Titanium Elbow

Updated : Jun. 26, 2025Titanium elbows meet ASTM B363 and ASME B16.9 standards.

They resist high temperatures and corrosion, and are ready for welding right out of the box after ultrasonic cleaning.

Formed in one piece with no wrinkles, they reduce weight and boost efficiency—an ideal choice for exhaust systems and industrial piping.

Titanium elbow standards

Our titanium elbows comply with international manufacturing and dimensional standards, including ASTM B363, ASME B16.9, ASME B36.19M, MSS-SP-43, and JIS B2312. EN 10204 3.1 material certificates are available upon request.

Standard marking is done by electrochemical etching, meeting ASME requirements for permanent identification.

We are certified to ISO 9001, GJB 9001, AS9100, PED, IATF 16949, and Lloyd’s Register (LR). Industry-specific compliance documents such as NACE MR0175 and NORSOK M-650 can also be provided.

Titanium elbow alloys

We offer a full range of titanium alloys, including Grade 1, 2, 5, 7, 9, and 12. These materials are widely used in industrial piping, seawater systems, and chemical processing equipment.

Grade 2 and Grade 7 are especially popular in the U.S. automotive exhaust modification market.

-

Grade 2 Titanium Elbow UNS R50400

Grade 2 Titanium Elbow UNS R50400General-purpose titanium elbows for chemical, pharmaceutical, and desalination industries.

cost-effective corrosion-resistant most popular -

Grade 1 Titanium Elbow UNS R50250

Grade 1 Titanium Elbow UNS R50250Ideal for low-pressure, low-temperature use like cooling or seawater systems.

high ductility easy to machine corrosion-resistant -

Grade 7 Titanium Elbow UNS R52400 Ti-0.2Pd

Grade 7 Titanium Elbow UNS R52400 Ti-0.2PdDesigned for elbows in highly corrosive environments, especially with chlorine or strong oxidizing media.

high stability chloride corrosion resistant crevice corrosion resistant -

Grade 5 Titanium Elbow UNS R56400 Ti-6Al-4V

Grade 5 Titanium Elbow UNS R56400 Ti-6Al-4VUsed in high-strength, high-temperature, high-pressure elbows for aerospace, deep-sea, or defense systems.

high strength heat resistant lightweight -

Grade 12 Titanium Elbow UNS R53400 Ti-0.3Mo-0.8Ni

Grade 12 Titanium Elbow UNS R53400 Ti-0.3Mo-0.8NiSuitable for elbows with high heat and stress corrosion resistance, such as heat exchangers and acid gas systems.

corrosion resistant heat resistant high strength -

Grade 9 Titanium Elbow UNS R56320 Ti-3Al-2.5V

Grade 9 Titanium Elbow UNS R56320 Ti-3Al-2.5VIdeal for titanium elbows requiring medium strength and lightweight design.

high strength good formability heat resistant

Titanium elbow popular products

We offer titanium elbows in a variety of angles from 30° to 180°, with 45°, 90°, and 180° being the most common. Custom angles and multiple end types—such as butt weld, threaded, and NPT—are available to fit exhaust and industrial piping needs.

Manufactured to ASME B16.9 standards, titanium elbows are available in sizes from 0.5 inch to 48 inches.

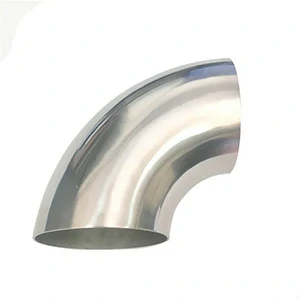

Titanium 90° elbows – the top choice for racing-grade performance

Titanium 90° Elbows

Size: 1″ – 4″

Radius: 1.0D, 1.2D, 1.5D, 3D

Wall thickness: 1 mm, 1.2 mm, 1.5 mm (Sch 10S / Sch 40S)

Grades: Grade 2, Grade 7, Grade 1

- Seamless – No weld crack risk, handles 35 bar.

- Heat resistant – Stays strong up to 600 °C.

- Pre-polished – Ready to weld, faster assembly.

- Ideal for: racing headers, turbo bends, high-temp pipes.

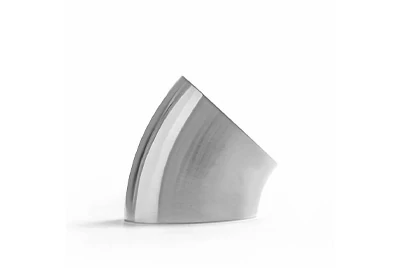

Titanium 45° elbows – lightweight and smooth exhaust bend

Titanium 45° Elbows

Size: 2.5″, 3″, 4″

Wall thickness: 1 mm, 1.2 mm (Sch 10S / 40S)

Radius: R 1.0D, R 1.5D

Grades: Grade 2, Grade 7

- Mandrel-formed – Smooth, wrinkle-free flow path for quieter exhaust.

- 1 mm / 1.2 mm wall – Only ~150 g per piece (2.5" × 1 mm).

- Precision ±0.5° – Easy alignment with V-band and titanium straight pipe.

