Titanium Materials for Eyewear

Updated : Nov. 24, 2025For eyewear and accessory OEMs, Chalco Titanium offers a one-stop supply of lightweight, hypoallergenic, corrosion-resistant titanium materials — wires, profiles, hinges, nose pad arms, bridges, tubes, and screws.

Standard cross-sections are available, along with custom designs from our own die tooling.

Why choose Chalco Titanium materials for eyewear

We cover over a thousand cross-sections, from 0.02 mm² to 18 mm², and support more than 30 grades of titanium and alloys.

- CNC cutting with precise length control and smooth, clean edges.

- Bright, burr-free surfaces ensure flawless appearance parts.

- Wide range of ready cross-sections and stocked sizes for fast delivery without new tooling.

- In-house die workshop enables quick mold opening for custom and non-standard profiles.

- Multiple surface finishes available, including polishing, sandblasting, anodizing, and PVD.

Chalco Titanium focuses on providing global eyewear and accessory manufacturers with a full range of titanium solutions — from wires and profiles to hinges, nose pad arms, bridges, tubes, and screws — supporting every stage from design and sampling to mass production.

Specifications of titanium materials for eyeglasses

- Material / Wire: ASTM B863 (Gr1 / Gr2 / Gr5 / β-Ti)

- Frame standards: ISO 12870 (sweat resistance, corrosion resistance, mechanical performance)

- Chemical and restriction compliance: RoHS / REACH

- Material certification: EN 10204 3.1 (heat number / chemical composition / mechanical properties)

Products available from Chalco Titanium

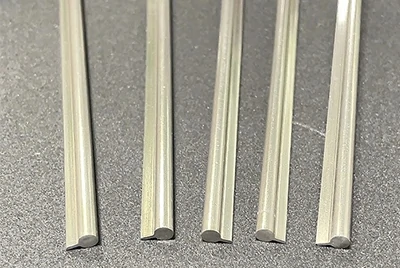

Titanium wire (eyewear wire / temple wire / wire-core)

Chalco Titanium offers a complete range of eyewear-grade titanium wires — from pure titanium and β-titanium to hardenable titanium alloys — covering temple wires, core wires, and V-frame wires.

- Custom cutting in any length with CNC precision for smooth, clean edges.

- Bright, burr-free surface, finely polished or anodized for a sleek appearance and safe, scratch-free wear.

- Three delivery forms: coils, rings, and straight lengths — to suit various assembly and production needs.

Popular specifications:

| Wire diameter (mm) | Tolerance (mm) | Delivery form | Grade | Surface finish |

|---|---|---|---|---|

| 0.80 | ±0.01 | coils / straight | Gr1 / β-Ti | Polished bright finish |

| 1.00 | ±0.01 | coils / rings | Gr2 / β-Ti | Anodized color |

| 1.20 | ±0.02 | straight | Gr2 / Ti-6Al-4V | Sandblasted matte |

| 1.50 | ±0.02 | coils / rings | β-Ti | PVD colored finish |

We offer various surface textures and decorative profiles, including smooth, fine-sand, and patterned finishes.

Custom cross-sections and surface effects can also be made according to your drawings or design requirements.

Titanium hinges / hinge plates

Titanium hinges are the key components connecting the eyewire front and temple arms — small in size but essential for smooth movement and long-lasting durability.

Chalco Titanium offers a wide range of structures, sizes, and materials to meet diverse needs in eyewear manufacturing, repair, and new frame design.

-

Barrel Hinge

Simple in structure and stable in installation, this is the most common hinge type.

-

Spring Hinge

Box-shaped with an internal elastic insert, it automatically returns to position and enhances wearing comfort.

-

Solder-on Hinge

Designed for stainless steel or mixed material frames, allowing easy assembly and repair.

- Hole position, diameter, and thickness controlled to jig-level tolerance (±0.02 mm).

- Each component is compatible with mainstream temple and eyewire jigs.

- Custom slot width, hole spacing, and screw hole diameters available per drawing.

Size range (mm):

| Type | Common width (mm) | Application |

|---|---|---|

| Standard hinge | 1.6 / 1.8 / 2.0 / 2.5 / 3.0 / 3.5 / 4.0 / 5.5 | General structure, new frame manufacturing, replacement and repair |

| Spring hinge | 2.4 / 2.6 / 3.0 / 3.5 / 4.0 | Flexible temples and comfort-focused designs |

Over 30 specifications available, with options for drawing-based customization, welding base matching, and integrated surface color finishing.

