Titanium Ball

Updated : Nov. 25, 2025Titanium balls, with their lightweight, high strength, and excellent corrosion resistance, have become an ideal alternative to steel and ceramic balls. Whether in high-precision bearings and valves, or in medical implants and jewelry accessories, titanium balls maintain stable performance in harsh environments.

Chalco specializes in supplying solid titanium spheres, hollow titanium spheres, and various machined titanium spheres, covering a full range of needs from industrial to medical grades. Leveraging our complete titanium material production chain and precision machining capabilities, we offer customized solutions in multiple sizes, alloys, and surface treatments, helping customers achieve lightweight and long-life solutions.

Basic Titanium Balls | Solid & Hollow Titanium Ball

Chalco offers a full range of products, from tiny precision spheres (Ø2 mm level) to large-diameter structural titanium spheres (Ø100 mm and above), covering both solid and hollow titanium spheres, which can meet the needs of high-precision mechanical parts as well as lightweight structural parts and decorative applications.

-

Solid Titanium Balls

Made from pure or alloyed titanium, providing strong, wear-resistant, corrosion-resistant, non-magnetic performance for valves, pumps, bearings, and high-load parts.

-

Hollow Titanium Balls

Hollow titanium spheres offer lightweight strength for decoration, display, and aerospace uses, with customizable wall thickness.

- Materials available: Gr1, Gr2, Gr5 (Ti-6Al-4V), Gr9, etc.

- Tolerance accuracy: ±0.005 mm – ±0.05 mm

- Diameter range: Ø 2 mm – Ø 100 mm (larger sizes available upon request)

| Gauge Size Chart (Hot-Selling Titanium Balls) | |||||

|---|---|---|---|---|---|

| 25g | 20g | 18g | 16g | 14g | 12g |

| 10 g | 8 g | 6 g | 4 g | 0g | 00g |

| Inch Diameter Chart (Popular Titanium Ball Sizes) | ||||||

|---|---|---|---|---|---|---|

| 3/32" | 1/8" | 5/32" | 3/16" | 7/32" | 1/4" | 9/32" |

| 5/16" | 3/8" | 7/16" | 1/2" | 9/16" | 5/8" | 11/16" |

| 3/4" | 7/8" | 15/16" | 1" | 1-1/8" | 1-1/4" | |

| Metric Diameter Chart (mm Titanium Balls) | ||||||

|---|---|---|---|---|---|---|

| 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| 12mm | 15mm | 18mm | 20mm | 25mm | 30mm | 35mm |

| 40mm | 45mm | 50mm | 60mm | 80mm | 100mm | |

For the full range of specifications, please visit our [ Detailed Titanium Ball Size Chart ]

Processed & Functional Titanium Balls

Building upon its foundation of solid and hollow titanium spheres, Chalco leverages its comprehensive titanium machining capabilities to offer a variety of functional titanium sphere products. Through CNC finishing, thread cutting, precision drilling, and surface treatment, we provide more practical options for the industrial, medical, and jewelry sectors.

Drilled Titanium Balls

Titanium balls with through holes can be machined into smooth holes or internal threads for use in chains, jewelry accessories, and medical fasteners.

Threaded Titanium Balls

The externally threaded sphere, CNC machined, is easy to install and not easily loosened, making it suitable for earrings and mechanical end components.

Bearing Titanium Balls

High-precision grinding with strict tolerances, widely used in high-speed bearings, valves and pump bodies.

Polished Titanium Balls

Mirror polishing/sandblasting finish provides an exquisite appearance and corrosion resistance, commonly used in high-end jewelry and architectural decoration.

Titanium Ball Chains

Chains made of multiple titanium beads strung together can be anodized and colored, and are commonly used in jewelry, decorations, and personalized accessories.

Decorative Titanium Beads

Individual titanium beads, anodized for coloring, suitable for jewelry, DIY ornaments, and chain accessories.

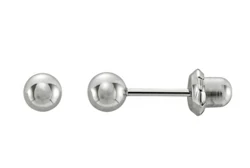

Titanium Earring Balls

Small titanium ball earrings with a polished surface, safe and comfortable for long-term wear.

Titanium Studs / Pins

Titanium studs with titanium balls at the ends are precision-machined and suitable for jewelry, piercing parts, and lightweight connections.

Medical-Grade Ti Balls

Utilizing Ti-6Al-4V / Ti-6Al-7Nb, it exhibits excellent biocompatibility and is used for implantation and medical perforation.

Ti-6Al-4V Titanium Balls

High-strength alloy titanium balls, suitable for aerospace, medical and high-load industrial applications.

3D Printing Titanium Balls

Additive manufacturing is a molding process suitable for complex structures or small-batch customization.

Customized Titanium Balls

Customizable diameter, structure, and surface treatment, covering processes such as drilling, tapping, and anodizing.

Chalco Titanium Ball Customization & Supply Capability

Chalco not only offers standardized specifications, but also provides highly customized production to meet your project needs, ensuring that its titanium balls are precisely suited to practical applications.

