Lead Dioxide Coated Titanium Anode

Updated : Jun. 24, 2025Dioxide titanium anode (PbO₂ -Ti anode) is an advanced electrochemical anode composed of a pure titanium substrate and an electrodeposited lead dioxide coating. It combines the excellent corrosion resistance and mechanical strength of titanium with the high catalytic activity and low oxygen evolution potential of PbO₂ , making it an efficient, energy-saving, and long-life industrial anode with far superior performance to traditional lead-based or graphite anodes.

Due to the excellent chemical stability of its coating over a wide pH range and its ability to operate for long periods at high current densities, PbO₂ - Ti anodes are particularly suitable for demanding industrial environments, significantly reducing maintenance frequency and improving operational reliability.

Lead oxide titanium anode technical parameters

| Coating structure | α- PbO ₂ , β - PbO ₂ or a mixture of both |

| Coating thickness | 0.5 – 1.0 mm optional |

| Maximum current density | ≤ 10,000 A/m² |

| Operating voltage range | About 1.5 – 1.6 V (oxygen evolution potential) |

| pH range | 0.1 – 12 (strong acid to neutral) |

| Titanium substrate standards | ASTM B265 Grade 1 or Grade 2 |

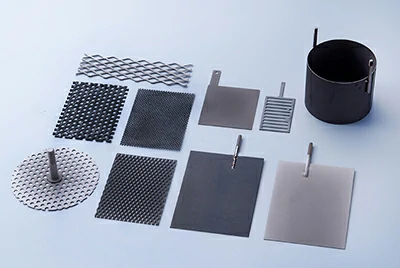

| Customizable structure | Flat plate, rod, mesh, tube, electrolysis basket, special-shaped customization |

Types of lead dioxide titanium anodes Chalco can provide

-

Flat-plate PbO₂-Ti anodes suit straight-plate equipment, offering large area and stable current for processes like hard chrome and copper plating. Surfaces may be smooth or roughened to improve adhesion and electrolyte contact.

-

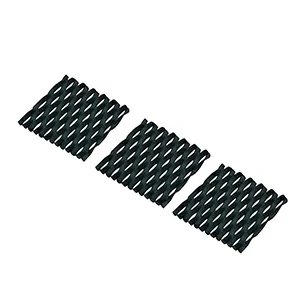

Titanium mesh or perforated plates with PbO₂ coating offer larger surface area and better electrolyte flow, ideal for oxidation and organic synthesis. The open structure helps gas release and lowers polarization.

-

Rod anodes suit vertical or tight spaces with compact design and easy installation. Tubular anodes, used in cylindrical cells and continuous electrolysis, have a closed structure that slows coating wear, ideal for wastewater treatment and electrowinning.

-

Chalco provides customized anode solutions for complex or special electrolytic cell structures, including titanium electrolytic baskets for loading conductive particles or catalysts and multi-curved anodes designed to fit special-shaped equipment.

Flat-plate PbO₂-Ti anodes suit straight-plate equipment, offering large area and stable current for processes like hard chrome and copper plating. Surfaces may be smooth or roughened to improve adhesion and electrolyte contact.

Titanium mesh or perforated plates with PbO₂ coating offer larger surface area and better electrolyte flow, ideal for oxidation and organic synthesis. The open structure helps gas release and lowers polarization.

Rod anodes suit vertical or tight spaces with compact design and easy installation. Tubular anodes, used in cylindrical cells and continuous electrolysis, have a closed structure that slows coating wear, ideal for wastewater treatment and electrowinning.

Chalco provides customized anode solutions for complex or special electrolytic cell structures, including titanium electrolytic baskets for loading conductive particles or catalysts and multi-curved anodes designed to fit special-shaped equipment.

Performance advantages of Chalco lead oxide titanium anode

High oxygen evolution potential

Lead dioxide has a high oxygen evolution potential of about 1.5-1.6 volts, which can significantly reduce the occurrence of side reactions and improve the efficiency of the main reaction. Therefore, it is very suitable for electrochemical processes that require higher cell voltages, such as electrolytic organic synthesis and advanced oxidation wastewater treatment.

Excellent acid and alkali corrosion resistance

The PbO₂ coating remains stable in electrolytes with a pH range of 0.1 to 12 and is suitable for most acidic and neutral process environments, including highly corrosive systems such as sulfuric acid, chromic acid and chlorides.

Dual-phase coating structure has strong conductivity

The structural design of the α-phase and β-phase combines high conductivity and high hardness, which can effectively improve the uniformity of current distribution and extend the service life while maintaining high deposition efficiency.

Long service life

Compared with traditional lead alloy or graphite anodes, the working life of PbO₂ - Ti anodes is typically increased by 2 to 3 times, making them suitable for continuous production and high-load applications, and can significantly reduce downtime and replacement frequency.

The coating is firmly bonded and the risk of lead precipitation is extremely low

By optimizing the electrodeposition process, the bonding force between PbO₂ and the titanium matrix is very strong and not easy to peel off. Under normal use conditions, the amount of lead precipitation is extremely low, which complies with environmental protection standards such as RoHS and REACH, and is suitable for industries sensitive to heavy metal emissions.

Can be refinished and repainted

When the anode shows signs of natural aging or slight wear, it can be recoated and regenerated, thereby extending the overall service life of the anode and further reducing the company's full life cycle operating costs.

