Titanium Fasteners

Our titanium fasteners are trusted by customers worldwide for their outstanding quality and performance.

From aerospace-grade fasteners built for extreme conditions to custom-designed parts tailored to your specs, Chalco Titanium delivers beyond expectations.

Why choose titanium fasteners?

- Grade 5 titanium bolts weigh about 45% less than 316 stainless steel, making your equipment instantly lighter.

- They offer up to 3× better pitting resistance in chlorides and seawater environments.

- With a tensile strength of 1100 MPa and a density of just 4.5 g/cm³, their strength-to-weight ratio is exceptional.

- Titanium is non-magnetic, with low thermal expansion and elastic modulus—ideal for precision electronics and high-temperature assemblies.

- Even at 400 °C, titanium fasteners maintain stable clamping force and resist vibration loosening.

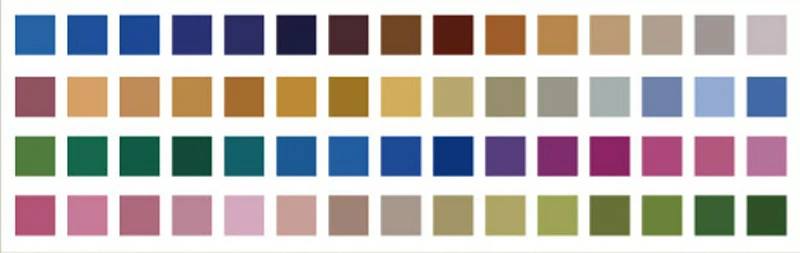

- Anodizing brings vibrant color options, combining performance with style and easy identification.

All titanium bolts, screws, nuts, and washers can be made to inch, metric, or custom specs—covering both standard and non-standard requirements. Quick Quote

Full-range titanium fasteners, one-stop sourcing

We offer titanium fastener solutions across 7 major product categories—all in one place.

Every item can be mixed and matched by project list, with options for surface finish, color, and material grade to meet your standard or custom needs.

Here are the titanium fasteners we can supply quickly—with quotes available in 24 hours:

Titanium Bolts

Titanium Screws

Titanium Nuts

Titanium Washers

Titanium Threaded Rods

Titanium Rivets

Titanium Threaded Inserts

Titanium bolts

- Size range: M2–M64, 1/4″–2″.

- Available in Grade 2, Grade 5, Grade 7, and Grade 9 to suit everything from corrosion resistance to high-strength applications.

- Compliant with DIN 931, DIN 933, DIN 912, DIN 7991, ISO 4014, ISO 4017, ISO 4762 standards.

- Optional anodized finishes in 10 colors or PVD coatings for enhanced durability and style.

- Standard sizes in stock, ready to ship within 24 hours with 3.1 material certificates.

Titanium Hex Head Bolts

Titanium Socket Cap Bolts

Titanium Flange Bolts

Titanium Shoulder Bolts

Titanium 12 Point Bolts

Titanium Button Head Bolts

Titanium Countersunk Bolts

Titanium U Bolt

Titanium Eye Bolt

Titanium screws

- Size range: M2–M24 / 3 mm–100 mm.

- Compliant with DIN 84, DIN 85, ISO 14583, DIN 7981, DIN 7982, DIN 7983, ISO 7049, ISO 7050, ISO 7380 standards.

- Torque recommendations provided; pre-ground thread tips ensure smooth installation and reduced risk of galling.

- All threads are roll-formed to boost fatigue life by over 30%.

- Ideal for housing assemblies, electronics, precision instruments, and decorative applications.

- Low minimum order quantity—perfect for custom projects or small batches.

Titanium Socket Head Screws

Hex Head Cap Screws

Titanium Shoulder Screws

Titanium Set Screws

Titanium Self Tapping Screws

Titanium Flat Head Screws

Titanium Button Head Screws

Titanium Torx Screws

Titanium Wood Screws

Titanium nuts

- Size range: M2–M48, 1/4″–1 1/2″.

- Compliant with DIN 934, ISO 4032, DIN 6926, ISO 4161, and ANSI B18.2.2; fully compatible with both metric and imperial thread systems.

