Titanium Materials for Heat Transfer Systems

Updated : Jun. 27, 2025In high-end heat transfer—chemical processing, seawater desalination, nuclear power, HVAC—materials must balance corrosion resistance, high strength-to-weight ratio, and wide temperature range. Titanium excels with its dense TiO₂ oxide film in harsh environments, low density (4.5 g/cm³ vs. copper's 8.96 g/cm³), and stable operation from -50°C to 300°C (short-term up to 400°C). It outperforms stainless steel and copper alloys, making it a preferred, irreplaceable material.

Chalco Titanium provides a full product range—from rolled titanium to sheets, seamless and welded tubes, and finned tubes—plus custom processing like bellows and tube sheets. Surface treatments (pickling, electro-polishing, micro-arc oxidation) and testing (chemical analysis, ultrasonic, metallography) ensure consistent quality, delivering efficient, durable titanium heat transfer solutions.

Quick Navigation

Titanium Rolled Products

Rolled titanium products are the fundamental material form in heat transfer systems, widely used for manufacturing plates of plate heat exchangers, equipment shells, tube sheets, and support structures. Leveraging vacuum arc remelting (VAR) titanium ingot technology combined with integrated hot and cold rolling lines, we provide a full range of rolled titanium products.

Titanium Sheets

-

Flat plates formed by hot or cold rolling, serving as primary raw materials for plate heat exchanger plates, tube sheets, and equipment end caps.

Alloys: Gr1, Gr2, Gr5 (Ti-6Al-4V), Gr7 (Ti-0.15Pd)

Dimensions: Thickness 0.5–155 mm; Width ≤ 2500 mm; Length ≤ 12000 mm

Standards: ASTM B265 / ASME SB265, GB/T 3621-2011

Secondary Processing: Can be cut into discs with diameters from 50 to 2000 mm per customer request, used for flange gaskets, tube sheet locating rings, and corner pieces of plate heat exchangers.

Applications: Plate heat exchanger plates, shell plates, tube sheets, equipment end caps.

Titanium Coils and Strips

-

Titanium sheets continuously coiled or slit into strips, used for high-speed stamping and precision forming, serving as key raw materials for automated plates, fins, and welded tubes.

Alloys: Gr1, Gr2

Dimensions: Thickness 0.2 - 6.0 mm (cold rolled); Width 10 - 1500 mm

Standards: ASTM B265 / ASME SB265, EN 10204 3.1

Applications: Automated stamped corrugated plates, microchannel plates, strip fin elements, welded tube substrates.

Titanium-Steel Bimetal Plates

-

Produced by explosive bonding or hot rolling bonding, combining titanium sheets (Gr2) with carbon steel/stainless steel (SA516 Gr.70) substrates. These plates integrate titanium's corrosion resistance with steel's high strength and weldability for tube sheets and pressure vessel shells.

Typical Structure: Titanium cladding 0.5–5 mm; Carbon steel substrate 6–50 mm

Bonding Methods: Explosive bonding, rolling bonding

Standards: ASTM B898 / ASME SB898

Applications: Shell-and-tube heat exchanger tube sheets, pressure vessel liners, composite structural parts.

Titanium Tubes

Titanium tubes are core heat transfer elements in heat transfer systems, widely used in shell-and-tube heat exchangers, plate/coil heat exchangers, condensers, and evaporators. With excellent corrosion resistance, high strength-to-weight ratio, and stability over a broad temperature range (-200°C to 400°C), titanium tubes ensure long-term stable operation, significantly extending equipment lifespan and reducing maintenance costs.

We operate an integrated production system from smelting, extrusion, cold drawing, rolling to precision welding, offering the following titanium tube products:

Titanium Seamless Tubes

Manufactured directly from solid billets via piercing or extrusion without any weld seam. Their uniform structure and high pressure resistance make them suitable for high-pressure, high-temperature, and highly demanding reliability environments.

Alloys: Gr1, Gr2, Gr5, Gr7, Gr9, Gr12

Outer Diameter: 6 – 500 mm

Wall Thickness: 0.3 – 8.0 mm

Standards: ASTM B338/B861, AMS 4943/4944/4945

Applications: High-pressure shell-and-tube exchangers, nuclear condensers, seawater desalination (MSF, MED).

