Platinized Titanium Mesh

Updated : Jul. 15, 2025Platinized Titanium Mesh is a high-performance functional anode material, which uses industrial pure titanium mesh as the substrate and uniformly coats a layer of precious metal platinum on its surface. This structure combines the strength and corrosion resistance of titanium with the excellent conductivity and chemical stability of platinum, and can maintain stable operation in various complex electrolytic environments.

Structure of platinum-coated titanium mesh anode

The platinum-coated titanium mesh anode is composed of two materials: one is the titanium metal mesh of the load-bearing structure, and the other is the platinum metal coating formed on its surface. This structural design gives full play to the performance advantages of both titanium and platinum, making the anode excellent in conductivity, chemical stability and mechanical strength.

Titanium mesh substrate

The main body of the anode uses industrial-grade pure titanium mesh as the base material, which is commonly Grade 1 or Grade 2. These two titanium materials have high purity, moderate strength, and outstanding corrosion resistance, and can withstand long-term corrosion in complex chemical environments such as acid and electrolyte.

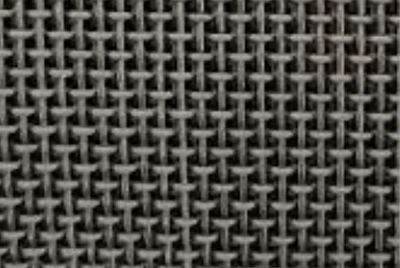

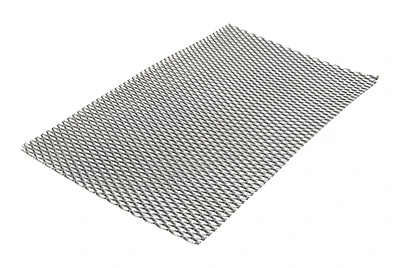

Titanium mesh is usually in the form of expanded metal mesh or woven metal mesh. This open-pore structure can provide a larger specific surface area while maintaining the rigidity of the anode, which is conducive to the uniform distribution of current and the smooth discharge of gas precipitation. In addition, the lightweight properties of titanium itself also make the entire anode weight low, which is easy to install and replace.

Platinum coating

On the surface of the titanium mesh, a dense platinum metal coating is evenly deposited through electrochemical plating or thermal decomposition technology. The thickness of the platinum layer is usually 1 micron, 3 microns or 5 microns, which can be customized according to the application conditions and service life requirements.

As a precious metal, platinum has extremely high chemical inertness and excellent electrical conductivity, and almost no oxidation reaction occurs in the electrolyte. This layer of platinum not only improves the current efficiency and electrical stability of the anode, but also ensures that it will not deteriorate or dissolve in harsh environments such as strong acid, high voltage, and high temperature for a long time.

The bonding between the platinum layer and the titanium substrate is enhanced by special treatment, and usually has good adhesion and can resist stress damage caused by thermal expansion, liquid erosion and long-term electrolysis. The surface treatment method will also be adjusted according to different uses, such as polishing, roughening or edge hemming to ensure that the anode is installed stably in various types of equipment without short circuit.

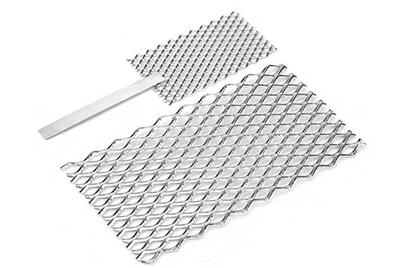

Handle and connection structure

Many platinum-coated titanium mesh anodes come with integrally formed or welded titanium handles for connection to anode clamps, power cords or electroplating equipment. The handle length, diameter and angle can be customized according to the customer's equipment interface to ensure firm contact and smooth current flow during use.

In some high-current application scenarios, reinforcement plates, copper-clad titanium transition sections or welded ribs are added to the edge or handle of the anode to improve the stability of the conductive path and prevent local overheating caused by heat accumulation.

