Aerospace Grade 6al-4v Titanium Bar

Aerospace grade 6Al-4V titanium rod, also known as Ti-6Al-4V or grade 5 titanium, is an alpha-beta titanium alloy named after its composition contains 6% aluminum and 4% vanadium. This titanium alloy is known for its high strength-to-weight ratio, excellent corrosion resistance and excellent high temperature resistance. It also has good processing performance and fatigue resistance. It is one of the most widely used titanium alloys at present.

Thanks to its light weight and reliability, 6Al-4V titanium rods are widely used in aircraft structural parts, engine core components and aviation fasteners, such as wing reinforcements, turbine blades and landing gear frames. They perform well in extreme environments and help improve aircraft performance and durability.

Chalco 6al-4v titanium bar specification

- MIL-T-9047

- AMS-T-9047

- AMS-4928

- AMS 4930

- AMS 4965

- ASTM B348

Chalco's popular aviation grade 6al-4v titanium bar

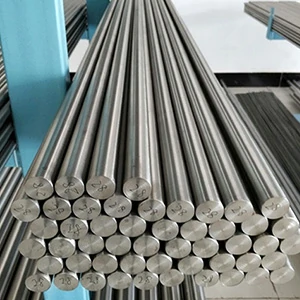

6al-4v titanium round bar

Titanium bar with round cross-sections are widely used in the aerospace field due to their uniform stress distribution, and are ideal for high-strength and high-precision components.

Contact us now

Titanium bar with round cross-sections are widely used in the aerospace field due to their uniform stress distribution, and are ideal for high-strength and high-precision components.

- Small diameter: 5mm - 20mm, mostly used for small structural parts such as fasteners and precision mechanical parts.

- Medium diameter: 20mm - 100mm, widely used in medium-sized parts such as aircraft frames, landing gear supports and engine shafts.

- Large diameter: 100mm - 300mm, mainly used for key structural parts that bear high loads, such as turbine shafts, compressor discs, etc.

- Length: usually 1 meter to 6 meters, suitable for the processing needs of most industrial and aerospace components.

- Advantages: good processing performance, strong fatigue resistance, suitable for bearing dynamic loads.

- Application scenarios: turbine engine shafts, fasteners, aircraft frame components, etc.

Chalco also has a lot of aerospace grade Ti-6al-4v aluminum round bars in stock, click to view specific sizes.

6al-4v titanium square bar

Square-section titanium bars are often used in structural components in the aerospace field that have strict requirements on high bending stiffness due to their large section moment of inertia.

Contact us now

Square-section titanium bars are often used in structural components in the aerospace field that have strict requirements on high bending stiffness due to their large section moment of inertia.

- Small size: 5mm - 20mm side length, mainly used for small structural parts, fasteners or precision parts.

- Medium size: 20mm - 100mm side length, widely used in medium-sized structural parts such as wing reinforcements, cockpit frames, etc.

- Large size: 100mm - 200mm side length, suitable for parts requiring high strength and rigidity, such as landing gear supports or large frame structures.

- Length: usually 1m - 6m or customized

- Advantages: easy to fix and assemble, with high structural stability.

- Application scenarios: aircraft wing reinforcements, cockpit frames and landing gear supports.

6al-4v titanium rectangular bar

The flat titanium rods enable lightweight design by reducing thickness while providing a large contact area to spread the load.

Contact us now

The flat titanium rods enable lightweight design by reducing thickness while providing a large contact area to spread the load.

- Thickness: 2mm - 100mm

- Width: 10mm - 500mm

- Length: 1-6m or customized

- Application scenario: aircraft skin stiffeners and guide rail systems.

- Advantages: Significantly lightweight, suitable for structural design in small spaces.

6al-4v titanium hex bar

Hexagonal titanium rods are used for special fasteners or high-precision mechanical parts.

Contact us now

Hexagonal titanium rods are used for special fasteners or high-precision mechanical parts.