Titanium Welded Tubes

Formed by continuous rolling of high-quality cold-rolled titanium strips and welded automatically by tungsten inert gas (TIG) welding without filler metal. Weld seams are flush, with performance matching the base metal, uniform wall thickness, and relatively lower cost, increasingly replacing seamless tubes in many applications.

Alloys: Gr1, Gr2, Gr7, Gr12

Outer Diameter: 15.88 – 56 mm

Wall Thickness: 0.6 – 2.5 mm

Standards: ASTM B338/B862, GB/T 3625

Applications: Large coils, shell-and-tube, and plate-fin heat exchanger tube bundles.

Titanium Coil Tubes

Titanium coil tubes are produced by bending straight titanium tubes (typically welded or small-diameter seamless tubes) into spiral or other coil shapes using bending equipment. Coil tubes facilitate installation in compact spaces and provide long, seamless piping runs, reducing leakage risks.

Alloys: Gr1, Gr2

Dimensions: OD 6.35 – 50.8 mm; WT 0.3 – 2.5 mm

Standards: ASTM B338 / ASME SB338

Applications: Compact or custom coil tube heat exchangers, RO preheaters, seawater desalination evaporators, cooling coils in chemical reactors.

Titanium U-Tubes

Titanium U-tubes are precisely bent from straight titanium tubes (seamless or welded) into a U-shape, primarily used in U-tube heat exchangers. This design effectively compensates for thermal expansion differences between the tube bundle and shell, with a simpler structure.

Alloys: Gr1, Gr2, Gr7, Gr12

Dimensions: OD 12.7 – 50.8 mm; WT 0.5 – 3 mm; Bend radius 3D–5D

Standards: ASTM B338 / ASME SB338

Applications: Floating head and fixed tube sheet shell-and-tube heat exchangers, high-pressure steam heat units.

Titanium Condenser Tubes

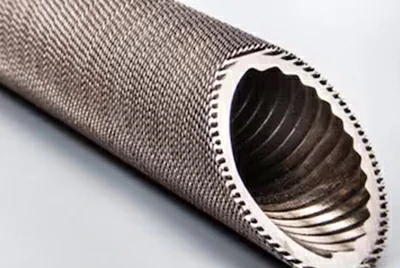

Based on thick-walled welded or seamless tubes, titanium condenser tubes undergo triple-axis skew rolling to form highly adjustable fine tooth structures on the outer tube surface. This greatly increases the heat exchange area. The grooves between fins utilize surface tension and siphon effects to break the condensate film, accelerating liquid removal and significantly enhancing condensation efficiency.

Alloys: Gr1, Gr2

Dimensions: OD 12.7 – 31.8 mm; WT 0.8 – 3 mm

Standards: ASTM B338 / ASME SB338

Applications: Shell-and-tube condensers, industrial condensers, seawater desalination condensers, electronic liquid cooling modules.

Titanium Flooded Evaporator Tubes

Titanium flooded evaporator tubes use thick-walled bases with grid-like fins made by three-roll skew rolling to boost nucleate boiling. The textured surface increases bubble sites, while grooves aid liquid replenishment and prevent dry-out, enhancing pool boiling performance.

Alloys: Gr1, Gr2

Dimensions: OD 12.7 – 31.8 mm; WT 0.8 – 3 mm

Standards: ASTM B338 / ASME SB338

Applications: Flooded evaporators, falling film evaporators, and boiling heat exchangers in chemical processes.

Titanium Inner Fin Tubes

Titanium inner fin tubes are manufactured by welding pre-grooved titanium strips with internal threads or teeth. The finned inner wall disrupts the fluid boundary layer, generating strong turbulence and significantly increasing the internal convective heat transfer coefficient.

Alloys: Gr1, Gr2

Dimensions: OD 6.35 – 19.05 mm; WT 0.3 – 1.5 mm; Fin height 0.2 – 0.6 mm

Tube Forms: Straight, coil, U-bend

Standards: ASTM B862

Applications: Air coolers, dry evaporators, and compact heat exchange or cooling modules.

Titanium Helical Grooved Tubes

Titanium helical grooved tubes are formed by spirally indenting smooth or inner fin tubes using external rolling tools. This process is efficient and cost-effective, enhancing both internal and external heat transfer with minimal increase in flow resistance.

Alloys: Gr1, Gr2

Dimensions: OD 8 – 50.8 mm; WT 0.3 – 1 mm; Customizable pitch and number of grooves

Standards: ASTM B338 / ASME SB338

Applications: Shell-and-tube and coaxial exchangers; a titanium alternative to inner-grooved copper tubes in refrigeration.

