Grade 2 Titanium Foil

Chalco Titanium offers Grade 2 titanium foil in thicknesses as thin as 0.00008 inches (0.002 mm), suitable for engineering applications requiring lightweighting and corrosion resistance. This product adheres strictly to ASTM B265, ASTM F67, and AMS 4902 standards, ensuring reliable performance and compliance in critical applications such as aerospace, medical devices, and energy and chemical industries.

Standards and certification

Gr2 titanium foil strictly adheres to international standards in production and quality control, and has passed multiple international and domestic authoritative certifications to ensure the reliable application of the material in aerospace, medical, military industry, scientific research and other fields.

Standard

- Strictly follow international standards: ASTM B265, ASTM F67 (medical grade pure titanium), AMS 4902

- EN 10204 3.1 material certification available

Certification

- ISO 9001

- AS9100

- Nadcap

Chalco titanium grade 2 foil product specifications

| Brand | Gr2 / Grade 2 Titanium (Commercially Pure Titanium) |

|---|---|

| Implementation standards | ASTM B265, ASTM F67, AMS 4902 |

| Thickness range | 0.00008"- 0.025" (0.002 – 0.635mm) |

| Width range | Depending on the thickness, the maximum can reach 444.5 mm |

| Supply form | Coils, sheets, discs (customizable punching) |

| Edge processing | Rolled edge/slitting edge (slitting burr <10% thickness) |

| Surface state | Bright, matte, chemically polished, Ra 1–16, no discoloration or defects |

| Heat treatment status | Annealed, As-rolled |

Thickness range and maximum width

| Thickness range (inch / mm) | Maximum width description |

|---|---|

| 0.025" – 0.003" (0.635 – 0.076 mm) | 17.5" (444.5 mm) with rolled edge 17.0" (431.8 mm) with notched edge |

| 0.0029" – 0.001" (0.0737 – 0.0254 mm) | 16.5" (419.1 mm) with rolled edge 16.0" (406.4 mm) with notched edge |

| 0.0009" – 0.0004" (0.023 – 0.01 mm) | 15.5" (393.7 mm), rolled edge 15.5" (393.7 mm), slit edge |

| 0.00039" – 0.00008" (0.0099 – 0.002 mm) | Maximum hem width is 4.25" (107.95 mm) and slit width is 4.0" (101.6 mm) |

Hot selling titanium foil types from Chalco Titanium

-

Industrial Titanium Foil Gr2 industrial titanium foil is suitable for corrosive environments such as heat exchangers, marine piping, and chemical linings, offering good formability and moderate strength. Customizable wide coils are available to meet high-volume industrial applications.

-

Punching Titanium Foil Grade 2 stamped titanium foil has excellent ductility and is suitable for precision stamping parts such as battery cases, shrapnel, and filter screens. The material has clean, burr-free edges and supports high-speed stamping and multi-station die forming.

-

Precision Titanium Foil Gr2 precision titanium foil can be manufactured to a thickness of ≤0.01 mm with tight tolerances and high surface cleanliness. It is widely used in high-precision applications such as sensors, fuel cells, and electromagnetic shielding.

-

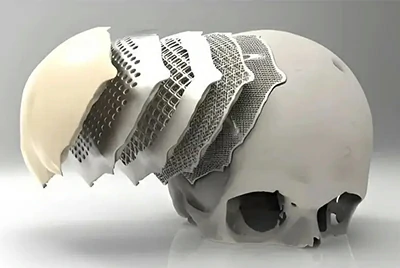

Medical Titanium Foil Gr2 medical titanium foil complies with ASTM F67 and exhibits excellent biocompatibility and resistance to body fluid corrosion. It is suitable for medical applications such as implantable devices, electrodes, and micro-battery housings.

-

Gr2 Ultra-thin Titanium Foil thicknesses range from 0.005–<0.01 mm and widths from 10–140 mm. Made from commercially pure Grade 2 titanium, it offers excellent ductility and a clean surface, making it suitable for precision applications such as flexible electronics, shielding films, and medical microstructures.

Stock sizes of gr2 titanium foil

Our stock of Titanium Grade 2 foil covers a variety of thicknesses and specifications to meet the different needs of scientific research, industry and special applications:

- Thickness range: 0.3mm – 2.0mm

- Width range: 10mm – 1000mm

- Length range: 10mm – 2000mm (some can reach 6000mm, customizable).

Click to view the inventory details to help you select your project and ensure fast delivery.

Typical applications of gr2 titanium foil

Aerospace

Gr2 titanium foil is widely used in aircraft skins, engine components, thermal insulation and electromagnetic protection layers due to its light weight and corrosion resistance, helping to reduce structural weight and extend service life.

Medical devices

Gr2 titanium has good biocompatibility and meets ASTM F67 standards. It is commonly used in medical applications such as cardiovascular stents, implantable battery housings, and microsurgical devices.

Energy and chemicals

In a highly corrosive environment, Gr2 titanium foil exhibits excellent stability and is suitable for use in key structures such as reactor linings, fuel cell bipolar plates, and battery current collectors.

Scientific research and electronics

Gr2 titanium foil is commonly found in precision electronic and scientific research devices such as electron beam equipment, vacuum system X-ray windows, high-purity containers, and speaker diaphragms for high-end audio.

Production process and quality assurance

Gr2 titanium foil is produced using a high-precision, multi-stand cold rolling process, achieving micron-level thickness control and widths up to 444 mm. During production, vacuum or bright annealing processes are used to ensure a uniform and clean surface, preventing discoloration and defects.

To ensure the coil's straightness and dimensional stability, the product undergoes tension leveling and clean-room slitting. Furthermore, eddy current and ultrasonic testing technologies are used during quality inspection to effectively eliminate internal defects, and burrs are strictly controlled during edge processing.

Through the above process, Gr2 titanium foil not only meets international standards in performance, but also ensures high consistency and traceability between batches.

Surface treatment

- Bright annealed surface - surface finish can reach Ra ≤ 0.2μm, suitable for electronics, medical and vacuum sealing scenarios.

- Sandblasted matte surface - Roughness can be adjusted from Ra 0.5 to 1.5μm, which enhances bonding performance and is commonly used for bonding composite materials and structures.

- Chemical polishing - High surface cleanliness, can remove ≤ 5μm oxide layer, ensuring welding and surface coating quality.

- PVD coating or surface modification can increase the surface hardness to HV ≥ 800, significantly improving wear resistance and functional performance.

By precisely controlling surface roughness (Ra 0.2–1.5μm controllable) and cleanliness (residue ≤ 20 mg/m²), customers can obtain high-performance customized titanium foils that meet the needs of welding, bonding or vacuum sealing processes.

Packaging and logistics

- Vacuum packaged and filled with inert gas to prevent oxidation and contamination.

- Add desiccant and use moisture-proof film to prevent moisture during transportation.

- Use end guards and locking rings to prevent the "telescopic effect."

- The outer layer is made of pearl cotton and fumigated wooden box, with multiple anti-collision and shock protection.

Delivery efficiency:

In-stock products are typically available for shipment within 48 hours.

Typical lead times for custom thicknesses and widths are 7–14 days.

FAQ

What is the minimum order quantity?

Gr2 titanium foil supports small MOQ orders, and can provide sample rolls or small-size pieces for customer testing.

Can you provide free samples?

Free samples of approximately 1 m² can be provided for proofing.

How to calculate coil weight?

Weight (kg) = density × thickness × width × length, where the density of Gr2 is 4.48 g/cm³.

What factors affect prices?

Thickness, width, tolerance, surface treatment, batch size and lead time all directly affect price.

Can you provide a material report?

All products shipped are accompanied by EN 10204 3.1 material certification to ensure traceability and compliance.

Typical mechanical properties of grade 2 titanium foil

Mechanical properties in annealed state

| Performance Project | Numerical |

|---|---|

| Tensile Strength UTS | 70 ksi (485 MPa) |

| Yield strength YS | 50 ksi (345 MPa) |

Gr2 titanium physical properties

| project | Numerical |

|---|---|

| density | 0.163 lb/in³ (4.48 g/cm³) |

| β transition temperature | 1680°F (915°C) |

| Melting point | 3034 °F (1668 °C) |

| Thermal conductivity | 12.60 Btu/hr·ft·°F (21.79 W/m·K) |

| Resistivity | 21 μΩ·in(0.53 μΩ·m) |

| Magnetic permeability | Non-magnetic |

| Young's modulus | 1.68 × 10 ⁷ lb/in² (116 GPa) |

| Shear modulus | 6.38 × 10 ⁶ lb/in² (44 GPa) |

| Poisson's ratio | 0.32 |

The physical properties data were measured at room temperature (approximately 20–25°C).

Grade 2 titanium foil stock size details

| Product | Thickness | Width |

|---|---|---|

| Titanium Grade 2 Foil 0.3mm(t) | 0.3mm | 25mm |

| Titanium Grade 2 Foil 0.3mm(t) | 0.3mm | 50mm |

| Titanium Grade 2 Foil 0.3mm(t) | 0.3mm | 100mm |

| Titanium Grade 2 Foil 0.3mm(t) | 0.3mm | 150mm |

| Titanium Grade 2 Foil 0.3mm(t) | 0.3mm | 300mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 20mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 25mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 50mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 100mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 150mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 300mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 250mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 500mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 10mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 200mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 475mm |

| Titanium Grade 2 Foil 0.5mm(t) | 0.5mm | 950mm |

| Titanium Grade 2 Foil 0.7mm(t) | 0.7mm | 25mm |

| Titanium Grade 2 Foil 0.7mm(t) | 0.7mm | 50mm |

| Titanium Grade 2 Foil 0.7mm(t) | 0.7mm | 100mm |

| Titanium Grade 2 Foil 0.7mm(t) | 0.7mm | 150mm |

| Titanium Grade 2 Foil 0.7mm(t) | 0.7mm | 300mm |

| Titanium Grade 2 Foil 0.7mm(t) | 0.7mm | 500mm |

| Titanium Grade 2 Foil 0.8mm(t) | 0.8mm | 25mm |

| Titanium Grade 2 Foil 0.8mm(t) | 0.8mm | 50mm |

| Titanium Grade 2 Foil 0.8mm(t) | 0.8mm | 100mm |

| Titanium Grade 2 Foil 0.8mm(t) | 0.8mm | 150mm |

| Titanium Grade 2 Foil 0.8mm(t) | 0.8mm | 200mm |

| Titanium Grade 2 Foil 0.8mm(t) | 0.8mm | 300mm |

| Titanium Grade 2 Foil 0.8mm(t) | 0.8mm | 500mm |

| Titanium Grade 2 Foil 0.8mm(t) | 0.8mm | 1000mm |

| Titanium Grade 2 Foil 1.2mm(t) | 1.2mm | 150mm |

| Titanium Grade 2 Foil 1.2mm(t) | 1.2mm | 300mm |

| Titanium Grade 2 Foil 1.5mm(t) | 1.5mm | 25mm |

| Titanium Grade 2 Foil 1.5mm(t) | 1.5mm | 50mm |

| Titanium Grade 2 Foil 1.5mm(t) | 1.5mm | 100mm |

| Titanium Grade 2 Foil 1.5mm(t) | 1.5mm | 150mm |

| Titanium Grade 2 Foil 1.5mm(t) | 1.5mm | 300mm |

| Titanium Grade 2 Foil 1.5mm(t) | 1.5mm | 500mm |

| Titanium Grade 2 Foil 1.5mm(t) | 1.5mm | 1000mm |

| Titanium Grade 2 Foil 1.0mm(t) | 1.0mm | 10mm |

| Titanium Grade 2 Foil 1.0mm(t) | 1.0mm | 25mm |

| Titanium Grade 2 Foil 1.0mm(t) | 1.0mm | 50mm |

| Titanium Grade 2 Foil 1.0mm(t) | 1.0mm | 100mm |

| Titanium Grade 2 Foil 1.0mm(t) | 1.0mm | 150mm |

| Titanium Grade 2 Foil 1.0mm(t) | 1.0mm | 300mm |

| Titanium Grade 2 Foil 1.0mm(t) | 1.0mm | 500mm |

| Titanium Grade 2 Foil 1.0mm(t) | 1.0mm | 1000mm |

| Titanium Grade 2 Foil 2.0mm(t) | 2.0mm | 25mm |

| Titanium Grade 2 Foil 2.0mm(t) | 2.0mm | 50mm |

| Titanium Grade 2 Foil 2.0mm(t) | 2.0mm | 100mm |

| Titanium Grade 2 Foil 2.0mm(t) | 2.0mm | 150mm |

| Titanium Grade 2 Foil 2.0mm(t) | 2.0mm | 300mm |

| Titanium Grade 2 Foil 2.0mm(t) | 2.0mm | 500mm |