NiTi Wire — Driving Tomorrow with Shape‐Memory & Superelasticity

Nitinol Wire is a smart metal alloy composed of nickel (Ni) and titanium (Ti), renowned for its unique Shape Memory Effect (SME) and Superelasticity (SE). It has revolutionized applications across orthodontics, medical devices, industrial systems, and advanced technologies. When deformed under stress, Nitinol undergoes a reversible phase transformation—returning from the martensitic to the austenitic state via temperature or stress changes—enabling true environmentally responsive adaptation.

As a professional titanium alloy manufacturer, Chalco Titanium offers high-quality Nitinol wire produced through a fully controlled process chain (melting → hot rolling → precision drawing → heat treatment). Our products comply with ASTM F2063 (standard for shape memory alloy materials) and ISO 13485 (quality management for medical devices), ensuring reliable phase transformation characteristics and certified biocompatibility.

Core Functionalities: Shape Memory Effect & Superelasticity

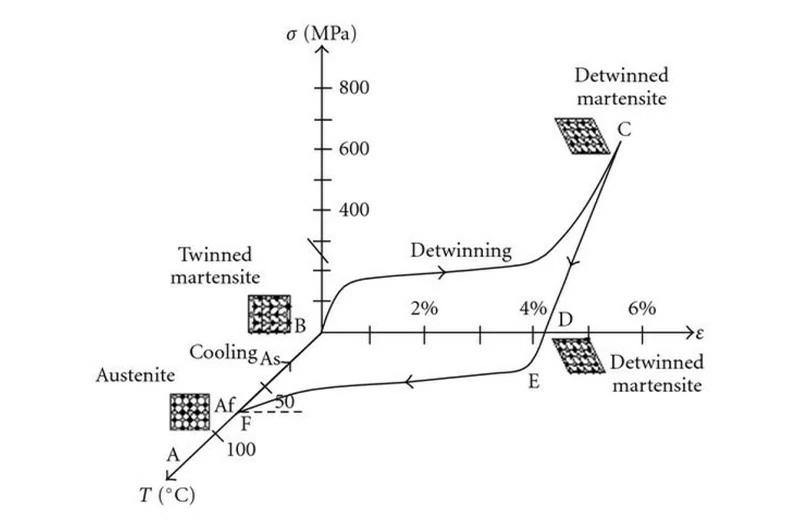

Shape Memory Effect, SME

When exposed to low temperatures or high stress, Nitinol wire undergoes a phase transformation from its high-symmetry austenitic state to a low-symmetry martensitic structure. In this martensitic phase, the material can sustain significant plastic deformation and retain its altered shape. Once the temperature rises above the transformation threshold or the stress is removed, the wire undergoes a reverse transformation—precisely recovering its original preset shape. This intelligent phase-change mechanism occurs within a tunable temperature range of -50 °C to 100 °C, adjustable by the Ni-Ti ratio. It enables millimeter-level recovery accuracy, making Nitinol ideal for applications such as self-expanding stents and thermally actuated devices.

Superelasticity, SE

When operating above the austenite finish temperature (Af), external stress induces a reversible martensitic transformation in the wire, enabling up to 8% recoverable "pseudo-elastic" strain. Upon unloading, the material fully reverts to its original shape, producing a distinct hysteresis loop. With a plateau stress range of 200–600 MPa—significantly higher than the elastic limit of conventional metals—combined with an ultra-high fatigue life (≥10⁷ cycles), Nitinol provides exceptional performance in demanding applications such as vascular guidewires and seismic-resistant connectors.

Main Product Categories of NiTi Wire

Superelastic NiTi Wire

Displays strong superelasticity at room temperature, recovering from up to 8% deformation with a stable stress plateau of 200–600 MPa—ideal for resisting permanent deformation.

Medical intervention: vascular and neuro guidewires

Industrial components: high-reliability connectors

Consumer electronics: foldable device hinges

Heat-Activated NiTi Wire

Activates shape memory by heating to a preset temperature (−30 °C to 100 °C), enabling millimeter-level recovery and integration with smart thermal systems.

