High-precision Ultra Thin Titanium Foil

In high-end batteries, foldable-screen smartphones, FPCs/connectors, precision spring components, heating films, and aerospace and defense equipment, traditional stainless steel foil and nickel foil are increasingly unable to meet the combined requirements of lightweighting, corrosion resistance, high specific strength, and long service life. In this context, high-precision ultra-thin titanium foil is becoming a new choice for procurement professionals.

Why choose ultra-thin titanium foil from Chalco Titanium?

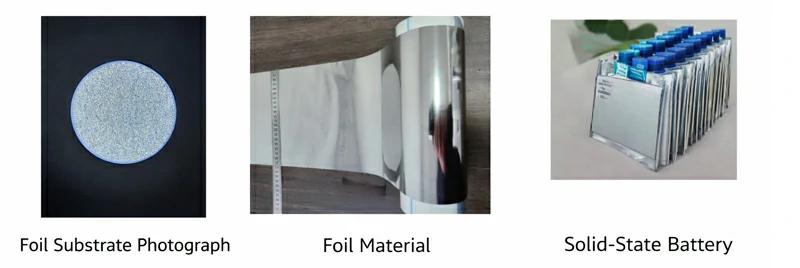

Chalco Titanium focuses on precision metal cold rolling and deep processing of titanium materials. With a self-owned precision cold-rolling factory, it has integrated production capability from raw materials to finished products.

The plant can supply steadily within a thickness range of about 0.003–0.20 mm and a width range of about 80–420 mm. Its products cover ultra-thin TA1 titanium foil of 3–5 μm up to 0.30 mm titanium spring strip, providing customers with a complete solution for precision titanium and titanium alloy foils/strips.

The company is equipped with precision rolling mills, precision slitting, annealing, cleaning, and a complete inspection system, enabling full-process quality control from forming to surface treatment and ensuring dimensional accuracy, surface quality, and stable performance.

Types of precision titanium foil available from Chalco Titanium

3–5 μm Ultra-thin titanium foil

Product size: thickness 3–5 μm, width 80–210 mm;

Thickness tolerance: ±0.1–0.2 μm;

Maximum tensile strength: ≈1500 MPa;

Contact us now

Capacity: 500 kg/month for 5 μm foil.

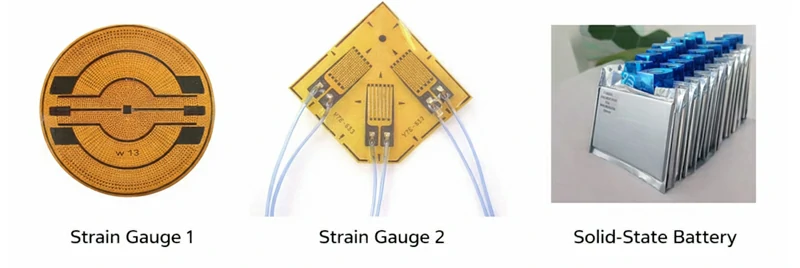

Applications: Solid-state lithium battery current collectors and capacitor electrodes. It can also be used as a lightweight, corrosion-resistant substrate for components such as strain gauges, film resistors, 3C electromagnetic shielding foils, power semiconductor soldering tabs, and magnetic head gap shims.

5–20 μm Ultra-thin titanium foil

Product size: Thickness 5–20 μm, width 80–420 mm;

Thickness tolerance: ±1–3%;

Maximum tensile strength: ≈2000 MPa;

Contact us now

Capacity: 15 tons/month for 10 μm foil.

Applications: TA1 / TC4 titanium foil is mainly used for solid-state battery current collectors, PV steel plate printing sheets, FPC stiffeners, heating resistance sheets, electromagnetic shielding materials, and high-reliability, corrosion-resistant components such as precision shims and blades.

High-precision-thickness titanium foil strip

Product size: Thickness 0.01–0.3 mm, width 80–400 mm;

Thickness tolerance: ±0.5–2%;

Surface roughness Ra: 0.03–0.4 μm;

Contact us now

Capacity: 25 tons/month for 0.15 / 0.3 mm strip.

Applications: TA1 / TC4 titanium foil is mainly used for solid-state lithium battery current collectors, capacitor electrodes, FPC stiffening and shielding, and precision sensor strain gauges, as well as other electronic components requiring lightweight, corrosion resistance, and non-magnetic properties.

Low-ductility titanium foil strip

Product size: Thickness 0.01–0.15 mm, width 80–400 mm;

Thickness tolerance: ±1–3%;

Surface roughness Ra: 0.04–0.1 μm;

Contact us now

Applications: TC4 titanium foil strip is mainly used for aerospace structural parts, substrates for resistive and heating films, and military motors, as well as other critical components requiring high strength, corrosion resistance, and non-magnetic properties.

Advantages of Chalco Titanium

Complete product range

Chalco Titanium can supply more than just titanium foil of a single thickness or grade. With cold-rolling capability covering a thickness range of 0.003–0.20 mm, we have formed a clear titanium product lineup:

- 3–5 μm ultra-thin TA1 titanium foil

- 5–20 μm ultra-thin TA1/TC4 titanium strip

- 0.01–0.30 mm titanium spring/structural strip

- 0.01–0.15 mm high-strength, low-ductility TC4 titanium strip (up to 1500 MPa)

Within the same project, customers can complete material selection and sourcing in one stop at Chalco Titanium—from ultra-thin functional layers to load-bearing and elastic structural components.

Ultra-high precision

Leveraging a precision cold-rolling system, Chalco Titanium maintains strict control over key parameters of ultra-thin titanium foil/strip:

- Thickness tolerance can be controlled within ±1–3% (depending on product and specification);

- Surface roughness for ultra-thin products can reach Ra 0.04–0.1 μm;

- Combined with precision slitting, we ensure strip width accuracy and edge quality to meet the requirements of high-speed stamping and roll-to-roll production.

Chalco Titanium's production capacity

Cold-rolling facility and dimensional capability

Chalco Titanium operates a physical cold-rolling plant in Wujiang, Suzhou, specializing in the R&D and production of precision metal materials. With a workshop area of several thousand square meters, it is capable of:

- Thickness range: approx. 0.003–0.20 mm (3 μm–0.20 mm)

- Width range: approx. 80–420 mm

This means Chalco Titanium can cover products from micron-level ultra-thin titanium foil up to around 0.2 mm medium-thickness titanium strip, meeting thickness requirements for various structural components.

Key equipment

Precision cold-rolling equipment

With an effective rolling thickness of approx. 0.003–0.20 mm and strip width of 80–420 mm, it supports multi-pass precision rolling for ultra-thin and very thin titanium foil/strip. Through multi-pass precise reduction and process control, it balances shape control and flatness, ensuring thickness tolerance can be kept within ±1–3%, providing a foundation for stable mass production of ultra-thin titanium foil.

Precision slitting equipment

Capable of slitting master coils into various widths from 80 to 420 mm to match die-width requirements for smartphones, FPCs, batteries, and more. The slit edges are neat with minimal burrs, meeting the consistency requirements for edge quality in high-speed precision stamping and roll-to-roll processes, helping improve downstream efficiency and yield.

Annealing and heat-treatment equipment

By adjusting protective atmosphere, heating/cooling profiles, and soaking schedules, it can flexibly match the strength/ductility window required by different products—enabling both high-strength, low-ductility TC4 strip and thin strip in spring temper with better formability. This ensures stable, repeatable mechanical properties from sampling through mass production.

Cleaning and surface-treatment line

Provides degreasing, cleaning, and surface finishing for rolled titanium foil/strip, effectively removing rolling oil and surface contaminants to improve surface cleanliness and consistency, delivering higher adhesion and reliability for subsequent processes such as coating, etching, plating, and bonding.

Supporting inspection and laboratory equipment

Includes thickness measurement, surface roughness inspection, and mechanical property testing. Key batch parameters are recorded and traceable, forming a closed-loop quality control system from master coil to finished product, ensuring consistent performance of ultra-thin titanium foil and very thin titanium strip across batches.

Services Chalco Titanium can provide

In addition to supplying high-end precision ultra-thin titanium foil and very thin titanium strip, Chalco Titanium also provides a complete set of supporting services throughout the full project lifecycle, helping customers bring new materials into mass production faster.

Material selection and solution optimization

Based on information such as operating temperature, media/environment, service life requirements, and forming methods (stamping / bending / etching / winding), we recommend suitable grades (TA1 / TC4, etc.), thickness ranges, and performance windows;

We also propose optimization suggestions for weight reduction, cost reduction, or longer service life—for example, when switching from stainless steel or nickel foil to titanium foil, how to adjust thickness or strength grade.

Small-batch sampling and trial-production support

We provide small trial coils or cut pieces for process validation, die tuning, and reliability testing in new projects;

Based on trial feedback, we can fine-tune strength, hardness, or surface condition to help customers quickly finalize mass-production specifications.

Customized dimensions and performance windows

We support customized thickness, width, and mechanical property ranges, such as specific tensile strength, yield strength, elongation, or elastic properties;

Based on customer tooling and equipment requirements, we can customize slitting widths (e.g., dedicated widths for FPC stiffeners and smartphone structural parts) to reduce downstream secondary processing.

Integrated supply of multiple materials

In addition to titanium and titanium alloys, Chalco Titanium also has production capabilities for precision foil/strip including stainless steel, copp

FAQ

What thickness range can Chalco Titanium provide for ultra-thin titanium foil and titanium strip?

Our overall thickness capability is approximately 0.003–0.20 mm, covering micron-level ultra-thin titanium foil up to titanium strip within 0.30 mm. For the specific thickness ranges of each series, please refer to the product type descriptions above.

What are the standard widths and delivery forms? Can you customize the width?

The standard width range is approximately 80–420 mm, mainly supplied in coils, and can also be delivered as slit strips or cut sheets. Slitting width can be customized to match your tooling or equipment requirements for direct production-line use.

How should I choose between TA1 and TC4 titanium foil/strip?

In general, TA1 is better suited for applications that prioritize formability and corrosion resistance, while TC4 is better for high-load components that prioritize strength, specific strength, and dimensional stability. Final selection can be supported by our engineering team based on your operating conditions.

What thickness tolerance and surface roughness can ultra-thin titanium foil typically achieve?

For standard products, thickness tolerance can generally be controlled at about ±1–3%, and premium products can achieve surface roughness of Ra 0.04–0.1 μm. Final values are subject to the mutually confirmed technical agreement.

What are the MOQ and lead time?

MOQ and lead time vary by specification. Mass-production items typically have a defined minimum order quantity, while new projects can start with small-batch trials. Once you provide the grade, thickness, width, and estimated demand, we can propose the corresponding MOQ and lead-time plan.

What information should be prepared in advance to develop a new ultra-thin titanium foil component?

It is recommended to prepare the application scenario, target thickness and width, preferred material grade, service environment and life requirements, and estimated demand, so we can quickly provide suitable material and process recommendations.