Titanium Alloy in Armored Vehicle

Modern armored vehicles must not only have strong protection capabilities on the battlefield, but also take into account mobility, fuel efficiency and combat performance in complex environments. This places higher requirements on lightweight and high strength materials.

Why choose titanium alloy?

The reason why titanium alloy is an ideal material in armored vehicle manufacturing is mainly based on the following key advantages:

- While the strength of titanium alloy is close to that of high-strength steel, its density is only about 60% of that of steel. It can significantly reduce the weight of the vehicle body without sacrificing protective performance, thereby improving maneuverability and fuel efficiency.

- Titanium alloys have excellent weather resistance and corrosion resistance, and are particularly suitable for armored vehicles operating in water, humid, hot or high-salt environments, extending their service life and reducing maintenance costs.

- Titanium alloys can be formed and welded through a variety of processes, making it easy to manufacture complex structures and realize a variety of design schemes to meet the modularization and customization needs of modern armored vehicles.

- Certain titanium alloys can provide effective ballistic protection at relatively small thicknesses, especially exhibiting superior energy absorption capabilities when facing fragments, bullets or blast waves.

Key titanium alloy components for armored vehicles

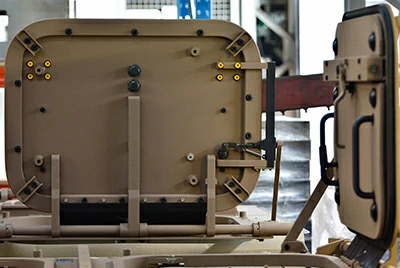

Armored vehicle roofs and hatches

The roof and hatch covers of armored vehicles are key structures that protect the personnel inside the armored vehicle from attacks from above. They usually need to balance a good observation field of view and ease of operation. Especially when encountering artillery attacks or debris attacks, the hatch covers need to have high bullet and impact resistance.

Compared with traditional aluminum alloys, Ti-6Al-4V (MIL-T-9046J) titanium alloy reduces weight by about 35%. While maintaining high strength, it significantly improves anti-ballistic performance, thereby effectively enhancing the maneuverability and safety of the entire vehicle.

In actual application, the U.S. Army M2 Bradley infantry fighting vehicle has upgraded the commander's hatch. The original aluminum alloy hatch has been replaced with Ti-6Al-4V titanium alloy, which significantly improves the vehicle's protection capabilities.

Main battle tank turret explosion venting plate

Guide the explosion shock wave to the outside in time when the ammunition explodes inside the turret to protect the crew's safety.

Contact us now

The application of Ti-6Al-4V titanium alloy has greatly reduced the weight, which not only improves the overall maneuverability of the tank turret, but also significantly enhances the structural reliability and impact resistance of the explosion-proof plate.

In actual use, the U.S. Army M1A2 Abrams main battle tank upgraded the turret explosion venting plate and used Ti-6Al-4V titanium alloy, which reduced the overall weight by about 420 kg.

Main battle tank NBC protection system cover

The NBC (Nuclear, Biological and Chemical) protection system cover is used to prevent contaminants under NBC attack conditions from entering the interior of the tank and is an important part of the tank's environmental protection system.

Contact us now

Ti-6Al-4V titanium alloy can significantly reduce component weight during manufacturing, improve the vehicle's maneuverability and fuel efficiency, and enhance resistance to harsh environments.

In actual application, the NBC system cover of the M1A2 Abrams main battle tank has been modernized and uses Ti-6Al-4V titanium alloy material, which further improves the overall performance and reliability of the equipment.

Modular external titanium armor

Modular external armor can be quickly disassembled and installed, and the armor protection level can be flexibly adjusted according to tactical requirements without changing the original structure of the vehicle.

Contact us now

Ti-6Al-4V rolled plates reduce weight by 30% to 40% compared to traditional steel external armor. It not only effectively improves the anti-penetration capability, but also enhances the deployment flexibility of the armor system.

In actual applications, modular external titanium armor is widely used in M113 armored personnel carriers and Stryker combat vehicles to significantly improve battlefield protection performance.

Turret and shield system

The turret and shield system is responsible for protecting the weapon operator and is usually required to provide maximum protection under limited weight conditions.