Customizable sizes: From micron-sized small diameters to large spheres, all sizes can be customized to meet the needs of medical implantation, precision machinery, architectural decoration and other scenarios.

Alloy selection: covering pure titanium (Gr1~Gr4) and various titanium alloys (such as Ti-6Al-4V, Ti-6Al-7Nb), taking into account lightweight, strength and corrosion resistance.

Structure and processing: Supports various structures such as solid, hollow, drilled, and threaded, and can perform subsequent processes such as tapping, thread rolling, polishing, and anodizing.

Precision and Surface Finish: Strict control over roundness and tolerances, offering mirror polishing, matte finish, or colored anodizing effects, balancing functionality and aesthetics.

Supply and delivery: Supports small-batch sample development and large-batch stable supply, with short delivery cycle, comes with EN 10204/3.1 report, and fast global shipping.

Titanium Ball Application & Cooperation Gallery

titanuim 's titanium balls, available in various diameters, precision levels, and alloy systems, are widely used in industrial, medical, aerospace, decorative, and sporting goods industries. The table below showcases typical specifications and corresponding application examples to help clients quickly identify project needs.

1 – 10 mm Titanium Ball

Tolerance: ±0.005 mm

Common Materials: Gr2, Gr5

Surface Finish: Polished/Anodized

Applications: Precision bearings, medical perforation fittings

11 – 30 mm Titanium Ball

Tolerance: ±0.01 mm

Common Materials: Gr2, Gr5

Surface Finish: Polished/Sandblasted

Applications: Valves, pump bodies, mechanical parts

31 – 80 mm Titanium Ball

Tolerance: ±0.02 mm

Common Materials: Gr2, Gr9

Surface Finish: Polished/Anodized

Applications: Decorative pieces, sports equipment

81 – 200 mm Titanium Ball

Tolerance: ±0.05 mm

Common Materials: Gr2, Gr5

Surface: Polished/Custom Coating

Applications: Architectural facades, aerospace structural components, large display spheres

Frequently Asked Questions (FAQ)

What are the advantages of titanium balls compared to steel and ceramic balls?

A1: Titanium balls are lighter, more corrosion-resistant, and non-magnetic, making them suitable for medical, jewelry, and marine environments; they are less prone to rusting than steel balls and are more resilient and flexible in processing than ceramic balls.

What are the largest and smallest sizes of titanium spheres you can provide?

We can produce spheres ranging from 1 mm in diameter to 200 mm in diameter, with tolerances controllable within ±0.005 mm, meeting diverse needs from precision parts to architectural decorations.

What specifications do threaded titanium balls support?

Internal and external threads can be machined according to customer needs, supporting common metric and imperial thread profiles, suitable for various applications such as jewelry piercing parts and mechanical fasteners.

Can you provide medical-grade titanium balls?

Yes, Chalco provides medical-grade alloy titanium balls such as Ti-6Al-4V and Ti-6Al-7Nb, which have excellent biocompatibility and can be accompanied by EN 10204/3.1 material reports and medical-grade testing certificates.

Can colors or surface treatments be customized?

We support a variety of processes such as mirror polishing, sandblasting, anodizing (including colored), and custom coatings, which can meet both functional and decorative needs.

Does it support small batch and fast delivery?

Yes, it supports small batch sample making and mass production. Common specifications are in stock and can be delivered quickly worldwide.

Choose Chalcotitanuim — More Than a Titanium Ball Supplier

We not only supply standard titanium balls, but also focus on the entire manufacturing and quality management process to ensure that every titanium ball meets the precision application requirements of our customers. This is why so many customers choose Chalco:

Full-process machining capabilities: covering CNC turning, drilling, thread rolling, tapping, polishing, anodizing, etc., flexibly meeting a variety of needs.

Micrometer-level precision control: Strict control over dimensions and roundness to ensure assembly stability and high-speed operation reliability.

Comprehensive testing system: Through microscopic inspection, ultrasonic testing and penetrant testing, we ensure that the product is internally dense and free of cracks and externally free of defects.

International certification guarantee: The production system complies with ISO9001 and AS9100 aviation standards, and can provide EN 10204/3.1 material reports and RoHS/REACH certification, meeting the stringent requirements of multiple fields such as medical, aviation, and industry.

Contact us today for a one-stop titanium ball solution tailored to your project needs. Chalco offers 24/7 rapid quotes, sample making, and global delivery support to help your business launch efficiently.

