Titanium Anode

Updated : Jun. 24, 2025Titanium anode, full name is titanium-based metal oxide coated anode (MMO Anode), also known as dimensionally stable anode (DSA Anode). It is an insoluble anode with pure titanium as the matrix and a catalytic coating of precious metals or their oxides coated on its surface.

Titanium anodes combine the mechanical strength of titanium with the electrocatalytic properties of precious metal oxides, offering the following advantages:

- Good electrocatalytic activity

- Excellent conductivity and conductivity uniformity

- Strong anti-oxidation and corrosion resistance

- Long electrolytic life, can be re-coated and reused many times

Chalco Titanium is a trusted manufacturer in the field of titanium anodes, focusing on the research and development and production of high-performance MMO anodes. Relying on many years of industry experience, we provide a variety of customized solutions covered with precious metal coatings such as ruthenium, iridium, platinum, etc., with excellent electrochemical performance and excellent cost performance.

Whether it is standard specifications or complex structures, Chalco Titanium can rely on mature manufacturing technology and strict quality control to tailor-make reliable and durable titanium anode products for customers.

Why is titanium the best choice for anode construction?

Titanium's high temperature resistance ensures that it can maintain reliable and stable performance under the most severe conditions. This feature makes it a reliable anode structural material.

Titanium is naturally resistant to corrosion in a variety of environments, both acidic and alkaline. This corrosion resistance enhances titanium's durability, ensuring a long life even in the harshest conditions.

Titanium's inherent strength, combined with its ability to maintain performance over a wide range of temperatures, makes it an adaptable and trusted material for numerous applications, cementing its position as the preeminent anode material.

Leveraging these exceptional properties, Chalco designs and produces anodes that not only meet but exceed performance expectations for a wide range of applications, ensuring superior functionality and longer durability.

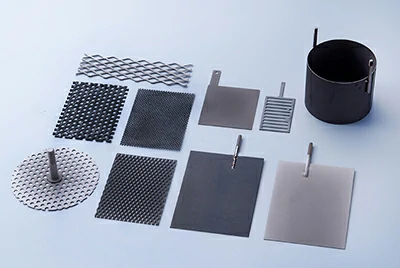

What types of titanium anode products can Chalco provide?

Ruthenium titanium anode

Ruthenium-based titanium anode is an insoluble anode coated with precious metal oxides such as ruthenium oxide, and is a chlorine-evolving anode. The anode has low chlorine evolution overpotential, excellent electrochemical stability and corrosion resistance, and is suitable for chlorine evolution reaction. Its structure can be customized as needed, has no pollution to the medium, and the titanium matrix can be reused after failure.

Chalco ruthenium titanium anode is often used in hydrochloric acid, seawater electrolysis and other environments. The technical parameters are as follows:

| Substrate | Gr1, Gr2 (TA1/TA2) |

|---|---|

| Coating Type | Pure ruthenium, ruthenium-iridium, ternary ruthenium-iridium, multi-component ruthenium-iridium mixed oxide formula |

| Usage Environment | Hydrochloric acid, electrolyzed seawater, electrolyzed brine, etc. |

| Sizes | Can be customized upon request |

| shape | Plate, mesh, tube |

| Current density | ≤2000 A/m² |

| Precious metal content | 10–45 g/m² |

| Temperature range | <70℃ |

Ruthenium-based titanium anode has good conductivity and electrocatalytic activity, which can effectively reduce overpotential and cell voltage and improve electrolysis efficiency. Its coating is stable and corrosion-resistant, suitable for long-term continuous operation, and supports customization of various shapes for easy integrated installation.

Ruthenium-based titanium anodes are widely used in electroplating, electrolytic copper foil, chlor-alkali industry, cathodic protection, hydrometallurgy, sodium hypochlorite generators and sewage treatment, etc., which have high requirements on reaction efficiency and stability.

Iridium MMO coated titanium anode

Iridium-based titanium anode is an insoluble anode. A layer of precious metal oxides such as iridium oxide is coated on the surface of the titanium substrate. It is an oxygen-evolving MMO (mixed metal oxide) anode. This anode has excellent electrocatalytic activity, conductivity and corrosion resistance, and is particularly suitable for oxygen evolution reactions in acidic environments.