- Available with matching anodized colors to pair seamlessly with bolts for a unified look.

- High locking strength, ideal for high-speed and high-vibration applications.

Titanium Hex Nuts

Titanium Flange Nuts

Titanium Cap Nut

Titanium washers

- Outer diameter: 4 mm–80 mm.

- Thickness: 0.8–6 mm.

- Compliant with DIN 125, ISO 7089, DIN 127, ISO 7090, DIN 6796 standards.

- Suitable for insulation, anti-loosening, and dynamic load absorption.

- Selected models withstand high temperature and pressure—ideal for aerospace thermal joints.

- Each washer is acid-cleaned and passivated, leaving a clean, oil-free surface for precision assembly.

Titanium Flat Washer

Titanium Fender Washers

Titanium Lock Washer

Titanium threaded rods

- Outer diameter: 4 mm–80 mm.

- Thickness: 0.8–6 mm.

- Meets DIN 125, ISO 7089, DIN 127, ISO 7090, and DIN 6796 standards.

- Ideal for insulation, anti-loosening, and vibration damping.

- Select models withstand high heat and pressure—perfect for aerospace thermal joints.

- Each washer is acid-cleaned and passivated, ensuring a spotless, oil-free surface for precision assembly.

Titanium Full Thread Studs

Titanium Double End Studs

Orthopedic Threaded Rod

Titanium rivets

- Available in solid, hollow, and POP-style heads

- Compliant with DIN 7337, ISO 15983, and NASM 3799 standards

- Offers significantly higher salt spray corrosion resistance than aluminum rivets

- Ideal for marine hardware, coastal installations, and custom panel assemblies

- Can be shipped together with titanium washers and other fasteners for one-stop sourcing

- Popular sizes in stock, with options for natural or anodized finishes

Titanium threaded inserts

- Specifically designed to reinforce low-strength materials like aluminum and plastic

- Common sizes include M4–M20, 8-32, 10-24, and more

- Compatible with UNC, UNF, metric, and imperial thread types

- Meets DIN 8140, NASM 21209, and NAS 1130 standards

- Self-tapping design for easy installation and reliable thread repair

- Ideal for precision equipment maintenance and 3D-printed structure reinforcement

Whether you're a project contractor, a distributor, or an individual custom buyer, we've got you covered:

- Bolts, nuts, washers, and more packed together as per your BOM—mixed orders welcome

- Get pricing, lead time, MOQ, and drawings within 24 hours

- Choose from multiple finishes: anodized colors, TiN, or dry film coatings

- Low minimum order quantities, flexible for any project size

Let us supply all your titanium fasteners in one go—no more piecing orders from different vendors. Quick Quote

Titanium material grade overview

| Grade | UNS | Yield Strength (MPa) | Tensile Strength (MPa) | Key Advantage |

|---|---|---|---|---|

| Gr 2 | R50400 | 275 | 350 | Excellent corrosion resistance |

| Gr 5 | R56400 | 1000 | 1100 | Exceptional strength-to-weight ratio |

| Gr 7 | R52400 | 275 | 345 | 0.2% Pd for maximum chloride resistance |

| Gr 9 | R56320 | 620 | 690 | Great cold formability |

There are many titanium grades used to produce fasteners, but the three most common are Grade 2, Grade 5, and Grade 7. So, how do you choose the right one?

- Grade 2 titanium is about 30% stronger than 316 stainless steel and is the most widely used grade for general-purpose titanium fasteners.

- Grade 5 titanium is twice as strong as Grade 2. It's the true workhorse alloy, offering an excellent balance of strength, weight savings, and corrosion resistance.

- Grade 7 titanium delivers the highest corrosion resistance among all titanium grades. It contains 0.12–0.25% palladium and is also the most expensive option.

Common applications of titanium fasteners

Automotive tuning (race cars, production vehicles, motorcycles)

On the track, every 100 grams saved can be the difference between winning and losing.

Our complete titanium fastener kits include U-bolts, clevis pins, brake and fuel system bolts—all pre-matched for your build.

