Titanium in Aviation

Titanium's superior strength-to-weight, corrosion resistance, and fatigue performance make it vital for airframes, lines, and fasteners, particularly in CFRP hybrids. We supply CP and aerospace-grade plate, bar, tube, and forgings with full MTRs, backed by AS/EN 9100 quality and Nadcap-approved processes.

Leading aircraft manufacturers choose titanium for one reason above all: its unmatched strength-to-weight ratio, outstanding corrosion resistance, and exceptional fatigue performance.

Leveraging these core advantages, aerospace-grade titanium alloys are integral to modern airframes—from load-bearing structures and high-pressure lines to critical fasteners. In hybrid structures with carbon-fiber-reinforced polymer (CFRP), titanium is the preferred interface material, enabling lighter, stronger aircraft designs.

As a dedicated aerospace titanium supplier, we deliver commercially pure titanium and aerospace-grade titanium alloys to international standards. Our portfolio covers titanium plate, titanium bar, titanium tube, and titanium forgings. Each shipment includes full MTR (Mill Test Report). Our quality system complies with AS/EN 9100, and special processes (heat treatment, welding, NDT) are performed by Nadcap-approved facilities.

Why Titanium in Aviation

Titanium is "irreplaceable” in modern aerospace not only because its density is ~60% of steel and its strength-to-weight ratio outperforms aluminum and most steels, but also because it maintains strength and dimensional stability in the mid-temperature range, offers High Fatigue Life, and has inherent Corrosion Resistance—all of which reduce inspection frequency and MRO costs. In composite airframes, titanium's compatibility with CFRP in electrochemistry and thermal expansion makes it the first choice for load-bearing joints, fasteners, and transition pieces.

Material Mass Share by Typical Aircraft Models (%)

| Model | First Flight | Aluminum(%) | Steel(%) | Titanium(%) | Composites(%) | Other(%) |

