MMO Titanium Mesh Anode

Updated : Jul. 15, 2025MMO titanium mesh anode (Mixed Metal Oxide Titanium Mesh Anode) is a functional anode material widely used in cathodic protection, water electrolysis, chlorine generation, electroplating and other fields. It is composed of industrial-grade pure titanium GR1 or GR2 matrix, with a high-performance precious metal oxide catalyst layer coated on the surface, and has excellent conductivity, corrosion resistance and ultra-long service life.

Why choose MMO titanium mesh anode?

Compared with traditional lead anodes, graphite anodes or ferrosilicon anodes, MMO titanium mesh anodes have the following advantages:

- Easy installation and simple construction

- Long service life, designed service life can reach more than 75 years

- Low and uniform coating shedding rate

- Stable performance, even in chloride-contaminated concrete

- Capable of operating at high current densities

- Through coating improvement, nano-scale grain refinement is achieved, so that the coating and the substrate are better bonded and the electrocatalytic effect is stronger

It is a key component in the current mainstream project upgrade or replacement selection.

The structure of MMO titanium mesh anode

The MMO titanium mesh anode (Mixed Metal Oxide Titanium Mesh Anode) consists of three core components: titanium substrate, mesh geometry, and MMO catalytic coating. The three work together to determine the conductivity, current distribution efficiency, and service life of the anode.

Titanium substrate

The base material of the anode is commercially pure titanium (Grade 1 or Grade 2) in accordance with ASTM B265. Titanium has excellent corrosion resistance, good mechanical strength and low resistivity, making it an ideal metal as a conductive carrier.

Grade 1 titanium is purer, more flexible and easier to form, while Grade 2 is stronger and more stable under mechanical shock or tension. Both remain chemically inert in the electrolytic environment, ensuring long-term stable operation of the anode.

Mesh structure design

The titanium matrix is mechanically expanded (Expanded Metal) or punched into a mesh to form a mesh or mesh belt with regular pores. The common hole type is diamond-shaped holes, and the standard sizes are 2.5 × 4.6 mm, 1 × 2 mm, 3 × 5 mm, etc.

The presence of the grid significantly increases the specific surface area per unit area, which helps to evenly distribute the current while reducing resistance and energy consumption. Depending on the usage scenario, the anode can be processed into a 10-76 mm bandwidth and 0.9-2 mm thickness, and supplied in sheets, strips or rolls to adapt to concrete tanks, electrolytic tanks or large-area layout systems.

MMO catalytic coating

A layer of precious metal composite oxide coating is applied on the surface of the titanium mesh by brushing, spraying or thermal decomposition. This coating is the key to the function of the anode. It is usually a mixture of metal oxides such as RuO₂ , IrO₂ , Ta₂O₅ , etc. , and has high catalytic activity and electrochemical stability.

The coating thickness is typically 5–15 μm, is evenly distributed, and has strong adhesion, which can significantly reduce the oxygen evolution potential (typical value ≤ 1.68 V), improve current efficiency, and resist acid or chloride ion corrosion.

MMO titanium mesh anode with different coating types

The core of the performance of MMO titanium mesh anode lies in the precious metal oxide coating on its surface. Different catalytic combinations determine the electrochemical reaction efficiency, corrosion resistance, applicable electrolyte types and service life of the anode. The following are the most common types of coatings currently available.

Ruthenium-Iridium titanium mesh anode

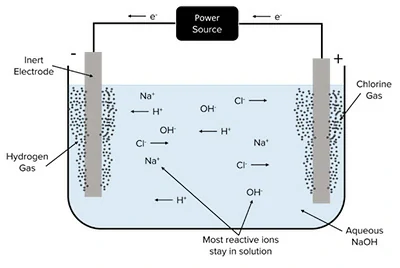

The ruthenium-iridium system is currently the most widely used MMO coating type, especially suitable for chlorine evolution reaction (Cl ₂ evolution ). It has a low operating voltage and a stable reaction potential, which can significantly improve the electrolysis efficiency of chlorine and reduce energy consumption.

Ruthenium has high catalytic activity, while iridium provides good corrosion resistance. This type of anode is commonly used in sodium hypochlorite generators, salt water electrolysis devices, swimming pool disinfection systems, etc. It is also suitable for chlorine-containing electroplating processes. The coating life can reach 75 years, which is suitable for continuous use environments.