Titanium Spiral Flattened Tubes

Titanium spiral flattened tubes are made by spirally compressing round tubes into a twisted flat shape. In bundles, they form spiral channels that boost shell-side turbulence. Their self-supporting design removes baffles, simplifies structure, and avoids flow-induced vibration.

Alloys: Gr1, Gr2

Dimensions: OD 9.52 – 25.4 mm

Standards: ASTM B338 / ASME SB338

Applications: Large and medium-sized shell-and-tube heat exchangers requiring high heat transfer efficiency and compact design.

Titanium Tube Fittings

Titanium tube fittings are essential components for pipeline connections and directional changes in titanium heat exchanger systems. They must offer the same corrosion resistance, high strength, and hygienic properties as the tubing itself. We supply a full range of titanium fittings in compliance with ASME/B16 series standards, supporting socket weld, butt weld, and threaded connections.Quick Quote

Titanium Flanges

Titanium flanges provide detachable connections between piping or exchanger shells and tube bundles. Available types include weld neck flanges, slip-on flanges, and blind flanges.

Standards: ASME B16.5

Alloys: Gr1, Gr2, Gr7

Titanium Elbows

Titanium elbows are used to change pipeline direction and are commonly available in 45°, 90°, and 180° angles. Available in socket weld and butt weld types.

Standards: ASME B16.9

Alloys: Gr1, Gr2

Titanium Tees

Titanium tees are fittings used for branching pipelines and are available as straight tees (equal diameter) or reduced tees (unequal diameter). Cross fittings are also available upon request.

Standards: ASME B16.9

Alloys: Gr2, Gr7

Titanium Reducers

Titanium reducers provide smooth transitions between pipes of different diameters and are offered in both concentric and eccentric types.

Standards: ASME B16.9

Alloys: Gr2, Gr12

Titanium Couplings / Nipples

Titanium couplings and nipples are short pipe segments or threaded fittings used for quick extensions or temporary branches. Available forms include stub ends, caps, and threaded couplings.

Standards: ASME B16.11

Alloys: Gr1, Gr2

Titanium Fasteners

Although titanium heat exchangers are primarily assembled by welding, titanium fasteners are widely used in areas such as flange end caps, maintenance covers, structural supports, and accessory mounting—ensuring reliable disassembly and long-term performance.

Why Use Titanium Fasteners Instead of Common Metals?

Galvanic Corrosion Prevention: Using dissimilar metal fasteners like stainless steel in seawater, acidic, or chlorinated environments can lead to galvanic corrosion when paired with titanium components, shortening equipment lifespan.

Consistent Corrosion Resistance: Titanium fasteners match the base material of the exchanger, ensuring uniform corrosion resistance and reducing the risk of seal failure or leakage.

Lightweight Advantage: Compared to stainless steel, titanium fasteners are significantly lighter—ideal for weight-sensitive or load-optimized applications.

Titanium Machined Parts

In titanium heat exchangers, not all critical components can be fulfilled by standard materials like titanium tubes and sheets. Many structural and connection elements require custom precision machining to ensure system integrity and long-term performance. We offer a wide range of titanium machined parts for structural reinforcement, fluid connection, and sealing in demanding applications.Quick Quote

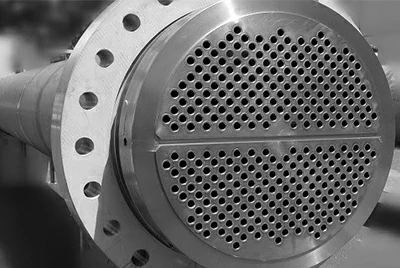

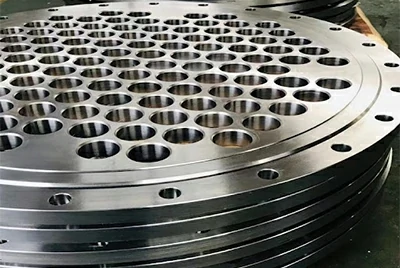

Titanium Tube Sheets

Titanium tube sheets are one of the core components used to connect tube bundles to the shell. We provide tube sheets with high drilling accuracy, excellent surface finish, and stable mechanical properties, suitable for various welding and expansion processes.