Chalco iridium titanium anode is specially designed for oxygen evolution environment, with excellent electrocatalytic performance and acid corrosion resistance, and is widely used in electrolysis, sewage treatment and other fields. The following are its typical technical parameters :

| Substrate | GR1, GR2 (TA1/TA2) |

| Coating Type | Iridium oxide, iridium tantalum, platinum iridium, ternary iridium tantalum, multi-element iridium tantalum mixed oxide formula |

| Work Environment | Typically used in sulfuric acid environments or other oxygen evolving anode applications |

| Sizes | Can be customized upon request |

| shape | Plate, mesh, tube or other customized shapes |

| Current density | ≤2500 A/m² |

| Precious metal content | 10–45 g/m² |

| Temperature range | <70℃ |

Chalco optimizes the coating formula and process of iridium titanium anodes to make the active layer on the anode surface more evenly distributed and more conductive, significantly reducing overpotential and cell voltage. It also supports customization of various shapes and specifications, taking into account both performance stability and application flexibility.

Iridium titanium anodes are widely used in metal foil, electrolytic copper foil, steel plate galvanizing, cathodic protection, organic electrolytic synthesis, circuit board electroplating, chromium electroplating, cyclone electrolysis, hydrometallurgy, HHO generator, sewage treatment and other industries.

Platinum-coated titanium anode

Platinum-plated titanium anode is an insoluble anode with high-purity titanium as the substrate and a layer of platinum group precious metal electroplated on the surface. It has both the structural strength of titanium and the electrochemical properties of platinum, and is suitable for oxygen and chlorine evolution environments. Compared with pure platinum electrodes, it has better mechanical properties, more stable structure, and greatly reduces the cost of use.

Platinum-plated titanium anodes combine the structural strength of titanium with the electrochemical properties of platinum and are suitable for high current and high corrosion environments. The following are its typical technical parameters:

| Substrate | Gr1, Gr2 (TA1/TA2) |

| Coating Type | Pure platinum, platinum iridium |

| Processing Technology | Electroplating, brush plating |

| Coating thickness | 0.3 – 10 μm |

| Current density | ≤4000 A/m² |

| Temperature range | <80℃ |

| shape | Usually in plate, mesh, tube, wire or customized shape; size can be customized according to actual needs |

The platinum titanium anode developed and produced by Chalco has the characteristics of high oxygen evolution potential, low hydrogen evolution potential, high current efficiency, strong corrosion resistance, long service life, electrode shape can be designed according to user needs, no pollution to the medium, and the electrode matrix can be reused.

Platinum-plated titanium anodes are widely used in electrolysis of water ions, electroplating, oxidation of acidic potential water, HHO generators, cathodic protection, metal electroplating, hydrogen-rich water machines and other fields.

Lead dioxide titanium anode

Lead dioxide titanium anode (Ti/ PbO ₂ anode) is an insoluble anode. It uses industrial pure titanium (TA1/TA2) as the substrate and forms a dense and stable lead dioxide ( PbO ₂ ) coating on its surface through an electrodeposition process. The anode is black in appearance and common structures include plate, mesh, and tubular. Special-shaped parts can also be customized on demand.

Lead dioxide titanium anode is widely used in highly oxidizing electrolysis environment due to its high oxygen evolution overpotential and excellent corrosion resistance. The following are its typical technical parameters:

| Substrate | Gr1 / Gr2 (TA1 / TA2) industrial pure titanium |

| Coating materials | Lead dioxide (β- PbO₂ or β- PbO₂ + X) |

| Coating thickness | 500–1000 μm |

| Operating voltage | ≤24 V (≤12 V recommended) |

| Current density | ≤5000 A/m² (up to 10000 A/m²) |

| pH range | 1–12 ( optimal range is 1–4) |

| Operating temperature | ≤60–80 ℃ |

| Fluoride ion concentration | <50–60 mg/L |

| Sulfuric acid concentration | ≤30% |

| Product shape | Plates, nets, rods, tubes and various special-shaped parts can be customized on demand |

Lead dioxide titanium anode has strong oxidation resistance (strong oxidation ability when electrolyzed in aqueous solution); high corrosion resistance ( high stability in strong acid HzS04 or HN03); high oxygen overpotential; good conductivity; strong bonding force; can pass large currents, etc.

Lead dioxide titanium anode is mainly used for fading treatment of electroplating, smelting, domestic sewage treatment, persulfate production, phenol-containing wastewater, oilfield wastewater, printing and dyeing wastewater, ammonia nitrogen wastewater, etc.

Characteristics of titanium anode

Compared with traditional graphite and lead anodes, titanium anodes have a series of significant advantages:

The titanium anode has excellent dimensional stability during the electrolysis process, which can maintain the consistency of the electrode spacing, thereby achieving uniform battery voltage output and improving the controllability and efficiency of the overall operation. Its catalytic performance is significantly enhanced, enabling it to achieve good electrolysis effects at lower voltages, further optimizing energy utilization.

