What Is Titanium Investment Casting?

Updated : Jul. 9, 2025Titanium investment casting is ideal for industries that demand high strength, corrosion resistance, and lightweight materials. It's the go-to process for producing complex, precision parts.

Thanks to its high melting point, excellent strength-to-weight ratio, and outstanding biocompatibility, titanium is widely used in aerospace, medical, and advanced industrial applications.

What is titanium investment casting?

Titanium investment casting is a precision process tailored for complex titanium parts. It uses a "wax pattern replication + ceramic shell molding + vacuum pouring" technique to produce titanium components with high strength, low weight, and excellent dimensional accuracy.

Because titanium reacts easily with air and ceramics at high temperatures, this process requires special ceramic materials like zirconia and must be carried out in vacuum or inert gas conditions. This ensures the final parts maintain their purity and mechanical integrity.

Put simply, it's like creating a custom ceramic mold for a titanium part, then pouring in molten titanium to shape and solidify. This method captures every detail—making it ideal for intricate parts that are difficult to machine.

Advantages of titanium castings

Complex geometries made possible

Investment casting enables highly intricate shapes, such as thin-wall airfoils, honeycomb structures, and topology-optimized parts.

Excellent surface finish

The ceramic shell delivers as-cast surface roughness as low as 16 μin (0.4 μm), reducing the need for polishing and secondary machining.

Significant reduction in machining

Near-net-shape castings minimize material allowance to the millimeter level, cutting down machining time and cost by 60–80%.

Overcomes material brittleness

The fine-grain as-cast structure improves ductility and toughness. With post-heat treatment, castings can match or even exceed forged part performance.

Lower total part cost

While unit casting cost is higher, savings from high material utilization, minimal post-processing, and no welding assembly make it more cost-effective overall.

Faster lead times

From design to finished part, production typically takes just 2–4 weeks—much faster than forging or welding—allowing quick turnaround for urgent projects.

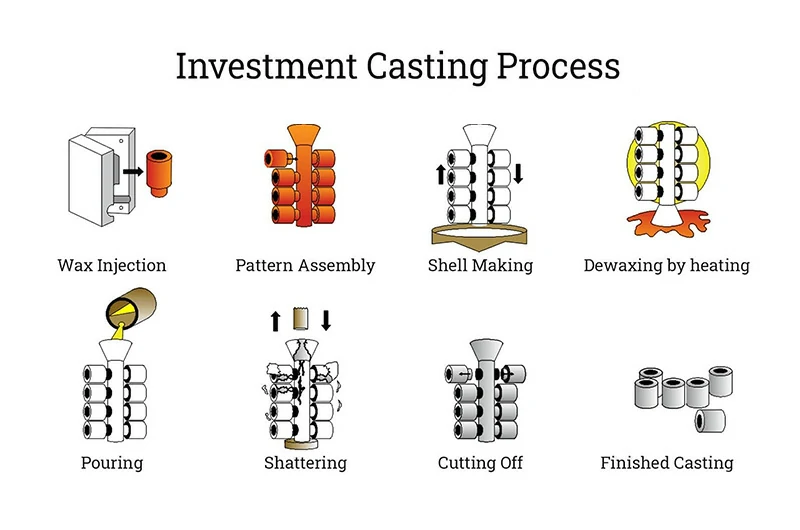

How is titanium investment casting done?

Mold creation

Molten wax is injected into a steel mold to form a precise wax pattern that matches the final titanium part.

These wax patterns can be solid or include wax cores for hollow castings.

Wax assembly

Multiple wax patterns are attached to a central sprue, creating a tree-like cluster that allows casting of several parts at once.

Ceramic shell building

The wax tree is repeatedly dipped in ceramic slurry and coated with sand to build up a strong ceramic shell.

Modern methods often use a three-layer shell for extra strength.

Dewaxing

Once the shell is complete, the wax is melted and drained using high-pressure steam or flash heating, leaving a clean hollow cavity.

Shell firing

The ceramic shell is fired at 1600–1800°F (about 870–980°C) to burn off residue and strengthen the mold, preparing it for casting.

Metal pouring

Molten titanium alloy is poured into the preheated shell under vacuum or centrifugal conditions to ensure full cavity filling.

Shell removal and cleaning

After the metal solidifies, the ceramic shell is removed using high-pressure water, vibration, or chemical methods to expose the titanium casting.