Titanium-Steel Clad Tube Sheets

Titanium-steel clad tube sheets combine a corrosion-resistant titanium layer with a pressure-bearing carbon steel base through explosive bonding or roll bonding. This solution balances corrosion resistance and mechanical strength, making it ideal for large-scale or high-pressure heat exchangers while helping to control costs.

Titanium Heads / End Caps

Titanium heads and end caps are used to seal the ends of equipment. Available shapes include elliptical heads, flat heads, conical heads, and blind flanges. Customization is available based on pressure and structural requirements.

Titanium Reinforcement Rings / Support Rings

Titanium reinforcement or support rings are used to strengthen shell structures, flange connections, or act as auxiliary sealing surfaces. These are commonly used in large-scale equipment or high-strength connection zones.

Titanium Heat Transfer Industry Solutions

Chemical Industry

The chemical industry—including petrochemicals, fine chemicals, and basic chemical production—often involves strong acids, alkalis, and chloride-containing media, with process temperatures up to 350 °C and pressures ranging from 0.5 to 5 MPa. Heat exchangers must not only withstand harsh corrosion environments but also ensure high thermal efficiency and long-term reliable operation to reduce downtime and maintenance.

Heat Exchanger Types: Shell-and-Tube Heat Exchangers, Plate Heat Exchangers, Reboilers, Condensers

Titanium Products

- Titanium Seamless Tubes

- Titanium Welded Tubes

- Titanium Evaporator Tubes

- Titanium Condenser Tubes

- Ti-Steel Clad Tube Sheets

- Titanium Tube Sheets

Oil & Gas Industry

The oil and gas industry, covering upstream extraction, midstream transportation, and downstream refining, involves processing crude oil, natural gas, and their derivatives. Process temperatures may reach 400 °C, and pressures can exceed 10 MPa. Heat exchangers must operate reliably under high pressure, high temperature, and sour/chloride-containing environments, while also meeting explosion-proof and leak-proof safety standards.

Heat Exchanger Types: Shell-and-Tube Heat Exchangers, Double-Pipe Heat Exchangers, Kettle Reboilers, Evaporators & Condensers

Titanium Products

- Titanium Seamless Tubes

- Titanium Welded Tubes

- Titanium U-bend Tubes

- Ti-Steel Clad Tube Sheets

- Titanium Tube Sheets

Offshore Engineering

Offshore engineering includes offshore oil platforms, subsea pipelines, floating structures, and marine mining equipment, all operating in extremely humid, chloride-rich environments with exposure to wave loads and seawater erosion. Heat exchangers must offer exceptional corrosion resistance and structural strength to withstand dynamic loads.

Heat Exchanger Types: Marine Condensers, Air-Cooled/Water-Cooled Heat Exchangers, Anti-Fouling Heat Exchangers

Titanium Products

- Titanium Seamless Tubes

- Titanium Finned Tubes

- Titanium Condenser Tubes

- Titanium Flanges

- Titanium Tube Sheets

Seawater Desalination

Seawater desalination processes (MSF, MED, RO) rely on large-area heat exchangers for evaporation, condensation, and film preheating. These systems handle high-concentration brine or salt solutions at 70–120 °C and 0.2–2 MPa. Equipment must resist severe fouling and corrosion while maintaining continuous, efficient operation.

Heat Exchanger Types: Multiple Effect Evaporators, Multi-Stage Flash Evaporators, RO Pre-Heaters, Condensers

Titanium Products

- Titanium Welded Tubes

- Titanium Evaporator Tubes

- Titanium Condenser Tubes

- Ti-Steel Clad Tube Sheets

Nuclear Power Industry

In nuclear power plants, heat exchangers are used in steam condensers and auxiliary cooling systems exposed to high temperatures, radiation, and alternating seawater/freshwater environments. These applications demand materials with superior corrosion resistance and dimensional stability. Titanium, with its resistance to radiation and corrosion, is the material of choice for nuclear condenser tube bundles.

Heat Exchanger Types: Steam Condensers, Feedwater Heaters, Auxiliary Cooling Heat Exchangers

Titanium Products

- Titanium Seamless Tubes

- Titanium U-bend Tubes

- Titanium Welded Tubes

- Titanium Flanges

- Titanium Tube Sheets

HVAC & Industrial Cooling

In high-end buildings, data centers, ships, and industrial cooling systems, heat exchangers must be compact, efficient, corrosion-resistant, and low-noise. Operating conditions range from 5 to 80 °C and 0.3 to 1.5 MPa. Titanium plate, finned tube, and microchannel exchangers perform exceptionally well in contaminated or harsh environments.