Types of platinum-coated titanium mesh anodes Chalco can provide

Chalco can provide two types of platinum-coated titanium mesh anodes according to different application requirements: standard type and high-durability type. The standard type is suitable for conventional electroplating, laboratory operations and other scenarios, taking into account both performance and cost; while the high-durability type is designed for high current density, long-term operation and harsh environments, with a thicker platinum layer, stronger structural stability and longer service life.

Below is a table of technical parameters for two types of platinum-coated titanium mesh anodes:

| Type | Standard selection | High durability |

|---|---|---|

| Substrate | GR1 / GR2 Industrial Pure Titanium | Finished GR1 Industrial Pure Titanium |

| Platinum layer thickness | 1 micron | 3–5 μm |

| Current density | ≤ 3000 A/m² | ≤ 8000 A/m² |

| Work Environment | pH 0–12, below 60 degrees Celsius | pH 0–12, long term operation |

| Mesh Specifications | 6×12, 8×16, etc. | Customizable |

| Certification | ISO 9001, EN 10204 3.1, SGS | ISO 9001, EN 10204 3.1, SGS |

Selection suggestion:

For daily electroplating operations, jewelry rhodium plating or medium-frequency use scenarios, it is recommended to choose standard anodes, which have good conductivity and corrosion resistance, high cost performance, and are suitable for laboratories, small batch processing or maintenance purposes.

If you are engaged in industrial continuous electroplating, water electrolysis for hydrogen production, and heavy-load electrolysis applications, it is recommended to use a high-durability anode. Its platinum layer is thicker, the current density carrying capacity is stronger, it is suitable for harsh environments such as high temperature and strong acid, has a longer service life, and can significantly reduce the replacement frequency and maintenance costs.

If there are special requirements (such as non-standard mesh, special-shaped size, current distribution optimization design), Chalco also supports customized development, and can provide technical selection suggestions and drawing support based on actual application conditions to ensure that the anode and equipment are accurately matched.

Popular sizes of platinum coated titanium mesh anodes

Platinum coated titanium mesh size

| Product | Size(inch) | Size(mm) |

|---|---|---|

| platinized titanium mesh anode 1″ × 4″ | 1″ × 4″ | 25 mm × 100 mm |

| platinized titanium mesh anode 2″ × 4″ | 2″ × 4″ | 50 mm × 100 mm |

| platinized titanium mesh anode 2″ × 6″ | 2″ × 6″ | 50 mm × 150 mm |

| platinized titanium mesh anode 4″ × 6″ | 4″ x 6″ | 100 mm × 150 mm |

| platinized titanium mesh anode 6″ × 12″ | 6″ x 12″ | 150 mm × 300 mm |

| platinized titanium mesh anode 12″ × 24″ | 12″ × 24″ | 300 mm × 600 mm |

| platinized titanium mesh anode 18″ × 24″ | 18″ × 24″ | 450 mm × 600 mm |

| platinized titanium mesh anode 24″ × 36″ | 24″ × 36″ | 600 mm × 900 mm |

Common mesh (opening /mesh) sizes

| Mesh spacing (mm × mm) | Mesh | Applicable features |

|---|---|---|

| 5 × 10 | 8 × 18 mesh | Uniform current distribution and good ventilation |

| 10 × 10 | 6 × 12 mesh | Universal, most common type of jewelry rhodium plating |

| 12 × 25 | 4 × 8 mesh | Medium to high flow rate electrolysis, high current density |

| 20 × 20 | 3 × 6 mesh | Industrial high current, strong bubble precipitation occasions |

Selection suggestions

For small-sized anodes (such as 1″ × 4″, 2″ × 4″, 2″ × 6″), 10 × 10 mm mesh is recommended. The current is evenly distributed and the liquid flows smoothly, which is suitable for fine electroplating processes such as jewelry rhodium plating.

Medium-sized anodes (e.g. 4″ × 6″, 6″ × 12″) are suitable for 10 × 10 mm or 12 × 25 mm mesh. Larger mesh is recommended for higher current densities, combined with a thicker platinum layer to reduce the risk of polarization.