|---|---|---|---|---|---|---|

| BoeingB777 | 1995 | ≈70 | ≈9 | ≈9 | ≈11 | ≈1 |

| BoeingB787 | 2006 | ≈20 | ≈10 | ≈15 | ≈50 | ≈5 |

| AirbusA340 | 1993 | ≈61 | ≈6 | ≈6 | ≈20 | ≈1 |

| AirbusA380 | 2007 | ≈61 | - | ≈10 | ≈25 | ≈1 |

| F-15 Fighter | 1972 | ≈37 | ≈6 | ≈26 | - | - |

| F-22 Fighter | 1997 | ≈16 | ≈6 | ≈39 | ≈24 | ≈15 |

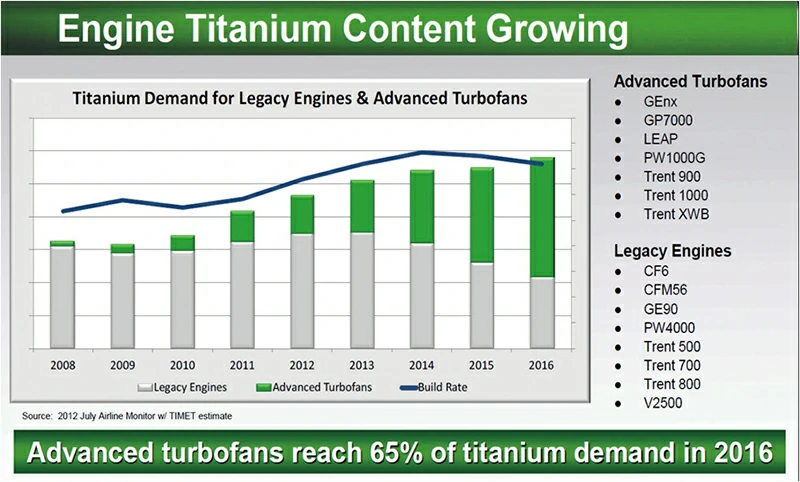

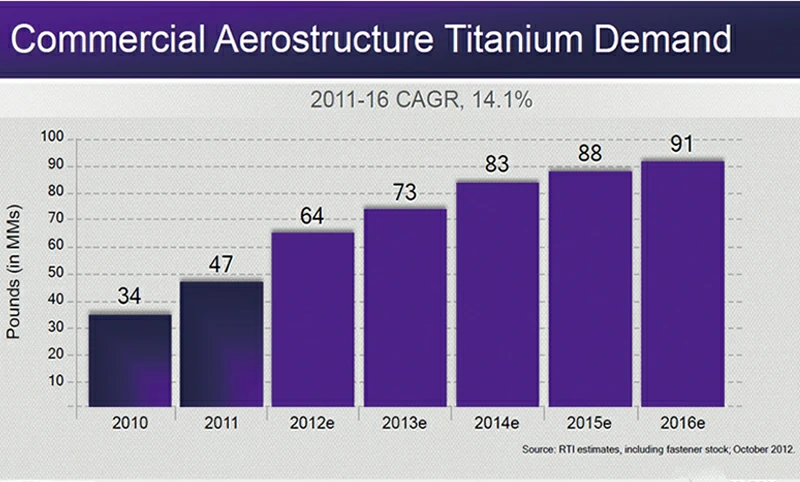

Commercial aerostructure titanium demand kept rising (2011–2016, CAGR 14.1%)

Aerospace Titanium Selection Paths

Aerospace titanium spans many applications and product forms. To help you find what you need fast, choose one of two paths:

- Engineers: browse by Application System to see how titanium performs in each assembly.

- Procurement/Supply Chain: browse by Product Form to view deliverables and standards.

Pick an entry to jump straight to the section, or click the top-right Request a Quote button anytime.

- Airframe

- Engine Front

- Landing Gear

- Tubes & Lines

- Fasteners

- Nacelle / Firewall

- Plate

- Sheet

- Forgings

- Tubes

- Bar / Profiles

- Fasteners

Select an entry to jump directly to its content; you can also click the top-right Request a Quote button anytime.

Alloy Overview & Selection Matrix

Commercially Pure Titanium (CP Ti)

-

CP Ti Grade 2

Commonly used for non-load-bearing airframe parts and hydraulic/fuel/inerting line accessories.

Forms: tube, plate/sheet, bar, profiles

-

CP Ti Grade 3

Higher strength than Gr2 for non-load-bearing supports and brackets.

Forms: plate/sheet, bar, tube

-

CP Ti Grade 4

Highest strength within CP Ti; suitable for higher-strength non-load-bearing parts.

Forms: plate/sheet, bar, tube

Titanium Alloys

-

Ti-6Al-4V (Grade 5)

The most widely used aerospace alloy; load-bearing airframe parts, fan/case, fastener stock.

Forms: plate/sheet, bar, ring/disc forgings, profiles, wire.

-

Ti-6Al-4V ELI (Grade 23)

Extra-low interstitial for higher fracture toughness; critical joints, fastener stock.

Forms: bar, wire, plate/sheet.

-

Ti-3Al-2.5V (Grade 9)

Thin-wall weldable/formable parts; hydraulic/fuel/bleed-air lines.

Forms: tube, thin sheet, strip.

-

Ti-6Al-6V-2Sn (6-6-2)

Higher-strength structural/connector applications.

Forms: plate/sheet, bar, forgings.

-

Ti-6Al-2Sn-4Zr-2Mo (Ti-6242)

Mid/high-temperature compressor disks/rings and cases.

Forms: ring/disc forgings, bar, plate/sheet.

-

Ti-8Al-1Mo-1V (Ti-811)

Mid/high-temperature compressor blades and diaphragms.

Forms: forgings, plate/sheet.

-

Ti-6Al-2Sn-4Zr-6Mo (Ti-6246)

Mid/high-temperature structures and compressor components.

Forms: forgings, bar, plate/sheet.

-

Ti-10V-2Fe-3Al (10-2-3)

Landing-gear beams/struts and other high-load forgings (high strength + high fatigue).

Forms: large forgings, bar.

-

Ti-5Al-5V-5Mo-3Cr (Ti-5553)

High-strength structures; thick-section hardenability; fastener stock.

Forms: bar, forgings, profiles.

-

Ti-15V-3Cr-3Sn-3Al (15-3-3-3)

Cold-formable thin sheet/profiles; complex formed panels.

Forms: sheet, strip, profiles.

-

Ti-17

High-strength fan disks/IBR, compressor disks & rings.

Forms: disk/ring forgings, bar.

