Weld Titanium to Stainless

Updated : Oct. 22, 2025In modern industry, welding titanium to stainless steel offers both performance and cost advantages. Stainless steel provides strength and economy, while titanium contributes light weight and corrosion resistance. Their combination not only extends equipment service life but also reduces overall costs, making it widely used in chemical, marine, aerospace, and nuclear applications

Why are titanium and stainless steel difficult to weld?

Although the combination of titanium and stainless steel offers clear advantages in performance and cost, there are several challenges in the welding process.

Melting point difference

Titanium melts at around 1668 °C, while stainless steel begins melting at 1400–1450 °C. In other words, during welding stainless steel enters the molten state first, while titanium remains solid. This uneven heating makes the weld pool difficult to control, leading to high welding stress and a tendency to crack.

Formation of brittle compounds

At high temperatures, titanium reacts with iron, chromium, and nickel in stainless steel to form brittle intermetallic compounds such as TiFe and TiFe₂. These compounds are very hard but extremely brittle, and under pressure they may crack like glass, significantly reducing joint strength and toughness.

Sensitivity to the environment

Titanium readily absorbs oxygen, nitrogen, and hydrogen from the air at high temperatures. Without sufficient shielding, the weld may develop porosity or become brittle, losing its toughness. This is why titanium welding must be performed under strict argon or vacuum protection.

Differences in thermal expansion and contraction

Titanium and stainless steel expand and contract at different rates during heating and cooling. Just like two materials cooling at different speeds, the mismatch creates residual stresses in the weld zone, further increasing the risk of cracking.

Common welding methods for titanium and stainless steel

Welding titanium to stainless steel is not impossible, but conventional fusion welding almost always fails. To obtain a reliable joint, you must use purpose-designed procedures and intermediate (transition) layers.

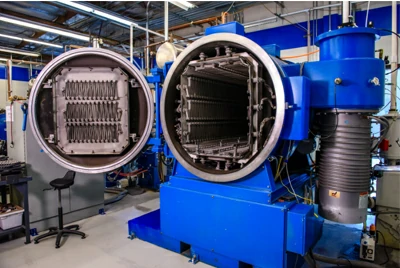

Vacuum brazing

Vacuum brazing is performed in a high-vacuum furnace. The chamber is pumped down to an ultimate pressure better than 1.3×10⁻³ Pa, effectively removing air so titanium will not react with oxygen, nitrogen, or water vapor at elevated temperatures. Instead of fully melting the titanium or stainless base metals, a dedicated filler (such as Ti–Zr–Cu–Ni brazing alloys or Ag–Cu based fillers) is melted and diffuses across the interface to join the dissimilar metals.

Why vacuum matters

Titanium "absorbs” gases at high temperature. If oxygen or moisture is present, a brittle layer forms and the joint can embrittle or crack. Vacuum minimizes these reactions and helps preserve the native strength and toughness of titanium.

Advantages

Uniform heating without degrading base-metal microstructure, minimal distortion after cooling, smooth and clean seams that often require no post-processing, and high joint strength suitable for most engineering needs. The process is stable and controllable, ideal for consistent batch production.

Limitations

Because the base metals do not fully melt, joint strength is typically below parent-metal strength, making true equal-strength joints difficult. Vacuum furnaces are expensive, so overall costs are higher. Best for small parts, thin walls, and precision assemblies—not for large thick plates or heavily loaded structures.

Typical applications

Small heat-exchanger subassemblies, parts for chemical equipment, precision medical devices, and laboratory apparatus where accuracy and corrosion resistance are critical.

