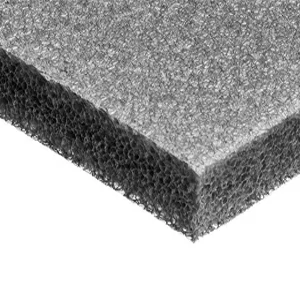

Titanium Foam

Updated : Oct. 22, 2025Titanium foam (also known as porous titanium) is a lightweight, porous advanced metallic material.

It is manufactured through powder metallurgy, space-holder sintering, or 3D printing processes, with porosity reaching 40–90% and pore sizes typically ranging from 100 to 1000 microns. This structure significantly reduces weight while retaining titanium’s corrosion resistance, high strength, and biocompatibility.

Compared with conventional dense titanium, titanium foam offers a larger specific surface area and an elastic modulus closer to that of human bone. It not only demonstrates high catalytic efficiency in new energy electrolytic electrodes but is also widely applied in medical implants, heat exchange and cooling, filtration, and energy absorption structures.

As a professional titanium foam supplier, we provide products in different grades such as Gr1, Gr2, and Gr23 (ELI), with customizable porosity, pore size, dimensions, and surface coatings (Pt, Ir, TiN) according to customer requirements. Standard stock specifications are available for fast delivery, and both small-scale sampling and large-scale industrial supply are supported.

Core advantages of titanium foam

Extreme light weight

Titanium foam has a density of only 0.5–1.0 g/cm³ (MSE Supplies LLC data), compared with 4.5 g/cm³ for dense titanium, achieving a weight reduction of over 70%. This lightweight characteristic significantly reduces system weight, improving specific power and overall efficiency in aerospace and portable devices.

Ultra-high specific surface area

With 75–95% porosity and 100–1000 µm open pore size (Techinstro data), titanium foam offers a much larger surface area than solid titanium. The expanded reactive surface enables higher electrochemical activity and faster mass transfer efficiency, making it ideal for electrolytic electrodes and catalyst supports.

Tunable mechanical properties

By adjusting porosity, titanium foam can balance structural support and energy absorption. Studies show: at 60% porosity, compressive strength is about 80 MPa and elastic modulus about 2.7 GPa (ACS Publications data); at 78% porosity, compressive strength is about 35 MPa and elastic modulus about 5.3 GPa (Northwestern University data). This demonstrates its ability to flexibly match mechanical performance to different application needs.

Biocompatibility & reduced stress shielding

Titanium foam's elastic modulus can be tuned to 0.5–5 GPa (PMC data), close to the 7–30 GPa range of human bone. This similarity effectively reduces stress shielding, promotes bone ingrowth and vascularization, making it an ideal material for medical implants.

Excellent corrosion resistance

Thanks to titanium's natural passive oxide film, titanium foam remains stable in chloride environments, seawater, and acidic media (Wikipedia data). This property makes it suitable for long-term use in harsh chemical, electrolytic, and marine conditions.

Superior electrical and thermal conductivity

Titanium foam retains titanium's inherent electrical and thermal conductivity. Its 3D porous structure provides more uniform current distribution and significantly reduced thermal resistance, enhancing both electrode catalytic efficiency and the performance of heat exchangers and radiators.

Types of titanium foam available from Chalco Titanium

-

Open-cell titanium foam

Features: Porosity up to 40–90%, pore size 100–1000 µm, density only 0.5–1.0 g/cm³, providing significant weight reduction.

Applications: Commonly used in heat sinks, catalyst supports, energy-absorbing structures, and filters.

-

Closed-cell titanium foam (energy-absorbing type)

Features: Closed bubble structure with higher plateau stress, providing thermal and acoustic insulation.

Applications: Commonly used in aerospace crash pads, automotive crash beams, and acoustic damping materials.

-

Medical-grade Ti-6Al-4V ELI titanium foam

Features: Elastic modulus of 0.5–5 GPa, close to that of human bone, with excellent biocompatibility.

Applications: Used for dental implants, intervertebral fusion devices, and bone repair implants.

-

Additive-manufactured lattice titanium foam (custom structures)

Features: Complex lattice and gradient porosity designs achieved via 3D printing.

Applications: Suitable for lightweight heat exchangers, aerospace energy-absorbing components, and customized implants.

