Titanium Anode Basket

Updated : Jul. 15, 2025Titanium anode baskets are key components in modern electroplating processes, mainly used to fix soluble anodes and maintain uniform current distribution. Compared with traditional stainless steel baskets or anode bags, titanium has become an increasingly popular product in the electroplating field due to its excellent corrosion resistance, mechanical strength and lightweight advantages.

Why choose titanium anode basket?

Titanium anode baskets are made of industrial-grade pure titanium (Gr1 or Gr2) and have excellent acid and alkali corrosion resistance, especially suitable for common electroplating media such as acid copper, nickel, chromium, etc. Compared with stainless steel, titanium is more stable in the electrochemical environment, not easy to oxidize or precipitate impurities, can maintain excellent conductivity for a long time, significantly reduce anode slag deposition, improve the quality of the coating and extend the life of the bath.

Charco's popular titanium anode basket types

Round titanium anode basket

The cylindrical anode basket is one of the most widely used structures in the electroplating industry. It has a standard tubular shape and is suitable for placement in the middle or on both sides of the electroplating tank. The cylindrical structure of titanium can achieve uniform current distribution in the electric field, which helps to improve the consistency of the coating thickness.

Contact us now

Due to its compact structure, convenient filling and smooth drainage, the cylindrical type is particularly suitable for filling anode particles or anode pellets, and is suitable for mainstream electroplating processes such as acid copper and acid nickel. Common sizes include diameter 2.5"-5", height 6"-36", and customization is supported.

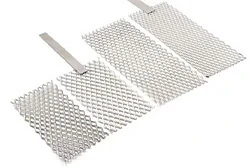

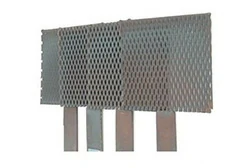

Rectangular Titanium Anode Basket

Rectangular anode baskets, with their large mesh area and high capacity, excel in electroplating large-size workpieces or production lines that require high coverage. The structure is a rectangular or cube design, which can be placed close to the tank wall to save space and increase the current output area.

Contact us now

The rectangular structure is not only suitable for carrying large volumes of anode materials, but also can be precisely adjusted according to the current density and workpiece size, improving plating consistency and production efficiency. Common widths range from 2 to 10 inches (50–250 mm) and 1.5 to 6 inches (38–150 mm), and can be extended from 6 inches to 50 inches in height (150–1270 mm).

Semi-circular titanium anode basket

The semicircular anode basket adopts a semicircular cross-section design, which is specially developed to save tank space and improve current symmetry. This structure is very suitable for the scene of multiple anodes being arranged at the same time. It can be installed close to the wall of the electroplating tank, effectively reducing the shielding effect and improving the uniformity of the electric field.

Contact us now

Semi-circular anode baskets are lightweight and flexible to operate. Semi-circular anode baskets are widely used in precision electroplating, batch processing of small parts, and equipment layouts with limited space. Common sizes that Chalco can provide are 2 to 5 inches in width (50–127 mm) and heights from 6 to 24 inches (150–600 mm).

Barrel-shaped titanium anode basket

The barrel anode basket is a conical barrel structure with different diameters at the top and bottom. It is often used to carry a large amount of anode materials to extend the electroplating time. The bottom is usually reinforced to ensure that the structure remains stable during high current density or long-term operation.

Contact us now

The common diameter of the barrel is 4 to 8 inches (100–200 mm), with a base of 2.5 to 6 inches (63–150 mm), and heights range from 10 to 36 inches (250–900 This type of basket is particularly suitable for high current density electroplating applications such as hard chrome and nickel alloys, which can effectively improve work efficiency and reduce the frequency of manual operations.

Titanium anode basket mesh type

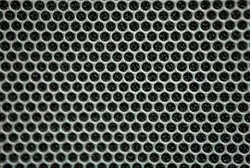

Perforated Grid

½" diameter on 11/16" staggered centers , 50% open area

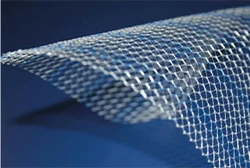

Micro-expansion mesh

3/16" SWD x 1/2" LWD , 65% mesh open area

Polypropylene mesh

1/4" diameter holes, 3/8" staggered centers, approximately 40% open area

Titanium anode basket hook design

Hook current carrying capacity and structural configuration

The hook of the titanium anode basket not only plays a hanging role, but also undertakes the key task of current conduction. Its structure and size must be precisely matched with the total current, ampere density and number of anode baskets in the electroplating tank to ensure safe and stable operation of the system and avoid thermal damage caused by current overload or poor contact.

