Titanium Round Bar Gr7

Gr7 titanium rods are made of a Ti–0.15% Pd alloy, specifically designed for environments with chlorides and strong oxidants. They are ideal for chemical, corrosion-resistant equipment, heat exchangers, and seawater engineering. With exceptional resistance to crevice and stress corrosion, they are widely used in bleaching processes, chlor-alkali plants, and marine engineering.

Chalco Titanium 's Gr7 titanium bars are available in stock from φ6– φ300 mm and can be cut to length. All products comply with ASTM B348 and come with an EN 10204 3.1 material report.

Why are customers keen on gr7 titanium round bar?

- Palladium microalloying improves crevice corrosion resistance, making it particularly suitable for strong oxidizing media such as wet chlorine, ClO₂, and sodium hypochlorite.

- Compared with Gr2, the corrosion rate of Gr7 in 90 ℃ sodium hypochlorite solution is reduced by 70%, and the measured service life is extended by more than 2 times.

- It has been in service for a long time in the chlor-alkali industry, bleaching equipment, seawater desalination and high-end heat exchange tube sheet connection systems.

- The mechanical properties are close to those of Gr2, and it has good cold working and welding properties.

- We have Ø6–300 mm in stock, can cut to the millimeter level, and ship the same day.

- strictly in accordance with ASTM B348, ASME SB348 and other standards to ensure consistency and traceability.

Chalco Titanium's Gr7 titanium rods with different processes

Rolled Titanium Bars

Diameter Range: Ø6 mm – Ø60 mm

Length Range: 1000 mm – 3000 mm

Advantages: Suitable for standard small-sized round bars, high dimensional accuracy, good surface quality, suitable for large-scale and fast delivery

Contact us now

Forged Titanium Rod

Diameter Range: > Ø300 mm

Length Range: 500 mm – 6000 mm

Advantages: refined grains, higher strength, high density, strong fatigue resistance and low internal stress.

Contact us nowExtruded Grade 7 Titanium Rod

Diameter Range: Ø8 mm – Ø80 mm

Length Range: up to 6000 mm

Advantages: Complete fiber streamlines, high straightness and neat surface.

Contact us now

Rolled titanium bars

Grade 7 rolled titanium bars are typically available in diameters between Ø6 mm and Ø60 mm and lengths between 1000 mm and 3000 mm.

Advantages: Suitable for standard small-sized round bars, high dimensional accuracy, good surface quality, suitable for large-scale and fast delivery

Forged titanium rod

The diameter of the forged Gr7 titanium rod can reach more than 300 mm, and the length range is mostly from 500 mm to 6000 mm.

Advantages: refined grains, higher strength, high density, strong fatigue resistance and low internal stress.

Extruded Grade 7 Titanium Rod

Gr7 titanium rods produced by extrusion process are generally available in diameters from Ø8 mm to Ø80 mm and lengths up to 6000 mm.

Advantages: Complete fiber streamlines, high straightness and neat surface.

Grade 7 titanium round bar in stock

We stock a wide range of Grade 7 titanium bar in common metric and imperial sizes, and can cut to order. Below are examples of popular sizes. We have ample stock and offer same-day shipping. Custom sizes are also available. Contact us for a quick quote.

Standard tolerance h9/h11, customizable polished surface or black leather state, suitable for various machining and welding requirements.

| Product | Diameter | Length |

|---|---|---|

| 0.250" Diameter Grade 7 Titanium Round Bar | 0.250" | 6m or customized cutting |

| 0.500" Diameter Grade 7 Titanium Round Bar | 0.500" | 6m or customized cutting |

| 0.750" Diameter Grade 7 Titanium Round Bar | 0.750" | 6m or customized cutting |

| 1.000" Diameter Grade 7 Titanium Round Bar | 1.000" | 6m or customized cutting |

| 1.250" Diameter Grade 7 Titanium Round Bar | 1.250" | 6m or customized cutting |

| 1.500" Diameter Grade 7 Titanium Round Bar | 1.500" | 6m or customized cutting |

| 2.000" Diameter Grade 7 Titanium Round Bar | 2.000" | 6m or customized cutting |

| 2.500" Diameter Grade 7 Titanium Round Bar | 2.500" | 6m or customized cutting |

| 3.000" Diameter Grade 7 Titanium Round Bar | 3.000" | 6m or customized cutting |

| 3.500" Diameter Grade 7 Titanium Round Bar | 3.500" | 6m or customized cutting |

| 4.000" Diameter Grade 7 Titanium Round Bar | 4.000" | 6m or customized cutting |

| 5.000" Diameter Grade 7 Titanium Round Bar | 5.000" | 6m or customized cutting |

| 6.000" Diameter Grade 7 Titanium Round Bar | 6.000" | 6m or customized cutting |

| 8.000" Diameter Grade 7 Titanium Round Bar | 8.000" | 6m or customized cutting |

| 10.000" Diameter Grade 7 Titanium Round Bar | 10,000" | 6m or customized cutting |

| 12.000" Diameter Grade 7 Titanium Round Bar | 12,000" | 6m or customized cutting |

Industry solutions and real cases

Chemical industry

Grade 7 titanium rods are widely used in equipment that handles highly corrosive media, such as hydrochloric acid absorption towers, sulfuric acid storage tank supports, hydrogen chloride gas pipeline supports, etc. They are particularly suitable for environments containing chloride ions or strong oxidizing media, and have both structural strength and long-lasting corrosion resistance.

A real-world example: In a hydrochloric acid absorption tower project in Malaysia, the client upgraded its Hastelloy support rods, previously replaced annually, to Grade 7 titanium rods (Ø40 × 1000 mm). The titanium has been in use for over four years with zero signs of corrosion, significantly reducing maintenance frequency and material costs. It is particularly suitable for structural anchoring in highly acidic environments.

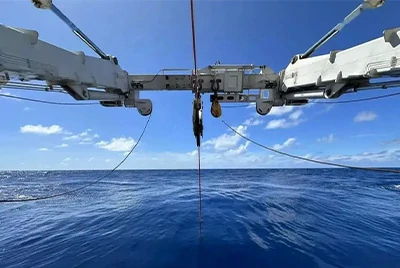

Marine engineering and desulfurization equipment

In seawater desulfurization towers, coastal equipment foundation reinforcement, and platform support rods due to their excellent resistance to chloride corrosion. They are particularly suitable for high-humidity and high-salt coastal or offshore applications.

A real-world example: A seawater desulfurization spray tower in Abu Dhabi was reinforced with Grade 7 Ø75 × 2000 mm titanium rods, replacing the corrosion-prone 316L stainless steel. The new material has operated in a high-salt, high-humidity environment for over two years without requiring replacement, demonstrating excellent marine corrosion resistance and making it suitable for offshore and flue gas desulfurization applications.

Pulp and paper industry

ClO₂ - containing corrosive areas such as bleaching and washing sections. Grade 7 titanium rods can be used for supporting structures, fixtures, and frame connections, reducing equipment maintenance frequency and improving operational stability.

Real-world case study: After a pulp mill in Vietnam replaced the carbon steel struts in its bleaching section with Grade 7 titanium rods, the operating cycle was extended from annual maintenance to every two years. This effectively resisted ClO₂ corrosion, improved operational safety, and made it suitable for highly oxidative bleaching processes.

Energy and petrochemical industries

In refineries, desulfurization reactors, and chlorine-containing cooling water systems, Grade 7 titanium rods are often used in structural parts such as heat exchanger tube sheet supports and flange connection reinforcements, effectively improving the system's corrosion resistance and operating life.

Real-world case study: In a cooling unit renovation project at a Middle Eastern refinery, the customer replaced nickel-based alloys with Grade 7 titanium round bars, effectively resolving corrosion issues caused by high-chloride water, reducing material costs, and successfully passing NACE MR0175 standard assessment. The material is suitable for chemical pipelines and heat exchanger support structures.

Grade 7 vs. Grade 2 Titanium rod

Choosing the right titanium bar is crucial for different corrosive environments. Grade 2 titanium bar is suitable for general corrosion resistance, while Grade 7 is designed for chloride-containing environments and offers enhanced protection. Understanding these differences will help you make more efficient and safer material choices.

| Comparison Dimension | Grade 2 (pure titanium) | Grade 7 (palladium titanium alloy) |

|---|---|---|

| chemical composition | Ti ≥ 99.2% | Ti ≥ 99.2%, containing 0.12–0.25% Pd |

| tensile strength | ≥ 345 MPa | ≥ 345 MPa |

| Yield strength | ≥ 275 MPa | ≥ 275 MPa |

| Corrosion resistance | Excellent, suitable for neutral or weak corrosive environment | Excellent, especially suitable for strong oxidizing or chlorine-containing environments |

| Typical application environment | Seawater, fresh water, general chemical equipment | High concentration hydrochloric acid, sodium hypochlorite, wet chlorine gas, ClO₂ and other highly corrosive media |

| cost | Lower cost, suitable for large-scale structural parts | The cost is slightly higher, but it is more economical in the long term under corrosive conditions |

| Application cycle | Generally 5–8 years depending on the environment | Up to 10-15 years, reducing frequent replacement and maintenance |

Select a recommended reference:

- If you are dealing with normal seawater, industrial water or a neutral corrosive environment, Grade 2 is a cost-effective choice.

- If there are strong oxidizing chemicals in the environment (such as ClO₂, wet chlorine, hydrochloric acid, etc.), Grade 7 can better ensure the stability and life of the equipment and is suitable for critical connections or long-term operation devices.

Value-added services and logistics solutions

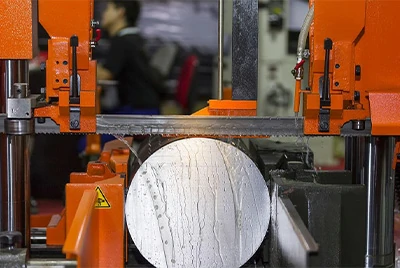

Precision cutting

Each Grade 7 titanium rod can be precisely cut to customer specifications, with a tolerance of ±0.5 mm. Stock lengths are 1000 mm, 2000 mm, and 3000 mm, with lengths as short as 50 mm possible, making it suitable for a variety of applications, including prototyping and small-batch assembly.

Diversified surface treatment

According to different usage requirements, titanium rods can be selected from the following surface conditions:

- Pickling and passivation: removes the oxide layer and cleans the surface, suitable for chemical equipment and welding applications.

- Polishing treatment: Ra ≤ 0.8 µm, suitable for structural parts that require aesthetics and smoothness.

- Rough turning/finishing surface: used for subsequent machining scenarios to save customer costs.

Material reports and certification documents can be issued

All titanium bars leaving the factory can provide EN 10204 3.1 material report, certificate of origin (CO), RoHS / REACH environmental declaration, MSDS and other customs clearance and technical information to meet the factory audit and compliance requirements of European and American customers.

Packaging specifications, international transportation safety guarantee

- Each titanium rod is wrapped with plastic film or anti-rust paper to prevent moisture and scratches

- Small-sized finished products are placed in thickened cartons, supplemented with foam and fixing fixtures

- Large size/large quantity are packed with vacuum bag + PVC sleeve + fumigated wooden box to meet the requirements of sea/air transportation

- Fully trackable express delivery services (such as DHL, FedEx, UPS), with delivery to most areas in Europe, America, Asia, and the Middle East within 3-7 working days after shipment

Small batch support + fast delivery

No minimum order, with a minimum order of one piece, suitable for project proofing and early trial production. In-stock sizes can be shipped on the same day of order confirmation; custom-sized and processed orders are typically dispatched within 2–4 business days.

Chemical composition

| Element | Content (%) |

|---|---|

| Fe | 0.3 |

| O | 0.25 |

| Pd | 0.12–0.25 |

| C | 0.08 |

| N | 0.03 |

| H | 0.015 |

| Other | 0.4 |

| Ti | Balance |

Grade 7 is an alloy with 0.12–0.25% palladium (Pd) added to commercially pure titanium, which significantly improves its resistance to crevice corrosion and pitting corrosion in acidic, chloride-containing environments. It is particularly suitable for chemical, marine and high-corrosion applications.

Typical mechanical properties

| Tensile strength (MPa) | 345–485 (typically 430) |

|---|---|

| Yield strength (MPa) | 275–350 (typically 340) |

| Elongation | 20–28% (typically 25%) |

| hardness | About 150 HV |

| elastic modulus | 103–112 GPa |

Gr7 titanium rod FAQ

Can you customize non-standard sizes or lengths?

We support customized diameters ranging from Ø6 mm to Ø200 mm, with lengths as short as 50 mm and as long as 6000 mm, and support millimeter-precision cutting and tolerance control.

Can you issue material certification and certification documents?

We can provide EN 10204 3.1 material report, certificate of origin (CO), RoHS/REACH declaration, MSDS, safety data sheet, etc. with the goods to meet the compliance and customs clearance requirements of the European and American markets.

Can Grade 7 titanium rod be welded?

Grade 7 can be used for conventional titanium welding processes such as argon arc welding and plasma welding. During welding, the purity of argon gas must be controlled to be >99.999%, and the welding area must be well protected by gas to prevent contamination.

How long is the delivery cycle?

Standard sizes are in stock and can be shipped within 24–48 hours after payment. Custom-sized, machined, or surface-treated orders are generally delivered within 3–5 business days. Large orders can be quickly scheduled.

Do you support small batch purchases or samples?

We offer a minimum order of 1 unit and can provide samples on demand for testing or certification, suitable for initial project evaluation.