-

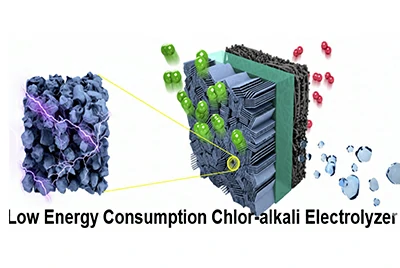

Platinum-coated titanium foam (electrocatalytic grade)

Features: Surface coated with a 2–5 µm Pt layer, enhancing electrochemical activity and achieving a service life of over 10,000 hours.

Applications: Primarily used in PEM/alkaline water electrolysis, electrochlorination, and electroplating anodes.

-

Iridium-coated titanium foam (high corrosion-resistant grade)

Features: Surface covered with approximately 1 µm Ir layer, stable and durable in strong acids and high-chloride environments.

Applications: Suitable for seawater electrolysis, harsh chemical electrodes, and fuel cells.

-

Titanium fiber felt (flexible porous titanium)

Features: Made by sintering fine titanium wires, with 70–80% porosity; sheets are flexible and bendable.

Applications: Commonly used in PEM electrolyzer transport layers, gas diffusion layers, and high-temperature filtration.

Specifications and customization options of titanium foam

Alloy grades

-

Gr1 / Gr2 (commercial pure titanium)

High electrical conductivity and corrosion resistance, suitable for electrochemical electrodes and heat sinks.

-

Gr23 ELI (Ti-6Al-4V ELI)

High purity with low interstitial elements, excellent biocompatibility, suitable for orthopedic implants.

-

Special customized alloys

Alloying elements such as Nb, Ta can be added on demand, or grades like Ti-6Al-4V and Ti-13Nb-13Zr can be provided.

Size range

| Form | Standard specifications | Notes |

|---|---|---|

| Sheets / plates | Thickness 0.5–10 mm; standard 100 × 100 mm, customizable up to 1200 mm length | ≤ 2 mm thickness can be supplied in rolls |

| Blocks | Minimum cutting size 100 × 100 × 10 mm; maximum single block 300 × 300 × 20 mm | Oversized pieces require mold evaluation |

| Rolls | Minimum thickness 0.4 mm; roll width ≤ 300 mm, roll length ≤ 1 m | Suitable for continuous coating or roll-to-roll processes |

| 3D-printed lattices | Maximum single piece 250 × 250 × 250 mm | Feasibility can be evaluated from CAD files |

Porosity and pore size

- Porosity: Four standard levels available: 40%, 60%, 75%, 90%; customizable in 5% increments.

- Pore size: Continuously selectable from 100 µm to 2 mm; ≥ 500 µm recommended for heat dissipation and filtration, ≤ 300 µm recommended for electrodes and implants.

Surface treatment and coatings

| Treatment / Coating | Function | Typical thickness |

|---|---|---|

| Pt coating | Reduces hydrogen overpotential, extends electrode life | 2–5 µm |

| Ir coating | Corrosion resistance in strong acid/high-chloride environments | ≈ 1 µm |

| TiN / TiO₂ ceramic coating | Increases hardness, wear resistance, or improves blood compatibility | 0.5–2 µm |

| Acid pickling + passivation | Removes surface oxides, enhances activity | — |

Typical applications of titanium foam

Hydrogen/Oxygen Electrodes for Water Electrolysis

Features: Pt or Ir coatings on titanium foam substrates reduce overpotential and significantly improve electrolysis efficiency.

Advantages: Open-porosity ensures rapid bubble release; cycle life exceeds 10,000 hours; applicable to PEM and alkaline electrolyzers.

Medical Implants and Bone Repair

Features: Medical-grade Ti-6Al-4V ELI titanium foam with interconnected porosity and elastic modulus close to human bone (0.5–5 GPa).

Applications: Dental implants, intervertebral fusion cages, customized bone defect scaffolds; promotes bone ingrowth and reduces stress shielding.

Heat Exchangers and LED Heat Sinks

Features: High porosity (≥75%) and multi-channel structures enhance convective and conductive heat transfer.

Advantages: Reduces weight by over 50%; applied in aerospace electronics cooling, EV battery packs, and high-power LED modules.

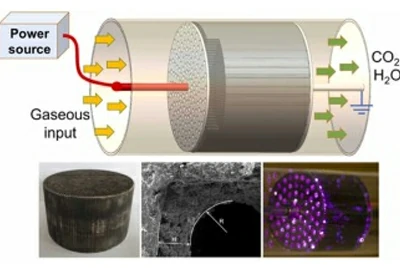

Filtration and Catalyst Supports

Features: Open porous network with excellent corrosion resistance.

