Titanium Grade 2

Updated : Nov. 26, 2025Chalco Titanium specializes in supplying commercially pure titanium Grade 2 materials, encompassing various product forms including plates, bars, tubes, wires, and forgings. Grade 2, as the most commonly used CP titanium grade, combines lightweight, moderate strength, and excellent corrosion resistance, making it widely applicable in industries such as chemical, marine, energy, aerospace, and medical devices.

With stable supply channels, rigorous quality testing, and global delivery capabilities, Chalco Titanium provides customers with Grade 2 titanium products that meet international standards such as ASTM, AMS, and ISO. We not only support spot supply of standard specifications but also offer OEM/ODM customized processing to meet the precision requirements of different projects.

Chalco Titanium Grade 2 Standards and Supply Forms

Chalcotitanium Grade 2 titanium products strictly comply with international standards:

- ASTM B265 / AMS 4902 – Titanium Plates, Strips, Sheets

- ASTM B348 – Titanium Rods and Ingots

- ASTM B338 / B861 – Seamless Titanium Tubes and Welded Tubes

- ASTM F67 / ISO 5832-2 – Medical Implant-Grade Pure Titanium

- AMS 4941 / 4942 – Welded Pipes and Seamless Pipes

- AWS A5.16 – Welding Wires and Electrodes

Supply formats include:

Titanium Plates & Sheets

Titanium Round Bars & Rods

Titanium Pipes & Fittings

Titanium Wire & Welding Wire

Titanium Forgings

Titanium for Additive Manufacturing

Chalco Titanium offers customized dimensions, tolerances, and surface finishes, and comes with EN 10204 3.1 material certification, while also supporting 3.2 third-party testing and certification to ensure the reliability and compliance of project delivery.

Titanium Grade2 Chemical Composition (Wt.%)

Chalco Titanium strictly controls the purity and impurity content of Grade 2 titanium materials to ensure compliance with standards such as ASTM/AMS/F67. It has excellent corrosion resistance and stability and is widely used in chemical, marine and medical fields.

| Element | Content (Max, wt.%) |

|---|---|

| C (Carbon) | 0.10 |

| Fe (Iron) | 0.30 |

| H (Hydrogen) | 0.015 |

| N (Nitrogen) | 0.03 |

| O (Oxygen) | 0.25 |

| Ti (Titanium) | Balance (≈ 99.2%) |

Titanium Grade 2 – Physical & Mechanical Properties

Chalco's Grade 2 titanium combines strength and ductility, with stable tensile strength, high elongation, and excellent fatigue and impact properties, meeting the long-term application needs of aerospace, chemical, and medical equipment.

| Property | Metric | English | Notes |

|---|---|---|---|

| Density | 4.51 g/cc | 0.163 lb/in³ | |

| Hardness, Knoop | 170 | 170 | |

| Hardness, Rockwell B | 80 | 80 | |

| Hardness, Vickers | 145 HV | 145 HV | |

| Tensile Strength, Ultimate | 344 MPa | 49,900 psi | |

| Tensile Strength, Yield | 275–410 MPa | 39,900–59,500 psi | |

| Elongation at Break | 20% | 20% | |

| Reduction of Area | 35% | 35% | |

| Modulus of Elasticity | 105 GPa | 15,200 ksi | In tension |

| Compressive Modulus | 110 GPa | 16,000 ksi | |

| Poisson's Ratio | 0.37 | 0.37 | |

| Izod Impact | 114–171 J | 84.1–126 ft·lb | |

| Fatigue Strength (10⁷ cycles, unnotched) | 300 MPa | 43,500 psi | |

| Fatigue Strength (30,000 cycles, unnotched) | 425 MPa | 61,600 psi | |

| Fracture Toughness | 66 MPa·m½ | 60.1 ksi·in½ | K(Q), annealed |

| Shear Modulus | 45 GPa | 6530 ksi |

Titanium Grade 2 – Corrosion Resistance

Titanium Grade 2 is renowned for its exceptional corrosion resistance, particularly in seawater, chemical media, and high-humidity environments, making it a widely chosen critical material. Simultaneously, it possesses moderate strength, good processability, and excellent biocompatibility, meeting the diverse needs of various industries.

