Ruthenium Iridium Titanium Anode

Updated : Jun. 24, 2025Ruthenium-iridium-titanium anode is essentially a metal oxide coated anode, which is mainly composed of ruthenium oxide and iridium oxide coated on the surface of titanium substrate. This type of anode is widely used in electrochemical industries such as chlor-alkali, water electrolysis, wastewater treatment, electroplating, and electrowinning.

Why use ruthenium and iridium?

Ruthenium oxide (RuO ₂) has extremely high electrocatalytic activity for chlorine evolution and is the main active ingredient in the chlorine evolution reaction.

Iridium oxide ( IrO ₂ ) provides good corrosion resistance and structural stability, extending the life of the coating.

The two are combined in a ratio (commonly 70:30) to achieve a good balance between electrocatalytic performance and stability.

Analysis of the structure and composition of ruthenium-iridium-titanium anode

The ruthenium-iridium-titanium anode mainly consists of two parts: substrate and coating.

Its base material is titanium, which has excellent mechanical strength and corrosion resistance, and can work stably for a long time in harsh environments such as strong acid and strong alkali. Titanium itself does not participate in the reaction during the electrolysis process, but only acts as a conductive carrier to provide stable support for the anode. It is currently recognized as an ideal anode matrix material in the electrochemical field.

A mixture of ruthenium oxide (RuO₂) and iridium oxide (IrO₂), usually compounded in a certain proportion. This coating has extremely high electrocatalytic activity, can significantly reduce the overpotential in the electrolysis reaction, improve energy efficiency, and is the main reaction layer for key reactions such as chlorine evolution and oxidation. At the same time, the addition of iridium also enhances the structural stability and corrosion resistance of the coating, extending the service life of the electrode.

Chalco Ruthenium Iridium Titanium Anode Technical Parameters

| Substrate | Grade 1 Titanium (Gr.1) or Grade 2 Titanium (Gr.2) |

| Coating Composition | RuO ₂ + IrO ₂ (ratio 70:30) |

| Coating Thickness | 6–15 µm |

| Current Density | ≤ 5000 A/m² |

| Operating Voltage | ≤ 24 V |

| Operating Temperature | ≤ 80°C |

| Corrosion Resistance | < 7 |

Chalco Ruthenium Iridium Titanium Anode Product Type

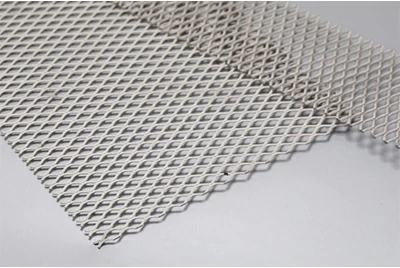

Ruthenium iridium titanium mesh anode

The ruthenium- iridium-titanium mesh anode has excellent permeability and specific surface area, and is suitable for applications that require sufficient electrolyte flow and uniform reaction distribution.

Contact us now

The thickness ranges from 0.5 to 2.0 mm, the aperture and opening rate can be customized according to the process requirements, and the size supports precise processing according to the drawings.

The current distribution is uniform, the reaction efficiency is high, the structure is light, and it is not easy to be blocked. While ensuring the electrolysis performance, it reduces the operation resistance and energy consumption.

Electroplating, swimming pool disinfection, chlor-alkali electrolysis, wastewater treatment, sodium hypochlorite generator and other scenarios that require large-area, high-throughput reactions.

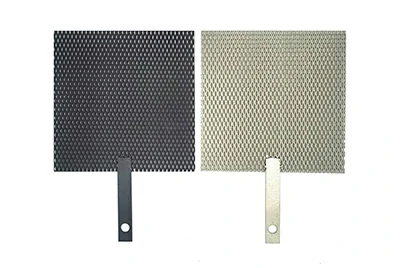

Ruthenium iridium titanium plate anode

Planar MMO electrodes with stable structure and long service life are widely used in standardized industrial electrolysis systems

Contact us now

The thickness ranges from 0.5 mm to 5 mm, which can meet the requirements of different processes and structural strength.

The hole design is flexible and diverse, and you can choose perforated plates with round holes, square holes or polygonal holes to adapt to various application scenarios.