Application of lead oxide titanium anode

Nonferrous metal smelting and recycling

PbO₂ - Ti anode is suitable for electrolytic extraction and recovery of copper, nickel, zinc and other metals in strong acidic solutions. Its excellent corrosion resistance ensures its stability in highly corrosive electrolytes such as sulfuric acid and nitric acid, which can improve metal purity and recovery efficiency, and is suitable for industries such as metallurgy and battery recycling.

Electroplating process

Chrome and decorative chrome electroplating in chromic acid systems, especially in chrome plating on steel surfaces and Wuxi steel manufacturing. PbO₂ - Ti anodes are more durable than traditional lead anodes, have more stable voltage, and are suitable for large-scale continuous electroplating production lines.

Preparation of inorganic oxidizing substances

In the production process of highly oxidizing inorganic salts such as sodium perchlorate, periodate, persulfate, chromic acid, etc., PbO₂ - Ti anode as anode material has the advantages of high potential, corrosion resistance, and no product pollution. It is a stable and reliable choice for the chemical industry.

Organic electrochemical synthesis

PbO₂ - Ti anode exhibits good electrocatalytic activity under acidic conditions and is suitable for the directional electro-oxidation of small organic molecules. It is widely used in fine chemicals, organic synthesis and the production of pharmaceutical intermediates.

Wastewater treatment and decolorization

The anode is suitable for electrochemical oxidation treatment of domestic sewage, phenolic wastewater, oilfield wastewater, printing and dyeing wastewater, ammonia nitrogen wastewater and other industrial and municipal fields. Its high oxidation capacity can effectively remove COD, ammonia nitrogen and chromaticity, meet environmental emission requirements, and support green manufacturing.

Lead oxide titanium anode and ruthenium iridium titanium anode

When choosing titanium-based anodes, lead-titanium oxide anodes (PbO ₂) and ruthenium-iridium-titanium anodes (MMO) are often used in different process scenarios. There are significant differences between the two in oxidation capacity, service life and cost structure. Understanding their comparison will help customers make the best choice based on actual needs.

| Compare Projects | PbO₂ titanium anode | Ruthenium-iridium-titanium anode (MMO) |

| Oxygen evolution potential | High (about 1.5–1.6V), suitable for strong oxidation processes | Low (about 1.3V), suitable for chlorine precipitation and reduction process |

| Current efficiency | Medium to high, suitable for organic/inorganic oxidation reactions | High, suitable for production processes such as chlor-alkali and sodium hypochlorite |

| Corrosion resistance | Strong, suitable for acidic and oxidizing electrolytes | Very strong, especially good stability to chloride system |

| Service life | 1–3 years (extended to 3–5 years with recoating) | 2–5 years, depending on coating thickness and working conditions |

| Can it be repainted? | Repaintable, low maintenance | Generally, repainting is not supported, replacement is the main |

| Cost Level | Medium, suitable for large-scale promotion | Higher, suitable for high-end continuous chlor-alkali system |

| Application Scenario | Electroplating, wastewater treatment, organic oxidation, electrolytic synthesis, etc. | Chlor-alkali, electrophoretic coating, drinking water treatment, disinfection, etc. |

Selection suggestions for you:

If your process focuses on strong oxidation, wastewater treatment or electrolysis of organic matter, it is recommended to give priority to lead oxide titanium anode (PbO ₂), which has higher oxygen evolution capacity and cost performance; if the process involves chlorine evolution, chlor-alkali system or extremely high requirements for chlorine resistance, ruthenium iridium titanium anode (MMO) is more suitable.

If you need assistance in model selection, please contact us and provide detailed working conditions. We will recommend the most suitable solution for you.

Precautions for using lead oxide titanium anode

To ensure safe and efficient use of PbO₂ - Ti anodes, please pay attention to the following operation and maintenance recommendations:

When handling lead oxide anodes, personal protective equipment such as chemical resistant gloves and goggles should be worn to prevent lead particles from contacting the skin or entering the eyes.

Be careful when handling anodes to avoid collisions, knocks or breaks to avoid cracking of the lead coating and the loss of particles.

Anodes should be stored in a cool, dry and well-ventilated place, away from direct sunlight and humid environment, and should be kept away from incompatible substances such as acids and alkalis.

When using, operate in a well-ventilated environment or fume hood to reduce the risk of inhalation of dust or fume.

It is prohibited to eat, drink or smoke near the anode. Wash your hands thoroughly after operation to prevent ingestion of lead residues.

Discarded or damaged anodes should be treated as hazardous waste and must not be thrown into general household waste. They must be handled in accordance with local regulations.

It is recommended to regularly check the anode surface for delamination, cracks or local corrosion, and replace it or send it to the factory for recoating if necessary to ensure safety and electrochemical performance.

Other titanium anode products from Chalco

Why choose Chalco?

Choosing a high-quality anode supplier not only affects product performance, but also affects process stability and long-term operating costs. With its deep accumulation of material technology and global service capabilities, Chalco has become a trusted partner for many industrial customers:

We have a technical team composed of material engineers and electrochemical experts who can provide you with full-process technical support including electrode selection, structure optimization, and electrochemical performance matching.

From titanium substrate procurement, surface treatment to PbO₂ coating electrodeposition, all are completed by our own factory to ensure product quality consistency and controllable delivery time.

It supports OEM and ODM services, and can produce a variety of structural forms according to drawings, including plates, tubes, nets, baskets and special-shaped parts, to meet the adaptation needs of anodes for complex equipment structures in multiple industries.

Chalco is ISO 9001 and ISO 14001 certified. Each batch of products is strictly tested for thickness, resistance, bonding strength and coating uniformity to ensure the reliability of the products leaving the factory.