High-precision Performance Titanium Forged Parts

Chalco Titanium has passed AS9100D aerospace quality system certification, ISO 9001 total quality management, and NADCAP special process certification (forging, heat treatment, non-destructive testing). It also has the nuclear power quality assurance outline and the international power industry qualified supplier qualification.

Chalco Titanium's accessories not only cover military and commercial aircraft engines, but are also widely used in gas turbines, aerospace engineering and nuclear power fields, making it the most trusted supplier of ring forgings and structural parts in the international market.

Titanium forging standards

| AMS 4965 | AMS 4966 | AMS 4967 | AMS 4970 | AMS 4971 |

| AMS 4973 | AMS 4974 | AMS 4976 | AMS 4979 | AMS 4981 |

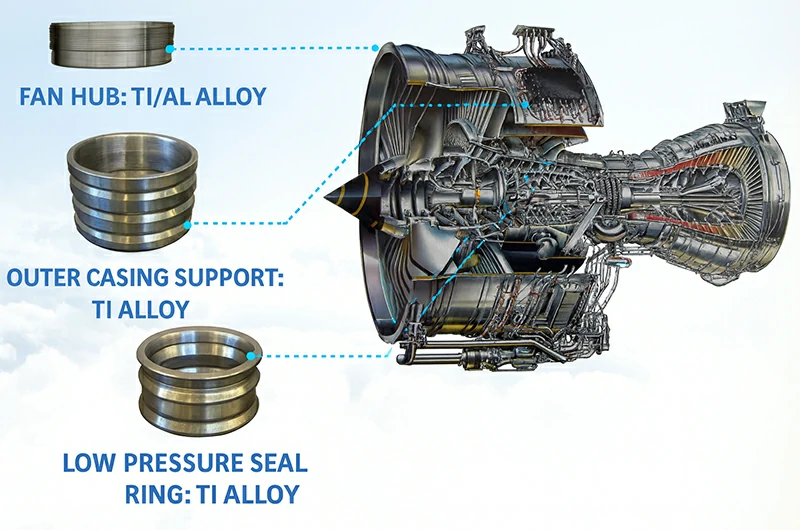

Aircraft engine parts

Aircraft engines are known as the "crown jewel of industry," and every critical component must operate under the dual requirements of high strength and high reliability. Chalco Titanium's cold-end titanium alloy components have been mass-produced in multiple models, including the GE9X, LEAP, Trent 1000, and the domestically produced C919 CJ1000 engine.

If you are looking for high-precision titanium forging solutions that meet international certifications and can be delivered in batches, please contact us now for technical support and customized quotes.

Fan case

The fan case is one of the most visible, large-diameter components of the engine, primarily manufactured from Ti-6Al-4V titanium alloy. It serves as both the load-bearing structure for the fan blades and the outer shell for the airflow path. More importantly, it fulfills the safety function of "blade arrest." If a fan blade breaks under extreme operating conditions, the case must stop the high-speed flying debris, preventing fatal damage to the aircraft and passengers.

This is the fan case for the LEAP-1C engine used in the COMAC C919 passenger aircraft. Made of Ti-6Al-4V titanium alloy and measuring approximately 2134 x 2047 x 600 mm, it is a key aircraft engine structural component.

This is the fan case for the LEAP-1C engine used in the COMAC C919 passenger aircraft. Made of Ti-6Al-4V titanium alloy and measuring approximately 2134 x 2047 x 600 mm, it is a key aircraft engine structural component.

Chalco Titanium is capable of manufacturing large fan cases, such as the Ti64 fan case (2134 × 2047 × 600 mm), which is used in the LEAP 1C and C919 domestically produced large aircraft engines. This achievement not only demonstrates Chalco Titanium's strength in forging and precision machining of ultra-large diameter titanium rings, but also demonstrates that its products fully meet the technical standards of international OEMs.