- Applications: race turn pipes, motorcycle exhaust mods, process line pressure drops.

Titanium 60° Elbows

Titanium 60° Seamless Elbows

Size: 1″, 1.5″, 2″, 2.5″, 3″ (up to NPS 12″)

Wall thickness: 1 mm / 1.2 mm (Sch 10S / 40S)

Grades: Standard R 1.5D

Radius: Grade 2, Grade 5

- Features: mid-angle bend design reduces back pressure; seamless construction with smooth inner and outer surfaces.

- Typical applications: custom exhaust mid-pipes, chemical flow reducers, vacuum system turns.

Titanium 180° Elbows

Titanium 180° Seamless Elbows

Size: 1/2″, 1″, 1.5″, 2″, 2.5″, 3″, 4″, 4.5″, 5″ (up to 16″)

Wall thickness: 1 mm, 1.2 mm, 2 mm (Sch 10S / 40S)

Radius: R 1.0D, R 1.5D

Grades: Grade 2, Grade 5

- Mandrel forming ensures uniform wall thickness for smooth steam/oil return flow.

- Chamfered and deburred ends—ready to weld and install.

- Applications: turbo oil return, heat exchanger coils, high-temp recirculation lines.

Titanium 30° Elbows

Titanium 30° Seamless Elbows

Radius: R 1.5D

Grade: Grade 2

Smallest bend angle, ideal for tight spaces.

For full elbow specifications or wall thickness weight charts, feel free to request them along with your inquiry email.

Quotes available within 24 hours; in-stock items ship in as fast as 3 days.

Contact our technical sales team today! Quick Quote

Titanium elbow connection types to suit different applications

We offer standard butt-weld elbows, flange-compatible elbows, NPT threaded elbows, and custom connection designs based on your project needs.

Supports various interface standards, including ANSI, DIN, and JIS.

Butt-weld titanium elbows

The most common connection type, ideal for medium to high-pressure industrial systems. Offers high weld strength and excellent sealing.

Contact us now

Socket Weld

Used for small to medium pipe sizes, often found in forged elbows or instrumentation fittings.

Contact us nowThreaded connection

Commonly used in small-diameter, low-pressure systems or instrument lines. Easy to install.

Contact us now

Flange connection

Ideal for systems that require frequent disassembly and maintenance, such as chemical equipment and heat exchanger inlets/outlets.

Contact us nowMultiple titanium elbow manufacturing options available

Whether it's standard seamless elbows or custom-welded large-diameter products, we provide tailored manufacturing solutions to meet your project needs.

Feel free to send us your drawings or specifications for a consultation.Quick Quote

Butt-weld bevel titanium elbows

Precision-machined bevels ensure stronger weld joints. Widely used in medium to high-pressure industrial piping systems. Compliant with ASME B16.9.

Seamless titanium elbows

Formed from seamless titanium pipes through hot pressing or pushing. Smooth inner surface and solid structure make them ideal for high-demand, small to medium-diameter applications like exhaust and ultra-clean piping.

Welded titanium elbows

Fabricated by welding titanium plates or pipes. Suitable for large-diameter elbows in projects such as chemical processing, desalination, and water treatment.

Forged titanium elbows

Made from titanium bars or billets by die forging. Higher strength, perfect for high-pressure or mission-critical systems in petrochemical, marine, and defense sectors.

Stamped / cast titanium elbows

Stamping is ideal for mass production of small and mid-sized elbows, while casting suits non-standard or complex-shaped designs.

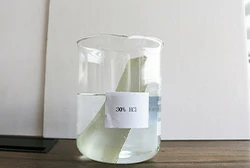

Surface finishing options

Titanium elbows commonly undergo pickling, sandblasting, or electropolishing to meet various needs—from industrial corrosion protection to ultra-clean process piping.

-

Pickling

A common default treatment that removes oxide scale and impurities from the heat-affected zone.

-

Sand blasting

Creates a uniform matte texture, often used for automotive exhaust modifications.

-

Electropolishing, EP

Enhances inner surface smoothness (Ra < 0.4 μm), ideal for high-purity applications.

-

Mechanical Polishing

Used for moderate surface smoothness, uniform appearance, and smooth weld transitions.

Anodizing and passivation are available to achieve both decorative color finishes and a stable TiO₂ oxide layer, meeting project requirements for appearance and corrosion resistance.

We can also customize surface finish standards—such as Ra value, passivation grade, and decorative color—based on your project requirements, ensuring both performance and appearance. Quick Quote

Titanium elbow advantages

- Excellent corrosion and fatigue resistance for long service life and reduced maintenance costs.

- Low density with high strength—superior strength-to-weight ratio compared to stainless steel, enabling weight reduction without sacrificing pressure capacity.

- Supports TIG and butt welding with stable performance and high assembly efficiency.

- Maintains structure and strength under high temperatures from 300–500 °C without deformation.

- Good toughness at low temperatures, no risk of embrittlement—ideal for extreme cold applications like LNG systems.

- Smooth inner walls reduce flow resistance and scaling, suitable for high-purity or corrosive media transport.