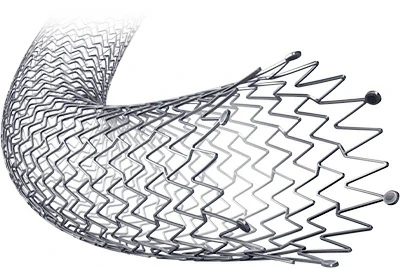

Medical devices: self-expanding stents

Industrial actuators: microfluidic valves

Aerospace systems: solar panel deployment mechanisms

Copper NiTi Wire

Alloyed with 3–5% copper to reduce hysteresis by 50% and enhance thermal stability, combining superelasticity and shape memory for high-precision applications.

Precision optics: tunable lens focus actuators

Energy systems: thermal energy recovery mechanisms

Teflon Coated NiTi Wires

PTFE coating lowers friction to 0.05–0.1 and adds superelasticity and lubricity, ideal for dynamic friction control.

Minimally invasive surgery: neuro guidewires

Precision robotics: micro-actuator joints

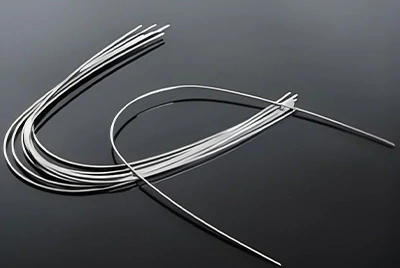

NiTi Orthodontic Wires

A specialized branch of NiTi wire designed for dental correction, including superelastic, heat-activated, and copper NiTi variants. These wires deliver gentle and continuous forces (50–300 g) to enable effective tooth movement.

Learn more: For detailed selection logic, archform customization, and stage-specific orthodontic strategies, see the guide: NiTi Archwire for Orthodontics.

Whether you're engineering ultra-smooth guidewires for minimally invasive devices, developing intelligent deployment mechanisms for aerospace environments, or optimizing mechanical control in dental correction, Chalco Titanium delivers NiTi wire solutions with tunable transformation performance and full process traceability.Quick Quote

Specifications & Supply Forms of NiTi Wire

Chalco Titanium offers two primary supply forms of NiTi wire, both conforming to ASTM F2063 standards. With a diameter tolerance of ±0.02 mm, these wires are engineered to meet the stringent requirements of medical and precision industrial applications.

| Parameters | Straight Lengths NiTi Wire | Spools NiTi Wire |

|---|---|---|

| Cross-section shape | Round / Rectangular | Round |

| Size range | Round: 0.10 mm - 2.00 mm (0.004" - 0.079") Rectangular: 0.20×0.20 mm - 1.0×1.0 mm | 0.05 mm - 1.0 mm(0.002" - 0.039") |

| Standard length | 150 mm / 300 mm / 450 mm | 50 m / 100 m / 200 m (per axis) |

| Surface treatment | Polishing (Ra ≤ 0.2 μm) / acid washing / Teflon coating | Polished (Ra ≤ 0.2 μm) / Acid washed / Teflon coated |

| Core advantages | High straightness (≤0.1mm/m) End-cutting without damage | Endless continuous wire Anti-tangling packaging |

| Application areas | Microfluidic valve push rod Nerve guide wire enhancement core Sensor wire | Non-vascular self-expanding stents Spring-driven elements Robotic tactile sensors |

For details, please refer to the dedicated technical guide: [NiTi Archwires for Orthodontics].

Core Applications of NiTi Wire

NiTi alloy wire leverages its unique Shape Memory Effect (SME) and Superelasticity (SE) to deliver irreplaceable value across medical, industrial, consumer, and orthodontic sectors.

Minimally Invasive Medical Devices

- Superelastic NiTi guidewires (Ø 0.1–0.4 mm) maintain >85% pushability through >90° coronary bends—compared to ≈60% with stainless steel—minimizing vascular wall trauma.

- Self-expanding stents braided from NiTi wire achieve >95% radial recovery after body-temperature activation, ideal for peripheral vascular stenosis treatment.

- Heat-activated NiTi actuator wires enable precise biopsy forceps control in endoscopic tools, achieving over 50,000 actuation cycles.

Advanced Industrial Components

- Heat-activated NiTi wires (Ø 0.2–0.5 mm) drive microfluidic valves with ±0.05 ml/min flow control accuracy, suitable for PCR chip systems.