Advantages: The special cross-sectional shape is suitable for manufacturing self-locking structural parts.

Application scenarios: Bolts, nuts and special connectors in the aerospace field.

Chalco 6al-4v titanium bar featured products

6Al-4V hot-rolled titanium bar is formed by rolling titanium alloy at high temperatures. It has a rough surface but a uniform internal structure. It offers good plasticity and low internal stress, making it suitable as a billet material for large aerospace structural components or parts that require further processing, such as wing reinforcements and support structures.

6Al-4V cold-drawn titanium bar is manufactured using a drawing process at room temperature. It has a smooth surface, high dimensional accuracy, and higher strength, but may retain internal stress. It is widely used in aerospace fasteners, high-precision shaft components, and small standard parts that do not require secondary processing, making it particularly suitable for applications with strict precision requirements.

6Al-4V forged titanium bar is formed through high-temperature forging. Its internal structure is dense and defect-free, offering exceptionally high strength and toughness, making it capable of meeting the demands of high-load and high-temperature environments in aerospace. It is typically used to manufacture landing gear, turbine components, and other critical load-bearing parts, demonstrating excellent reliability and durability.

The characteristics of aerospace-grade 6al-4v titanium bar

High strength

The tensile strength of 6al-4v titanium alloy reaches up to 830 MPa, with a yield strength close to 795 MPa, demonstrating exceptionally high strength characteristics. This makes 6al-4v titanium bar particularly suitable for structural components in aerospace that need to withstand heavy loads, such as aircraft frames and landing gear, significantly improving the overall stability and safety of the structure.

High temperature stability

6Al-4V titanium alloy maintains excellent mechanical properties at temperatures above 400°C, exhibiting outstanding thermal stability. Titanium bars made from this alloy are particularly suitable for high-temperature components in aerospace engines, such as compressor discs and fasteners in the combustion chamber, where they can maintain reliability in high-temperature environments.

Lightweight design advantage

6al-4v titanium alloy has a density of only 4.43 g/cm³, about 40% lighter than steel, yet with comparable or even higher strength. As a result, 6al-4v titanium bar is the preferred choice for lightweight design, helping to reduce weight in aerospace vehicles, improve fuel efficiency, and lower overall energy consumption of the aircraft.

Excellent fatigue and crack resistance

Due to its high fatigue limit and excellent crack resistance, titanium bars made from 6Al-4V titanium alloy can maintain structural integrity under repeated loading and vibration. This characteristic makes it ideal for key components, such as aircraft landing gear and power system connections, which are subjected to dynamic loads over long periods.

Corrosion resistance

6Al-4V titanium alloy exhibits strong resistance to corrosion from common environmental factors in aviation, such as moisture, high-salinity gases, and aviation fuels. Titanium bars made from this alloy perform excellently in exposed aircraft parts, such as external fasteners and wing supports, significantly reducing maintenance and replacement costs caused by corrosion.

Excellent machinability

6Al-4V titanium alloy combines good machinability and weldability, making titanium bars produced from it more efficient in the manufacturing of complex aerospace structural components. This machining advantage not only reduces production difficulty but also improves product precision and consistency.

The tolerances of aerospace-grade 6Al-4V titanium bar

Chalco's aerospace-grade 6Al-4V titanium bar strictly follows international standard dimensional tolerance requirements to ensure the high-precision application needs in the aerospace field. For specific tolerances, please refer to the table below. If you have special requirements, please discuss your tolerance needs in advance.