Chalcotitanium Titanium Ball Size Reference Table

| Diameter (inch) | Diameter (mm) | Tolerance | Notes / Typical Use |

|---|---|---|---|

| 1/32 in | 0.781 mm | ±0.001 in | Micro titanium ball |

| 1/16 in | 1.5625 mm | ±0.001 in | Small titanium ball |

| 5/64 in | 1.9844 mm | ±0.001 in | Jewelry & accessory use |

| 3/32 in | 2.3813 mm | ±0.001 in | Precision small ball |

| 7/64 in | 2.7344 mm | ±0.001 in | – |

| 1/8 in | 3.175 mm | ±0.001 in | Common industrial size |

| 5/32 in | 3.9688 mm | ±0.001 in | – |

| 3/16 in | 4.7625 mm | ±0.001 in | – |

| 7/32 in | 5.5469 mm | ±0.001 in | – |

| 15/64 in | 5.9063 mm | ±0.001 in | – |

| 1/4 in | 6.35 mm | ±0.001 in | General industrial ball |

| 17/64 in | 6.7375 mm | ±0.001 in | – |

| 9/32 in | 7.2188 mm | ±0.001 in | – |

| 5/16 in | 7.9375 mm | ±0.001 in | – |

| 11/32 in | 8.5875 mm | ±0.001 in | – |

| 3/8 in | 9.525 mm | ±0.001 in | Larger precision ball |

| 13/32 in | 10.3188 mm | ±0.001 in | – |

| 13/31 in | 10.4194 mm | ±0.001 in | – |

| 7/16 in | 11.1125 mm | ±0.001 in | – |

| 29/64 in | 11.4844 mm | ±0.001 in | – |

| 15/32 in | 11.9063 mm | ±0.001 in | – |

| 31/64 in | 12.3875 mm | ±0.001 in | – |

| 1/2 in | 12.70 mm | ±0.001 in | Standard medium size |

| 17/32 in | 13.4813 mm | ±0.001 in | – |

| 9/16 in | 14.2875 mm | ±0.001 in | – |

| 19/32 in | 15.1625 mm | ±0.001 in | – |

| 5/8 in | 15.875 mm | ±0.001 in | – |

| 21/32 in | 16.4813 mm | ±0.001 in | – |

| 11/16 in | 17.4625 mm | ±0.001 in | – |

| 23/32 in | 18.3625 mm | ±0.001 in | – |

| 3/4 in | 19.05 mm | ±0.001 in | Large titanium ball |

| 7/8 in | 22.225 mm | ±0.001 in | – |

| 15/16 in | 23.8125 mm | ±0.001 in | – |

| 1 in | 25.40 mm | ±0.001 in | Standard 1-inch ball |

| 0.5 mm | 0.02 in | ±0.025 mm | Ultra micro titanium ball |

| 0.7 mm | 0.028 in | ±0.025 mm | – |

| 0.8 mm | 0.031 in | ±0.025 mm | – |

| 1.0 mm | 0.039 in | ±0.025 mm | Precision micro ball |

| 1.2 mm | 0.047 in | ±0.025 mm | – |

| 1.3 mm | 0.051 in | ±0.025 mm | – |

| 1.5 mm | 0.059 in | ±0.025 mm | – |

| 2.0 mm | 0.079 in | ±0.025 mm | Common jewelry ball |

| 2.5 mm | 0.098 in | ±0.025 mm | – |

| 3.0 mm | 0.118 in | ±0.025 mm | Piercing & accessory size |

| 3.5 mm | 0.138 in | ±0.025 mm | – |

| 4.0 mm | 0.157 in | ±0.025 mm | – |

| 4.5 mm | 0.177 in | ±0.025 mm | – |

| 5.0 mm | 0.197 in | ±0.025 mm | Jewelry & industrial use |

| 5.5 mm | 0.217 in | ±0.025 mm | – |

| 6.0 mm | 0.236 in | ±0.025 mm | Industrial common size |

| 6.5 mm | 0.256 in | ±0.025 mm | – |

| 7.0 mm | 0.276 in | ±0.025 mm | – |

| 7.5 mm | 0.295 in | ±0.025 mm | – |

| 7.98 mm | 0.314 in | ±0.025 mm | – |

| 8.0 mm | 0.315 in | ±0.025 mm | – |

| 8.5 mm | 0.335 in | ±0.025 mm | – |

| 9.0 mm | 0.354 in | ±0.025 mm | – |

| 9.5 mm | 0.374 in | ±0.025 mm | – |

| 10.0 mm | 0.394 in | ±0.025 mm | Widely used size |

| 11.0 mm | 0.433 in | ±0.025 mm | – |

| 11.5 mm | 0.453 in | ±0.025 mm | – |

| 12.0 mm | 0.472 in | ±0.025 mm | – |

| 13.0 mm | 0.512 in | ±0.025 mm | – |

| 14.0 mm | 0.551 in | ±0.025 mm | – |

| 15.0 mm | 0.591 in | ±0.025 mm | – |

| 16.0 mm | 0.630 in | ±0.025 mm | – |

| 17.0 mm | 0.669 in | ±0.025 mm | – |

| 18.0 mm | 0.709 in | ±0.025 mm | – |

| 19.0 mm | 0.748 in | ±0.025 mm | – |

| 20.0 mm | 0.787 in | ±0.025 mm | – |

| 21.0 mm | 0.827 in | ±0.025 mm | – |

| 22.0 mm | 0.866 in | ±0.025 mm | – |

| 23.0 mm | 0.906 in | ±0.025 mm | – |

| 24.0 mm | 0.945 in | ±0.025 mm | – |

| 25.0 mm | 0.984 in | ±0.025 mm | Larger titanium sphere |