Real-world tests on sprint cars show a 1.4 kg weight reduction, using 140 ksi high-strength titanium that handles high-impact launches without loosening under stress.

Titanium Motorcycle Bolts

Titanium License Plate Screws

Titanium Fender Bolts

Titanium Shock Bolts

Titanium Fairing Bolts

Titanium Lug Bolts

Titanium Brake Caliper Bolts

Titanium Steering Wheel Bolts

Mountain and road bike upgrades

Want your bike to be lighter and look sharper? A set of M6×20 or M8×25 anodized titanium bolts delivers instant results.

They can shave off up to 420 grams from your mountain bike—and take just 20 minutes to install.

With rolled threads, these bolts won't seize even after repeated installs, and the anodized colors perfectly match seat clamps and brake caliper screws.

Titanium Sprocket Bolts

Titanium Bottle Cage Bolts

Titanium Stem Bolts

Chemical processing lines

Chlor-alkali, soda ash, and PVC plants face constant threats from chloride pitting.

We recommend Grade 7 titanium bolts with 0.2% palladium, offering better corrosion resistance than even Hastelloy.

Once installed, titanium fasteners can extend maintenance intervals from 18 months to 5 years, reducing costly downtime.

Marine and offshore

In high-salinity seawater, regular bolts rust out in under two years.

Our 140 ksi Ti-64 titanium bolts and washers passed 2,000 hours of salt spray testing with no white rust—and real-world installs have lasted over 20 years with minimal maintenance.

All sizes follow standard dimensions and fit seamlessly into existing 90° countersunk holes—no re-drilling required.

Aerospace and defense

In one UAV project, we replaced 550 M5 steel bolts with Grade 5 titanium, cutting 6.2 kg from total weight and boosting flight endurance by 18%.

Every part was produced under the AS9100 system and shipped with 3.1 material certificates—ensuring a smooth approval process during final assembly and flight readiness checks.

Custom design based on your application drawings

Even if all you have is a sketch on a napkin—send it over. We can turn it into a high-performance titanium part for almost any application.

Our team will take your concept, render it into a 3D mechanical drawing, and begin production based on your custom order. The entire process is faster than you think.

We offer highly competitive pricing and ship worldwide. If you can imagine it, we can make it happen. Quick Quote

Popular titanium fastener sizes

We stock a full range of titanium fasteners in metric (M2–M20), standard (DIN/ISO), and imperial (UNC/UNF) sizes—ready to ship globally with low minimum order quantities.

M2 Titanium Screws

M3 Titanium Screws

M4 Titanium Screws

M5 Titanium Screws

4-40 Titanium Screws

8-32 Titanium Screws

6-32 Titanium Screws

2-56 Titanium Screws

M3 Titanium Bolts

M4 Titanium Bolts

M5 Titanium Bolts

M6 Titanium Bolts

M7 Titanium Bolt

M8 Titanium Bolt

M10 Titanium Bolts

M12 Titanium Bolts

M14 Titanium Bolt

Surface treatments for titanium alloy fasteners

Titanium fasteners are available with a variety of surface treatments to meet different application needs:

- Electrolytic anodizing offers up to 10 vibrant colors—perfect for custom builds or visual accents. It also provides a very low friction surface to help prevent galling.

- PVD coatings like TiN and TiCN deliver hardness levels over 2000 HV (TiN ≈ 2100 HV, TiCN ≈ 3000 HV), making them ideal for high-heat and high-wear conditions. Common finishes include gold and gunmetal.

- Moly dry-film coating offers an ultra-low friction coefficient (~0.1), making it ideal for high-torque applications. It prevents thread seizing and features a matte gray finish.