Standard rectangular anode baskets are usually equipped with 50A double-contact hooks to meet the load requirements of conventional electroplating lines. For applications with higher current density, we offer a variety of specifications, including 75A, 100A, 150A and even 200A hook structures, which are suitable for large-scale electroplating or continuous heavy-load scenarios.

Calculate the current required per basket

In actual selection, the required carrying current of each anode basket can be calculated by the following formula:

Required AMPS per basket = Total bath current ÷ Total number of anode baskets

For example, if the total current of the plating tank is 600A and it is equipped with 6 anode baskets, each basket should use a hook that supports at least 100A.

Comparison of different hook specifications and current carrying levels

We offer a variety of hook specifications to meet different current requirements. Common configurations are as follows:

- 25A : 1/8" × 1" double contact hook, or 3/8" square rod hook

- 50A : 1/4" × 1" double contact hook, or 1/2" square rod hook

- 75A : 3/8" × 1" double contact hook, or 5/8" square rod hook

- 100A : 1/2" × 1" double contact hook, or 3/4" square rod hook

All hooks can be customized in terms of angle, length and connection method (such as U-shaped, L-shaped or straight hanging) to match plating tanks of different depths and busbar structures.

Hook selection advice

The titanium anode basket is equipped with a variety of hook and loading options: the inverted " V" and inverted "U" hooks are suitable for conventional hanging, the "T" handle hook is convenient for manual positioning, the reverse hook ensures a stable lifting angle, and the diving hook is suitable for deep tank installation; the four-sided grid design and loading chute device simplify anode filling and improve electrolyte circulation and current distribution uniformity.

For heavy-load or high-current applications, Chalco provides weighted titanium alloy or titanium-clad copper hooks, thickened mesh materials and side channel structures to enhance the load-bearing strength, current-carrying capacity and anti-deformation performance, ensuring structural stability and efficient conductivity under harsh working conditions.

Advantages of titanium anode basket

The annual corrosion rate is less than 0.02 mm

Titanium anode baskets exhibit extremely low annual corrosion rates ( <0.02 mm/year), greatly improving service life and reducing replacement frequency, making it suitable for long-term continuous operation.

5–8% reduction in voltage losses

The high conductivity structural design can effectively reduce the voltage loss of the anode system, save energy, and improve the efficiency of the entire line. It is especially suitable for high current electroplating applications.

Anode slag reduced by more than 30%

Titanium materials have strong stability and can significantly reduce the precipitation of impurities caused by uneven anode dissolution, reduce anode slag pollution, extend the service life of the electroplating solution, and improve the quality of the coating.

Temperature resistant up to 400°C

Uncoated titanium anode baskets can operate stably at 400°C and are suitable for high-temperature, high-current-density, heavy-load electroplating processes without structural deformation or performance degradation.

Application of titanium anode basket

-

Electroplating industryTitanium anode basket plays a key role in the electroplating process, which can stably carry the anode material and ensure the uniform distribution of metal ions in the electrolyte. Its excellent corrosion resistance makes it particularly suitable for acidic and high temperature electroplating environments, and is an ideal choice for processes such as acid copper, nickel plating, and hard chrome plating.

-

Chemical processingIn the chemical industry, titanium baskets are often used to hold catalysts or reactive raw materials. They are highly resistant to corrosive media such as acids and chlorides, and can operate stably for a long time in harsh environments such as high corrosion and high temperature without polluting or interfering with the chemical reaction process.

-

Water treatmentTitanium anode baskets are widely used in seawater desalination, wastewater purification and electrolytic water treatment systems to hold filter materials or electrode auxiliary media. With its ability to resist salt water and chemical corrosion, titanium baskets can maintain structural stability under continuous humid and corrosive conditions, ensuring efficient operation of the system.

Precautions for using titanium basket anode

Titanium anode baskets are widely used in electroplating processes due to their excellent corrosion resistance and structural stability. However, in order to ensure their optimal performance in actual operation and avoid structural damage, the following key usage specifications must be followed:

The basket mouth should be above the liquid level

Ensuring that the opening of the titanium basket is slightly higher than the level of the electroplating liquid helps prevent anode material or metal residue from entering the electrolyte, thereby contaminating the electroplating bath and affecting the quality of the coating and the stability of the chemical composition.

