Titanium vs Carbon Bike

Updated : Jun. 23, 2025With the continuous development of bicycle technology, titanium alloy and carbon fiber, two high-end frame materials, have been widely applied in road bikes, gravel bikes, mountain bikes, and touring models. Although both belong to lightweight materials, they have distinct characteristics and obvious differences in performance, durability, maintenance costs, and usage scenarios.

Whether you are a cycling enthusiast, a complete bike brand, or a materials purchaser, gaining an in-depth understanding of the core differences between these two materials will help you make a more professional and rational choice.

Weight difference

One important reason why carbon fiber is favored by professional riders is its extremely low density. Most mid-to-high-end carbon fiber frames on the market weigh between 800 grams and 1.1 kilograms, giving them a significant advantage in climbing races.

In contrast, titanium alloy frames generally weigh between 1.3 and 1.6 kilograms. Although slightly heavier, when paired with wider tires, suspension components, or luggage gear, the overall weight difference becomes less noticeable.

Riding comfort

Titanium alloy has a natural elastic structure that effectively absorbs subtle vibrations from the ground, especially providing stable and smooth performance during long rides or on gravel and dirt roads. This "tough yet resilient” riding experience is difficult for carbon fiber to fully replicate.

Carbon fiber itself is very stiff and requires structural design, seatpost suspension, or tire width adjustments to compensate for its hardness. Although high-end carbon bikes can achieve a certain level of comfort, they generally remain firm and deliver greater physical impact during long rides.

Durability

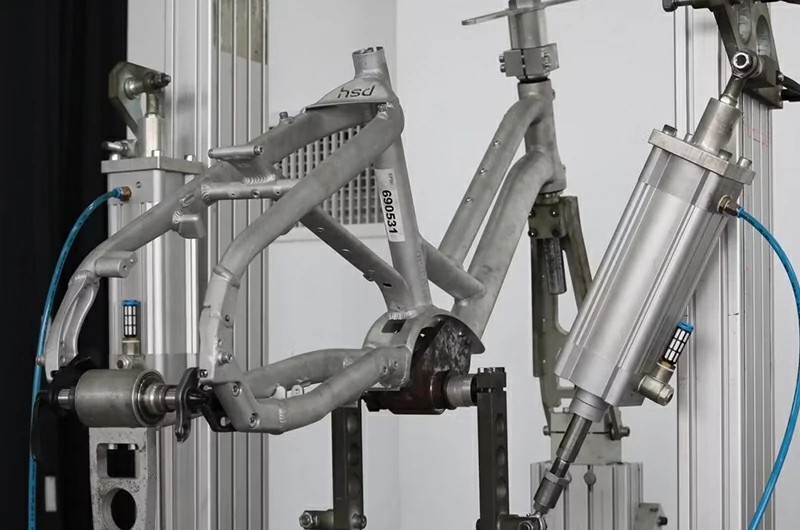

A significant advantage of titanium alloy is its excellent fatigue resistance. Unlike aluminum or steel, it does not weaken structurally after prolonged use. As long as it is reasonably designed and used properly, titanium frames commonly last more than 10 years.

Carbon fiber faces structural fatigue issues. Long-term high-intensity use or exposure to moisture and ultraviolet light can cause gradual delamination between laminate layers. Impact damage can lead to hidden cracks that are difficult to detect, posing latent risks.

Impact resistance

When subjected to external impact, titanium alloy usually only suffers minor surface deformation or scratches, while maintaining structural stability and usability. Moreover, titanium can be re-polished and repaired by welding to extend its service life.

Carbon fiber is different. Once impacted at edges or corners, internal structural fractures often occur. These cracks are often invisible to the naked eye and may suddenly cause failure during subsequent rides, creating safety hazards.

Maintenance and care

Titanium alloy does not rust or peel, and even after long exposure to rain, sweat, or sea air, corrosion is not a concern. Routine cleaning with water is sufficient, with no need for waxing, painting, or special protective treatments.

Carbon fiber itself does not rust but has paint or resin coatings that are easily scratched. If scratches are deep or cracks appear, professional carbon repair services must be sought for inspection and treatment, which is costly and time-consuming.

Service life

Titanium frames typically last over 15 years, with many riders still using them after 20 years. This "lifetime” material is especially suitable for users who value long-term investment.

Carbon fiber is more suited for competitive users seeking lightweight performance within a shorter cycle. Most carbon bikes require replacement or performance decline after 5–7 years, with professional riders and brands generally replacing more frequently.