Titanium hinge samples:

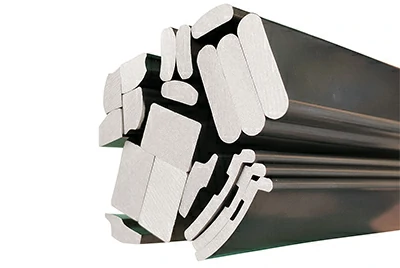

Custom extruded titanium profiles

Our in-house cross-section library allows direct matching, using existing dies to significantly reduce tooling costs and lead time.

For special designs, we can quickly create new dies in our own workshop, provide mold cycle and cost estimates, and help optimize the cross-section structure.

We offer drawing-based custom extrusion services for titanium profiles with precise dimensions, high strength, and lightweight performance.

Contact us now

- Common cross-section sizes (mm): 1.60×0.80 / 1.85×1.00 / 2.00×1.10 / 2.00×1.45

- Delivery forms: coils / rings / straight lengths

- Tolerance control: cross-section ±0.02 mm; straightness ≤0.2 mm/m

- Multiple surface finishes available — polishing, sandblasting, anodizing, and PVD.

- Secondary processing such as cutting, slotting, micro-bending, and drilling available to shorten production cycles.

Customers can provide 2D drawings or STEP files; we will conduct DFM review and offer the optimal extrusion solution.

Titanium screws for eyeglass frames

Chalco Titanium supplies high-precision titanium screws designed for all types of eyeglass frames.

Made from pure titanium, they are lightweight, hypoallergenic, and corrosion-resistant — ideal for eyewear assembly and repair.

- Material: pure titanium (nickel-free and hypoallergenic)

- Specification: M1.4 × 10 mm; head diameter 2.6 mm, thickness 0.6 mm

High strength and rust-free, suitable for securing temples, nose pads, and hinges.

The threads are precisely machined for smooth tightening without stripping, ensuring long-term stability.

Available in natural titanium, anodized, or PVD color finishes.

Titanium sleeves for eyeglasses

Chalco Titanium specializes in producing titanium sleeves used for structural connections and temple coverings in eyeglass frames.

Titanium eyeglass sleeves are known for their high-precision thin walls and micro inner diameters, combining light weight with durability.

Contact us now

- Outer diameter (OD): 1.5–3.0 mm; wall thickness: 0.10–0.30 mm, customizable on request.

- Available in pure titanium and β-titanium — lightweight, corrosion-resistant, and nickel-free hypoallergenic.

- Excellent roundness and smooth, burr-free ends ensure easy assembly and a refined appearance.

Titanium nose pad arms, titanium bridges, and temple spring inserts

-

Titanium Nose Pad Arms Available in pure titanium or β-titanium, with embedded, U-shaped, or gooseneck structures. Compatible with titanium frame welding and insert or screw mounting for plastic, acetate, aluminum, or wooden frames. Lightweight, hypoallergenic, and easy to assemble.

-

Rimless titanium bridges Made of pure titanium with a natural, uncoated finish. Bridge length 16–20 mm (overall length 33 mm / hole spacing 3.0 mm). Designed for quick assembly of rimless glasses with matching sleeves and silicone nose pads.

-

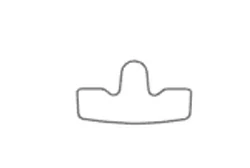

Temple spring inserts Fit 2.8–3.0 mm temples, providing outward flexibility and automatic return for titanium temple arms (sold individually).

- Standardized dimensions and included small parts reduce adjustment time; compatible with mainstream frame types and hole spacing.

- Lightweight and hypoallergenic titanium combined with stable spring rebound ensures lasting comfort without loosening.

- Available in anodized or PVD colors for a unified frame tone and texture.

- Stocked specifications and customizable options (hole spacing / bridge length / structure) support both pilot production and mass manufacturing.

Popular dimensions

Chalco Titanium offers a wide range of titanium profile and wire cross-sections for eyeglass frames, covering common shapes such as U-type, T-type, Logo-type, Patterned-type, and High Rim-type structures.

All cross-sections can match mainstream tooling or be customized according to customer drawings.