Applications: VOC catalytic combustion, seawater filtration, wastewater treatment, and chemical processes with long-term stable operation.

Energy Absorption and Acoustic Damping

Features: Closed- or open-cell titanium foam with plateau stress 30–50% higher; porous structure enables dual protection.

Applications: Aerospace and automotive crash systems, sound insulation, and thermal damping materials.

Mechanical properties of titanium foam

Titanium foam combines the advantages of lightweight, anisotropy, and bone-like elasticity. Its low density provides significant weight reduction potential, and the three-dimensional structure formed via non-spherical space-holder sintering can exhibit certain anisotropic behavior. These features allow titanium foam to maintain mechanical strength while more closely mimicking the mechanical behavior of human bone, thereby reducing stress shielding effects, making it especially suitable for medical implants and energy-absorbing structural applications.

| Property | Range | Corresponding value / benefit |

|---|---|---|

| Elastic Modulus | 15.5 – 36 GPa (close to human bone 7–30 GPa) | Effectively matches bone stiffness, reduces stress shielding |

| Yield Strength | 147 – 170 MPa (close to cortical bone) | Ensures load-bearing capacity, suitable for implants and structural parts |

| Compressive Strength | 0.5 – 1.5 MPa | Provides energy absorption and cushioning, suitable for filtration/catalyst substrates or light-load structures |

Common manufacturing methods of titanium foam

Powder metallurgy routes

This is the most common method, typically using the space-holder technique. Titanium powder is mixed with removable space-holder particles such as NaCl, urea, or cassava starch, compacted, and sintered. The porosity is then created by dissolving the space-holder.

Advantages: Porosity, pore size, and connectivity are controllable, suitable for batch production of different grades of titanium foam.

Applications: Widely used for electrodes, catalyst supports, and medical implants requiring precise pore structure control.

Casting and infiltration

Porous structures are created via molten or freeze-casting processes, or through electrochemical dealloying, selectively dissolving an element from an alloy to form pores.

Advantages: Can achieve anisotropic or elongated pore structures with strong interconnectivity.

Applications: Suitable for filtration and heat transfer components that require directional transport or specialized pore architectures.

Gas expansion method

Porous structures are produced by gas expansion at high temperature (e.g., hydrogen, nitrogen) or superplastic expansion accompanied by α–β phase transformation.

Advantages: No space-holder needed, relatively uniform porosity, simpler process.

Applications: Mainly used for R&D and small-batch laboratory production, as well as for samples requiring uniform pore distribution.

FAQ – Common Questions

What advantages does titanium foam have over nickel foam?

Titanium foam offers higher corrosion and temperature resistance, capable of long-term stable operation in strong acids, chloride environments, and high temperatures (≤ 600 °C). Its elastic modulus is close to human bone, making it suitable for medical implants. Although the cost is slightly higher, it provides greater overall benefits in electrode lifespan, structural strength, and biocompatibility.

Is higher porosity always better? How to choose porosity and pore size?

Not necessarily. Higher porosity increases specific surface area and weight reduction, but reduces mechanical strength.

- 60%: Balanced strength and activity, suitable for electrode substrates.

- 75%: High activity or suitable for bone ingrowth in implants.

- 90%: Maximum specific surface area, ideal for catalyst supports or thermal/acoustic insulation.

Pore size recommendations: ≤ 300 µm for electrodes/implants; ≥ 500 µm for filtration/heat dissipation.

Can titanium foam be welded or machined?

Yes. Laser welding or vacuum brazing is recommended. Machining can be done using carbide tools with shallow cuts, high spindle speed, and compressed air cooling. Post-machining acid pickling and passivation are suggested to remove residual stresses and oxide layers.

What is the service life of Pt/Ir coatings?

Under continuous water electrolysis at 10 A·cm⁻² and 80 °C, our Pt-coated titanium foam has passed 10,000 h testing. Ir-coated foam maintains a corrosion rate < 0.02 mm/y in 3 M HCl. Actual lifespan depends on current density, temperature, and electrolyte composition; accelerated aging curves can be provided per project.

What is the minimum order quantity (MOQ) and lead time?

- Free samples: sheets ≤ 100 × 100 mm or rolls ≤ 100 × 50 mm.

- MOQ: Standard sheets – 5 pieces; rolls – 1 roll; 3D lattices – 1 piece.

- Lead time: In-stock 7–10 days; custom 3–4 weeks; with coating +1–2 weeks.