-

Beta-C (Ti-3Al-8V-6Cr-4Mo-4Zr)

High-strength/elastic fasteners; selected high-load joints.

Forms: bar, forgings, wire.

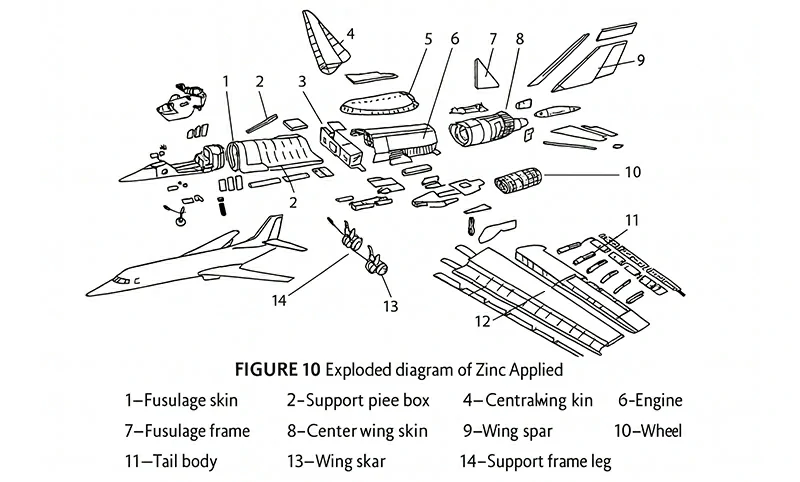

Aerospace Application Systems

Airframe & CFRP Interfaces

With higher composite content, joints and load paths face thermal-expansion mismatch and galvanic corrosion risks. Titanium has a closer CTE to CFRP, plus high corrosion resistance and crack tolerance—ideal for high-load areas near composites.

Recommended Alloys & Forms: Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI (Grade 23) plates/bars/rings and precision forgings; matching titanium bushings and fasteners.

Standards: ASTM B265 (sheet/plate/strip), ASTM B348 (bar), ASTM B381 (forgings); common AMS 4911/4928.

QA & Selection: Edge shot peen/roller burnish to improve fatigue life; use insulating washers & sealants at CFRP interfaces to suppress galvanic corrosion; critical structures: UT + FPI.

Engine Front (Fan & LPC/MPC | ≈ 300–500 °C)

Front-section parts see cyclic loads at mid-temperatures; they require high specific strength, creep resistance, and cleanliness.

Recommended Alloys & Forms:

- Fan blades/cases/LPC: Ti-6Al-4V (plate, ring/disk forgings).

- IPC/HPC blades & disks: Ti-6Al-2Sn-4Zr-2Mo (Ti-6242), Ti-6Al-2Sn-4Zr-6Mo (Ti-6246), Ti-8Al-1Mo-1V (Ti-811); disks/IBR can use Ti-17.

Standards: ASTM B381 (forgings), ASTM B348 (bar); supply per part drawing/AMS alloy & condition.

QA & Selection: Isothermal/precision forging + STA/anneal; 100% UT + FPI on rings/disks; control inclusion ratings; for ≥500 °C duty, evaluate Ni/Fe-based superalloys.

Landing Gear & High-Load Forgings

Landing imposes impact plus high-cycle loads—demanding high yield strength, fracture toughness, and reliable hardenability.

Recommended Alloys & Forms: Ti-10V-2Fe-3Al (10-2-3), Ti-5Al-5V-5Mo-3Cr (Ti-5553) for large closed-die/ring forgings; high-strength/elastic connectors: Beta-C.

Standards: ASTM B381 (forgings), ASTM B348 (bar); supply per drawing/AMS alloy & condition.

QA & Selection: Section-wise UT, FPI, hardness & residual-stress control; verify transverse properties & hardenability; for critical load paths, perform FAI (AS9102) and life assessment.

Tubes & Ducts (Hydraulics / Fuel / Inerting / Bleed-Air)

Lightweight and corrosion-resistant systems need thin-wall capability, weldability, and clean inner surfaces.

Recommended Alloys & Forms: Ti-3Al-2.5V (Grade 9) CWSR/annealed seamless or welded tube; non-structural corrosion-resistant parts: CP Grade 2/3.

