Aerospace Grade Gr2 Titanium Bar

Grade 2 titanium bar is commercially pure titanium, with a titanium content of 99.2% – 99.5%. Grade 2 titanium bars have slightly higher strength compared to Grade 1, along with excellent corrosion resistance and good machinability, making them commonly used in the aerospace industry.

Chalco grade 2 titanium bar specification

- ASTM B348

- ASME SB348

- MIL-T-9047

- AMS 4902

Chalco's popular aerospace-grade gr2 titanium bar

Chalco can produce various types of gr2 titanium bars, including round, square, hexagonal, and flat shapes, with a range of sizes available.

Gr2 titanium round bar

Round cross-section titanium bars are the most common type and are widely used, typically in aerospace applications for shaft components.

Contact us now

Diameter: 0.125” – 6”

Length: Typically 1 meter to 6 meters or customized.

Advantages: Good machinability, strong fatigue resistance, suitable for handling dynamic loads.

Chalco also has a large stock of aerospace-grade Ti-Grade 2 titanium round bars, with the following specific sizes:

| Diameter | Product |

|---|---|

| 0.125" | 0.125" Titanium Round Bar Grade 2 |

| 0.25" | 0.25" Titanium Round Bar Grade 2 |

| 0.5" | 0.5" Titanium Round Bar Grade 2 |

| 0.75" | 0.75" Titanium Round Bar Grade 2 |

| 1" | 1" Titanium Round Bar Grade 2 |

| 1.25" | 1.25" Titanium Round Bar Grade 2 |

| 1.5" | 1.5" Titanium Round Bar Grade 2 |

| 1.75" | 1.75" Titanium Round Bar Grade 2 |

| 2" | 2" Titanium Round Bar Grade 2 |

| 2.25" | 2.25" Titanium Round Bar Grade 2 |

| 2.5" | 2.5" Titanium Round Bar Grade 2 |

| 3" | 3" Titanium Round Bar Grade 2 |

| 3.5" | 3.5" Titanium Round Bar Grade 2 |

| 4" | 4" Titanium Round Bar Grade 2 |

| 4.25" | 4.25" Titanium Round Bar Grade 2 |

| 4.5" | 4.5" Titanium Round Bar Grade 2 |

| 5" | 5" Titanium Round Bar Grade 2 |

| 5.5" | 5.5" Titanium Round Bar Grade 2 |

| 6" | 6" Titanium Round Bar Grade 2 |

| 6.5" | 6.5" Titanium Round Bar Grade 2 |

| 7" | 7" Titanium Round Bar Grade 2 |

| 7.5" | 7.5" Titanium Round Bar Grade 2 |

| 8" | 8" Titanium Round Bar Grade 2 |

The sizes listed above are popular reference sizes. If they do not match your ideal dimensions, please contact us. We will leverage our extensive inventory to help meet your needs.

Grade 2 titanium square bar

Square cross-section titanium bars have a square shape, offering structural stability. They are commonly used in the frame structures and load-bearing components of aircraft and spacecraft.

Contact us now

Size: Side length 5mm - 150mm

Length: Typically 1 meter - 6 meters or customized

Advantages: Easy to secure and assemble, with high structural stability.

| Side Length(inch) | Product |

|---|---|

| 0.25" | 0.25" x 0.25" Titanium Grade 2 Square Bar |

| 0.5" | 0.5" x 0.5" Titanium Grade 2 Square Bar |

| 0.75" | 0.75" x 0.75" Titanium Grade 2 Square Bar |

| 1" | 1" x 1" Titanium Grade 2 Square Bar |

| 1.25" | 1.25" x 1.25" Titanium Grade 2 Square Bar |

| 1.5" | 1.5" x 1.5" Titanium Grade 2 Square Bar |

| 2" | 2" x 2" Titanium Grade 2 Square Bar |

| 2.125" | 2.125" x 2.125" Titanium Grade 2 Square Bar |

| 2.25" | 2.25" x 2.25" Titanium Grade 2 Square Bar |

| 2.5" | 2.5" x 2.5" Titanium Grade 2 Square Bar |

| 3" | 3" x 3" Titanium Grade 2 Square Bar |

| 3.25" | 3.25" x 3.25" Titanium Grade 2 Square Bar |

| 3.5" | 3.5" x 3.5" Titanium Grade 2 Square Bar |

| 4" | 4" x 4" Titanium Grade 2 Square Bar |

The above are popular reference sizes. For custom orders, please contact us in a timely manner.

Grade 2 titanium rectangular bar

With a rectangular cross-section, it offers good rigidity, making it suitable for long spans and high-strength applications. It is primarily used in aerospace for wing spars, support rods, and other high-stress structural components.

Contact us now

Thickness: 2mm - 100mm

Width: 10mm - 500mm

Length: 1-6m or customized

Grade 2 titanium hex bar

Hexagonal titanium bars offer excellent machinability, making them ideal for threading and mechanical processing. They are used in the manufacturing of aerospace fasteners and connectors, such as nuts, bolts, etc., and are suitable for components that require high precision in connections.

Contact us now

The features of aerospace-grade gr 2 titanium bar

Excellent corrosion resistance

CP Grade 2 titanium bar offers excellent corrosion resistance, capable of withstanding moisture, salt spray, and high-temperature corrosion. It is suitable for components exposed to harsh environments in aerospace, such as fuselage skins, brackets, and conduit systems.