- Superelastic NiTi interconnect pins used in USB-C connectors pass 50,000 insertion cycles with zero failure (IEC 60512 certified).

- Space-deployable folding wings use thermal gradients (−80 °C → 150 °C) to trigger shape recovery with deployment angle error <1°.

Consumer Products

- Superelastic NiTi eyeglass frames withstand >30° twisting and recover fully, offering 3× longer life than standard titanium frames.

- Heat-activated NiTi bra underwires (Af ≈ 35 °C) adapt to body temperature, enhancing pressure uniformity by 40%.

- Superelastic NiTi-based antennas compress by 60% and rebound with <0.5 dB signal loss in 5G millimeter wave bands.

Orthodontic Treatments

NiTi archwires provide consistent, biocompatible forces for efficient tooth movement, reducing treatment time by up to 30% compared to stainless steel wires.

Supply Chain Reliability & Quality Assurance

Chalco Titanium has established a full-cycle quality control system from raw material to delivery, ensuring each batch of NiTi wire precisely meets the mechanical and functional requirements of medical, industrial, and orthodontic applications.

Production & Process Control

- Vacuum Melting & Hot Rolling: Uses VAR (Vacuum Arc Remelting) and VIM (Vacuum Induction Melting) to minimize impurities. Hot rolling and forging are followed by acid pickling to remove oxide scale and residual stress.

- Multi-Pass Drawing & Annealing: Fine diameter control with ±0.02 mm tolerance through multi-stage cold drawing. Intermediate and final annealing optimize grain structure and improve ductility.

- Surface Finishing: Pickling, polishing, or micro-arc oxidation enhances surface smoothness and corrosion resistance.

Certification & Quality Testing

- All NiTi wire products comply with ASTM F2063 (shape memory alloy wire), ISO 15841 (orthodontic archwire performance), and ISO 13485 (medical device quality system).

- Standardized inspection procedures include chemical composition analysis, optical/ultrasonic flaw detection, tensile/bending tests, and transformation temperature (Af/Mf) testing.

- Full documentation available per batch, including SDS, superelastic fatigue performance, and defect screening reports.

Customization & Batch Supply

- Supports custom machining of straight wire, spooled wire, and preformed archwires (e.g., Ovoid, D-form, Reverse Curve) according to client drawings or specifications.

- Standard wire: 7–10 working days; custom preformed wire: 10–15 working days. Small batch prototyping available on request.

Packaging & Logistics

- Multi-layer anti-moisture and anti-oxidation packaging or vacuum-sealed bags with batch numbers, production date, and QR code. Spools include anti-slip wire holders.

- Partnered with major international logistics providers for door-to-door delivery and customs clearance support, ensuring on-time shipment worldwide.

Frequently Asked Questions (FAQ)

What is the transformation temperature range of NiTi wire, and how can it be adjusted?

Standard NiTi wire has a transformation temperature range from -50°C to +100°C. The Af point can be fine-tuned by adjusting the Ni-Ti atomic ratio (±0.1 at.% shifts Af by 5–10°C) or adding 3–5 at.% Cu to stabilize phase behavior.

What is the maximum recoverable strain of superelastic NiTi wire?

Superelastic NiTi wire can withstand up to 8% fully reversible strain, far exceeding stainless steel (<1%) and titanium alloys (<2%). Fatigue life exceeds 10⁷ cycles, as verified by ASTM F2516 standards.

How is the biocompatibility of NiTi alloy ensured?

Medical-grade NiTi wires comply with ISO 10993-5 cytotoxicity standards. Nickel ion release is controlled below 0.1 μg/cm²/day (via electrolytic polishing and Teflon® coating), well under the EU implant threshold of 0.2 μg/cm²/day.

What is the actuation speed and service life of industrial NiTi actuators?

Thermally activated NiTi wires (≤0.5 mm diameter) respond in 0.1–1 seconds. Service life:

- Superelastic mode: >10⁷ cycles

- Shape memory mode: >10⁵ cycles under ≤300 MPa load

How should NiTi wire be cleaned and stored?

- Industrial-grade wire: Clean using ultrasonic + anhydrous ethanol

- Medical-grade wire: Rinse with sterile saline

Store in vacuum-sealed, moisture-proof packaging, away from light and physical stress, ideally at 10–30°C.