Standards: ASTM B338 (seamless), ASTM B861 (welded); AMS 4943/4944 (Gr9).

QA & Selection: Orbital GTAW with inert protection & dew-point control; inner-wall cleanliness + pickling; 100% hydro/air-leak testing; match bend radius & springback to material temper.

Fasteners & Joints

Mixed composite/metal airframes need weight reduction and galvanic protection.

Recommended Alloys & Forms: Ti-6Al-4V, Ti-6Al-4V ELI (Grade 23) bars/wire rod & finished fasteners; ultra-high-strength/elastic items: Beta-C.

Standards: NAS/AS/MS series; blanks to ASTM B348; finished parts to AMS mechanical classes with lot traceability.

QA & Selection: Hardness/tensile/torque, thread gauging, FPI sampling; CFRP interfaces with insulating collars & sealants; optional anodize or solid film lubricant (SFL).

Nacelle & Firewalls

Near hot/erosive zones, materials must resist heat, allow repair, and form complex shapes.

Recommended Alloys & Forms: Ti-6Al-4V thin sheet/profiles; local hot spots: Ti-6242; often combined with honeycomb sandwich (titanium face sheet), compatible with SPF/DB.

Standards: ASTM B265 (sheet/plate), AMS 4911 (Gr5 sheet/strip/plate).

QA & Selection: Control forming window (temperature/strain rate) and dimensional stability; apply corrosion/erosion protection on service faces; FPI plus hardness/residual stress checks.

SEO terms: Nacelle, Firewall, SPF/DB, AMS 4911, Ti-6Al-4V.

Aerospace Titanium · Products & Supply Capabilities

Titanium Sheet / Plate

Features:Delivers stable strength and formability for load-bearing airframe parts, nacelle/firewall panels, and case liners. Supports laser/waterjet/CNC blanks and formed parts.

Contact us now

Alloy Coverage: Gr2/3/4 (CP Ti), Gr5 (Ti-6Al-4V), Gr23 (ELI), 6-6-2, Ti-6242, Ti-6246, Ti-811.

Typical Sizes: thin sheet 0.4 - 4.75 mm; plate 4.75 - 100 mm (thicker by drawing); common width ≤ 1,250 mm, length ≤ 3,000 mm.

Delivery Condition: Annealed or STA (Solution Treated & Aged); optional scale removal and shot peening.

Standards: ASTM B265; common AMS 4911 (Gr5 sheet/strip/plate); other AMS grades/conditions per drawing.

Typical Uses: door/window frames, beams/frames/ribs, nacelle & firewall structures, compressor-adjacent insulation and skins.

Quality Assurance: MTR (chemistry + mechanicals); microstructure & grain size per AMS; optional UT/FPI (PT); full heat-treat records traceable.

Titanium Forgings

Features:For fan/compressor disks & rings, case flanges, landing-gear beams, and large load-bearing nodes. Near-net-shape with isothermal/precision forging options.

Contact us now

Alloy Coverage: Gr5/Gr23, Ti-17, Ti-6242, Ti-6246, Ti-811, Ti-10V-2Fe-3Al (10-2-3), Ti-5Al-5V-5Mo-3Cr (Ti-5553), Beta-C.

Typical Capability: disk/pancake forgings Ø200–1,200 mm; ring forgings Ø250–2,000 mm; bars/blocks & closed-die specials up to 600 kg (larger per drawing review).

Delivery Condition: Annealed / STA; controlled grain flow and isothermal forging; machining allowances on request.

Standards: ASTM B381 (forgings), ASTM B348 (bar stock); AMS 4928 (Gr5 bar), part-specific AMS/OEM specs as required.

Typical Uses: fan disks/IBR, compressor disks/rings, case rings, landing-gear main struts and load beams.

Quality Assurance: 100% UT + FPI; tensile/toughness/directionality; H/O/inclusion control; FAI (AS9102) package and process capability records on request.

Titanium Tubes

Features:Lightweight, corrosion-resistant piping for hydraulic, fuel/inerting, bleed-air/anti-ice, and ECS lines; compatible with orbital welding.

Contact us now

Alloy Coverage: Ti-3Al-2.5V (Grade 9, CWSR/annealed); CP Gr2/Gr3 for non-structural service.