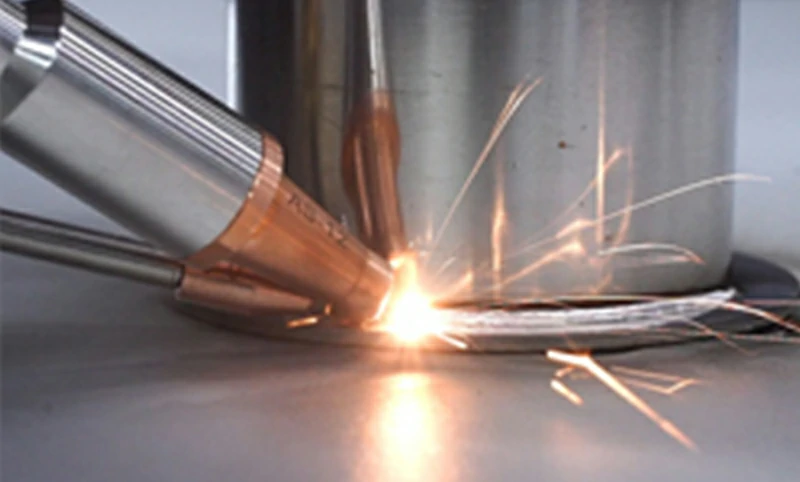

TIG brazing

TIG brazing uses a gas-tungsten arc as the heat source to melt only the filler; the base metals remain solid. The filler wets and diffuses at the titanium–stainless interface to create a sound bond. The process is conducted under high-purity argon shielding to prevent oxidation or nitriding of hot titanium.

Advantages

Low heat input, low distortion, smooth appearance, and excellent base-metal integrity. Equipment is widely available—standard TIG machines can be adapted—and the method is amenable to automation for small to medium production.

Limitations

Joint strength depends heavily on filler choice and tight process control; stability under high loads can be limited. It demands very pure argon and rigorous shielding coverage—any lapse risks porosity or embrittlement—so operator skill must be high.

Typical applications

Process piping, thin-wall vessels, small structures, and field work or repairs—especially where seam appearance and dimensional stability matter.

Laser / electron-beam welding

Laser and electron-beam (EB) welding use high-energy-density beams to melt and rapidly solidify the interface. Heat input is highly localized and dwell time is short, so the heat-affected zone is minimal. To avoid forming brittle Ti–Fe intermetallics, a transition layer (such as copper, tantalum, or nickel) is commonly inserted between titanium and stainless steel.

Advantages

Concentrated energy and fast cooling produce narrow, precise welds with minimal part distortion—excellent for thin walls and precision joints. Laser welds are easy to automate; EB welds in vacuum can achieve greater penetration.

Limitations

Tight process windows and stringent fit-up are required; without a transition layer, brittle compounds readily form. Inadequate shielding in laser welding leads to oxidation; EB welding must be done in vacuum and requires costly equipment.

Typical applications

Aerospace precision parts, high-end heat-exchanger joints, electronic components, and specialized research joints where weld size, profile, and microstructure are tightly controlled.

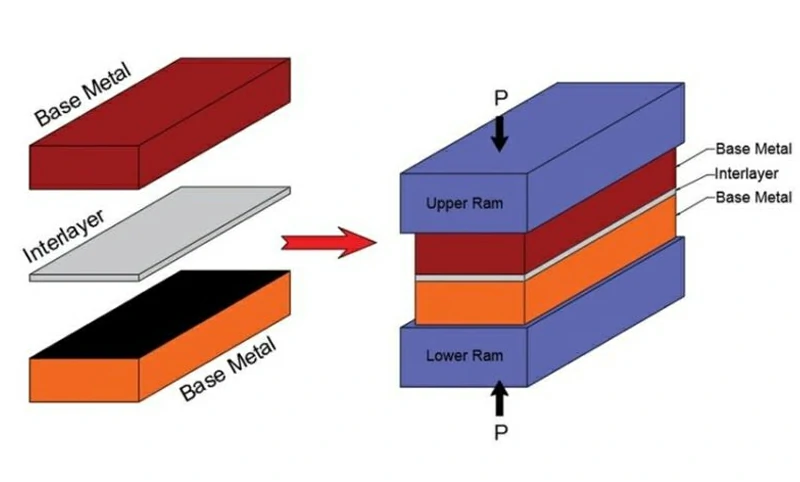

Diffusion bonding

Diffusion bonding is a solid-state process performed under high temperature, pressure, and vacuum for an extended hold time, allowing atoms to diffuse and form a metallurgical bond without bulk melting. Transition interlayers such as nickel foil, Cu–V composites, or silver-based layers are often used to suppress brittle Ti–Fe phases.

Advantages

Dense, uniform joints with stable properties and excellent dimensional accuracy. With suitable interlayers, brittle phases are effectively suppressed, improving toughness and load capacity. Ideal for small parts requiring high precision.

Limitations

Requires expensive vacuum equipment and long cycle times; parameters are sensitive. Not suited to large, thick plates or big assemblies; most common in R&D and high-end manufacturing.

Typical applications

Aerospace, nuclear, and precision instrumentation—tube sheets, transition rings, small brackets, and experimental dissimilar-metal joints where interfacial microstructure is critical.