Due to the low working voltage, titanium anodes can effectively reduce DC power consumption, saving 10% to 20%. At the same time, the material itself has excellent resistance to chlorine and alkali corrosion, allowing it to maintain a service life of 5 to 7 years in harsh environments, far exceeding the less than one year service life of traditional graphite anodes.

In terms of environmental protection, the titanium anode will not dissolve during the electrolysis process, thus avoiding the risk of contamination of the electrolyte and cathode products, ensuring product purity and environmental safety. Its excellent conductivity can also increase current density and electrolysis efficiency, showing strong economic value in large-scale industrial applications.

Precious metal coatings such as iridium and ruthenium further enhance the corrosion resistance of titanium anodes, allowing them to operate stably in strong acid and alkali environments. In addition, titanium anodes can avoid common lead anode deformation and short circuit problems, effectively improving the smoothness of operation and system reliability. Titanium-based materials are easy to process and shape, making anode design and manufacturing more flexible and meeting a variety of process requirements.

Titanium anodes stand out for their robustness, efficiency and environmental friendliness, offering a comprehensive range of advantages that make them superior to conventional anodes in a variety of industrial applications.

How to choose the ideal titanium anode?

Choosing the right titanium anode is not only related to electrolysis efficiency and product quality, but also directly affects the stability of equipment operation and maintenance costs. Different application environments have different requirements for anode performance. Only by scientifically selecting according to specific working conditions can we ensure long-term efficient operation of the system, reduce energy consumption, and extend the service life of the anode, thereby achieving a higher return on investment.

Clarify the application context

First, determine the specific application area of the anode, such as non-ferrous metal electrolysis (copper, zinc, aluminum, etc.), chlor-alkali electrolysis, sodium hypochlorite production, seawater electrolysis, cathodic protection or organic electrolysis, etc. Different processes correspond to different anode types and coating systems.

Analyze solution components

The chemical stability and adaptability of the anode are highly dependent on the main components of the electrolyte (such as Cl ⁻, SO ₄ ² ⁻, NO ₃⁻, etc.). Ruthenium-based MMO anodes are recommended for high-chloride environments, iridium-based MMO anodes are recommended for strong acid environments, and platinum or multi-component composite coatings can be considered for organic electrolysis.

Current density evaluation

Calculate the current density per unit area based on the equipment structure and target capacity, and select an anode structure that matches the current load. For example, the recommended current density for conventional MMO anodes is ≤2000 A/m², the current density for platinum anodes is ≤4000 A/m², and the current density for PbO₂ anodes is ≤10000 A/m².

Temperature and PH conditions

The temperature and pH value of the working environment directly affect the stability of the coating. Iridium-tantalum coating is recommended for high temperature and high acid; RuO₂ anodes are more stable in neutral and alkaline environments; PbO₂ anodes are suitable for strong oxidation systems with a pH of 1-4.

Titanium anode type selection

Depending on the reaction type and target performance, choose from the following common anodes:

The type of titanium anode should be selected according to the specific electrolytic reaction and expected performance to achieve the best operation effect and service life.

Ru -Ir MMO anode is suitable for chlorine evolution reaction and is often used in scenarios such as swimming pool disinfection and brine electrolysis. It has good chlorine evolution efficiency and stability.

Ir -Ta MMO anode is mainly used for oxygen evolution reaction and is particularly suitable for operation in a strong acidic environment. It is widely used in fields such as metal foil electrolysis that require high anode stability.

Platinized anodes are suitable for general hydrogen and oxygen evolution reactions and can withstand high current densities. They are commonly used in electroplating and water treatment, where strong electrolytic performance is required.

PbO₂ anode is more suitable for high oxidation reaction systems, such as wastewater purification and electrolytic oxygen separation, and has strong oxidation ability and a long service life.

Lifespan matches replacement cycle

Based on the project life cycle and equipment maintenance plan, select an anode type with a matching service life (e.g., MMO: 3–7 years, platinum anode: 2–5 years, PbO₂ anode : hundreds to thousands of hours, depending on the environment).

Financial budget and cost performance

the most cost-effective anode system under the premise of meeting technical indicators . Cooperate with anode manufacturers (such as Chalco) to optimize coating formula and structure according to budget to achieve a balance between performance and cost.

How does Chalco create industry-leading titanium anodes?

Chalco is committed to transforming raw titanium materials into high-performance titanium anodes. The entire production process covers every detail from substrate selection to finished product delivery, ensuring that the anodes reach industry-leading levels in electrocatalytic efficiency, corrosion resistance and service life.