- Easy to cold bend, hot bend, and machine, perfect for customized non-standard designs.

Titanium elbow applications

Automotive & racing exhaust

45° and 90° seamless thin-wall titanium elbows (1–1.2 mm) withstand exhaust temperatures up to 600 °C. They reduce vehicle weight and minimize weld points.

Contact us now

Chemical & petrochemical

Titanium elbows operate reliably in pipelines carrying concentrated sulfuric acid, hydrochloric acid, and chlorine-containing media, preventing pitting and reducing downtime.

Contact us nowSeawater & marine engineering

Ideal for FPSO cooling systems, desalination units, and ship pipelines. Titanium offers about 150% better seawater corrosion resistance than stainless steel.

Contact us now

Oil & gas / LNG

Titanium elbows in high-pressure oil and gas or low-temperature LNG lines ensure both pressure resistance and anti-brittle performance, enhancing system safety.

Contact us nowHeat exchange systems

Maintain strength and shape stability at 300–400 °C, reducing downtime caused by thermal deformation.

Contact us now

Aerospace

Grade 5 titanium elbows are used in fuel, hydraulic, and intercooler lines to achieve both weight reduction and 500 °C heat resistance.

Contact us nowSmall-diameter / forged elbows

¼″–¾″ NPT or SW titanium forgings are used in pneumatic and hydraulic control loops, balancing formability and corrosion resistance.

Contact us now

Real case: titanium elbows used in U.S. automotive exhaust system

Velocity Motorsport, a California-based team specializing in American street and track car modifications, selected our Grade 2 90° and 45° seamless titanium elbows for their Toyota GR Supra (A90) exhaust upgrade project.

The goal was to reduce weight, lower temperatures, and improve exhaust flow without sacrificing power.

The original stainless steel exhaust system weighed nearly 18 kg. After switching to titanium elbows and mid-pipes, total weight dropped by about 45%, saving over 8 kg.

In real-world testing, engine bay temperature dropped by around 10 °C, weld joints were reduced by more than two, and exhaust backpressure significantly decreased.

The corrosion resistance and structural stability of the titanium elbows allowed the vehicle to maintain consistent performance during extended high-RPM and high-temperature runs.

No weld cracking or joint leakage occurred, earning high praise from multiple track customers.

Quality control & production assurance

We are equipped with advanced manufacturing and testing systems, including plasma welding machines, CNC machining centers, pipe pushing machines, plate rollers, spectrometers, and X-ray inspection.

These ensure high precision, stable quality, and reliable performance for every titanium elbow.

All production follows strict international standards, with rigorous quality checks to guarantee each titanium elbow meets the highest standards of accuracy and reliability.

Hydrostatic pressure test

Intergranular corrosion test

Surface quality inspection

Dimensional accuracy inspection

Mechanical property test

Chemical composition analysis

We guarantee that every batch of products is delivered with material certificates, dimensional records, and, when required, third-party test reports (such as SGS or TÜV), ensuring trusted quality for our global customers. Quick Quote

Packaging & shipping information

All titanium elbows are ultrasonically cleaned before shipping to remove oil and impurities. After sealed packaging, they are ready for welding right out of the box—ensuring clean, safe, and efficient installation.

We offer various packaging options based on product size and export requirements:

- Small fittings are packed in PP boxes with multilayer protective film and outer cartons.

- Standard bulk orders use custom cartons with reinforced foam padding and pallet strapping.

- Export shipments are packed in fumigated or fumigation-free wooden crates, each about 1 cubic meter and under 1 ton.

- Large elbows are packed individually in wooden crates with shock and impact protection.

Each package includes clear labeling with size, material, batch number, manufacturer details, and customer-specific markings for easy receiving and traceability.

Related products

If you need to purchase multiple materials or fitting combinations, we offer one-stop project solutions and bundled quotations. Feel free to contact us for more details.

Titanium tees

Titanium reducers

Titanium flanges

Titanium welding wire & rods

Titanium seamless pipes

Titanium welded pipes

Frequently asked questions (FAQ)

Why is titanium called "titanium”?

The name "titanium” comes from the Titans in Greek mythology, symbolizing strength and durability. In 1795, German chemist Martin Klaproth discovered the element in rutile and named it after the Titans.

What is ASME B16.9?

ASME B16.9 is a manufacturing standard for industrial pipe fittings. It defines dimensions, tolerances, and forming requirements for elbows, tees, reducers, and includes both short-radius and long-radius elbows.

What's the difference between 90° and 45° titanium elbows?

A 90° elbow makes a sharp directional change, suitable for layouts where space allows. A 45° elbow provides a smoother transition, ideal for reducing pressure loss or for gradual turns.

Which high-temperature systems can use titanium elbows?

Titanium elbows withstand continuous temperatures up to 600°C, making them ideal for exhaust manifolds, turbo hot sides, and heat exchangers.

Are titanium elbows suitable for welding?

Yes. Titanium has excellent weldability and is commonly joined by TIG or butt welding. Our elbows are ultrasonically cleaned before delivery—ready to weld out of the box, saving installation time.