Large anode plates ( 12″ × 24″ and above) are often equipped with 12 × 25 mm or 20 × 20 mm mesh, which has lower pressure drop and smoother gas evolution. It is suitable for continuous electroplating and industrial electrolysis systems. It is recommended to use a 3-5 µm platinum layer and weld reinforcement ribs.

The hole layout and mesh density can be customized for special-shaped equipment or special flow fields, supporting laser cutting and CNC punching to match the cathode plate structure and improve the overall electrolysis efficiency.

The core advantages of Chalco platinum-coated titanium mesh anode

The platinum-plated titanium mesh anode provided by Chalco is designed to meet high-standard electroplating and electrolysis applications based on advanced manufacturing technology and high-quality raw materials. The product combines conductive stability, corrosion resistance, economy and sustainability, and is widely used in jewelry electroplating, electronic electrolysis, hydrogen energy systems and various precision electrochemical environments.

High temperature sintering technology ensures strong adhesion of the platinum layer

Chalco uses a vacuum sintering furnace to perform high-temperature treatment (≥1200°C) on the platinum-coated titanium mesh, so that the platinum layer is firmly bonded to the titanium substrate, significantly improving adhesion and stability. Compared with traditional electroplating processes, this method effectively avoids the problem of platinum layer peeling or partial shedding. The coating is tightly bonded, and the consumption rate of platinum is extremely low and uniform, ensuring that the anode maintains stable performance under long-term use.

Applicable to various high acid electroplating processes

Chalco platinum-plated titanium mesh anode can be stably used in a variety of precious metal electroplating solutions, especially for rhodium plating and acid gold plating processes. The platinum layer has excellent chemical inertness, and the titanium matrix has strong corrosion resistance. It is still stable in strong acid and strong oxidizing environments, does not precipitate impurities, and does not pollute the plating solution, providing reliable protection for precision electroplating of high-end jewelry, electrical contacts, etc.

Surface treatment process improves current uniformity

Chalco platinum-plated titanium mesh anode is flattened and annealed after the platinum layer is deposited to make the titanium mesh surface smoother and flatter, which helps to evenly distribute the current and avoid coating defects caused by local overcurrent. This process is particularly suitable for applications with high surface consistency requirements such as mirror coating and bright white rhodium plating, and also helps to extend the service life of the plating solution.

Vacuum sintering furnace

High acid plating

Surface treatment

Reusable design reduces long-term costs

Titanium as a substrate is not only lightweight, high-strength and corrosion-resistant, but its biggest advantage is that it can be reused. After the platinum layer of Chalco's anode is exhausted after the first use, it can be refurbished with platinum for a second or even multiple times to restore its original performance. This feature greatly reduces the frequency of customer replacement and saves downtime, and is especially suitable for industrial users who pursue equipment utilization and process continuity.

Energy saving and environmental protection, in line with the trend of sustainable development

At a time when maintenance costs are rising and environmental regulations are becoming increasingly stringent, the durability and refurbishment capabilities of Chalco's platinum-coated titanium mesh anodes not only effectively reduce the generation of industrial waste, but also reduce the consumption of raw materials required per unit output. This not only helps customers control costs, but also meets the global market's expectations for green manufacturing and sustainable electroplating solutions.

Applicable scenarios of Chalco platinum-coated titanium mesh anode

The platinum-coated titanium mesh anode provided by Chalco has shown wide applicability in multiple electrochemical fields due to its excellent conductivity, corrosion resistance and long-term stability, and can meet the needs of different working conditions from precision electroplating to heavy-duty industrial electrolysis.

Rhodium Plating for Jewelry and Accessories

In the jewelry industry, platinum-coated titanium mesh is often used in rhodium plating processes. As a high-end electroplating material, rhodium requires extremely high anode purity. Platinum-coated titanium mesh has irreplaceable advantages in such applications because it does not release impurities and does not affect the color of the coating. In daily use, it is usually used with a small electroplating machine, and the size of 1×4 inches is the industry standard.

Acid precious metal plating

In the manufacturing process of electronic components and precision devices, Chalco anodes are suitable for precious metal electroplating such as gold plating and palladium plating in acidic environments. Its stable platinum layer can maintain structural integrity and release no impurities in strong acid electrolytes for long-term use, ensuring the performance of the coating and the life of the electroplating solution.