The following is our standard production process for titanium anodes. Each step is strictly controlled to ensure stable product performance, reliable quality, and meet the diverse application needs of customers:

First, according to customer drawings and application requirements, Gr1 or Gr2 industrial pure titanium is selected as the base material from titanium plates, sheets, meshes or bars to ensure that the base material has excellent corrosion resistance, electrical conductivity and dimensional accuracy.

Next, sandblasting is carried out to remove the oxide layer on the surface of the titanium material through mechanical sandblasting to increase the surface roughness, thereby enhancing the adhesion of the subsequent precious metal coating and the uniformity of electrocatalysis.

The titanium is then processed using high-precision laser cutting equipment to obtain burr-free, dimensionally accurate edges, ensuring the integrity and precision of the overall structure.

During the structural assembly stage, argon arc welding, spot welding or large-area welding processes are selected according to the design to ensure that the weld has sufficient strength, excellent electrical conductivity, and meets the subsequent electrolysis conditions.

Subsequently, the titanium substrate is immersed in a 10% oxalic acid solution for heated pickling to thoroughly remove the residual oxide film and trace impurities on the surface, laying a clean foundation for the adhesion of the coating.

According to different application requirements, composite solutions of ruthenium-iridium, iridium-tantalum or platinum-based precious metals are formulated to improve the electrocatalytic efficiency and corrosion resistance of the anode.

The coating process is carried out by multiple manual brushing to ensure that the coating thickness is stably controlled at 8–10 μm, obtaining a uniform active surface and stable reaction performance.

After coating, sintering and annealing are carried out in a special sintering furnace according to the set temperature curve to further improve the crystallization quality and bonding strength of the coating and enhance the long-term stability of the anode.

After being manufactured, all anodes must pass electrocatalytic activity tests and durability enhancement tests to ensure that each product has efficient, stable and consistent performance in actual operation.

Finally, the finished anodes will be sealed and packaged with anti-corrosion and anti-vibration packaging materials to ensure that they are not damaged during transportation and delivery and are delivered to the customer site safely and intact.

Chalco titanium anode price analysis

Understanding the price of titanium anodes requires understanding the factors that influence their cost. As a leading titanium anode manufacturer, Chalco Titanium is committed to clarifying every factor that affects the price of titanium electrodes.

Titanium substrate cost

The price of titanium anodes is primarily affected by the type and specifications of the titanium substrate used, such as titanium plates, meshes, rods or sheets. Its cost fluctuates according to market conditions, and the rise and fall of raw materials will directly affect the anode price.

Precious metal coating costs

Chalco titanium anodes are coated with precious metals such as ruthenium, iridium, and platinum. To ensure performance and life, most raw materials are selected from internationally recognized precious metal suppliers (such as Heraeus). The prices of these metals are highly dependent on international market conditions and fluctuate greatly on a daily basis, which is one of the core variables affecting anode costs.

Manufacturing and processing costs

Although the manufacturing process is relatively stable, factors such as labor, energy, equipment maintenance and management costs may still cause certain price fluctuations. Key process flows such as high-precision laser cutting, welding, pickling, sintering, etc. will also affect the overall processing cost according to the complexity of customization.

What services can Chalco provide for you?

Chalco provides free professional technical consultation and recommends the most suitable titanium anode type and coating formula based on the customer's electrolysis conditions, such as solution composition, current density, pH value and temperature, to ensure accurate selection.

We support customized design services and can process non-standard products according to customer drawings. The size, shape (including plate, tube, mesh, rod and special shape) and coating thickness of the anode can be flexibly customized to meet the needs of different equipment and processes.

According to different application environments, such as chlorine evolution, oxygen evolution or organic electrolysis, the ratio of precious metal coating liquid is optimized, and precious metal components such as ruthenium, iridium and platinum are reasonably allocated to achieve the best balance between performance maximization and cost control.

Support small batch sample provision and proofing verification to help customers conduct preliminary testing, ensure that product performance is highly matched with actual needs during bulk purchases, and reduce project risks.

Anodes of common specifications are in stock, and the delivery time of customized orders is flexible and controllable, which can meet the urgent needs of customers' project progress to the greatest extent.

A complete test report is provided at the time of shipment, including third-party or internal certification such as material certification, coating thickness and electrocatalytic performance testing, to ensure transparent and traceable product quality.

Comprehensive after-sales service provides technical guidance, abnormal problem analysis and repair support during the use of anodes, helping customers to extend the service life of anodes and improve the overall operating efficiency of the system.