Customizability

Titanium frame tubing can be freely cut and welded, allowing flexible adjustment of geometry such as head tube angle, chainstay length, and top tube slope according to user needs. This makes it ideal for high-end custom or functional frames.

Carbon fiber relies on molds for shaping, making personalized customization not only time-consuming but also costly due to mold expenses. Small-batch or single-piece customization is generally unsupported, limiting flexibility.

Appearance

Titanium frames do not require painting; brushed or sandblasted surfaces reveal a unique metallic texture. Over time, natural oxidation forms a metal sheen that gains character with use.

Carbon fiber can be painted in various colorful finishes, but the coatings are easily scratched. Scratches often occur during transport, crashes, or locking, eventually causing loss of gloss or paint peeling, which affects overall aesthetics.

Environmental sustainability

Titanium metal is 100% recyclable with low environmental impact during smelting. Its long service life makes it regarded as a green, low-carbon metal material in European and American markets.

Carbon fiber’s resin components cannot be recycled. Damaged carbon fiber is typically landfilled or incinerated, causing high pollution and energy consumption, increasingly conflicting with global environmental procurement trends.

Cost

Titanium frames have a higher initial cost, especially for custom demands due to complex processing and expensive materials. However, they are durable, corrosion-resistant, repairable, and nearly maintenance-free. Their long service life results in lower average annual costs, making them suitable for long-term investment.

In contrast, carbon fiber frames have a relatively lower starting price and are easier to mass-produce but remain high-end materials. Their structure is brittle with limited lifespan and difficult to repair. In the long run, maintenance and depreciation costs are higher, making their overall cost-effectiveness inferior to titanium alloy.

How to choose between a titanium alloy or carbon fiber frame?

When choosing a frame material, you should not base your decision solely on price or marketing claims. Instead, consider multiple factors comprehensively, such as your intended use, riding style, usage duration, and willingness to maintain.

Riding purpose

For racing, road competitions, and climbing challenges, carbon fiber is the preferred choice. It is lightweight, highly rigid, and offers efficient power transfer, better meeting the extreme demands for speed and climbing performance.

For gravel roads, touring rides, or multi-day expeditions, titanium alloy is more suitable. It provides good stability and shock absorption, can carry luggage, and is less prone to damage, making it ideal for complex and variable riding conditions.

In urban commuting or all-terrain exploration, titanium alloy also performs excellently. It is corrosion-resistant, almost maintenance-free, and resistant to rain and scratches from locking the bike, offering a more worry-free and reliable experience.

Riding duration and frequency

If your rides typically last over two hours or you cycle multiple times a week, titanium alloy offers greater comfort, helping to reduce fatigue in your arms and back.

If you only ride occasionally on short trips, the lightweight advantage of carbon fiber provides a more agile and responsive handling experience.

Environment and maintenance capability

For riding often in humid, rainy, mountainous, or coastal environments, titanium alloy’s excellent corrosion resistance better adapts to these climates and road conditions.

Riders who prefer minimal maintenance or frame inspections will appreciate titanium alloy’s near "lifetime use” characteristic, without worries about aging, paint peeling, or cracks.

Those with prior experience using carbon fiber bikes and willing to perform regular inspections and maintenance can also meet most riding needs with carbon fiber frames.

Need for customization or personalized design

If you want a custom frame tailored to your body or specific uses, such as long-wheelbase touring bikes or multiple mounting points, titanium alloy supports flexible customization.

Carbon fiber frames usually rely on molds with fixed dimensions, resulting in higher customization costs and limited options.

Service life and budget planning

If you plan to ride the same bike for over ten years and want some degree of resale value, titanium alloy is undoubtedly the wiser long-term investment.

With a relatively limited budget and more focus on short-term performance, mid-range carbon fiber frames paired with suitable components can also provide a lightweight and smooth riding experience.

What can Chalco do for you?

Chalco is a professional titanium supplier specializing in the global export of titanium alloy tubing. Our clients include complete bicycle manufacturers, custom frame brands, and component makers. We offer:

- Aviation-grade titanium alloy tubing (Grade 9 / 3Al-2.5V)

- Custom cutting, drilling, CNC machining, and surface treatments (brushing, sandblasting, ceramic coating)

- Support for both small-batch and large-volume orders with flexible delivery

- One-stop services including samples, drawings, and export documentation

Feel free to contact us for detailed information and cooperation quotes.