Eyerim profile

Logo profile

Patterned profile

U profile

High rim profile

T profile

Titanium profile and wire cross-section dimensions:

| Width (mm) | Height (mm) |

|---|---|

| 1.750 | 1.100 |

| 1.600 | 0.800 |

| 1.600 | 0.900 |

| 1.850 | 1.000 |

| 1.600 | 0.900 |

| 2.000 | 1.100 |

| 2.000 | 1.450 |

| 2.100 | 1.200 |

| 1.750 | 1.100 |

| 1.600 | 0.800 |

| 1.600 | 0.900 |

| 1.850 | 1.000 |

| 1.600 | 0.900 |

| 2.000 | 1.100 |

| 2.000 | 1.450 |

| 2.100 | 1.200 |

Delivery options:

- Shaped wire: Supplied in coils for continuous feeding and automated production, reducing changeover time.

- Thin shaped wire: For micro structures and small-scale trials, convenient for manual assembly.

- Shaped bars: Supplied in straight lengths for machining, cutting, or decorative parts — easy for secondary processing.

Whether you need mass-produced standard parts or unique custom cross-sections, Chalco Titanium delivers reliable titanium profile solutions for eyewear manufacturing with fast response and consistent quality.

Surface and color finishes for titanium eyewear materials

To meet the aesthetic and durability standards of eyewear-grade components, we offer multiple surface treatments — polishing, sandblasting, anodizing, and PVD — with measurable surface roughness and color deviation control to ensure consistent appearance from sampling to mass production.

- Polished: High-gloss mirror finish with a smooth tactile feel; typical Ra control 0.4–0.8 µm (reference range).

- Satin / Sandblasted: Fine matte texture, fingerprint-resistant, and scratch-tolerant.

- Anodized titanium: Voltage-controlled coloring with stable blue, violet, gold, and other tones — can be color-matched with stainless steel parts.

- PVD titanium parts: Gold, gunmetal, rose gold, and more; superior wear and sweat resistance, ideal for high-contact areas.

- Chemical cleaning / passivation: Removes oil and impurities, enhancing surface cleanliness and corrosion resistance for skin-contact applications.

Standard color charts and samples are provided to ensure uniform hue and texture across anodized/PVD, sandblasted, and polished finishes in different production batches.

Advantages of titanium in eyewear

Titanium combines light weight, high strength, and hypoallergenic properties, bringing value to both eyewear manufacturing and everyday wear.

- About 40% lighter than stainless steel yet stronger and more fatigue-resistant — less prone to deformation or breakage.

- Can be processed into micro cross-sections, thin walls, and fine tubes with dimensional accuracy up to ±0.02 mm, ideal for precision frame structures.

- Compatible with multiple processes such as laser welding, cold bending, anodizing, and PVD — offering both structural and aesthetic excellence.

- Maintains stability in humid, sweaty, or coastal environments — no fading, no rust.

- Nickel-free and safe for sensitive skin, ensuring long-term comfort and safety.

Titanium materials make production more precise and reliable with fewer reworks, while providing wearers with lighter, more comfortable, durable, and premium-quality eyewear.

Titanium alloy selection for eyewear

Chalco Titanium offers a full range of materials — from commercial pure titanium (CP-Ti) to high-performance alloys (β-Ti, Gr5, Ni-Ti) — providing precisely matched solutions for eyewire fronts, temples, hinges, and nose pad components.

| Material type | Key properties | Recommended applications |

|---|---|---|

| Gr1 / Gr2 (TA1 / TA2) | Hypoallergenic, corrosion-resistant, easy to polish | Bridges, nose pad arms, decorative parts, visible components |

| β-Ti (Ti-15333 / TB13 / Ti-15Mo / Ti-21S) | High elasticity, fatigue resistance, customizable rebound | Temple wires, flexible structures, spring joints |

| Gr5 (Ti-6Al-4V / TC4) | High strength, wear resistance, dimensional stability | Hinge plates, screws, micro components |

| Gr9 (Ti-3Al-2.5V) | Good formability, moderate strength | Fine tubes, sleeves |

| Gr6 (Ti-5Al-2.5Sn) | Excellent weldability, stable strength | Small structural parts, connection areas |

| Ni-Ti shape memory alloy (Nitinol) | Shape memory and super elasticity | Kids’ frames, sports eyewear elastic components |

Recommended alloys by application:

- Gr1 / Gr2 (Pure titanium): Hypoallergenic with a refined surface, ideal for skin-contact and decorative parts.

- β-Ti (TB13 / Ti-15333): Highly elastic and flexible, comfortable to wear, and resistant to deformation.