Finishing

Final steps include removing sprues, grinding, machining, surface treatment, and dimensional adjustments as needed.

Which industries benefit from titanium investment casting?

With its high strength, light weight, corrosion resistance, and suitability for complex shapes, titanium investment casting is widely used across advanced industries.

It's especially ideal for sectors that demand exceptional material performance, tight structural tolerances, and high design flexibility.

Aerospace

Titanium alloy is indispensable in aerospace manufacturing. Its high-temperature strength and lightweight properties make it ideal for high-speed, high-load, and high-heat environments.

Contact us now

- Turbine blades and compressor impellers.

- Engine brackets, nacelles, and housings.

- Landing gear components and hydraulic system parts.

- Structural frames and aerodynamic control elements.

- Drone, missile, and satellite structural parts.

Medical industry

Titanium offers excellent biocompatibility and mechanical performance. Investment casting allows near-net shaping, making implants and instruments more precise and efficient.

Contact us now

- Orthopedic implants (hip joints, knees, spinal fixators).

- Dental implants and denture bases.

- Surgical tools, bone saws, and stents.

- Medical device housings, components, and low-magnetic parts.

- Prosthetics and custom rehabilitation equipment.

Marine and chemical equipment

Titanium offers exceptional resistance to salt spray and chemical corrosion, making it an ideal material for harsh marine and industrial environments.

Contact us now

- Seawater heat exchangers, propeller shafts, and monitoring devices.

- Oil exploration and seismic mapping components.

- Pumps, valves, fittings, heat exchangers, and reactor vessels.

- Equipment for handling corrosive media like chlorides, sulfuric acid, and phosphoric acid.

Automotive industry

With the push for high performance and lightweight design, titanium castings are widely used in racing, electric vehicles, and premium engine systems.

Contact us now

- Turbocharger impellers.

- Suspension and drivetrain components.

- Valve mechanisms and exhaust parts.

Consumer goods and high-end applications

Titanium's unique appearance and strength make it a popular choice in premium consumer markets and luxury applications.

Contact us now

- Laptop and smartphone frames, watches, eyeglass frames, titanium jewelry, cast titanium cookware.

- Golf clubs, tennis rackets, and bicycle components.

- Musical instruments, luxury goods, and architectural décor parts.

Tools and machinery manufacturing

Titanium cast tools combine high strength with excellent wear resistance, making them ideal for heavy-duty and long-life applications.

Contact us now

- Construction tools (crowbars, hammer heads, impact drill parts).

- Precision power tools and high-strength hand tools.

Military and defense

Titanium withstands extreme impact and corrosion. Its reliability and structural integration enhance the performance and weight reduction of combat systems.

Contact us now

- Armor plates and submarine structures

- Howitzer components, missile parts, and firearm elements

- Battle tanks and airborne weapon systems

Common titanium alloys used in investment casting and their key properties

Grade 2 Titanium (Ti-CP)

Offers excellent corrosion resistance, weldability, and formability. Its outstanding biocompatibility and low reactivity also make it a preferred material for medical devices.

Contact us now

Grade 5 Ti (Ti-6Al-4V)

Renowned for its high strength, heat resistance, and corrosion resistance, Ti-6Al-4V is widely used in critical aerospace engine and structural components. It’s also a top choice for medical implants with strict biocompatibility requirements.

Contact us nowGrade 19 Ti (Beta-C)

As a beta titanium alloy, it offers excellent formability and high-temperature stability. In investment casting, it allows for the easy production of complex, heat-resistant structural parts.

Contact us now

Grade 23 Ti (Ti-6Al-4V ELI)

While maintaining strength, it provides enhanced biocompatibility and fatigue resistance. It’s widely used in precision medical applications such as orthopedic implants and dental restorations.

Contact us now

Production capacity and equipment for titanium investment casting

Titanium investment casting relies on a full set of high-precision equipment to ensure process stability and product quality. Key equipment includes wax injection machines, drying chambers, dewaxing autoclaves, vacuum melting furnaces, high-temperature sintering kilns, and ultrasonic testing instruments.

Typical titanium castings range from 5 grams to 30 kilograms. Dimensions can be customized based on customer drawings and project requirements, making the process suitable for everything from miniature medical parts to medium-sized structural components. Quick Quote

Surface treatment methods for titanium castings

After casting, titanium components often undergo surface treatments tailored to their application.

These treatments enhance corrosion resistance, wear resistance, or meet specific functional and aesthetic needs.