Contact us now

The application of Ti-6Al-4V titanium alloy significantly reduces the weight of the system, effectively improving the overall performance of the vehicle while maintaining or even exceeding the original protection level.

In actual use, the U.S. Special Operations Command (SOCOM) widely adopts the all-titanium version of the Universal Turret Kit (O-GPK) to improve the performance and survivability of combat platforms.

Suspension system torsion bar spring

The torsion bar spring of the suspension system is mainly used to absorb impact during driving and ensure the vehicle's handling stability and stability.

Contact us now

The torsion bar made of Ti-3Al-8V-6Cr-4Mo-4Zr titanium alloy has higher fatigue strength and lower elastic modulus, which not only significantly extends the service life and reduces maintenance costs, but also effectively reduces the overall weight of the suspension system.

In actual applications, this titanium alloy is used in the research upgrade plan for the suspension system of the US Army M1 Abrams main battle tank as one of the key materials to improve performance and reliability.

Advanced composite armor

Advanced composite armor utilizes the combined properties of multiple materials, especially in the field of armor-piercing projectiles, and can effectively resist a variety of threats.

Contact us now

The application of titanium-tungsten composite materials and titanium-steel composite materials in armor structures has greatly improved the penetration resistance of the front of the turret, effectively making up for the shortcomings of traditional steel armor in dealing with high-intensity attacks.

In actual application, the turret armor of the German Leopard 2A4 main battle tank has been modernized and upgraded to use the above-mentioned composite materials, which significantly enhances its protective performance.

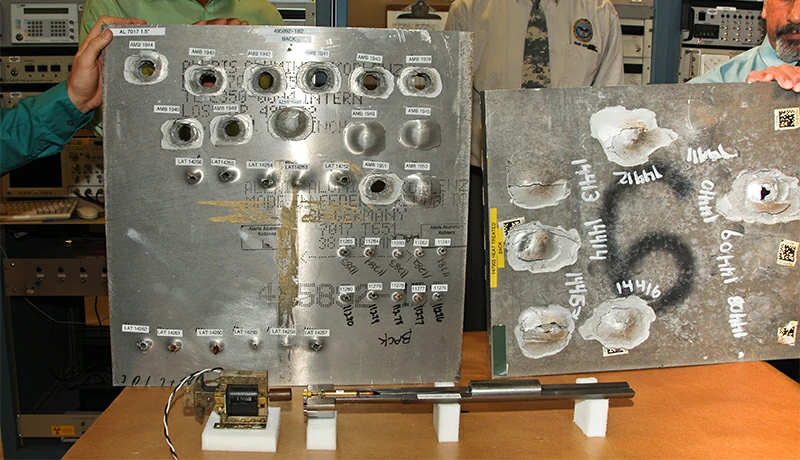

Chalco titanium alloy armor plate anti-ballistic performance test

Material: Ti-6Al-4V titanium alloy plate

| Thickness(mm) | Projectile Type | Test V ₅₀ (m/s) | Required V₅₀ ( m/s) |

|---|---|---|---|

| 25.35 | 20 mm FSP | 1016 | 950 |

| 26.72 | 20 mm FSP | 1023 | 1008 |

| 38.79 | 20 mm FSP | 1493 | 1362 |

| 38.3 | 20 mm FSP | 1496 | 1352 |

| 63.96 | 30 mm APDS | 932 | 889 |

| 63.83 | 30 mm APDS | 941 | 888 |

Parameter description:

V₅₀ refers to the velocity that a projectile reaches when there is a 50% probability of penetrating a material and is often used to measure the ballistic performance of a material.

FSP is a projectile used to simulate metal fragments in battlefield explosions, and is mainly used to test the protective effect of materials against fragments.

APDS is a high-penetration projectile used for heavy armor testing. It simulates the attack mode of long-rod armor-piercing projectiles and is often used to evaluate the protective ability of armor under extreme impact. The V₅₀ of all test samples is higher than the design requirements, proving that Chalco Ti-6Al-4V titanium alloy has reliable ballistic performance and is fully suitable for high protection requirements such as vehicle shells, turret shields, and chassis structures.

Chalco Titanium Composite Armor Technology and Delivery Capabilities

Titanium-steel composite armor plate

Chalco uses processes such as explosive welding and hot rolling composite to firmly combine Ti-6Al-4V titanium alloy with high-strength armor steel to form a structurally stable titanium-steel composite armor plate.