- Gr5 (Ti-6Al-4V): High strength and wear resistance, suitable for hinges and load-bearing parts.

- Gr9 (Ti-3Al-2.5V): Lightweight and bendable, ideal for thin tubes and connectors.

- Ni-Ti shape memory alloy: Super elastic and shape-restoring, perfect for sports and children's eyewear.

Our machining services

Chalco Titanium not only supplies titanium materials but also provides complete machining and assembly support for engineers and designers, ensuring precision and efficiency from drawing to mass production.

- Precision cutting / stamping / wire EDM: Suitable for high-accuracy parts such as small hinge plates, slots, screw holes, and chamfers.

- Bending and forming (β-Ti controlled): Expertise in β-titanium cold bending and rebound parameters ensures consistent temple shaping without spring-back.

- Welding / brazing: Supports laser and resistance welding, with intermediate layer or joint solutions for titanium-to-dissimilar materials (stainless steel, nickel silver, acetate) to prevent heat impact and delamination.

- Drilling / threading / tolerance fitting: Provides jig-level specifications for hole position, diameter, thread type, and assembly tolerance recommendations.

Quality inspection and assurance

- Dimensional inspection: 100% measurement of key dimensions using high-precision micrometers and digital gauges to ensure ±0.02 mm consistency.

- Appearance inspection: 100% visual check to control scratches, burrs, and color variations, meeting "eyewear-grade appearance standards.”

- Hardness testing: Titanium alloy strength verified using HV-5 microhardness testers and Rockwell hardness instruments.

- Elasticity and fatigue testing: Rebound consistency and fatigue life tests conducted for β-titanium materials.

- Corrosion and sweat resistance tests: Verified according to ISO 12870 or customer-specified methods (e.g., NSS salt spray test) to ensure anti-rust and sweat-resistant performance.

Packaging, delivery, and logistics

- Wires: Protected with anti-scratch reels, moisture-proof sealed bags, and positioning rings. Labels include heat number, wire diameter, tolerance, and batch number.

- Profiles and hinge parts: Packed in compartmentalized foam trays to prevent friction, with small bags (100–500 pcs/bag) for easy assembly line access.

- Sleeves / thin tubes: Both ends capped to prevent deformation, placed in custom pallets for anti-crush and anti-bend protection.

- Batch control system: Triple labeling for color, cross-section, and size, with attached packing list and QR code traceability.

- Accompanying documents: Includes MTC 3.1 certificate, inspection report, dimension sheet, packing list, and batch trace sheet.

We support multiple trade terms — EXW, FOB, CIF, and DDP — along with flexible logistics options such as DHL, FedEx, UPS, air freight, and sea consolidation, ensuring safe and on-time delivery.

Frequently asked questions (FAQ)

Is titanium suitable for eyeglass frames?

Absolutely. Titanium is lightweight, strong, hypoallergenic, and corrosion-resistant — making it the ideal material for high-end eyeglass frames that combine comfort with durability.

Who makes the best titanium eyeglass frames?

Wenzhou and Shenzhen in China, along with Italy and Japan, are the world's leading centers for titanium eyewear manufacturing.

Many international brands — such as LINDBERG, ic! berlin, and DITA — use premium titanium materials, and Chalco Titanium is one of the professional suppliers serving these manufacturers.

Chalco Titanium focuses on the R&D and production of titanium materials for eyewear, offering a full range from titanium wires and profiles to hinges, nose pad arms, bridges, sleeves, and screws, with options for drawing-based customization and small-batch prototyping.

Can titanium eyeglass frames be bent?

Yes. β-titanium (Beta Titanium) features high elasticity and fatigue resistance — temples can flex within a certain range and return to their original shape without deformation.

How can I tell if my eyeglass frames are made of titanium?

Genuine titanium frames are lighter, non-magnetic, and rust-free. You can test them with a magnet (titanium is not attracted) or check the inside engraving for markings such as "TITANIUM” or "β-TITANIUM.”

What are the advantages of titanium over stainless steel or nickel silver?

Titanium is about 40% lighter yet stronger, with superior corrosion resistance and hypoallergenic performance, offering long-lasting comfort and durability.

What's the difference between pure titanium and β-titanium?

Pure titanium (Gr1 / Gr2) is softer, hypoallergenic, and easy to polish — ideal for skin-contact and decorative parts.

β-titanium offers greater elasticity and fatigue strength, making it perfect for temple wires and flexible structures.