Water electrolysis and hydrogen generation system

Chalco anodes are suitable for PEM electrolyzers and other water electrolysis systems, serving as the anode for oxygen evolution reactions. With high current density capacity and extremely low corrosion rates, they ensure long-term stability under continuous operation, making them an ideal choice for hydrogen production systems.

Chemical wastewater treatment and heavy metal recovery

In the process of electrolytic treatment of wastewater or recovery of precious metals, the platinum-coated titanium mesh anode can maintain stable conductivity in harsh chemical environments, effectively remove pollutants or promote metal deposition, and is widely used in electroplating plant waste liquid treatment, electrolytic gold extraction and other fields.

Electrochemical experiment and scientific research equipment

Universities, research institutes and corporate laboratories often use Chalco anodes for electrochemical experiments, such as polarization curve tests, reaction mechanism studies, potential control experiments, etc. The anode surface has high consistency and good electrochemical reaction stability, providing a reliable basic condition for scientific research.

PEM electrolyzer

Chemical wastewater

Electrochemical experiments

Platinum-coated titanium mesh anode vs MMO titanium mesh anode

Titanium-based anodes are widely used in the electrochemical industry, of which platinum-coated titanium mesh and MMO titanium mesh anodes are the two mainstream types. Both are based on pure titanium, but the surface coating is different, resulting in significant differences in their performance, applicable environment and cost.

| Project | Platinum-coated titanium mesh anode | MMO titanium mesh anode |

|---|---|---|

| Substrate | Industrial pure titanium (GR1 or GR2) | Industrial pure titanium (GR1 or GR2) |

| Coating materials | High purity platinum (Pt) | Mixed metal oxides such as iridium (Ir), ruthenium (Ru), and titanium (Ti) |

| Conductive properties | Excellent (precious metal platinum, low resistance) | Good (less conductive than platinum) |

| Corrosion resistance | Excellent in acidic environment, especially suitable for precious metal electroplating solution (such as rhodium plating) | Particularly suitable for chloride ion environment, seawater, alkaline or chlorine-containing strong oxidizing solution |

| Electrolytic properties | Suitable for high-precision, stable current environment | Suitable for industrial electrolysis with high current density and long-term power supply over a large area |

| Service life | Medium (depending on platinum layer thickness, typically 1–5 µm) | Long life, the coating can be designed to last for more than 5-20 years |

| Cost Level | Higher cost (contains precious metal platinum) | Relatively low cost (oxide costs much less than platinum) |

FAQ

Does the thickness of the platinum layer affect the service life?

Yes, the thicker the platinum layer, the better the corrosion resistance and service life, 1 µm supports medium frequency use, 3–5 µm is more suitable for continuous plating or high current density environments.

How to determine whether the anode needs to be replaced or refurbished?

This can be judged by uneven plating current, increased anode resistance or blackened surface. We provide refurbishment services to extend the service life.

Can you provide material certification and test reports?

Yes. We support EN 10204 3.1 certification, third-party testing (such as SGS, TÜV), and meet export and factory audit requirements.

Why choose Chalco?

- Equipped with advanced equipment such as vacuum sintering furnace, precision mesh flattening machine, platinum layer thickness control system, etc. to ensure product consistency and batch stability

- We have many years of experience in precious metal anode manufacturing, mature technology and stable technology.

- Provide standard and customized platinum-coated titanium mesh to meet the needs of different electroplating and electrolysis scenarios

- High temperature vacuum sintering process is adopted, the platinum layer is firmly attached, long life and stable performance

- With automatic welding line and high-purity electroplating system, efficient manufacturing and uniform coating are achieved

- Support small batch orders, quick response, and meet project samples and flexible production

- Can provide EN 10204 3.1, SGS and other quality certifications and third-party testing

- Provide anode refurbishment and secondary platinum plating services to reduce use costs and be environmentally sustainable

- Professional technical team supports model selection, structural optimization and application solution suggestions