Moderate strength

Compared to Grade 1 titanium, CP Grade 2 titanium offers higher strength while maintaining good formability and ductility. It is suitable for aircraft frames, brackets, and other critical components.

Easy to manufacture

It has excellent machinability and weldability, allowing it to be easily shaped into complex forms, making it ideal for the manufacturing and repair of customized structural components in aerospace.

Non-magnetic

The non-magnetic properties of CP Grade 2 titanium make it highly suitable for use around avionics, preventing electromagnetic interference from affecting the equipment.

High ductility

The material has high ductility, making it suitable for cold forming and bending, and can be used to manufacture complex aerospace components and piping.

Temperature stability

CP Grade 2 titanium maintains stable performance in both high and low temperature environments, making it suitable for applications in extreme temperature variations, such as high-altitude aircraft and space equipment.

Tolerance of aerospace-grade gr2 titanium round bar

Chalco's aerospace-grade Grade 2 titanium bars strictly follow international standard size tolerance requirements to ensure high-precision applications in the aerospace field. For specific tolerances, please refer to the table below. If you have special requirements, please discuss your tolerance needs in advance.

| Alloy | Diameter | Diameter Tolerance |

|---|---|---|

| Grade 2 | <0.25" | +/- 0.005" |

| Grade 2 | 0.25" - 0.3125" | +/- 0.005" |

| Grade 2 | 0.3125" - 0.4375" | +/- 0.006" |

| Grade 2 | 0.4375- 0.625" | +/- 0.007" |

| Grade 2 | 0.625" - 0.875" | +/- 0.008" |

| Grade 2 | 0.875" - 1" | +/- 0.009" |

| Grade 2 | 1" - 1.125" | +/- 0.010" |

| Grade 2 | 1.125" - 1.25" | +/- 0.011" |

| Grade 2 | 1.25"- 1.375” | +/- 0.012" |

| Grade 2 | 1.375" - 1.5” | +/- 0.014" |

| Grade 2 | 1.5"- 2” | +/- 1/64" |

| Grade 2 | 2"- 2.5” | + 1/32" |

| Grade 2 | 2.5"- 3.5” | + 3/64" |

| Grade 2 | 3.5"- 4.5” | + 1/16" |

The physical properties of aerospace-grade gr2 titanium bar

The density of Grade 2 titanium bar is 4.51 g/cm³, which is about 60% of the density of steel. This makes ASTM B348 UNS R50400 bars an ideal material for lightweight applications. Its melting point is 1660°C, and its boiling point is 3260°C, meaning it can withstand high temperatures.

| Property | Value |

|---|---|

| Density | 0.163 lb/in³, 4.51 g/cm³ |

| Average Thermal Expansion Coefficient | 70–212°F (20–100°C): 4.78 x 10⁻⁶ (8.6 mm/m°C) |

| Thermal Conductivity | 70°F (21°C): 114 BTU-in/h-ft-°F (16.4 W/m-K) |

| Elastic Modulus | 2 x 10³ ksi (105 x 10³ MPa) Tension |

| Melting Point | 3040°F (1670°C) |

The chemical composition of aerospace-grade gr2 titanium bar

| Element | Composition (%) |

|---|---|

| C | ≤ 0.10 |

| Fe | ≤ 0.30 |

| H | ≤ 0.015 |

| N | ≤ 0.030 |

| O | ≤ 0.25 |

| Ti | Balance |

Chalco's recommended aerospace products

Aerospace-grade Gr2 titanium plate

Aerospace-grade Gr2 titanium tube

Aerospace-grade Gr2 titanium wire

What services can Chalco provide?

For aerospace-grade Grade 2 titanium bars, Chalco provides comprehensive customization services to meet the diverse needs of customers, including the following aspects:

Size customization

Chalco offers a wide range of size options to meet different diameter, length, and shape requirements.

Diameter customization: Provide any specification within the standard diameter range according to customer requirements.

Length adjustment: Support custom lengths to fit specific engineering applications.

Non-standard sizes: Special titanium bars can be produced based on customer design drawings.

Surface treatment

To enhance product performance and adapt to special environments, Chalco offers a variety of surface treatment services:

- Anodizing: Improves corrosion resistance and customizes colors and hardness as needed.

- Sandblasting and Polishing: Provides smooth surfaces or matte finishes to suit different applications.

- Coating Treatment: Adds high-temperature resistance, anti-slip, or other functional coatings as required by the application.

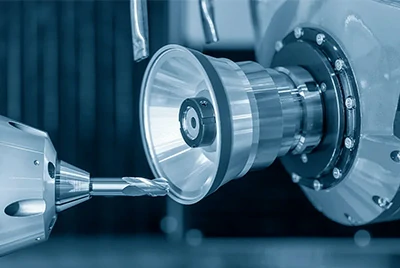

Machining Services

Chalco can provide further processing services for titanium bars to reduce the complexity of subsequent manufacturing stages:

- Turning and milling: Precision machining to meet specific mechanical part requirements.

- Drilling and cutting: Accuracy that meets the strict tolerance standards required by the aerospace industry.

- Shaping: Manufacturing titanium bar components with complex geometric shapes based on customer designs.

Customer service

Chalco always puts the customer first, offering high-quality pre-sales and after-sales services:

- Technical support: An expert team provides material selection, design, and application consultations.

- Fast delivery: Optimized supply chain management ensures timely product delivery.

- Quality assurance: Certification reports meeting international standards (such as AMS 4928, ASTM B348) are provided.

- Custom solutions: Tailored solutions for special projects to meet the specific requirements of the aerospace field.