Heat Exchanger Types: Plate Heat Exchangers, Fin-Tube Heat Exchangers, Microchannel Heat Exchangers

Titanium Products

- Titanium Plates

- Titanium Strips

- Titanium Finned Tubes

- Titanium Inner Fin Tubes

- Titanium Stamped Plates

Food & Pharmaceutical Industry

The food and pharmaceutical industries demand sanitary-grade heat exchangers that are non-toxic, easy to clean, and highly corrosion-resistant. Typical operating conditions are 5–120 °C with pressures up to 1 MPa. Titanium's chemical inertness and smooth surface finish meet HACCP, FDA, and EHEDG hygiene standards.

Heat Exchanger Types: Sanitary Plate Heat Exchangers, Sanitary Shell-and-Tube Heat Exchangers

Titanium Products

- Titanium Plates

- Titanium Seamless Tubes

- Titanium Sanitary Fittings

- Titanium Gaskets

Chalco Titanium – Titanium Expert in Heat Transfer Applications

Chalco Titanium, relying on its fully integrated rolling–tubing–fabrication platform, provides one-stop solutions for heat transfer systems, covering everything from titanium base materials to functional components. With rigorous quality control, we ensure stable and reliable performance in high-end industries such as chemical processing, desalination, nuclear power, HVAC, and pharmaceuticals.

Equipment Capabilities & Production Range

Rolling & Extrusion:

Plate and Strip Lines: Hot-rolled plates 6.0–150 mm, annual capacity 3,000 tons; Cold-rolled strips 0.5–6.0 mm, annual capacity 1,200 tons

Extrusion Press: 3,000-ton class; capable of extruding various tube billets Ø 0.5–219 mm

Tube Processing:

Cold Drawing Units: Seamless tubes with annual capacity of 1,500 tons; straight tube length up to 18 m

TIG/Orbital Welding Lines: Welded tubes with annual capacity of 1,000 tons; OD 15–600 mm, wall thickness 0.5–12.7 mm

Fabrication & Assembly: CNC bending, laser welding, 3D printing; monthly output over 100 sets of tube sheets and heads

Heat Transfer Component Production Capabilities

- Full-Range Titanium Plates/Strips: Thickness 0.5–150 mm; width ≤ 2,500 mm

- Multiple Tube Types: Seamless tubes, welded tubes, coil tubes, U-tubes, finned tubes, helical tubes, evaporator/condenser tubes, capillary tubes

- Tube Sheets & Clad Plates: Titanium tube sheets, titanium–steel clad tube sheets; titanium layer thickness 0.5–5 mm, steel base 6–50 mm

- Titanium Fittings & Fasteners: Complete range of flanges, elbows, tees, reducers, bolts/nuts, gaskets

We respond quickly to diverse material and component needs for various heat exchanger types, including shell-and-tube, plate, evaporators, and condensers.

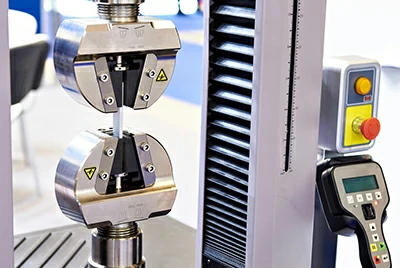

Strict Quality Control & Technical Assurance

- Chemical & Mechanical Testing: Spectral analysis + tensile, bending, and hardness tests, in compliance with ASTM B338/B861, GB/T 3624-1995

- Non-Destructive Testing (NDT): Online ultrasonic (UT), X-ray, and penetrant testing (PT) to ensure zero defects in welds and base material

- Pressure & Sealing Tests: Air tightness and hydrostatic tests according to ASME BPVC VIII-1, GB 50251

- Surface Quality: Automated sandblasting, pickling, polishing, anodizing, and anti-scaling coatings to extend service life

- Third-Party Certifications: ISO 9001/14001, OHSAS 18001, with inspection reports available from TUV, SGS, and more

This complete system guarantees every batch of titanium materials and machined parts features high purity, consistency, and traceability, securing the long-term performance of mission-critical heat transfer equipment.

With advanced facilities, full-range component manufacturing, and professional quality assurance, Chalco Titanium is a trusted supplier of titanium-based heat transfer solutions for global industries including chemicals, desalination, nuclear energy, HVAC, and pharmaceuticals.