Excellent corrosion resistance: Stable performance in seawater, salt spray, oxidizing acids and humid environments, making it ideal for ships, chemical equipment and energy engineering.

Strength and ductility are balanced: the yield strength is ≥275 MPa and the elongation is about 20%, which can meet the structural load-bearing requirements and has good formability.

Excellent machinability and weldability: Supports cold working, hot working and various welding processes, reducing manufacturing costs and improving design flexibility.

Excellent biocompatibility: Meets ASTM F67 medical implant standards and is suitable for surgical instruments and long-term implants.

Lightweight advantages: with a density of only 4.51 g/cm³, it is about 40% lighter than steel, significantly reducing weight while maintaining strength.

| Environment / Medium | Performance |

|---|---|

| Sea Water (up to 315°C / 600°F) | Excellent resistance |

| Humidity | Excellent |

| Salt Spray (NaCl) | Excellent |

| Acetic Acid | Excellent |

| Sulfuric Acid | Moderate |

| Sodium Hydroxide | Moderate |

| Sour Oil / Gas | Moderate |

| Nitric Acid (oxidizing) | Good |

| Wet Chlorine / Bromine Gas (with O₂/H₂O present) | Resistant |

| Strong Reducing Acids / Molten Chloride Salts | Not recommended |

| Alkaline Peroxide Solutions | Not recommended |

Chalco Titanium Grade 2 Product Advantages

Titanium Grade 2 combines excellent corrosion resistance, strength, and processability, making it the most representative commercially available grade of pure titanium. Its balanced performance makes it suitable for a variety of critical applications, from marine engineering to medical implants.

Medium strength & excellent ductility: Yield strength ≥275 MPa, elongation maintained at around 20%, which can meet the structural load-bearing requirements and has good formability.

Overall corrosion resistance: It can maintain long-term stability in seawater, chemical media and high humidity environments, making it an ideal material for the marine and chemical industries.

Excellent weldability: Compatible with various welding processes such as TIG, MIG, electron beam, and laser, ensuring the strength and stability of the joint.

Excellent machinability: Supports both cold and hot working, flexible forming, and suitable for manufacturing complex structural parts.

Biocompatibility: Meets ASTM F67 medical-grade pure titanium standards and can be used in surgical implants and medical devices that come into long-term contact with the human body.

Additive manufacturing compatibility: High-purity titanium wire is available , compatible with 3D printing processes such as SLM, EBM, and DED, to meet the needs of advanced manufacturing.

Chalco Titanium Grade 2 Cooperation Fields

Chalco Titanium's Grade 2 products, with their superior corrosion resistance and stable performance, are widely used in various industries. We not only offer standard plates, bars, tubes, and forgings, but also provide customized product solutions to meet different working conditions and standard requirements.

Chemical Industry

Typical applications: reaction vessels, heat exchangers, condensers, pressure vessels

Supply types: titanium plates, seamless pipes, welded pipes, forged accessories

Marine Engineering

Typical applications: seawater desalination equipment, marine piping, condenser tube bundles, marine structural components

Supply forms: pipes, fittings, rods, plates

Medical Field

Typical applications: surgical implants, orthopedic fixation devices, surgical instruments

Supply format: Medical grade bars, wires, and forgings (compliant with ASTM F67 standard)

Aerospace

Typical applications: fuselage skin, air ducts, brackets, lightweight components

Supply forms: plates, bars, profiles, forgings

Energy & Cryogenic Technology

Typical applications: heat exchangers, cryogenic containers, power system components

Supply forms: pipes, welding wire, forgings

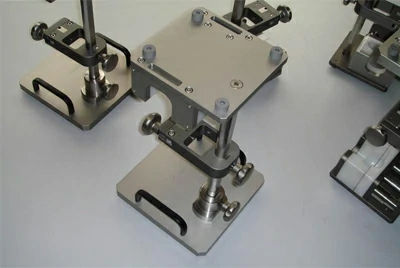

Electrochemical Industry

Typical applications: cathode plates, jigs, and fixtures for electroplating.