| Alloy | Diameter | Diameter Tolerance |

|---|---|---|

| 6AL-4V | <0.25" | +/- 0.005" |

| 6AL-4V | 0.25" - 0.3125" | +/- 0.005" |

| 6AL-4V | 0.3125" - 0.4375" | +/- 0.006" |

| 6AL-4V | 0.4375- 0.625" | +/- 0.007" |

| 6AL-4V | 0.625" - 0.875" | +/- 0.008" |

| 6AL-4V | 0.875" - 1" | +/- 0.009" |

| 6AL-4V | 1" - 1.125" | +/- 0.010" |

| 6AL-4V | 1.125" - 1.25" | +/- 0.011" |

| 6AL-4V | 1.25"- 1.375” | +/- 0.012" |

| 6AL-4V | 1.375" - 1.5” | +/- 0.014" |

| 6AL-4V | 1.5"- 2” | +/- 1/64" |

| 6AL-4V | 2"- 2.5” | + 1/32" |

| 6AL-4V | 2.5"- 3.5” | + 3/64" |

| 6AL-4V | 3.5"- 4.5” | + 1/16" |

The physical properties of aerospace-grade 6Al-4V titanium bar

| Property | Min Value | Max Value |

|---|---|---|

| Density | 4.429 g/cm³ (0.160 lb/cu in) | 4.512 g/cm³ (0.163 lb/cu in) |

| Young's Modulus | 104 GPa (15.1×10⁶ psi) | 113 GPa (16.4×10⁶ psi) |

| Shear Modulus | 40 GPa (5.8×10⁶ psi) | 45 GPa (6.5×10⁶ psi) |

| Bulk Modulus | 96.8 GPa (14.0×10⁶ psi) | 153 GPa (22.2×10⁶ psi) |

| Poisson's Ratio | 0.31 | 0.37 |

| Tensile Yield Stress | 880 MPa (128,000 psi) | 920 MPa (133,000 psi) |

| Tensile Ultimate Stress | 900 MPa (130,000 psi) | 950 MPa (138,000 psi) |

| Hardness | 36 Rockwell C (Typical) | -- |

| Uniform Elongation | 5% | 18% |

The chemical composition of aerospace-grade 6Al-4V titanium bar

| Element | Composition (%) |

|---|---|

| V (Vanadium) | 3.5 - 4.5 |

| Al (Aluminum) | 5.5 - 6.75 |

| Fe (Iron) | ≤ 0.3 |

| O (Oxygen) | ≤ 0.2 |

| C (Carbon) | ≤ 0.08 |

| N (Nitrogen) | ≤ 0.05 |

| H (Hydrogen) | ≤ 0.015 |

| Y (Yttrium) | ≤ 0.005 |

| Remainder Each | ≤ 0.1 |

| Remainder Total | ≤ 0.3 |

| Ti (Titanium) | Balance |

Chalco's recommended aerospace products

Aerospace-grade 6Al-4V titanium plate

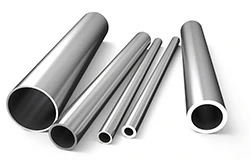

Aerospace-grade 6Al-4V titanium tube

Aerospace-grade 6Al-4V titanium wire

Chalco aerospace-grade 6Al-4V titanium bar hot-selling stock sizes table

| Product | Diameter | Specification |

|---|---|---|

| 3/8" Dia 6AL-4V Grade 5 titanium bar | 3/8" | AMS 4928,MIL-T-9047 |

| 1/2" Dia 6AL-4V Grade 5 titanium bar | 1/2" | AMS 4928,MIL-T-9047 |

| 5/8" Dia 6AL-4V Grade 5 titanium bar | 5/8" | AMS 4928,MIL-T-9047 |

| 3/4" Dia 6AL-4V Grade 5 titanium bar | 3/4" | AMS 4928,MIL-T-9047 |

| 7/8" Dia 6AL-4V Grade 5 titanium bar | 7/8" | AMS 4928,MIL-T-9047 |

| 1" Dia 6AL-4V Grade 5 titanium bar | 1" | AMS 4928,MIL-T-9047 |

| 1 1/8" Dia 6AL-4V Grade 5 titanium bar | 1 1/8" | AMS 4928,MIL-T-9047 |

| 1 1/4" Dia 6AL-4V Grade 5 titanium bar | 1 1/4" | AMS 4928,MIL-T-9047 |

| 1 3/8" Dia 6AL-4V Grade 5 titanium bar | 1 3/8" | AMS 4928,MIL-T-9047 |

| 1 1/2" Dia 6AL-4V Grade 5 titanium bar | 1 1/2" | AMS 4928,MIL-T-9047 |

| 1 5/8" Dia 6AL-4V Grade 5 titanium bar | 1 5/8" | AMS 4928,MIL-T-9047 |

| 1 3/4" Dia 6AL-4V Grade 5 titanium bar | 1 3/4" | AMS 4928,MIL-T-9047 |

| 1 7/8" Dia 6AL-4V Grade 5 titanium bar | 1 7/8" | AMS 4928,MIL-T-9047 |