By delivering large-diameter fan cases, Chalco Titanium helped customers achieve a combination of lightweighting and high safety, while also meeting the stringent dimensional accuracy, strength, and fatigue resistance requirements of aircraft engines. The successful application of this type of product further solidifies Chalco Titanium's leading position in the global aviation engine ring forging market.

Outer duct support

The duct support is a load-bearing ring in the engine bypass duct. Its task is to maintain the concentricity and structural rigidity of the duct and maintain the stability of the engine under aerodynamic loads.

Because they need to withstand long-term alternating loads, Chalco Titanium uses Ti-6Al-4V or Ti-6242 titanium alloy to manufacture these support rings, ensuring they have high strength and fatigue resistance to meet the life requirements of commercial and military engines.

Low pressure sealing ring

The low-pressure seal ring is a critical sealing component in the low-pressure section of the compressor. It isolates the airflow channel from the external environment, preventing air leakage and ensuring compression efficiency. Chalco Titanium utilizes Ti-2.5Cu and Ti-6Al-4V materials to manufacture this seal ring, ensuring both lightweight performance and excellent sealing performance, effectively improving engine efficiency.

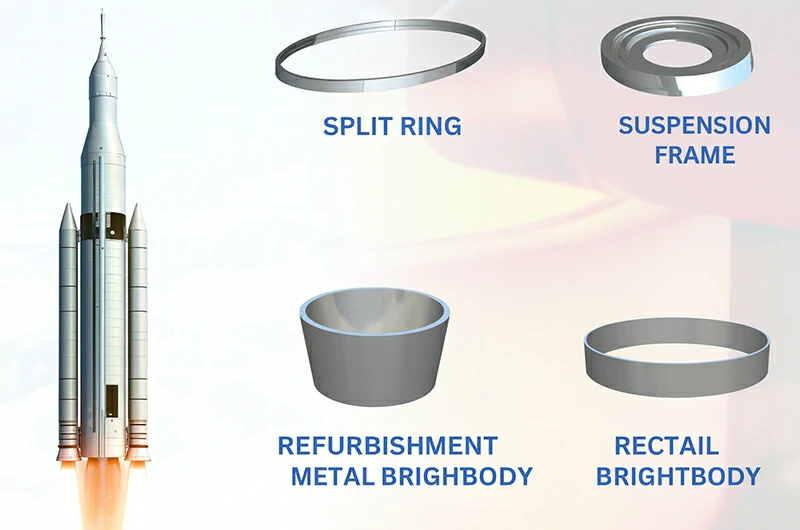

Aerospace accessories

The aerospace industry places even more extreme demands on materials. Rockets and spacecraft must be as lightweight as possible while maintaining reliability in low-temperature, vacuum, and even high-radiation environments.

Chalco Titanium provides titanium and aluminum alloy ring forgings, which are widely used in rocket structures and cabin hulls. If you are looking for a high-reliability aerospace component supplier, please contact us for customized solutions and technical support.

Fork ring

Fork rings are critical interface components in aerospace structures, primarily responsible for connection and force distribution. Chalco Titanium's titanium alloy fork rings offer high stiffness and stability, making them widely used in launch vehicle and satellite engineering.

Hanging frame

The pylon frame is a crucial structural component connecting rocket segments. It must not only withstand immense stress but also ensure stability during launch and separation. Chalco Titanium manufactures pylon frames using Ti-6Al-4V, achieving both lightweight and high strength to withstand the extreme conditions of rocket launch.

Correction cabin metal shell

The cabin hull is a critical load-bearing outer shell of a spacecraft. Chalco Titanium uses Ti-5Al-2.5Sn titanium alloy and 2219 and 2618 aluminum alloys to manufacture the cabin hull. These materials have excellent low-temperature toughness and weldability, enabling reliable operation in deep space environments.

Rear skirt shell

The aft skirt shell is a critical load-bearing and connecting component of the rocket's tail section, directly bridging and securing the rear section of the rocket body to the engine thrust frame. During launch, the aft skirt shell must withstand the combined effects of thrust loads, aerodynamic pressure, and thermal stress, making it a critical component for ensuring the rocket's stable flight and separation.

Chalco Titanium utilizes Ti-6Al-4V titanium alloy and 2219 aluminum alloy in the rear skirt shell. The former boasts exceptionally high specific strength and high-temperature resistance, while the latter combines weldability and low-temperature toughness. Ring rolling for near-net-shape formation, heat treatment for microstructure stabilization, and precision machining ensure the shell maintains geometric stability under complex stress conditions.

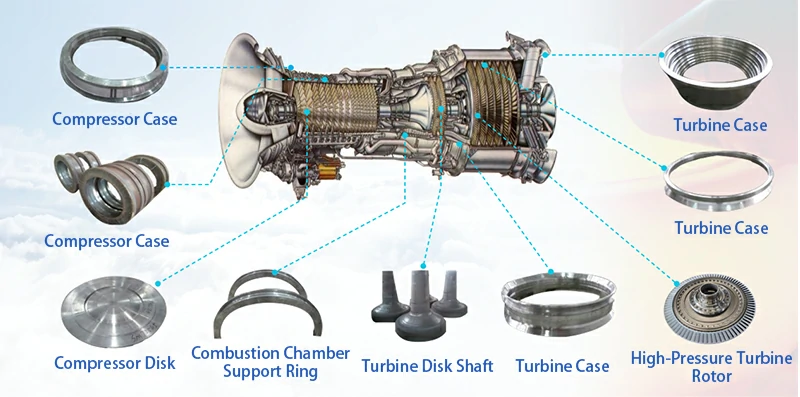

Gas turbine accessories

Gas turbines are widely used in the power, petrochemical, and energy equipment industries and are essential for modern energy conversion and efficient power generation. Their core components must maintain reliability under high-temperature, high-pressure, and long-term continuous operation. Leveraging advanced titanium and aluminum alloy forging technologies, Chalco Titanium provides a range of key rings and structural components for gas turbines. Get a quick quote.

Compressor casing

The compressor casing is one of the most important annular components at the front end of a gas turbine. Its primary function is to form the compressor airflow path and provide a load-bearing housing for the blades. During long-term operation, it must withstand the pressure and vibration caused by high-speed airflow.

Chalco Titanium manufactures the compressor case from Ti-6Al-4V and 2219 aluminum alloys. Ring rolling and near-net-shape forming followed by Nadcap heat treatment ensure uniform wall thickness and stable geometric accuracy. This component significantly improves airflow compression efficiency and unit lifespan while reducing maintenance costs.

Compressor disc

The compressor disc is installed in the rotor system and is a key component that connects the blades and transmits power. It must maintain strength and toughness under high speeds and alternating loads.

Chalco Titanium manufactures compressor discs from high-strength titanium alloys (Ti64/Ti-6242). Through precision machining and non-destructive testing, fatigue life and dimensional accuracy are guaranteed. This product has been widely used in power plant gas turbines, effectively improving compressor efficiency and overall reliability.

Combustion chamber support ring

The combustion chamber support ring is located in the combustion zone. Its main function is to fix the combustion chamber and maintain structural stability. It needs to withstand both high-temperature airflow and structural loads.

Chalco Titanium uses Ti-2.5Cu and Ti64 alloys, along with heat treatment and surface protective coating, to ensure the support ring maintains strength and oxidation resistance even in high-temperature environments. The reliability of this component is directly related to combustion efficiency and unit safety.

Gas turbine casing

The turbine casing is located in the high-temperature zone, surrounding the gas turbine and subject to the pressure and thermal stress from the high-temperature gas. It must have good heat resistance and structural stability.

Chalco Titanium manufactures turbine cases from titanium and high-performance aluminum alloys, employing near-net-shape ring rolling technology to significantly reduce machining allowances. These products are certified by NADCAP for heat treatment and testing, ensuring geometric accuracy and sealing performance over tens of thousands of hours of operation.

Gas turbine casing WASPALOY 2132*1616*607mm

Compressor disc Ti6242 480*262*178mm

Low-pressure turbine guide vane assembly 700*90*110 mm

Nuclear power accessories

Nuclear power plants operate in high-temperature, high-pressure, and highly corrosive water environments for extended periods of time. Failure of any critical component can directly impact unit safety. Leveraging its expertise in titanium and aluminum alloy forging, Chalco Titanium provides high-reliability components for nuclear power clients worldwide, covering core components such as reactors, steam generators, condensers, and piping systems.

Extension flange

Extension flanges are used for sealing connections between reactors and pipelines and are essential interface components in nuclear power equipment. These components must maintain their sealing properties and strength over decades of operation.

Chalco Titanium manufactures extended flanges from Ti-6Al-4V and Ti-2.5Cu titanium alloys, offering excellent corrosion resistance and stress corrosion cracking resistance. Ring rolling to near-net shape and Nadcap heat treatment ensure precise flange geometry and long-term reliability. For customers, extended flanges mean reduced risk of leaks and longer maintenance intervals.

Trunnion forgings

Trunnion forgings are often used for the support and rotation interfaces of steam generators and reactor pressure vessels, and are subject to huge loads and complex stress states.

Chalco Titanium uses a high-speed forging process to produce trunnion forgings. Using high-strength titanium alloy, they ensure both load-bearing capacity and weight reduction. Ultrasonic and radiographic testing ensures internal defects, meeting the stringent standards of the nuclear power industry. The reliability of these components contributes to more stable operation of nuclear power equipment.

Tube sheet

Tube sheets are key components of nuclear power heat exchangers, used to secure a large number of heat exchange tubes and isolate the cooling water from the primary circuit medium. They must withstand high pressures while resisting long-term corrosion from the cooling water.

Chalco Titanium utilizes Ti-6Al-4V and corrosion-resistant aluminum alloys to manufacture its tubesheets. Precision machining and corrosion-resistant coatings enhance resistance to pitting and crevice corrosion. The use of titanium alloy tubesheets significantly extends the heat exchanger's operating life and reduces lifetime costs.

Venturi tube

The Venturi tube is used to measure and control the fluid velocity and flow in the reactor cooling circuit and is an important component to ensure stable reactor operation.

Chalco Titanium utilizes a single-piece forged titanium alloy Venturi tube, featuring high-precision geometry and excellent corrosion resistance. Through precision machining, its measurement accuracy and long-term stability meet nuclear power standards, providing reliable data support for reactor cooling systems.

Damper support pad

Damper support pads are used in reactor cooling systems to provide support, vibration reduction, and energy absorption. They must maintain stable performance over time in environments with high-frequency vibrations and high-pressure water flow.

Chalco Titanium manufactures damper support pads using high-strength titanium alloys and precision forging processes, ensuring excellent vibration damping and wear resistance. The stability of this component ensures the safe operation of the reactor cooling circuit.

Nozzle

Nozzles are key channels for cooling water and steam flow in nuclear power equipment. Because they are exposed to high-temperature, high-pressure water environments year-round, nozzles place extremely stringent requirements on the corrosion resistance of their materials.

Chalco Titanium uses Ti-2.5Cu and Ti-6Al-4V materials to produce nozzles. These nozzles undergo multiple heat treatments and undergo non-destructive testing to ensure they possess excellent strength, toughness, and corrosion resistance. The use of titanium alloy nozzles significantly extends the operating life of the cooling system.

Instrument tube

Instrument tubes are used in monitoring and measurement systems within nuclear power plants, connecting various sensors and control devices. They require high dimensional accuracy, strong corrosion resistance, and long-term stability. Chalco Titanium's titanium alloy instrument tubes undergo precision rolling and surface treatment to ensure stable performance over long service life, safeguarding the safe monitoring of nuclear power equipment.