Maintain a reasonable gap between the workpiece

100-150 degrees away from the workpiece to be plated. This spacing prevents current from concentrating on the bottom of the part, thereby effectively reducing the risk of burning, uneven coating or workpiece damage due to local overheating.

Ensure that the hook has good conductive contact with the busbar

The titanium anode basket must be firmly connected to the power anode to ensure continuous conductivity and close contact at the hook. If the contact is poor, the potential will increase, causing local oxygen and chlorine evolution reactions, which will not only damage the titanium surface, but also accelerate the oxidation of organic additives in the solution, affecting the overall bath life and performance stability.

Other titanium anode products Chalco can provide

Platinum-coated titanium anode

Lead oxide titanium Anode

Ruthenium Iridium titanium anode

Titanium anode basket size chart

| Product name | Size | Structural shape |

|---|---|---|

| Titanium 24″L x 2.75″W x 6″H Anode Basket | 24″L × 2.75″W × 6″H | Rectangular basket |

| Titanium 30″L x 2.75″W x 6″H Anode Basket | 30″L × 2.75″W × 6″H | Rectangular basket |

| Titanium 32″L x 3″W x 6″H Anode Basket | 32″L × 3″W × 6″H | Rectangular basket |

| Titanium 34″L x 2.5″W x 6″H Anode Basket | 34″L × 2.5″W × 6″H | Rectangular basket |

| Titanium 36″L x 1.5″W x 6″H Anode Basket | 36″L × 1.5″W × 6″H | Rectangular basket |

| Titanium 36″L x 2.5″W x 4″H Anode Basket | 36″L × 2.5″W × 4″H | Rectangular basket |

| Titanium 36″L x 2.5″W x 6″H Anode Basket | 36″L × 2.5″W × 6″H | Rectangular basket |

| Titanium 36″L x 2.5″ x 6″H Anode Basket | 36″L × 2.5″ × 6″H | Rectangular basket |

| Titanium 36″L x 3″W x 6″H Anode Basket | 36″L × 3″W × 6″H | Rectangular basket |

| Titanium 38″L x 2.5″W x 6″H Anode Basket | 38″L × 2.5″W × 6″H | Rectangular basket |

| Titanium 38″L x 3″W x 6″H Anode Basket | 38″L × 3″W × 6″H | Rectangular basket |

| Titanium 39″L x 2.5″W x 6″H Anode Basket | 39″L × 2.5″W × 6″H | Rectangular basket |

| Titanium 39″L x 3″ x 6″ Anode Basket | 39″L × 3″ × 6″ | Rectangular basket |

| Titanium 40″L x 2.75″ x 6″ Anode Basket | 40″L × 2.75″ × 6″ | Rectangular basket |

| Titanium 30″L x 2.5″ Dia. Anode Basket | 30″L × 2.5″Dia. | Cylindrical basket |

| Titanium 34″L x 2.5″ Dia. Anode Basket | 34″L × 2.5″Dia. | Cylindrical basket |

| Titanium 38″L x 3″ Dia. Anode Basket | 38″L × 3″ Dia. | Cylindrical basket |

| Titanium 39″L x 2.25″ Dia. Anode Basket | 39″L × 2.25″Dia. | Cylindrical basket |

FAQ

Can the titanium anode basket be custom made to fit my electroplating tank dimensions?

Yes, we support fully customized services. Customers only need to provide the tank size, current load and anode type used, and we can provide drawings and recommended structures within 24 hours to ensure that the anode basket size, current load and hook match your process needs.

What coatings are available for titanium anode baskets?

We offer a variety of functional coatings, including MMO (mixed metal oxide), platinum (Pt), ruthenium-iridium (Ru-Ir) and titanium primary (uncoated). Different coatings are suitable for different electroplating environments. MMO and platinum coatings are particularly suitable for use in high current or alkaline solutions, which can significantly extend the service life and improve the electrochemical performance.

Are material quality inspection reports and certifications provided?

Yes, all anode baskets come with a material inspection certificate and welding inspection report. If required, we can also provide third-party testing services such as XRF material analysis, titanium purity testing, dimensional tolerance report, etc.

What is the lead time for titanium anode baskets?

7–15 working days , depending on the complexity of the structure . We support expedited production services and can arrange global air or sea shipments.

Are samples of anode baskets available?

Yes, we can provide standard mesh or structure samples for testing and verification. For bulk orders, samples can be deducted from part of the order amount.