Titanium and Titanium Alloy Equipment

Updated : Jun. 26, 2025Titanium alloys have become an important material for the manufacture of high-end industrial and consumer equipment due to their excellent corrosion resistance, strength-to-weight ratio and good processing performance. From chemical, pharmaceutical, energy to sports and fitness and outdoor sports, titanium alloy equipment has shown wide adaptability and significant advantages in various scenarios.

Chalcotitanium is committed to providing high-performance titanium alloy equipment for various demanding industries. Relying on advanced welding technology, custom manufacturing capabilities and strict quality control system, our equipment is widely used in chemical, pharmaceutical, marine engineering, power, environmental protection and consumer products and other fields, meeting the stringent requirements for strength, corrosion resistance and long-term stability in extreme environments.

- Chalcotitanium Titanium Alloy Equipment Product Type & Industry Supporting Description

- Chalcotitanium Titanium Alloy Sports/Outdoor Equipment Products

- Chalcotitanium titanium alloy equipment production and processing capabilities

- Advantages and application prospects of titanium alloy equipment

Chalcotitanium titanium alloy equipment product type & industry supporting description

Chalcotitanium provides a variety of titanium alloy equipment, including titanium heat exchangers, titanium storage tanks, titanium reactors, titanium coils and titanium pressure vessels. Our titanium alloy equipment has excellent corrosion resistance, high temperature resistance and strength, and can maintain long-term stable operation in harsh working environments, meeting the needs of high cleanliness, high corrosion and high strength applications.

We provide titanium alloy equipment solutions for multiple industries, including chemical, pharmaceutical, energy, marine engineering and other fields. Our products are widely used in key process links such as chemical medium treatment, seawater cooling system, fine chemical reaction and high-pressure container storage, providing customers with reliable and efficient equipment support.

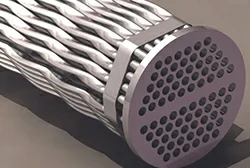

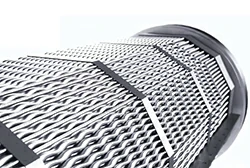

Titanium heat exchanger equipment

Titanium alloy heat exchangers offer excellent corrosion resistance and thermal conductivity, making them ideal for harsh environments. Chalcotitanium provides shell-and-tube, plate, and coil types using TA1, TA2, Gr.2 alloys, suitable for seawater, chemicals, and pharmaceuticals.

Contact us now

Shell and Shell Heat Exchanger

Seawater cooling system, oil refining, power station cooling system ...

Plate Heat Exchanger

Desalination equipment, pharmaceutical cooling and heating equipment, food processing equipment …

Condenser and Evaporator

Industrial refrigeration equipment, air conditioning systems, volatile chemical cooling and recovery equipment …

Floating Head Heat Exchanger

Heat exchange system of thermal power or nuclear power plant, high temperature steam and cooling medium...

Shell and Tube / Multi-Tube Heat Exchanger

Chemical processing equipment, seawater cooling equipment, wastewater treatment and gas purification equipment …

Coil Heat Exchanger

Chemical plant reaction tower cooling, cooling tower and cooling water system...

Threaded Twisted Tube Heat Exchanger

Seawater desalination cooling equipment, chemical reaction cooling equipment, food production heating and cooling equipment ...

Twisted Tube Heat Exchanger

Efficient, energy-saving heat exchangers for petroleum, chemical, and natural gas high-temperature fluids…

U-Tube Heat Exchanger

Liquid gas exchange equipment for petroleum refining process, cooling or heating equipment for chemical reaction liquid ...

Titanium tank

Chalcotitanium titanium alloy storage tanks are widely used to store highly corrosive chemicals, pharmaceutical solutions and high-purity substances. Due to the excellent corrosion resistance of titanium alloys, these tanks can maintain stability for a long time in highly corrosive environments, ensuring safe storage and efficient use of products.