Supply form: titanium plates, bars, machined parts

Grade 2 Comparison with Other Materials

Among numerous material options, Titanium Grade 2 stands out for its balanced strength, excellent corrosion resistance, and lightweight properties. Compared to other titanium grades and stainless steels, it exhibits a performance combination more suitable for specific industries. With its consistent quality and comprehensive product range, Chalco Titanium provides customers with more cost-effective and reliable solutions.

-

Comparison with other CP titanium grades Grade 1: Higher ductility, but lower strength than Grade 2, suitable for applications with extremely high formability requirements. Grade 3 / Grade 4: Higher strength, but poorer formability and weldability; Grade 2 has a more balanced overall performance.

-

Compared to Grade 5 titanium alloy Grade 5 (Ti-6Al-4V) has a much higher strength than Grade 2, making it more suitable for load-bearing and high-temperature applications. Grade 2 is cheaper and has better corrosion resistance, making it more advantageous in marine, chemical, and medical fields.

-

Compared with stainless steel Grade 2 has a yield strength comparable to austenitic stainless steel, but is much lighter (density of only 4.51 g/cm³, about 40% lighter than steel). In long-term seawater and acidic media, Grade 2 exhibits far superior corrosion resistance compared to stainless steel.

Why choose Chalco Titanium?

As a professional titanium supplier, Chalco Titanium not only provides Grade 2 products that meet international standards such as ASTM, AMS, and ISO, but also provides customers with efficient and reliable solutions through its comprehensive production system and global delivery capabilities.

Complete supply chain: covering smelting, rolling, forging, CNC finishing to additive manufacturing powder, ensuring full control over the product process.

Strict quality assurance: Provides EN 10204 3.1 material certification, with optional 3.2 third-party testing, meeting the stringent requirements of industries such as aviation, chemical, and medical.

Diverse product forms: We can supply plates, bars, tubes, wires, forgings and 3D printing powders to meet the needs of different industries and working conditions.

Global supply capability: We maintain a constant stock of various specifications and support OEM/ODM customization to ensure fast delivery.

Technical and service support: Our engineering team provides material selection guidance and application solutions to help customers reduce costs and improve efficiency.

Frequently Asked Questions (FAQs)

What's the difference between Titanium Grade 2 and Grade 5?

Grade 2 is commercially pure titanium, emphasizing corrosion resistance and processability, suitable for chemical, marine, and medical applications; Grade 5 (Ti-6Al-4V) has higher strength and is more suitable for aerospace and high-temperature load-bearing structures. Chalco can supply both, helping customers choose the material that best suits their needs.

Can Grade 2 titanium be used in marine environments long-term?

Yes. Grade 2 exhibits excellent corrosion resistance in seawater and high-salt-spray environments, withstanding seawater corrosion up to 315°C. Chalco has been a long-term supplier to numerous marine engineering and shipbuilding customers.

Can it be used for medical implants?

Yes. Grade 2 meets ASTM F67 medical standards, has excellent biocompatibility, and is widely used in orthopedic implants and surgical instruments.

Does the company support small-batch customization?

Yes. Chalco has readily available stock of various specifications and can provide samples or small-batch customization, while also meeting large-volume OEM/ODM supply needs.

Can it be used for 3D printing?

Yes. Chalco Titanium's high-purity Grade 2 titanium wire can be used in advanced 3D printing processes such as WAAM (Wire Additive Manufacturing), offering advantages such as high deposition efficiency and high material utilization, ensuring stable performance of printed parts.

Chalco Titanium offers flexible supply capabilities and expert technical support, ensuring you can quickly obtain reliable Grade 2 titanium solutions whether you need standard specifications, custom-made materials, or additive manufacturing materials.