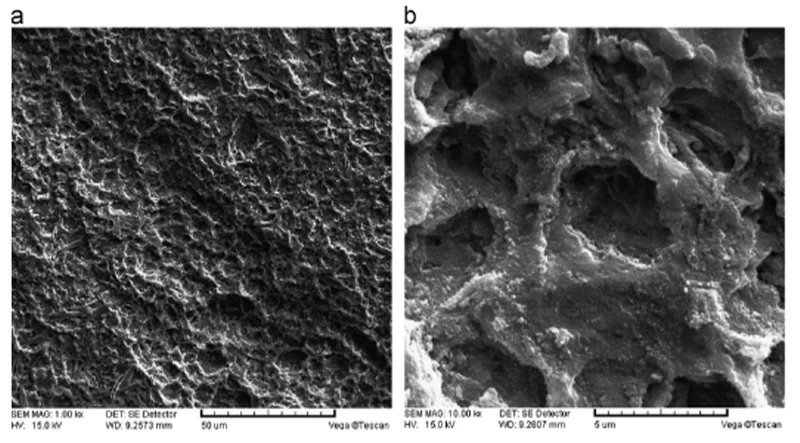

In order to study why the life of the ruthenium-iridium-titanium anode is so long, SEM micrographs of the Ru/Ti sample at different magnifications after the accelerated life test revealed :

Low magnification, it can be observed that the surface of the RuO₂ / IrO₂ mixed coating is evenly distributed, with no obvious peeling or micropores, and is an ideal continuous and dense film layer. This structure ensures uniform conduction of current density on a large scale.

High magnification, it can be observed that IrO₂ particles are uniformly embedded in the RuO₂ matrix , forming an interfacial passivation layer between particles, which effectively alleviates the stress concentration between lattices. This phenomenon of "nanoscale grain refinement" and "grain boundary passivation" is the microscopic basis for its high stability and long life.

Iridium-tantalum titanium mesh anode

The Ir-Ta system is mainly used for oxygen evolution reaction, which is commonly seen in neutral or alkaline hydrolysis, anodic oxidation, electrolytic organic reaction, metal electrodeposition and other applications.

Iridium has strong acid resistance, while tantalum oxide can improve the stability of the coating and the uniformity of current distribution. This formula is more resistant to extreme pH and high voltage shocks, and is suitable for engineering projects with high stability requirements. The typical design life is more than 75 years , which is particularly suitable for concrete cathodic protection or electrolytic cell environment.

Technical parameters of MMO titanium mesh anode

Technical parameters of different coating types

| Coating Type | Current density (long term ≤) | Short-term current density | Oxygen evolution potential | Coating thickness | Service life | Application Environment |

|---|---|---|---|---|---|---|

| Ru-Ir MMO | 110 mA/m² | 220 mA/m² | ≤ 1.65 V | 8–15 μ m | 75 Over 10 years | Chlorinated environments (swimming pools, electrolyzed brine, cathodic protection) |

| Ir-Ta MMO | 110 mA/m² | 220 mA/m² | ≤ 1.68 V | 6–12 μ m | Over 75 years | Concrete cathodic protection and water treatment field |

Technical parameters of different specifications

| Specification | Output Current | Mesh size (mm) | Design service life (years) |

|---|---|---|---|

| 10mm x 76mm | 2.8 mA/m2 | 2.5 x 4.6 x 0.6 | 20, 30, 50, 75 |

| 13mm x 76mm | 3.5A/m2 | 2.5 x 4.6 x 0.6 | 20, 30, 50, 75 |

| 19mm x 76mm | 5.28A/m2 | 2.5 x 4.6 x 0.6 | 20, 30, 50, 75 |

| 1.10m x 76mm | 18.8A/m2 | 34 x 76 x 0.64 | 20, 30, 50, 75 |

| 1.20m x 76mm | 24.4A/m2 | 34 x 76 x 0.89 | 20, 30, 50, 75 |

| 1.20m x 76mm | 37.8A/m2 | 25 x 51 x 0.89 | 20, 30, 50, 75 |

Application cases of MMO titanium mesh anode

Howard Frankland Bridge & Crescent Beach Bridge, Florida

Since 1987, the piers of these two cross-sea bridges have been equipped with titanium mesh and titanium strip ICCP systems. The additional contract in 2009 buried approximately 11,628 ft² (1,080 m²) of titanium mesh anodes in the pier cladding, with a design current density of 20 mA/m² and a budget of US $3.87 million. By 2021, the mesh anodes will be in service for >30 years, and the monitored polarization potential still meets the NACE – 850 mV standard, significantly delaying steel corrosion and maintaining full load operation .

A Norwegian offshore concrete bridge (ICCP in operation for 17–18 years)

After over 17 years in service, the embedded titanium mesh anodes in this offshore concrete bridge continue to deliver stable current output. In the tidal zone, where chloride concentrations reach 3–4%, the coating remains intact, and the steel rebar potential stays above −750 mV (SCE), meeting cathodic protection standards. The system operates with long-term stability and reliability.

PCB acid copper electroplating production line

A continuous circuit board plating line replaced the traditional lead anode with a Ru-Ir MMO titanium mesh anode (patented formula). The measured through-hole/surface plating thickness ratio is close to 1:1, the current efficiency is improved by 8%, and the uniform current distribution is maintained after 10,000 hours of cycling; the user confirmed that the anode life can reach more than 5 years without the need to replenish lead foil.