Contact us now

Vertical Titanium Storage Tank

Large chemical storage, petrochemical, pharmaceutical industry

Horizontal Titanium Storage Tank

Food and beverage industry, storage of hazardous goods

Customized Titanium Tanks

Storage requirements for special environments or special requirements

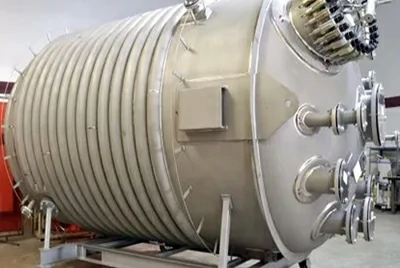

Titanium Reactor

Chalcotitanium titanium alloy reactors are often used in chemical, pharmaceutical and other highly corrosive environments, and are suitable for strong corrosion and strong oxidation reaction conditions. Titanium alloys maintain their corrosion resistance under extreme temperatures and pressures, ensuring the efficiency and safety of chemical reactions.

Contact us now

High Pressure Titanium Reactor

High-pressure synthesis reactions, such as polymerization reactions in petrochemicals

Low Temperature Titanium Reactor

Reactions of liquefied gases, low temperature chemical reactions

Fully Enclosed Titanium Reactor

Pharmaceutical and food industries with high cleanliness requirements

Titanium pressure vessel

Chalcotitanium titanium alloy pressure vessels have good strength and corrosion resistance, can carry high-pressure gas or liquid, and are widely used in petrochemical, energy and environmental protection, hydrogen energy and other fields to ensure safe and reliable storage and transportation functions.

Contact us now

Titanium Gas Cylinder

High-pressure gas storage and transportation, gas compression system

Titanium Liquid Storage Container

Chemical liquid storage, hazardous goods storage

Titanium Pressurized Vessel

High-pressure chemical reactions, oil and gas refining

Chalcotitanium titanium alloy sports/outdoor equipment products

In addition to various types of industrial titanium alloy equipment, Chalcotitanium also has the ability to manufacture and customize high-performance titanium alloy products for the sports and outdoor fields. With our technical accumulation in titanium material processing, welding, precision forming, etc., we provide a variety of titanium alloy products including mountaineering equipment, bicycle parts, and fitness equipment to multiple professional brands and end users, meeting their stringent requirements for strength, lightness, corrosion resistance, and long-term reliability.

Titanium Climbing Equipment

Trekking poles, climbing hooks, rope buckles, etc.

Titanium Alloy Fitness Equipment

Dumbbells, barbells, pullers, strength training racks, etc.

Titanium Bicycle Parts

Frame, stem, crank, seat post, pedal spindle, etc.

Titanium Ski Equipment Parts

Ski poles, bindings, connecting structures, etc.

Titanium Camping Cookware and Tools

Titanium pots, cups, knives and forks, portable tools, etc.

Titanium Alloy Sports Auxiliary Accessories

Sports bottles, buckles, glasses frames, back clips, etc.

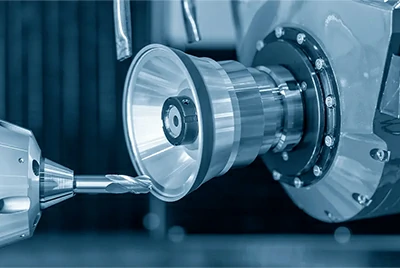

Chalcotitanium titanium alloy equipment production and processing capabilities

As a professional manufacturer of titanium alloy equipment and products, Chalcotitanium has integrated manufacturing capabilities from raw material selection to finished product delivery, covering a variety of welding processes, precision machining, heat treatment, surface treatment and other key links, fully meeting the customization needs of complex structural parts and high-standard application scenarios. With advanced processing technology and strict quality control, we serve multiple industries such as chemical, medical, energy, and sports, providing customers with titanium alloy product solutions with reliable performance and precise structure.