Surface treatments to improve corrosion resistance

- Thermal or electrochemical oxidation enhances the natural oxide layer on titanium.

- Precious metal coatings such as platinum or gold are used for superior corrosion protection.

- Dry coatings like CVD or PCVD apply thin films of TiC, TiN, or TiAl on the surface.

- Ion or electron beam coatings use advanced composite methods such as Pb+Pt systems.

Surface treatments to improve wear resistance

- Wet coatings involve chemical plating or spraying to enhance surface durability.

- Thermal diffusion introduces elements at high temperatures to harden the surface layer.

- Welding-based alloy reinforcement uses laser cladding or plasma surfacing to fuse wear-resistant alloys onto the surface.

- PVD sputtering deposits hard ceramic coatings like TiN or TiC.

- CVD, PCVD, and PCD (diamond coatings) are ideal for high-end applications requiring extreme wear resistance.

- Ion implantation alters the surface structure by injecting high-energy ions.

Functional and aesthetic treatments

- Mirror polishing significantly improves surface smoothness and visual appeal.

- Passivation or anodizing stabilizes the surface and allows for various color options while boosting corrosion resistance.

Challenges of titanium investment casting

- Molten titanium reacts strongly at high temperatures with oxygen, nitrogen, hydrogen, and ceramic mold materials, often leading to inclusions, porosity, or cracking.

- With a melting point around 3000°F (1649°C), titanium requires highly specialized equipment and precise temperature control during melting and pouring.

- Titanium alloys have a high solidification shrinkage rate—up to 2.2%—demanding accurate dimensional compensation and controlled cooling rates.

- Complex details and uneven wall thicknesses are difficult to cast, requiring extremely precise molds and advanced venting systems.

- Fine titanium powders are flammable, so processing and cleanup must follow strict safety protocols.

Titanium casting services

Chalco Titanium offers high-performance titanium investment casting services, delivering customized solutions for global leaders in aerospace, defense, energy, and heavy industry.

We provide end-to-end manufacturing—from design to mass production—with a strong focus on precision casting of complex geometries, thin-wall parts, and high-strength applications.

Our capabilities support custom parts ranging from 5 grams to 30 kilograms. We also assist with alloy selection, heat treatment guidance, and product optimization to enhance overall project performance and reliability.

To learn how we can support your titanium casting project, contact us for technical consultation and a personalized quote. Quick Quote

Explore our titanium casting capabilities

We showcase a wide range of titanium investment castings—from complex structural parts to high-precision medical components.

Our custom solutions support weights from 5g to 30kg, offering high strength, excellent surface finish, and dimensional stability—perfect for demanding industries like aerospace, medical, and energy.

Titanium cast valve

Titanium pipe fitting

Titanium part broaching arrowhead

Titanium casting impeller

Titanium fastener

Titanium quick release for bicycle

Titanium bicycle stem tube

Titanium broaching tool with wide head

Titanium valve body

Frequently asked questions (FAQ)

Can titanium be investment cast?

Yes. Titanium and titanium alloys can be investment cast to produce complex parts with high dimensional accuracy—especially for aerospace, medical, and energy applications.

However, due to titanium's high reactivity at elevated temperatures, the process must be carried out in a vacuum or inert atmosphere.

What is titanium investment casting?

Titanium investment casting is a precision near-net-shape process. A wax model is created, coated with ceramic, dewaxed, and sintered. Molten titanium alloy is then poured into the mold under vacuum, followed by shell removal and final finishing.

This process is ideal for producing high-precision, thin-walled, and complex titanium components.

What mold materials are used for titanium casting?

Zirconia-based ceramics are the most commonly used. They offer high-temperature stability and excellent chemical inertness, preventing reaction with molten titanium and ensuring casting quality.

Why is titanium difficult to cast?

Titanium readily reacts with oxygen, nitrogen, and hydrogen at high temperatures. It also has a high melting point, poor fluidity, and significant shrinkage during cooling—all of which complicate the casting process and increase defect risk.

Therefore, vacuum conditions, specialized shell materials, and precise process control are essential.

Who are the leading titanium investment casting companies?

Chalco Titanium offers full investment casting capabilities for aerospace, medical, defense, and industrial applications. We deliver high-quality titanium castings quickly and reliably, making us a trusted supply partner.

Chalco can provide you the most comprehensive inventory of titanium products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote