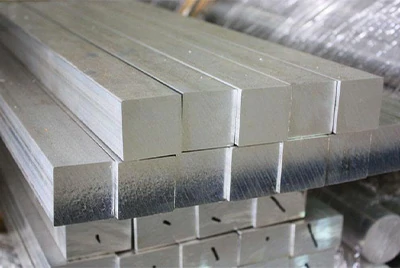

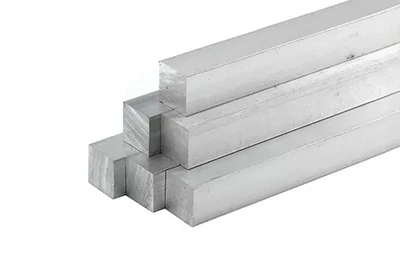

Ti-6Al-4V Titanium Square Bar

Ti-6Al-4V Titanium Square Bar (Grade 5 Titanium Square Bar)

Ti-6Al-4V titanium square bar (Grade 5 titanium square bar) is a high-performance titanium alloy known for its high strength, lightweight, and corrosion resistance. Composed of 6% aluminum, 4% vanadium, and the remainder pure titanium, it accounts for nearly 50% of the global titanium market and is the material of choice for industries such as aerospace, medical, and industrial.

Chalco's Grade 5 titanium square bar strictly complies with aerospace standards such as ASTM B348 and AMS 4928, combining lightweight and high strength to maintain stable performance even in extreme environments. Factory direct supply, full traceability, custom-cut lengths, and fast global shipping ensure efficient procurement of high-quality titanium.

Grade 5 Titanium Square Bar Product Series

Chalco Titanium offers a variety of Grade 5 titanium bar types to meet diverse performance and precision requirements, from aerospace components to medical implants. Choose the processing method and size range that best suits your application.

Forged Titanium Square Bar

Side Length: 20–150 mm

Length: 500–2000 mm

Uniform strength and dense structure , suitable for heavy-loaded structural parts or aviation parts requiring high strength

Contact us now

Hot Rolled Titanium Square Bar

Side Length: 10–80 mm

Length: 2000–6000 mm

Good dimensional stability and high cost performance. Click to view tolerance details.

Contact us nowCold Rolled Titanium Square Bar

Side Length: 6–40 mm

Length: ≤ 4000 mm

Smooth surface and high dimensional accuracy. Click to view tolerance details

Contact us now

Extruded Titanium Square Rod

Side Length: 6–60 mm

Length: 1000–6000 mm

Made through continuous extrusion process, it has a dense structure and is suitable for industrial parts, fasteners , etc.

Contact us nowCharacteristics of Gr5 Titanium Square Bar

Excellent strength-to-weight ratio

Ti-6Al-4V offers comparable mechanical strength to high-strength steel, yet boasts a density of only 4.43 g/cm³, making it approximately 45% lighter than steel (~7.8 g/cm³). With a tensile strength of approximately 900–950 MPa and a yield strength of ≥880 MPa, it significantly reduces weight while still being able to withstand high loads. This makes it particularly well-suited for lightweight design in aviation, racing, and precision structural components.

Corrosion resistance and durability

Grade 5 titanium square bars exhibit strong corrosion resistance in seawater, hot and humid climates, and various acidic and alkaline environments. Actual tests show that the corrosion rate is less than 0.01 mm/year after continuous exposure to natural seawater for 90 days. Compared to conventional stainless steel, the service life of Ti-6Al-4V titanium square bars can be extended by 2–5 times in high humidity, salt spray, and chlorine-containing environments, significantly reducing equipment maintenance and replacement costs.

High temperature stability

Grade 5 titanium square bars can maintain stable mechanical properties at high temperatures, with a long-term working temperature of 350–400 °C, and can withstand more than 500 °C without significant loss of strength. In extremely cold environments, it still maintains good toughness and is not prone to brittle cracking. It is suitable for hot and cold alternating working conditions such as jet engine structural parts, LNG system support parts and aerospace parts.

Machinability and machining

Although grade 5 titanium square bars are slightly more difficult to process, using a cutting speed of 15–30 m/min, a feed rate of 0.05–0.2 mm/rev, combined with carbide tools and strong cooling, enables efficient turning and drilling.

Welding characteristics

Grade 5 titanium square bars have good welding performance and are commonly connected by TIG or electron beam welding. Welding should be done under argon protection (O₂ < 50 ppm). For large-scale or critical stress-bearing parts, double-sided welding with back-side shielding gas is recommended to ensure weld strength and stability.

Reliability and fatigue resistance

Annealed Grade 5 titanium square bars offer excellent fatigue properties, with a fatigue strength of up to 510 MPa and a fracture toughness of 55–75 MPa·√m, ensuring stable service under vibration and cyclic loading. Combined with excellent corrosion resistance, they are ideal for use in aerospace fasteners, submersible structures, and heavily loaded components, outperforming aluminum and steel, offering greater durability and reliability.

Common Applications of Ti-6Al-4V Square Bars

Aerospace and Defense

Used in aircraft structural connectors, brackets, fasteners, and other lightweight high-strength components such as missiles and satellites.

Medical and Surgical Devices

For surgical tool components, MRI equipment structures, rehabilitation devices, and other non-implantable medical applications.

Industrial and Chemical Equipment

For valve seats, pump connectors, agitator bases, resistant to acid, alkali, and chloride corrosion.

Marine Engineering and Oil and Gas Equipment

For ROV components, deep-sea connection blocks, desalination supports, excellent seawater resistance.

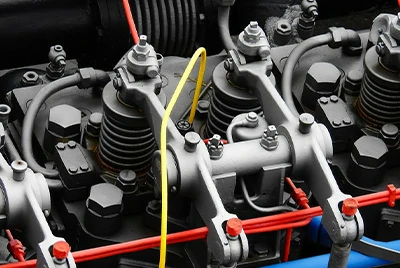

High-Performance Auto Parts

For engine tappets, suspension blocks, drive accessories in F1 racing cars and high-end modifications.

Scientific Research and Electronic Equipment

For NMR brackets, particle instrument structures, non-magnetic, corrosion-resistant high-strength parts.

6Al-4V Titanium Square Bars in Stock

| Product Name | Section side length (inches) | Cross-section length (mm) | Length range |

|---|---|---|---|

| 0.25"*0.25" 6Al-4V titanium square bar | 0.25" * 0.25" | 6.35mm * 6.35mm | 1–6m or customized |

| 0.375"*0.375" 6Al-4V titanium square bar | 0.375" * 0.375" | 9.53mm * 9.53mm | 1–6m or customized |

| 0.5"*0.5" 6Al-4V titanium square bar | 0.5" * 0.5" | 12.7mm * 12.7mm | 1–6m or customized |

| 0.625"*0.625" 6Al-4V titanium square bar | 0.625" * 0.625" | 15.88mm * 15.88mm | 1–6m or customized |

| 0.75"*0.75" 6Al-4V titanium square bar | 0.75" * 0.75" | 19.05mm * 19.05mm | 1–6m or customized |

| 1"*1" 6Al-4V titanium square bar | 1" * 1" | 25.4mm * 25.4mm | 1–6m or customized |

| 1.25"*1.25" 6Al-4V titanium square bar | 1.25" * 1.25" | 31.75mm * 31.75mm | 1–6m or customized |

| 1.5"*1.5" 6Al-4V titanium square bar | 1.5" * 1.5" | 38.1mm * 38.1mm | 1–6m or customized |

| 1.75"*1.75" 6Al-4V titanium square bar | 1.75" * 1.75" | 44.45mm * 44.45mm | 1–6m or customized |

| 2"*2" 6Al-4V titanium square bar | twenty two" | 50.8mm * 50.8mm | 1–6m or customized |

| 2.5"*2.5" 6Al-4V titanium square bar | 2.5" * 2.5" | 63.5mm * 63.5mm | 1–6m or customized |

| 3"*3" 6Al-4V titanium square bar | 3" * 3" | 76.2mm * 76.2mm | 1–6m or customized |

| 3.5"*3.5" 6Al-4V titanium square bar | 3.5" * 3.5" | 88.9mm * 88.9mm | 1–6m or customized |

| 4"*4" 6Al-4V titanium square bar | 4" * 4" | 101.6mm * 101.6mm | 1–6m or customized |

At Chalco Titanium, all our titanium square bars are manufactured to exacting dimensional tolerances in accordance with ASTM B348. Depending on the processing method (hot working or cold working), the permissible dimensional deviations may vary slightly.

The following table lists the standard dimensional tolerances for hot-worked and cold-worked titanium square bars. If your project requires higher dimensional accuracy, we can also provide more stringent tolerance control and custom processing services. Please contact us for a proposal and quote.

6Al-4V Titanium Square Bar Tolerance

Tolerances of Hot Worked Square Bars

| Nominal Size Range (inches/mm) | Dimensional Tolerances (inches/mm) | Out-of-Square Tolerance (inches/mm) |

|---|---|---|

| ¼ to ⁵ ⁄ ₁₆ (6.35 to 7.94) | ±0.005″ (±0.13 mm) | 0.008″ (0.20 mm) |

| Over ⁵⁄₁₆ to ⁷⁄₁₆ (7.94 to 11.11) | ±0.006″ (±0.15 mm) | 0.009″ (0.23 mm) |

| Over ⁷⁄₁₆ to ⁵⁄₈ (11.11 to 15.88) | ±0.007″ (±0.18 mm) | 0.010″ (0.25 mm) |

| Over ⁵⁄₈ to ⁷⁄₈ (15.88 to 22.22) | ±0.008″ (±0.20 mm) | 0.012″ (0.30 mm) |

| Over ⁷⁄₈ to 1 (22.22 to 25.40) | ±0.009″ (±0.23 mm) | 0.013″ (0.33 mm) |

| Over 1 to 1⅛ (25.40 to 28.58) | ±0.010″ (±0.25 mm) | 0.015″ (0.38 mm) |

| Over 1⅛ to 1¼ (28.58 to 31.75) | ±0.011″ (±0.28 mm) | 0.018″ (0.46 mm) |

| Over 1¼ to 1⅜ (31.75 to 34.92) | ±0.012″ (±0.30 mm) | 0.018″ (0.46 mm) |

| Over 1⅜ to 1½ (34.92 to 38.10) | ±0.014″ (±0.36 mm) | 0.020″ (0.51 mm) |

| Over 1½ to 2 (38.10 to 50.80) | +1⁄64″ (+0.40 mm) | 0.023″ (0.58 mm) |

| Over 2 to 2½ (50.80 to 63.50) | +1⁄32″ (+0.79 mm) | 0.023″ (0.58 mm) |

| Over 2½ to 3½ (63.50 to 88.90) | +3⁄64″ (+1.19 mm) | 0.035″ (0.89 mm) |

| Over 3½ to 4½ (88.90 to 114.30) | +1⁄16″ (+1.59 mm) | 0.046″ (1.17 mm) |

- Out-of-round refers to the difference between the maximum diameter and the minimum diameter on the same cross section, and is used to describe the degree of deviation of a round bar.

- Out-of-square refers to the difference between the two sets of opposite side dimensions on the same cross section of a titanium square bar (i.e. the difference in side lengths in two directions).

- Dimensional tolerance refers to the maximum positive and negative deviation allowed for side length;

- Suitable for hot forging and hot rolling titanium square bars;

- If you need higher precision (such as polishing rod h8/h7/h6), please specify separately.

Tolerances for Cold-Worked Titanium Square Bars

| Nominal Size Range (inches/mm) | Dimensional Tolerances (inches/mm) |

|---|---|

| Over ½ to 1 (12.70 to 25.40), incl | +0 / − 0.004″ ( − 0.10 mm) |

| Over 1 to 2 (25.40 to 50.80), incl. | +0 / − 0.006″ ( − 0.16 mm) |

| Over 2 to 3 (50.80 to 76.20), incl. | +0 / − 0.008″ ( − 0.20 mm) |

| Over 3 (76.20 mm) | +0 / − 0.010″ ( − 0.25 mm) |

If heat treatment or heat treatment plus pickling is required after cold working, the dimensional tolerances of the final product will usually be doubled than the values in this table due to special hardness or mechanical property requirements.

Quality Assurance and Certification

All titanium square bars are manufactured in strict accordance with ASTM B348 standards. Aerospace orders meet AMS 4928 requirements, while medical applications can be supplied in accordance with ASTM F136 (ELI) or F1472 standards. Tell us your application, and we'll deliver the compliant product.

Comply with international standards

All titanium square bars are manufactured in strict accordance with ASTM B348 standards. Aerospace orders meet AMS 4928 requirements, while medical applications can be supplied in accordance with ASTM F136 (ELI) or F1472 standards. Tell us your application, and we'll deliver the compliant product.

Full set of material test report (MTR)

Each batch of materials is accompanied by a complete test report, including test data for chemical composition (such as aluminum, vanadium, iron, oxygen, etc.) and mechanical properties (tensile strength, yield strength, elongation, etc.). The material standard and heat number are marked to facilitate quality traceability and internal review.

Strict inspection process

All titanium bars undergo chemical analysis and dimensional testing. For aviation orders, we also perform ultrasonic testing (UT) in accordance with ASTM B594 and AMS 2631 to ensure the absence of internal defects. Additional testing for hardness and microstructure is performed when necessary to ensure that every bar leaves the factory in good condition.

Passed ISO and AS certification system

We are ISO 9001:2015 and AS9100D (Aerospace Quality Management) certified. From raw materials to shipment, every step is carried out according to standards to ensure batch consistency and long-term stable supply.

Support third-party inspection

If required by the client or project, we can cooperate with third-party organizations such as TUV and Lloyd's Register to conduct witnessed inspections or certifications to ensure smooth external project or terminal acceptance.

Global delivery and service guarantee

- We support fast delivery of in-stock products. Regular orders are usually shipped within three business days, and custom cutting or processing orders are generally delivered within one to two weeks.

- For urgent projects, we can arrange priority cutting and air shipment, which can be delivered within a few days, greatly shortening the delivery cycle.

- With rich export experience, we can deliver products stably to North America, Europe, Asia, Oceania and other places.

- Provide complete export documents, including commercial invoice, packing list, certificate of origin, EN 10204 3.1 quality certificate, etc.

- Each titanium square bar is treated with anti-rust and anti-scratch treatment and packed in a sturdy wooden box for transportation, meeting international transportation standards to ensure it is delivered intact.

- Maintain communication with customers throughout the entire process, promptly confirm orders, update production and logistics progress, and provide logistics tracking information.

- The on-time delivery rate exceeds 95%. In case of special circumstances, we can coordinate batch shipments or expedited delivery to ensure customer progress.

- A variety of international transportation terms such as FOB, CIF, DDP according to customer needs, and also support customers to designate freight forwarders or express accounts for delivery.

- We provide after-sales service support. If you encounter product size deviation or transportation damage, we will quickly assist with returns and exchanges and provide technical advice.

Frequently Asked Questions (FAQ)

Can I order in small quantities?

No minimum order quantity. Whether it's a single sample or a large-volume project order, we can flexibly arrange production and delivery.

Do you provide free samples of grade 5 titanium square bars?

We support the provision of small samples for testing or evaluation, regular specifications such as 10×10 mm, 20×20 mm, etc., 100–150 are available free of charge Sample size 1–2 mm (subject to stock availability). Custom sizes or special requests may be priced at cost. Shipping costs are generally borne by the customer, but may be waived if shipped with a subsequent order.

What shipping methods are supported? Is it exportable?

We support express, air and sea transportation, and can export to many places around the world. We have complete export experience and standard packaging, and support various trade methods such as FOB, CIF, DDP, etc.

What should I do if the goods I receive have quality or size issues?

We are committed to quality. If there are any discrepancies or problems, please contact us immediately and we will quickly assist in processing returns or technical support.

Grade 5 and Grade 23 titanium square bars?

The two have the same chemical composition, but grade 23 (ELI) titanium has lower impurity content and greater ductility, making it more suitable for medical implants, while grade 5 titanium is commonly used in structural parts and industrial applications.