Typical Sizes: OD Ø6–38 mm; wall 0.4–1.5 mm; straight lengths, coiled, or cut-to-length; inner/outer pickled finish with cleanliness control.

Delivery Condition: CWSR (cold-worked stress-relieved) / annealed; end-forming and flange/fitting pre-assembly per drawing.

Standards: ASTM B338 (seamless), ASTM B861 (welded); AMS 4943/4944 (Gr9 tubing).

Typical Uses: airframe hydraulic trunks, fuel/inerting lines, engine bleed-air & anti-ice, ECS tubing.

Quality Assurance: 100% air-leak/hydrostatic test; inner-wall cleanliness & dew-point control; welding WPS/PQR support; FPI/UT as required.

Titanium Bars / Profiles

Features:For machined parts, load-bearing joints, rails, and fastener stock, covering general α-β and high-strength near-β systems.

Contact us now

Alloy Coverage: Gr5/Gr23, 6-6-2, Ti-17, Ti-10-2-3, Ti-5553, Beta-C; CP Ti Gr3/Gr4 for non-structural use.

Typical Sizes: bar Ø6–200 mm (larger on request); square/flat/profiles per drawing; straightness & surface roughness to aerospace tolerances.

Delivery Condition: Annealed / STA; surfaces peeled/turned/ground; fixed or random lengths.

Standards: ASTM B348; common AMS 4928 (Gr5 bar), AMS 4965/4967 etc. (specified by alloy & application).

Typical Uses: airframe load-bearing joints/supports, seat & rail systems, fastener blanks, engine accessories.

Quality Assurance: MTR, hardness/tensile, UT on large diameters, surface-defect control and dimensional gauging.

Titanium Fasteners

Features:Preferred joining solution for mixed composite/metal airframes—balancing weight reduction and galvanic corrosion protection.

Contact us now

Material Systems: Ti-6Al-4V, Ti-6Al-4V ELI (high toughness), Beta-C (high strength/elastic components).

Specification Families: NAS/AS/MS; metric & inch supported; supplied as bolts, nuts, rivets, lockbolts, bushings, and cable/wire clamps.

Surface & Isolation: Anodize, solid film lubricant (SFL); insulating collars/coatings and sealant solutions for CFRP interfaces.

Standards: Blanks to ASTM B348; finished parts to AMS mechanical classes & inspection; lot traceability and MSA (Measurement System Analysis) available on request.

Quality Assurance: Hardness/tensile/torque tests, thread gauging and dimensional checks; FPI sampling; corrosion and assembly validation support.

Manufacturing & QA

End-to-end assurance from melting to delivery—meeting targets for strength, toughness, fatigue, and full traceability.

-

Raw Material & Process

VAR double/triple melting, low inclusions

Isothermal / precision forging with controlled grain flow

Anneal / STA with recorded heat-treat curves

-

Inspection & First Article

100% UT on disks/rings and thick sections

Surface FPI (PT) sampling

AS9102 FAI + production SPC

-

Standards & Documentation

Supplied per ASTM/AMS aerospace specifications

AS/EN 9100 quality system; Nadcap special processes

Shipment pack: MTR, NDT reports, heat-treat records

FAQ

Do you supply to aerospace standards?

Yes. We supply per AMS/ASTM (e.g., AMS 4911/4928, ASTM B265/B348/B381/B338) with full lot traceability and MTR.

What certifications do you hold?

AS/EN 9100 quality system; special processes via Nadcap facilities (heat treatment/welding/NDT). Certificates available for review.

Can you make custom forgings/cut parts from drawings? What's the MOQ?

Yes—near-net forgings and cut blanks from your drawing. Pilot runs and small lots are available; MOQ depends on size and alloy.

Which alloys and sizes are commonly stocked?

Gr5/Gr23, Ti-6242/6246, Ti-17, 10-2-3, 5553, Gr9, etc. Typical sheet/plate: 0.4–4.75 mm (sheet), 4.75–100 mm (plate); bar: Ø6–200 mm; tube: Ø6–38 × 0.4–1.5 mm.

What test reports are delivered with the goods?

Standard UT/FPI, chemistry/mechanical results, heat-treat curves, and dimensional reports; optional CMM, hardness, and inclusion rating on request.