Friction welding

Friction welding is a solid-state method where one part rotates rapidly against the other, generating heat by friction until the interface softens; axial pressure then forges the joint. Because the base metals do not melt, interfacial microstructure is stable. It is widely used for bar-to-bar and tube-to-tube titanium–stainless joints in electrochemical, aerospace, and energy equipment.

Advantages

Fast, efficient, and no shielding gas is required. As a solid-state process, it minimizes brittle intermetallic formation; joints can achieve good strength and fatigue life with little material waste.

Limitations

Geometry is restrictive—best for axisymmetric bars and tubes, not complex or large-area seams. Bending ductility and impact toughness may be lower; post-weld machining is often needed to restore dimensions.

Typical applications

Current-carrying rods in electrolytic systems, aerospace shafts and rods, and tube-to-tube joints in energy equipment—well suited to high-volume, axisymmetric parts.

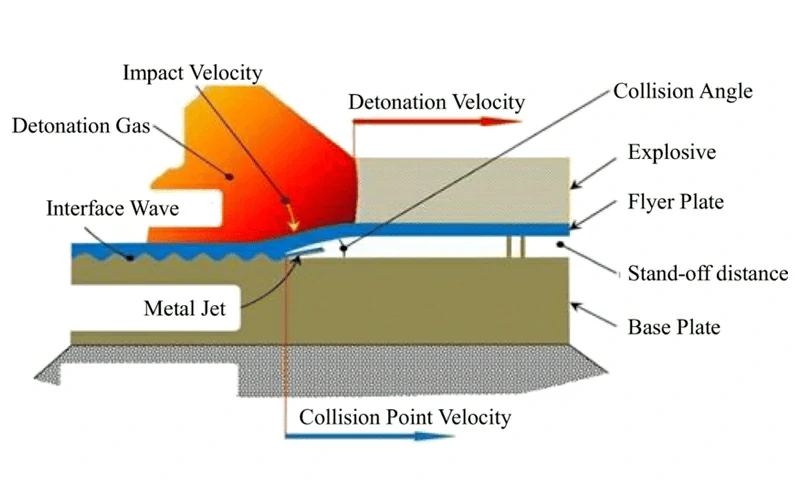

Explosive welding

Explosive welding is a solid-state cladding process that uses a controlled detonation to accelerate one plate into another, producing a wavy metallurgical interface between titanium and stainless steel. Bond strength is high and reliability is excellent; the method is standard for producing large-area clad plates and transition joints used in pressure equipment and heat exchangers.

Advantages

Capable of large-area, thick-plate cladding; joint strength approaches that of the parent metals. Industrial maturity is high, making it the mainstream solution for titanium–steel transition joints in pressure vessels and heat exchangers.

Limitations

Some brittle intermetallics may form at the interface, which can limit ductility and high-temperature performance. The process requires dedicated sites and safety measures; clad plates are typically manufactured by specialized suppliers and then fabricated downstream.

Typical applications

Titanium–stainless clad plate, heat-exchanger tube sheets, titanium-lined stainless shells, and titanium–steel transition joints—an established, large-scale route for deploying titanium in chemical processing, marine engineering, and energy equipment.

Transition layers and filler selection for titanium–stainless welding

Importance of transition layers and filler metals

In welding titanium to stainless steel, the choice of transition layer or filler metal often determines whether the joint will be truly reliable. If titanium comes into direct contact and fuses with iron, large amounts of brittle Ti–Fe intermetallic compounds (such as TiFe and TiFe₂) inevitably form. Although these compounds are hard, they fracture easily and can cause weld failure under pressure.

To avoid this, engineers introduce suitable intermediate materials between the two metals. On the one hand, they block the direct reaction between titanium and iron; on the other, through their own melting and diffusion, they help create a stable metallurgical bond.