Chalco Titanium's certification and qualifications

In the high-end equipment manufacturing sector, certification is not only a guarantee of quality but also a passport to access the international supply chain. Chalco Titanium strictly adheres to global standards and has obtained certifications from major aircraft engine manufacturers and nuclear power companies, ensuring smooth product distribution in key industries such as aviation, aerospace, energy, and nuclear power.

Management system certification

Chalco Titanium has passed a number of international and national system certifications, covering the entire chain of management such as quality, environment, safety and compliance:

- Quality Management : ISO 9001, AS9100D, GJB 9001C

- Environmental management : ISO 14001

- Laboratory Capabilities : ISO 17025

- Occupational health and safety : ISO 45001

- Energy management : ISO 50001

- Integration of Industrialization and Informationization : GB/T 23001

- Intellectual Property Management : GB/T 29490

- Safety production : Safety production standardization second-level enterprise

- International Trade Compliance : AEO Advanced Certified Enterprise

These certifications provide customers with confidence that the entire process is traceable, environmentally friendly, and delivered in compliance with regulations .

Specialty process certification (NADCAP)

In the aerospace industry, NADCAP certification is essential for accessing the supply chain of international OEMs. Chalco Titanium holds the following process certifications:

- NADCAP MMM (Forging)

- NADCAP HT (Heat Treatment)

- NADCAP NDT (Non-Destructive Testing)

This means that Chalco Titanium not only has the ability to manufacture complex ring forgings, but can also meet the most stringent process and testing standards to meet the needs of global aerospace customers.

One-stop solution for precision forging and intelligent manufacturing

In the high-end equipment sector, customers require not only reliable components but also systematic solutions from materials to finished products. Leveraging our comprehensive process capabilities, Chalco Titanium offers a complete service system, from complex structural component molding to precision machining and intelligent delivery.

Complex molding solutions for high-end equipment

Leveraging advanced ring rolling and rapid forging processes, combined with the strengths of titanium and aluminum alloys, Chalco Titanium is capable of manufacturing large ring forgings exceeding two meters in diameter and complex structural components. Through near-net-shape technology, Chalco Titanium achieves a perfect balance of lightweight, high strength, and high reliability while minimizing machining allowances, providing optimal structural solutions for aviation, aerospace, and energy equipment.

Precision machining and surface treatment

Chalco Titanium boasts world-class precision machining capabilities, achieving micron-level accuracy, ensuring components meet stringent assembly and operational requirements. Surface treatment encompasses the entire process chain, including heat treatment, coating, and polishing, enhancing component wear and corrosion resistance while significantly extending service life.

Intelligent and automated manufacturing

By introducing flexible forging production lines and intelligent workshops, Chalco Titanium has achieved full process automation, from robotic machining and automated testing to logistics and transportation. Every product is traceable, significantly reducing lead times while maintaining high quality.

This system helps customers enter the "New Era of Forging 3.0" and enjoy more efficient and reliable supply chain services.

Is Chalco Titanium a trusted partner ?

In the field of aero-engine and high-end equipment manufacturing, strength and qualifications determine the value of cooperation. Chalco Titanium has become the most trusted ring forging supplier for customers by virtue of its leading production line scale, strict international qualifications and long-term global partnerships. Contact us

Asia's largest | Global leader

- Asia's largest supplier of ring forgings for commercial aircraft engines, with annual production capacity and equipment level ranking among the top in the industry.

- It is the only ring forging company in Asia that has the qualification to supply all the major aircraft engine manufacturers in the world, and its products have entered the international core supply chain.

Advanced equipment | Excellent technology

- An investment of 200 million yuan was made to build the ring forging production line with the largest rolling weight in Asia at that time, establishing the company's leading position in the industry.

- It has an 8MN fast forging hydraulic press unit, which enables efficient forming and mass production of large rings.

International certification | Military industry support

- It was the first to pass the military qualification review and became the first company in China to obtain the core qualification for titanium alloy and high-temperature alloy ring forgings.

- We have obtained the qualification to supply ring forgings for engines such as LEAP and GE9X, and our products are used in more than 70 types of aircraft engines.