The material has high mechanical strength, ensuring a stable and reliable structure in long-term operation. The electrocatalytic reaction surface is uniform and stable, the coating is evenly distributed and supports multiple recoating, which greatly improves the service life and performance stability, and is very suitable for working conditions that require continuous and long-term operation.

widely used in chlor-alkali industry, water electrolysis to produce hydrogen, swimming pool electrolysis equipment and seawater desalination, etc., meeting the needs of large-scale industrial production and environmental protection treatment.

Ruthenium iridium titanium rod anode

Ruthenium -iridium-titanium rod anode is a linear, high-strength anode product suitable for environments with precise requirements such as local electrolysis, structural conductivity or experimental research.

Contact us now

The diameter range is from 10 mm to 50 mm.

ruthenium- iridium-titanium rod anode has high conductivity and excellent corrosion resistance. It can be used for a long time in a high-strength electrolyte environment without deformation or loss, and supports repeated use.

It is widely used in electroplating probes, micro-electrolysis reactors, anode support rods, and local positioning electrolysis equipment.

Ruthenium iridium titanium wire anode

The ruthenium -iridium-titanium wire anode is an extremely flexible and extremely fine-diameter electrode designed for precision electrolysis scenarios or compact space layouts.

Contact us now

The diameter ranges from 0.5 mm to 10 mm, and the length can be cut to size or supplied in roll form to suit a variety of assembly requirements.

The ruthenium -iridium-titanium wire anode has good flexibility, is not easy to crack when bent, and has a stable and uniform coating, making it particularly suitable for wiring or fine anode structures inside complex equipment.

It is mainly used in precision electroplating, electrochemical sensing, electrolysis probes, small water treatment equipment and other occasions that require miniaturization and directional response.

Ruthenium iridium titanium tube anode

The ruthenium-iridium-titanium tube anode is a functional electrode with a hollow structure that has both structural support and electrolytic reaction capabilities, and is suitable for flow or embedded electrolysis environments.

Contact us now

The diameter ranges from 10 to 200 mm, the length can be customized according to needs, and the wall thickness can be flexibly adjusted to meet different load and pressure requirements.

The ruthenium-iridium-titanium tube anode supports double-sided coating inside and outside, and has the advantages of large reaction area, high utilization rate and convenient installation. It is especially suitable for three-dimensional space power distribution structure.

It is widely used in large-scale electrolytic equipment, electroplating automatic lines, heavy metal recovery systems and other fields that have dual requirements for structural integrity and conductive efficiency.

Ruthenium iridium titanium basket anode

Ruthenium -iridium-titanium basket anode is a containment anode specially used in the field of electroplating. It is mainly used to load the metal particles of the plating solution and stably release the metal ions.

Contact us now

Common sizes and opening structures can be customized according to the customer's anode frame to ensure that the anode basket fits well in the electroplating tank and flows smoothly.

The ruthenium -iridium-titanium basket anode does not dissolve, does not pollute the electroplating solution, releases metal ions evenly, and is easy to replace and reuse particles, which greatly improves the quality and efficiency of electroplating.

It is mainly used in high-demand electroplating processes such as copper plating, nickel plating, and silver plating, and is especially suitable for occasions where the anode material needs to be replaced frequently.

Why do customers choose our ruthenium iridium titanium anode?

At the recommended current density of 200–400 A/m², the service life of the Ru-Ir-Ti anode can exceed 5 years, ensuring long-term stable operating performance and reducing the cost and maintenance work of frequent replacement.

The ruthenium-iridium-titanium anode has an extremely low chlorine evolution overpotential of about -70 mV, which means that it can more efficiently promote the precipitation of chlorine during the electrolysis process, thereby improving the overall electrochemical reaction efficiency.

The material can maintain excellent corrosion resistance in a wide pH range (from 1 to 14) and adapt to various strong acid and strong alkali environments, ensuring that it still has excellent durability and stability under different working conditions.

The ruthenium-iridium-titanium anode can withstand an operating temperature of up to 80°C, meeting the needs of high-temperature operation while maintaining stable structure and performance, making it suitable for various industrial electrolysis scenarios.

Ruthenium-iridium-titanium anodes can be provided in a variety of specifications and forms according to customer needs, including mesh, plate, rod, tube and basket, which can be flexibly adapted to different equipment structures and process requirements.