| 2" Dia 6AL-4V Grade 5 titanium bar | 2" | AMS 4928,MIL-T-9047 |

| 2 1/8" Dia 6AL-4V Grade 5 titanium bar | 2 1/8" | AMS 4928,MIL-T-9047 |

| 2 1/4" Dia 6AL-4V Grade 5 titanium bar | 2 1/4" | AMS 4928,MIL-T-9047 |

| 2 3/8" Dia 6AL-4V Grade 5 titanium bar | 2 3/8" | AMS 4928,MIL-T-9047 |

| 2 1/2" Dia 6AL-4V Grade 5 titanium bar | 2 1/2" | AMS 4928,MIL-T-9047 |

| 3" Dia 6AL-4V Grade 5 titanium bar | 3" | AMS 4928,MIL-T-9047 |

| 3 1/2" Dia 6AL-4V Grade 5 titanium bar | 3 1/2" | AMS 4928,MIL-T-9047 |

| 7" Dia 6AL-4V Grade 5 titanium bar | 7" | AMS 4928,MIL-T-9047 |

The above sizes can serve as a reference. If your required dimensions are not listed, please contact us promptly. Rest assured, our extensive inventory will meet your needs. Quick Quote

What services can Chalco provide?

For aerospace-grade 6Al-4V titanium bar, Chalco offers comprehensive customization services to ensure the diverse needs of customers are met. These include the following aspects:

Size customization

Chalco offers a wide range of size options, covering different diameter, length, and shape requirements.

- Diameter customization: Provides any specification within the standard diameter range according to customer requirements.

- Length adjustment: Supports customization of any length to fit specific engineering applications.

- Non-standard sizes: Can produce titanium bars with special specifications based on customer design drawings.

Surface treatment

To enhance product performance and adapt to specific environments, Chalco offers a variety of surface treatment services:

- Anodizing: Enhances corrosion resistance and customizes different colors and hardness as required.

- Sandblasting and polishing: Provides a smooth surface or matte finish to suit various applications.

- Coating treatment: Adds high-temperature resistance, anti-slip, or other functional coatings based on application needs.

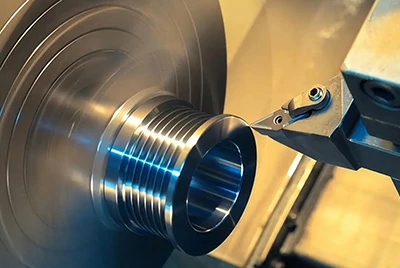

Further processing services

Chalco can provide further processing services for titanium bars, reducing the complexity of subsequent manufacturing steps:

- Turning and milling: Precision machining to meet specific mechanical component requirements.

- Drilling and cutting: Precision that meets the strict tolerance standards required by the aerospace industry.

- Forming: Manufacturing titanium bar components with complex geometries based on customer designs.

Customer service

Chalco is always customer-centric, offering high-quality pre-sales and after-sales services:

- Technical support: An expert team provides material selection, design, and application consulting.

- Fast delivery: Optimized supply chain management ensures on-time product delivery.

- Quality assurance: Certification reports conforming to international standards (such as AMS 4928, ASTM B348) are provided.

- Customized solutions: Tailored solutions for special projects to meet the unique requirements of the aerospace industry.