MMO titanium mesh anode vs platinum-coated titanium mesh anode

In various electrochemical systems, MMO titanium mesh anode and platinum-plated titanium mesh anode are the two most common types of anodes . They both use titanium substrates, have good conductivity and corrosion resistance, but have obvious differences in coating composition, applicable environment, service life and cost.

| Project | MMO titanium mesh anode | Platinum-coated titanium mesh anode |

|---|---|---|

| Coating composition | Composite metal oxides such as RuO₂ , IrO₂ , Ta₂O₅ | Platinum metal (Pt), deposited by electroplating or thermal decomposition |

| Oxygen evolution potential | About 1.65–1.70 V | About 1.50–1.55 V (lower) |

| Applicable media | Neutral/alkaline/chlorinated environments, such as seawater, swimming pools, concrete protection, electrolytic brine | Strong acid, highly corrosive media, such as sulfuric acid, hydrofluoric acid, electroplating solution |

| Conductive properties | excellent | Excellent (Platinum is a precious metal) |

| Electrocatalytic activity | high | Very high |

| Service life | 15–75 years (depending on coating and current density) | 5–20 years (coating thickness has a great influence) |

| cost | Low, suitable for large-scale applications | Expensive (high platinum cost), mostly used in high-precision applications |

How to choose a suitable MMO titanium mesh anode?

Specify the application medium

For chlorine-containing media such as seawater and electrolytic brine, Ru-Ir coating is recommended; for neutral or alkaline environments such as concrete protection systems, Ir-Ta coating is more suitable.

Determining current density and lifetime

The general design current density does not exceed 110 mA/m² , when the service life requirement is greater than 20 years, a high stability coating should be selected, referring to the manufacturer's service life data.

Choose the appropriate mesh size

Common hole type is 2.5×4.6 mm, thickness 0.9–2.0 mm, mesh belt width and coil length can be customized according to the layout method.

Consider installation method

Equipment systems are mostly welded, and concrete structures can be tied or bonded. Some anodes support coating repair, which is conducive to reuse.

Common sizes of MMO titanium mesh anodes

| Product | Thickness | Size |

|---|---|---|

| Titanium MMO Anode Mesh 0.9mm Thick x 100mm x 100mm | 0.9mm | 100mm x 100mm |

| Titanium MMO Anode Mesh 0.9mm Thick x 200mm x 200mm | 0.9mm | 200mm x 200mm |

| Titanium MMO Anode Mesh 1.0mm Thick x 25mm x 25mm | 1.0mm | 25mm x 25mm |

| Titanium MMO Anode Mesh 1.0mm Thick x 100mm x 100mm | 1.0mm | 100mm x 100mm |

| Titanium MMO Anode Mesh 1.0mm Thick x 200mm x 200mm | 1.0mm | 200mm x 200mm |

| Titanium MMO Anode Mesh 1.0mm Thick x 300mm x 300mm | 1.0mm | 300mm x 300mm |

| Titanium MMO Anode Mesh 1.2mm Thick x 100mm x 200mm | 1.2mm | 100mm x 200mm |

| Titanium MMO Anode Mesh 1.2mm Thick x 300mm x 300mm | 1.2mm | 300mm x 300mm |

| Titanium MMO Anode Mesh 1.5mm Thick x 100mm x 100mm | 1.5mm | 100mm x 100mm |

| Titanium MMO Anode Mesh 1.5mm Thick x 200mm x 300mm | 1.5mm | 200mm x 300mm |

| Titanium MMO Anode Mesh 2.0mm Thick x 200mm x 200mm | 2.0mm | 200mm x 200mm |

| Titanium MMO Anode Mesh 2.0mm Thick x 400mm x 400mm | 2.0mm | 400mm x 400mm |

FAQ

How long is the service life of the MMO titanium mesh anode?

At normal design current density (≤110 mA/m²), the service life is typically 20–75 years, depending on the coating type (e.g., Ru-Ir or Ir-Ta), the operating environment (e.g., pH value, chlorine content), and maintenance conditions.

What regular sizes do you offer? Can you customize?

We provide regular sizes such as 25×25mm, 50×50mm, 100×100mm, 200×200mm, and thicknesses ranging from 0.9mm to 2.0mm. We also support customized shapes, opening forms, and edge treatments according to customer drawings.

What material is the MMO coating made of? Will it fall off?

Commonly used are precious metal mixed oxides such as ruthenium oxide (RuO ₂ ) and iridium oxide (IrO ₂ ), which are firmly bonded to the titanium substrate by high-temperature sintering or brushing. As long as it is used under the specified current density and environment, it is not easy to fall off.

What applications are MMO titanium mesh anodes suitable for?

It is widely used in cathodic protection systems (bridges, tunnels, storage tanks), water electrolysis, sodium hypochlorite generators, electroplating, seawater treatment, swimming pool chlorination and other fields.

Can it be reused or refurbished?

Yes. If the coating is worn away after use but the titanium substrate is intact, we can provide coating repair services without replacing the entire anode, which can significantly reduce long-term operating costs.