In addition, the manufacturer also provides professional re-coating services to effectively extend the service life of ruthenium iridium titanium anodes, reduce overall operating costs and improve economic benefits.

Special applications of ruthenium iridium titanium anode

Fruit and vegetable disinfection machine

Ruthenium-iridium coated electrodes improve the sterilization efficiency of fruit and vegetable disinfection equipment and extend the service life of electrodes. Its stable performance helps to improve food safety and protect consumer health.

Contact us now

Sodium hypochlorite production

Electrodes ensure a stable and efficient electrolysis process and are an important component of the industrial preparation of sodium hypochlorite. They are widely used in key areas such as water treatment, disinfection and cleaning.

Contact us nowChlor-alkali industry

In the chlor-alkali industry, electrodes are corrosion-resistant and highly efficient, supporting the efficient production of chlorine and caustic soda. They optimize processes, reduce energy consumption, and contribute to the development of green chemical industry.

Contact us now

Pool water disinfection

Ruthenium-iridium electrodes can continuously produce active chlorine, effectively killing bacteria and algae in the water. They reduce the use of chemical agents and maintain the cleanliness and environmental protection of swimming pool water.

Contact us nowWastewater treatment

The electrodes can effectively degrade organic pollutants in wastewater treatment and purify the effluent to meet the standards. Their environmental performance helps promote sustainable management of water resources and ecological protection.

Contact us now

Chalco ensure the quality of ruthenium iridium titanium anodes?

At Chalco, quality and performance are at the heart of what we do. We specialize in providing best-in-class Ruthenium-Iridium coated electrodes, and are committed to excellence in every detail. This commitment is reflected in our strict quality control system - each electrode must pass a series of comprehensive in-house tests before delivery to ensure that it works stably and efficiently in a variety of electrochemical applications.

Our quality assurance team consists of experienced technicians who are responsible for supervising and executing all testing processes to ensure that every product meets the most stringent standards required by the industry and our customers.

To achieve this goal, Chalco has developed the following key test items and evaluation criteria:

| Test items | Test conditions | Require |

| Integrate strength | 3M tape test | No black marks on the tape |

| Round shaft bending test | Φ12mm round shaft, bent 180° | No peeling at the bend |

| Uniformity test | X-ray fluorescence spectrometer | ≤15% |

| Coating thickness | X-ray fluorescence spectrometer | 2–10 μm |

| Chlorination potential | 2000A/m², saturated NaCl, 25±2℃ | ≤1.08V |

| Chlorine evolution polarization rate | 200/2000A/m², saturated NaCl, 25±2℃ | ≤35 mV |

| Extend service life | 40000A/m², 1mol/LH ₂ SO ₄, 40±2℃ | ≥45 hours (iridium + ruthenium 8g) |

| Deep Weightlessness | 20000A/m², 8mol/L NaOH, 95±2℃, electrolysis for 4 hours | ≤10 mg |

Precautions for use of ruthenium-iridium coated titanium anode

When avoiding scratches, try to avoid direct contact with the surface of the ruthenium iridium titanium anode with hard objects to prevent mechanical damage to the coating, which will affect its electrochemical properties and service life.

After use, the anode should be rinsed with clean water in time to remove residual electrolyte and impurities, and then stored in a dry, well-ventilated environment to effectively prevent corrosion and contamination and ensure the long-term stability of the anode.

During use, the current density should be strictly controlled to avoid long-term operation under high current conditions and keep it within the range recommended by the manufacturer. This can significantly extend the service life of the anode and ensure its working efficiency.

Ruthenium-iridium-titanium anodes are not suitable for media environments containing fluoride ions. Fluoride ions will damage the coating, causing performance degradation or even failure, so they should be avoided in such environments.

The anodes should be inspected regularly, with a focus on whether there is wear, corrosion or other abnormal phenomena, and maintenance and care should be carried out in a timely manner to prevent potential failures and ensure safe and reliable operation of the equipment.

During operation and maintenance, the instructions and operating guidelines provided by the manufacturer must be strictly followed. Only in this way can the ruthenium iridium titanium anode be guaranteed to perform at its best, extend its service life, and improve its overall economic benefits.