This material has both the lightness and high strength of titanium alloy and the high hardness of steel. It can effectively resist mine explosions, IED impacts and penetration by medium-caliber kinetic energy bullets. It is suitable for use in key protection areas such as chassis, side armor and top hatches.

Titanium-steel composite plates are particularly suitable for scenarios where the weight of the vehicle needs to be controlled while improving the protection level, such as light tactical vehicles and urban combat platforms.

Titanium-ceramic composite armor plate

To resist the impact of high-speed armor-piercing projectiles (such as APDS and API), Chalco provides titanium-ceramic composite plates, which are suitable for high-protection areas such as the front of the turret and the front of the vehicle.

The structure usually consists of boron carbide or alumina ceramics as the front layer and titanium alloy as the back plate. The ceramic layer is responsible for breaking the bullet and dissipating energy, while the titanium layer absorbs residual impact and prevents penetration.

Chalco can also assist customers in designing protective layer structures, including thickness ratio, layer layout and ballistic impact simulation, to optimize the balance between protective effect and cost.

Personalized customization and engineering supporting services

Chalco supports full-size customization of titanium composite armor plates, including the thickness combination of titanium layer, steel layer, and ceramic layer, structural dimensions, and installation hole processing.

For special structural parts, we can provide special-shaped cutting, edge processing and pre-assembly support to meet customers' integration needs for complex armored components.

The company has a military quality system and rapid delivery capabilities, supporting the entire process from sample verification, small-batch trial production to mass production, and is widely used by domestic and foreign protective equipment manufacturers.

Chalco can provide a variety of application needs

In view of the structural characteristics and combat requirements of different types of tactical platforms, Chalco can provide differentiated titanium alloy material selection and structural solutions to ensure that weight, cost and integration difficulty are taken into account while meeting protective performance.

For light tactical vehicles (such as MRAP ambush-proof vehicles), Chalco recommends using Ti-6Al-4V titanium plates with a thickness of less than 10 mm to significantly reduce vehicle weight, improve load-bearing capacity, and enhance resistance to explosive fragments.

For medium assault vehicles, such as infantry fighting vehicles or rapid assault platforms, Chalco recommends the use of a composite structure of Ti-6Al-4V and armored steel. This combination not only takes into account structural rigidity and protection performance, but also effectively controls the overall material cost, making it suitable for mass deployment needs.

For core platforms such as main battle tanks (MBTs) that carry high-intensity firepower and thick armor, Chalco recommends the use of high-performance titanium alloys such as Ti-6-2-4-2, combined with ceramic modules to form a layered armor structure, which is particularly suitable for use in engine areas, high-temperature combat areas and turret fronts to resist penetrating strikes from high-speed kinetic energy projectiles.

In the field of unmanned ground platforms (UGVs), due to their small space and limited load characteristics, Chalco provides Ti-6Al-4V titanium plate components with customized shapes and thicknesses to help customers achieve lightweight design, extend endurance and improve anti-interference and sabotage capabilities.

Why choose Chalco?

Full process manufacturing, stable quality

Chalco has a complete titanium alloy production system, which integrates sponge titanium smelting, hot rolling, processing and heat treatment to ensure that each batch of titanium plates for armor has stable mechanical properties and dimensional consistency.

International standard certification, military-grade quality

We provide titanium alloy plates that meet international standards such as MIL-T-9046, MIL-DTL-46077F, ASTM B265, etc., meeting the strict requirements of different countries and platforms for armor materials.

Strong ability in developing composite panels

Chalco has the ability to manufacture titanium-steel and titanium-ceramic composite plates, supporting special needs such as structural customization, thickness ratio adjustment, and special-shaped cutting. It is widely used in key protection areas such as vehicle chassis and turret fronts.

Rich export experience and professional service

We provide export services to defense customers in many countries, supporting multilingual technical information, international transport packaging and fast delivery, with mature project experience and efficient cooperation.

Choosing Chalco means choosing a one-stop titanium alloy protection solution. We not only supply materials, but also help you build a reliable and high-performance armor platform. Welcome to contact us for samples and quotation support.