Popular titanium fastener color options:

Blue Titanium Bolts

Gold Titanium Bolts

Black Titanium Bolts

Orange Titanium Bolts

Red Titanium Bolts

Purple Titanium Bolts

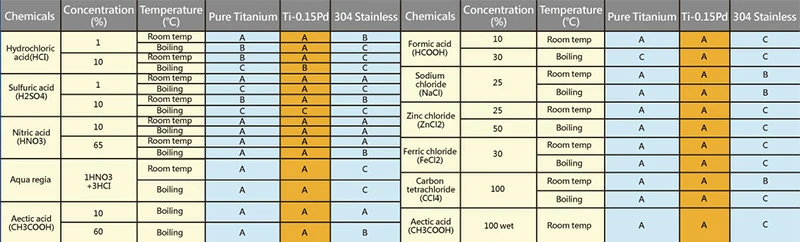

Titanium corrosion resistance across chemical environments

From room temperature to boiling, and in concentrations ranging from 1% to 65%—including harsh acids like hydrochloric, sulfuric, nitric, and even aqua regia—pure titanium and Grade 7 titanium (with 0.15% Pd) consistently receive an "A” corrosion rating.

This means their maximum corrosion depth is less than the thickness of a human hair after one year of exposure. In contrast, 304 stainless steel frequently falls into the "C” range under the same conditions—meaning it could completely fail in less than a year.

The takeaway is clear:

If your equipment is exposed to strong acids or chlorides long-term, switching to titanium fasteners can extend your maintenance cycle from once a year to once every few years. That's the real-world advantage of titanium over stainless steel. Quick Quote

A = Highly resistant (corrosion rate ≤ 0.127 mm/year)

B = Moderately resistant (0.127–1.27 mm/year)

C = Not resistant (≥ 1.27 mm/year)

Titanium fastener interchangeability and dimensional consistency

From our experience, one of the biggest concerns for customers is bolts that don't fit, washers that don't match nuts, or on-site rework that wastes time and money. That's why we ensure every titanium fastener is ready to install—no adjustments needed.

Global dimension standards

We cross-reference ISO, DIN, and ASTM systems to guarantee compatibility between metric and imperial specs.

Threads follow ISO 6g / UNC-2A tolerances, and flatness and perpendicularity meet ISO 4759 standards.

Integrated cold heading and 5-axis CNC finishing

Cold heading preserves the fiber structure of the material, preventing cracks.

CNC machining ensures surfaces are flat and clean, with tolerances controlled within 0.05 mm.

Multi-axis clamping eliminates concentricity errors in a single pass.

Rolled threads, not cut threads

Thread rolling produces cleaner, stronger threads with up to 30% less dimensional variation.

They resist galling even with repeated assembly and disassembly.

100% thread gauge and CMM inspection

Every batch is checked with go/no-go gauges on site.

Samples go through CMM (coordinate measuring machine) to verify pitch, diameter, and head symmetry.

Inspection reports are shipped with your order.

First article inspection & PPAP

New tooling or drawings go through FAI (First Article Inspection).

For automotive and aerospace customers, we can provide PPAP Level 3 documentation to guarantee full batch consistency.

So no matter which batch or project your titanium fasteners come from, they'll fit right the first time.

You focus on tightening them—we'll handle the precision behind it. Quick Quote

To ensure every titanium fastener fits perfectly on the first try, we use CMM with ±2 µm accuracy and a 2.5D vision system for precise dimensional control.

A 50 kN tensile tester and Vickers hardness tester verify strength and hardness, while a digital torque wrench simulates real-world tightening.

From size to performance to assembly fit—everything is checked upfront, saving you from any rework hassles.

Frequently asked questions (FAQ)

How tight should I torque an M6 Grade 5 socket head screw?

Recommended torque is 13 N·m. Apply a small amount of MoS₂ anti-seize paste on the threads for smooth tightening and to prevent damage.

How do I prevent galling with titanium bolts?

Use threads with dry film or TiN coatings. Apply anti-seize paste before assembly to avoid direct titanium-on-titanium contact.

Will anodized colors fade over time?

No. After 2,000 hours of xenon arc weathering, color retention stays above 95%. Still bright and vivid even outdoors.

Can titanium parts undergo non-destructive testing?

Yes. We use fluorescent penetrant testing combined with ultrasonic inspection to ensure internal integrity.

What's the minimum order quantity?

We support low-volume orders.

Different sizes and colors can be mixed in a single shipment—same pricing applies.

Chalco can provide you the most comprehensive inventory of titanium products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote