Titanium Targets: Born For High-Performance Coatings

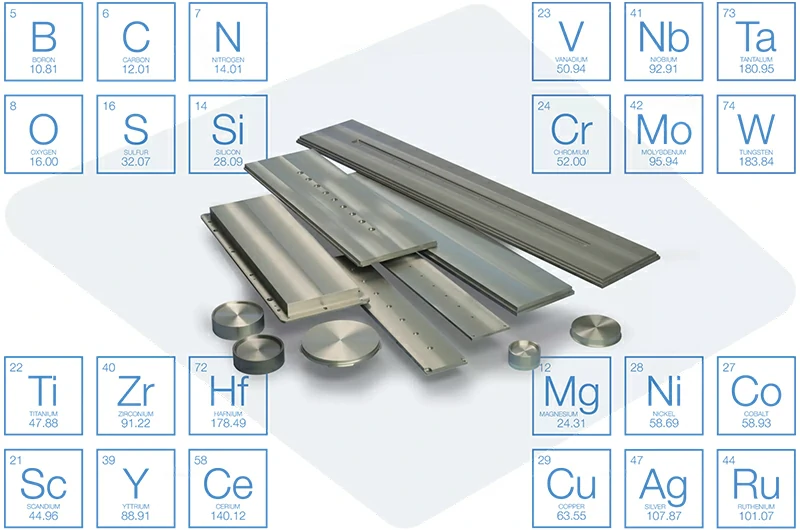

In the PVD vacuum coating process, titanium targets have become the core materials for many high-precision fields such as semiconductors, optics, decoration and tool coatings due to their excellent purity, density and high-temperature stability. We provide titanium targets in various specifications and structural forms, covering high-purity titanium and titanium alloy solutions to meet customers' diverse requirements for performance, size and compatibility.

- High-purity titanium target: purity up to 99.99 5 %, suitable for semiconductor and functional film layers;

- Customized titanium alloy target: aluminum, chromium, zirconium, molybdenum and other elements can be added as needed to enhance the performance of the film layer;

- Various product forms: flat targets, tube targets, round targets, and cathode targets are all available;

- Supports mainstream PVD processes such as reactive magnetron sputtering and arc evaporation ( click to view titanium target technical parameters )

Chalcotitanium sputtering target product types

-

Round target

Compatible with most coaters, available in various sizes, and widely used in optical and hard coatings.

Diameter <350mm; Thickness>1mm

-

Rectangular target

Suitable for applications that require large area coating. Rectangular targets can provide more uniform coating results.

Length 1800mm; Width 400mm

-

Tubular target

Ideal for rotating target systems, offering uniform coatings for decorative and high-temp wear-resistant applications.

Outer diameter 20mm~160mm; Wall thickness 2-20mm

-

Customized target

We offer fully customized titanium targets in different alloys and specific sizes based on our customers’ application needs.

Customized outer diameter>160; Thickness>8mm

Chalcotitanium titanium target alloy customization

Chalcotitanium titanium target products include pure titanium targets, high-performance titanium alloy targets and special material targets, such as titanium dioxide (TiO ₂) and TiC targets, to meet the requirements of different coating applications.

In addition, with our profound experience in the field of titanium targets, we can also blend different metal elements and customize the composition of the alloy according to the specific needs of customers, ensuring that the performance of each alloy target achieves the best effect in the customer's application.

Pure titanium target

We provide pure titanium targets of various specifications, covering two categories: industrial grade titanium and high purity titanium, which are widely used in high-precision thin film deposition fields such as semiconductors, optics, decoration, and medical treatment. Industrial pure titanium targets (Grade 1~4) have excellent chemical stability and corrosion resistance, while high purity titanium targets can reach 99.99% and 99.995% purity, with extremely low impurity content and uniform microstructure, and are particularly suitable for applications with extremely high requirements for film purity.

- Semiconductor industry (metal electrodes, barrier layers)

- Optical coating (mirrors, optical filters)

- Decorative coating (mobile phone housing, eyeglass frames, etc.)

- Medical devices (implants, device surface treatment)

- Nanoelectronics and functional thin films

- 99.99% high purity ti target

- 99.995% ultra-high purity

- Grade 1 CP Titanium

- Grade 2 CP Titanium

- Grade 3 CP Titanium

- Grade 4 CP Titanium

Special material targets

In addition to industrial pure titanium, we also provide a variety of special titanium target materials, including titanium dioxide (TiO ₂), titanium aluminum (Ti-Al), titanium silicon (Ti-Si), etc., suitable for special application requirements. These materials have excellent optical properties, oxidation resistance, hardness and other characteristics, and are widely used in optical coatings, solar cells, hard coatings and other fields.

-

Titanium Dioxide (TiO₂) Target

With a purity of 99.99%, titanium dioxide is a common target material valued for its excellent optical transparency and chemical stability. It is widely applied in optical coatings, photocatalytic materials, and the solar photovoltaic industry.

-

Titanium Carbide (TiC) Target

Titanium carbide targets feature extremely high hardness and wear resistance, making them ideal for hard coatings, protective surfaces, and applications in microelectronics.

-

Titanium Nitride (TiN) Target

Titanium nitride offers a unique combination of metallic luster, electrical conductivity, and wear resistance. It is commonly used in decorative coatings, durable hard coatings, and as barrier layers in microelectronic devices.

Titanium alloy target

Chalcotitanium provides a wide range of custom alloy titanium target services. According to your specific requirements, we can adjust the alloy composition by adding elements such as aluminum, tantalum, molybdenum, tungsten, etc. to optimize properties such as corrosion resistance, strength, high temperature resistance, hardness, etc. Our custom alloy titanium target solutions ensure that they can meet your unique needs in various thin film deposition.

- Coated tools: Improve the wear resistance of the tools and extend their service life.

- High temperature coating: for tools and parts in high temperature environments.

- Electronic equipment coatings: Improve durability and corrosion resistance.

-

Ti-Al alloy target and cathode

Titanium-aluminum target and cathode materials enable the formation of hard, oxidation-resistant nitride coatings (TiAlN) on drills, milling cutters, indexable inserts and other tools.

-

Ti-Nb alloy target

Titanium-niobium alloy has good high temperature resistance and is suitable for high temperature application environments.

-

Ti-W alloy target

Titanium tungsten alloy has good oxidation resistance and high temperature stability and is often used in coating applications in high temperature environments.

-

Ti-Si alloy target

Titanium silicon alloys have enhanced hardness and wear resistance and are widely used in tool and mold coatings.

-

Ti-Ta alloy target

Enhanced anti-oxidation and corrosion resistance, suitable for films in harsh environments

-

Ti-Mo alloy target

With high strength and excellent corrosion resistance, it is suitable for electronic component coating

Product advantages: sputtering performance and micro-control advantages

Grain structure

By optimizing the melting, forging and heat treatment processes, a uniform and fine grain structure can be achieved, which helps to improve the sputtering rate and film consistency and ensure stable film performance.

Purity assurance

We provide high purity titanium targets up to 99.995%, with impurities controlled at ppb level, meeting the extremely high purity requirements of semiconductor and optical levels and avoiding film contamination and defects.

High density and degassing treatment (Densification & Outgassing Control)

Through hot isostatic pressing (HIP) technology and vacuum degassing process, the density of the target material can be effectively improved, the gas release rate can be reduced, and the adhesion and reliability of the film can be improved.

Uniformity & sputtering stability

The target material has uniform thickness and dense structure, which ensures balanced erosion of the target material during sputtering, reduces abnormal arc discharge, and improves equipment operation efficiency and film formation consistency.

Chalcotitanium titanium target customized production and application support integrated solution

At Chalcotitanium, we not only provide high-precision, customized titanium targets, but also help customers achieve efficient and stable thin film deposition production through full-process services from design and development to equipment adaptation.

Material design and custom development

According to the customer's coating performance requirements, we assist in selecting appropriate alloy elements and designing the composition and structure to ensure that the target material performance is highly matched with the application requirements.

Interface structure customization and welding technology

It supports a variety of high-reliability welding methods (such as diffusion welding and hot-pressing welding), and can customize circular, rectangular, and tubular target structures and cathode connection interfaces according to different equipment requirements to achieve seamless matching of equipment.

Rich experience in equipment adaptation

We are familiar with the specifications of mainstream PVD / CVD equipment manufacturers (such as ULVAC, AJA, Kurt J. Lesker, Singulus, etc.), and can accurately meet the key parameter requirements such as size, electrode structure and cooling method.

Rapid prototyping and process collaboration

We provide customers with rapid prototyping services and initial parameter recommendations to help process engineers quickly complete equipment commissioning, parameter optimization and batch operation.

Batch consistency guarantee

Through a strict quality control system, we ensure the stability of target materials in terms of dimensional tolerance, purity and performance, and achieve long-term stable supply.

Chalcotitanium titanium target product application cooperation areas

Chalcotitanium's titanium targets are widely used in a variety of industries. Our expertise and high-quality products play a vital role in the following industries:

Automotive glass and WEB coating

Supplying sputtering targets for high-performance architectural, automotive, photovoltaic glass, and mirrors.

Semiconductor materials

Our compound semiconductor materials (99.99%–99.995% purity) come in various forms for advanced research and production.

Wear-resistant coating

Enhances wear resistance and lifespan of cutting tools, molds, and mechanical parts, boosting efficiency.

Optical coating

Our optical coatings meet strict industry standards and are used in sunglasses, headlights, filters, and laser systems.

Solar

Our sputtering targets enable thin-film PV, solar thermal, and CSP systems for sustainable energy.

Electronics

Providing high-purity materials for the rapidly growing electronics industry to produce resistors, semiconductors and other components.

Compound semiconductor materials

High-purity titanium targets support advanced research and are ideal for semiconductors and new electronics.

Decorative coating

Used to enhance appearance, corrosion and scratch resistance; widely applied in electronics, appliances, and building materials.

Aerospace

Titanium targets resist corrosion and oxidation, ideal for aerospace applications in extreme environments.

Chalcotitanium titanium target product technical parameters

To ensure that each batch of titanium targets is highly consistent in performance, structure and environmental standards, Chalcotitanium adheres to a strict quality management system. All of our products can provide material test reports, and some products have passed RoHS environmental certification and meet ISO standard system requirements. Based on the different equipment and application requirements of customers, we can provide titanium targets with a variety of purity levels, alloy compositions and physical performance parameters to ensure the best results in high-precision deposition processes.

Product specifications range

Chalcotitanium can provide titanium targets with various structures and sizes according to customers' different equipment and process requirements, and support interface welding and composite customization services to ensure process compatibility and efficient operation.

| Project | Range/Type | Illustrate |

|---|---|---|

| Target shape | Round, rectangular, ring, tubular | Can be customized according to equipment structure |

| Size range | Diameter: ≤ 450 mm | |

| Thickness: ≤ 40 mm | Extra-large size can be customized | |

| Surface treatment | Machining, polishing, sandblasting, single-sided mirror treatment | Provide different surface conditions according to deposition requirements |

| Back plate welding method | Diffusion welding, hot pressure welding, explosion welding | High reliability welding, suitable for various cathode connection structures |

| Interface structure customization | Single target, composite target, T-type target, cathode built-in structure, etc. | Supports a variety of cathode equipment configurations |

| Matching precision tolerance control | Dimensional tolerance ±0.05 mm | |

| Flatness ≤ 0.1 mm | Precision processing can be performed according to customer drawings |