Common transition layers and filler types

| Type | Applicable welding methods | Characteristics | Advantages | Limitations |

|---|---|---|---|---|

| Nickel-based (Ni) | Vacuum brazing, diffusion bonding | Fillers such as BNi2, BNi7, commonly used where high strength is required | Stable interface, high strength, good toughness | High temperature, high energy consumption, costly |

| Copper-based (Cu) | Laser welding, electron-beam welding, diffusion bonding | Commonly used as copper foil or Cu–V composite layers | Prevents Ti–Fe reaction, cost-effective | Requires strict process sequence, thickness must be precisely controlled |

| Silver-based (Ag) | Vacuum brazing, TIG brazing | Ag–Cu–Zn or Ag–Pd fillers | Good wettability, low-temperature brazing, minimal distortion | Limited affinity with titanium, relatively low strength |

| Tantalum / vanadium (Ta / V) | Laser welding, electron-beam welding | High-end transition metals | Excellent compatibility with titanium, high-temperature and corrosion resistance | Very expensive, complex process |

| Multi-element alloys (Ti–Zr–Cu–Ni) | Vacuum brazing, diffusion bonding | Specially designed composite fillers | Balanced strength, diffusion, and corrosion resistance | Complex composition, high cost |

How to choose the right filler or transition layer

- For high strength and long-term stability, nickel-based fillers or multi-element alloys are suitable.

- For high precision and minimal deformation, silver-based fillers are recommended.

- For large-scale, cost-sensitive applications, copper-based transition layers are appropriate.

- For extreme high-temperature or highly corrosive environments, tantalum or vanadium is preferred.

Application scenarios of titanium–stainless steel welding

The combination of titanium and stainless steel offers complementary benefits: stainless steel is economical and weldable, while titanium is lightweight and corrosion resistant. Proper welding produces structures with high performance and reduced cost.

Chemical industry

Applications: Heat exchangers, reactor linings, corrosion-resistant pipelines

Role: Enhance corrosion resistance, extend service life, reduce maintenance frequency

Contact us now

Marine engineering

Applications: Ship pipelines, pump housings, seawater desalination units, deep-sea equipment

Role: Resist chloride corrosion, ensure long-term stability in high-salinity environments

Contact us nowAerospace

Applications: Fuel systems, lightweight structural parts, high-temperature components

Role: Reduce weight, improve corrosion resistance, and control costs

Contact us now

Nuclear and energy

Applications: Condenser tube sheets, heat exchangers, critical pipelines

Role: Withstand high temperature and pressure, prevent corrosion failure, enhance safety and reliability

Contact us nowCost and economy

Welding titanium to stainless steel is not a low-cost process. Vacuum brazing requires expensive vacuum furnaces, explosive welding needs special facilities and safety measures, and laser or electron-beam welding relies on advanced equipment and skilled operators. However, from a full life-cycle perspective, this type of welding still offers significant economic value.

On the one hand, composite structures can greatly reduce the amount of pure titanium required—while maintaining strength and corrosion resistance—cutting raw material costs by 40–60%. On the other hand, the longer corrosion-resistant service life means less maintenance or replacement, which substantially lowers long-term operating expenses.

Therefore, for industries such as chemical, marine, and energy, although the initial investment is relatively high, the savings in service life, maintenance frequency, and downtime often offset or even exceed the upfront costs.

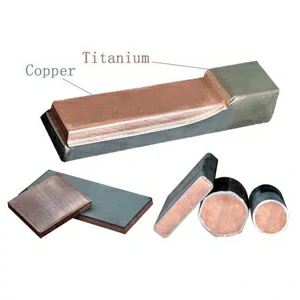

Titanium clad materials offered by Chalco Titanium

As a leading supplier of titanium and clad metal solutions, Chalco Titanium not only provides conventional titanium plates, bars, and tubes, but also supplies a wide range of titanium clad materials through advanced processes such as explosive welding, diffusion bonding, and vacuum brazing.

-

Titanium clad steelCombines titanium’s corrosion resistance with steel’s strength and low cost. Used in pressure vessels, heat exchangers, and reactor linings. Typically made by explosive welding or vacuum brazing into large clad plates.

-

Titanium clad copperMerges copper’s high conductivity with titanium’s corrosion resistance. Applied in electrodes and busbars for electrolysis, electroplating, and chlor-alkali industries. Usually produced by explosive welding or diffusion bonding into clad bars or plates.

-

Titanium clad aluminumCombines titanium’s corrosion resistance with aluminum’s light weight and thermal conductivity. Used in chemical heat exchangers, seawater desalination, and aerospace components. Made by explosive welding or roll bonding, followed by brazing or inert gas welding.

-

Titanium clad nickelIntegrates nickel’s high-temperature and corrosion resistance with titanium’s light weight. Applied in evaporators, heat exchangers, and brine treatment equipment. Typically manufactured by diffusion bonding or vacuum brazing into tube sheets or components.

If you have any requirements for titanium clad materials, please feel free to contact Chalco Titanium. We will provide you with professional material selection advice and welding solutions.