Welding process capability

TIG welding (tungsten inert gas welding): widely used for high-quality welding of small and medium-sized equipment and thin-walled parts, suitable for scenes with high requirements for weld cleanliness;

MIG welding (metal inert gas welding): suitable for high-efficiency welding of thicker workpieces;

Automatic welding and orbital welding technology: used for high-precision welding of key parts such as pipeline systems and pressure vessels to ensure the consistency and strength of welds;

Vacuum welding and local inert gas shielded welding: used for processing titanium components with high cleanliness requirements in medical, aviation and other fields.

Precision processing and customization capabilities

We can perform high-precision cutting, turning, milling, drilling, curling and other processing operations on titanium materials, and provide a variety of surface treatment processing methods to meet different structural design and functional requirements:

- Supports processing of thin-walled parts with a wall thickness starting from 0.5mm and large-diameter container structures;

- It can realize multi-section butt welding of titanium equipment, manufacturing of conical structures and special-shaped pipe fittings;

- We provide customized services from structural design optimization to whole machine assembly, covering both small batch and multi-variety and large batch stable production needs.

- Provide heat treatment such as annealing and solution treatment to improve material structure, ductility and fatigue resistance;

- We provide sandblasting, pickling, electropolishing, anodizing surface treatment, etc. to enhance the corrosion resistance, cleanliness and aesthetics of the titanium surface.

Quality control system

We strictly implement international quality standards to ensure the consistency of performance and reliability of each titanium alloy product:

- ASTM, GB, PED, ISO 9001, ISO 13485 and other related standards;

- Welds can be subjected to non-destructive testing such as X-ray testing (RT), ultrasonic testing (UT), and penetration testing (PT) as required;

- Provide complete material reports, process records and third-party testing and certification to ensure that the source of materials and processes are traceable.

Titanium alloy equipment: Why is it becoming the first choice for more and more companies?

"Previously, when we were dealing with heat exchange equipment in chlorinated environments, we had to replace core components almost once a year. Later, we switched to titanium alloy equipment, and there have been no corrosion problems in five years." This is feedback from one of our chemical customers.

Titanium alloys have always been very tough.

- It hardly corrodes in working conditions such as strong acid and seawater;

- It is much lighter than stainless steel, but strong enough, saving a lot of cost in transportation and installation;

- When making food and drug equipment, cleanliness is very important, and the stable oxide film on the surface of titanium is very easy to handle.

Because of this, titanium alloy equipment is no longer just a "high-end alternative", but a standard configuration for more and more companies. Especially in the fields of new energy, medicine, fine chemicals, and even outdoor sports, titanium is rapidly replacing traditional materials and becoming a new direction for equipment materials.

The rise and development prospects of titanium alloy equipment: from high-end materials to future mainstay

As the manufacturing industry continues to increase its requirements for equipment performance, service life, and operating energy efficiency, titanium alloy equipment is gradually evolving from special material applications to a wider range of industrial main equipment. Driven by the rapid development of green manufacturing, high-end equipment, new energy, and clean technology, titanium alloy equipment has shown strong market growth potential.

Several key industries are accelerating the adoption of titanium equipment to achieve long-term cost reduction and efficiency goals:

- In the field of new energy and marine engineering, the application of titanium alloys in wind power, hydrogen energy and seawater process systems is expanding;

- In the pharmaceutical and fine chemical fields, its corrosion resistance and easy-to-clean properties make it an ideal material for clean equipment;

- In high-end personalized fields such as sports and medical treatment, lightweight, high-strength titanium equipment is more in line with the needs of modern users.

With the continuous breakthroughs in titanium alloy processing technology and material application engineering, the cost-effectiveness of titanium equipment is steadily improving and market acceptance is expanding.

Chalcotitanium will continue to rely on professional material research and development, equipment processing capabilities and cross-industry service experience to promote the implementation and innovative application of titanium alloy equipment in more cutting-edge fields. Our technical and sales staff at Chalcotitanium welcome your technical consultation and project communication at any time.