Chemical composition of pure titanium target (GDMS analysis results)

| Typical analysis for 99.995% Purity, Analysis by GDMS | |||

|---|---|---|---|

| Element | ppm | Element | ppm |

| Li | <0.01 | Nb | <0.2 |

| Be | <0.005 | Mo | <0.5 |

| B | <0.01 | Ru | <0.01 |

| Na | <0.01 | R | <0.05 |

| Mg | 0.05 | Pd | <0.01 |

| Al | 0.01 | Ag | <0.05 |

| Si | 0.21 | Cd | <0.05 |

| P | <0.01 | In | <0.05 |

| S | 0.02 | Sn | <0.05 |

| K | <0.01 | Sb | <0.05 |

| Ca | <0.2 | Te | <0.05 |

| Sc | <0.05 | Ba | <0.005 |

| V | 0.01 | Ce | <0.005 |

| Cr | 0.06 | Hf | <0.01 |

| Mn | 0.06 | Ta | < 2 |

| Fe | 1.5 | W | <0.01 |

| Co | <0.01 | Re | <0.01 |

| Ni | 0.16 | Os | <0.01 |

| Cu | 0.2 | Ir | <0.01 |

| Zn | <0.05 | Pt | <0.05 |

| Ga | <0.05 | Au | <0.05 |

| Ge | <0.05 | Hg | <0.1 |

| As | 0.02 | Pb | <0.01 |

| Se | <0.05 | Bi | <0.01 |

| Zr | <0.05 | Th | <0.0001 |

Physical performance parameters (reference values)

| Project | Unit | Index (industrial pure titanium) |

|---|---|---|

| density | g/cm³ | 4.51 |

| Resistivity | μΩ·cm | 42~48 |

| hardness | HV | 140~160 |

| Grain size control | μm | ≤ 50 (customizable) |

| Density | % | ≥ 99.5 |

| Surface roughness | Ra (μm) | ≤ 0.3 (single-side polishing) |

Note: The specific composition and performance parameters of titanium alloy targets can be customized according to customer requirements. For details, please contact us to obtain detailed formulas and test reports.

Titanium target material technical parameter table

| Item | Unit | Specification |

|---|---|---|

| Material Type | Titanium | |

| Symbol | Ti | |

| Atomic Weight | 47.867 | |

| Atomic Number | 22 | |

| Color/Appearance | Silvery Metallic | |

| Thermal Conductivity | W/m·K | 21.9 |

| Melting Point (°C) | °C | 1,660 |

| Coefficient of Thermal Expansion | x 10⁻⁶/K | 8.6 |

| Theoretical Density (g/cc) | g/cm³ | 4.5 |

| Z Ratio | 0.628 | |

| Sputter | DC | |

| Max Power Density | W/Square Inch | 50* |

| Bond Type | Indium, Elastomer | |

| Comments | Alloys with W/Ta/Mo; evolves gas on first heating. |

Service and support: FAQ on purchasing titanium targets

Titanium target purchase packaging and delivery

To ensure the safety and integrity of the target during transportation, we use multiple packaging methods of anti-static bags + foam cushioning + sturdy wooden boxes, which are suitable for domestic and export transportation standards. We support multiple logistics methods such as air transportation, sea transportation and express delivery. The delivery cycle is flexibly arranged according to the product type and quantity, and can be shipped within 7 working days at the fastest.

How to choose the right type of titanium target?

You can choose according to your coating process, power type (DC or RF), equipment interface structure and other factors. We also provide selection suggestions and technical consulting services.

Do you provide third-party test reports?

Yes, we can provide SGS, RoHS, ISO and other related testing and certification reports upon request to ensure that the products meet the customer's quality system requirements.

What should we pay attention to when storing and maintaining titanium targets?

Please store in a dry and ventilated environment to avoid direct contact with water vapor and corrosive gases. It is recommended to keep the unused targets in the original sealed packaging.

Can you provide samples or trials?

Support small batch samples and rapid proofing services to help customers complete process testing as quickly as possible.

Get exclusive solutions

Whether you are looking for stable and efficient standard titanium targets or require customized products with special properties, Chalcotitanium can provide you with reliable support.

Welcome to contact our technical consultants to obtain product details, proofing solutions and customized quotations.