1–2 | 1 | 1 |

Which titanium grade for which water quality?

Material choice should be based on chloride level, temperature, and corrosion risk. Use the table below for guidance.

| Water Quality | Application Scenario | Recommended Grade | Notes |

|---|---|---|---|

| River/Municipal (<100 ppm) | District heat exchangers, condensers | Gr 2 | Low cost, full corrosion immunity |

| Typical seawater (35–70 ppm Cl⁻) | RO inlets, ship cooling systems | Gr 2 | Withstands up to 260 °C, SCC immune |

| High-chloride seawater (70–150 ppm) | MED/MSF evaporators, produced water | Gr 7 | Pd-alloyed for crevice corrosion to 150 °C |

| H₂S-containing seawater | Subsea pipelines, fire mains, FPSOs | Gr 12 | Certified by NACE MR0175, up to 120 °C |

| High strength + pressure | Pumps, subsea bolts, turbine condensers | Gr 5 / Gr 23 | High strength for harsh conditions |

Seawater corrosion standards for titanium

In seawater corrosion environments, the application of titanium materials must strictly adhere to the latest international standards to ensure material reliability and safety.

- ISO 21457:2022 recommends Pd-Ti for conditions ≤120 °C, Cl⁻ ≤100 ppm.

- NACE MR0175:2024 allows Gr 12 for sour seawater up to 120 °C.

- ASTM B338-24 adds specs for thick-walled Gr 23 tubes.

- DNV RP-F112 (2025 draft) requires erosion verification for ≥35 m/s seawater flow and design life of 40 years.

Field case study: Ras Al Khair Desalination Plant, Saudi Arabia

Commissioned in 2014, this 1.036 million m³/day SWRO plant used ~6000 tons of Gr 2 + Gr 7 titanium. Operating at 110 °C, Cl⁻ 67–90 ppm for 11+ years with zero maintenance or replacement—saving over $85 million USD to date.

Frequently Asked Questions (FAQ)

Q: Does titanium really not corrode in seawater?

A: With the right grade (e.g., Gr 2 or Gr 7), titanium exhibits extremely high corrosion resistance under ≤90 ppm Cl⁻ and ≤260 °C. Measured rates are < 0.0001 mm/y.

Q: When is Pd-alloyed titanium necessary?

A: In evaporators or heat exchangers where Cl⁻ >100 ppm or temp >100 °C, Gr 7 (with Pd) is recommended to prevent crevice corrosion.

Q: Why is titanium worth the cost compared to 316L?

A: Though initial costs are 2–3× higher, titanium typically lasts 20+ years with no replacement, lowering total lifecycle cost by 20–30%.

Q: Can titanium be welded? Can it be joined to stainless steel?

A: Titanium can be TIG welded. It cannot be directly welded to stainless steel and requires explosion-bonded transition joints.

Q: What certifications can you provide?

A: Chalco offers ISO 9001, AS9100, EN 10204 3.1/3.2, SGS, TÜV and more.

Contact Chalco Titanium – Guaranteed 20-Year Corrosion Resistance

Serving clients in power, water, desalination, chemicals, marine, and offshore sectors. Facing any of the following?

Frequent tube failure and high downtime costs, Unexpected seawater corrosion beyond design, Uncertainty choosing Gr 2 / Gr 7 / Gr 12, Drafting specs or bidding proposals.

Let Chalco Titanium assist with:

- Free grade & dimension selection

- Full certifications, test data & welding support

- Matching inventory to drawings; 24h quoting

- Engineering samples & early-stage validation support

Request your sample kit → Gr 2 / Gr 7 tubes (200 mm each)

Join 1000+ global projects → See 20 years of zero-corrosion in action