Titanium Pipe Caps

Updated : Jul. 16, 2025Titanium end caps are built for high-corrosion, high-pressure environments. They deliver excellent strength, tight sealing, and long-lasting performance.

Available in multiple styles—elliptical, conical, flat, and diffusion—they fit a wide range of piping and vessel systems with precision and reliability.

Titanium end caps specifications

Our titanium end caps are manufactured in strict accordance with international pipe fitting standards, ensuring safety and reliability in highly corrosive and high-pressure environments.

- ASTM B363 / ASME SB363

- ASME B16.9 / ANSI B16.9

- ASME B16.25 / ANSI B16.25

- DIN 2605 / 2615 / 2616 / 2617 / 28011

- EN 10253-1 / EN 10253-2

- MSS SP-43

- MSS SP-75

Contact us for specification confirmation, standard matching advice, and fast quotation service! Quick Quote

Titanium end caps alloys

| Alloy Grade | Standard Equivalent | Key Advantages |

|---|---|---|

| Grade 2 (CP-Ti) | DIN: 3.7035 / UNS: R50400 / JIS: TP340 / BS: TA2 | Commercially pure titanium. Excellent corrosion resistance, good weldability, cost-effective. |

| Grade 5 (Ti-6Al-4V) | DIN: 3.7165 / UNS: R56400 / JIS: TAP6400 / BS: TC5 | High strength, fatigue resistance, and heat resistance. Good welding properties. |

| Grade 7 (Ti-Pd) | UNS: R52400 / Palladium-alloyed CP titanium | Superior resistance to chloride corrosion. Ideal for bleach, chlor-alkali, and aggressive chlorine environments. |

We offer in-stock availability or fast customization for the above titanium grades, along with third-party testing and MTC certificates.

Not sure which alloy to choose? Just tell us your media, temperature, and pressure—we'll recommend the most suitable solution.

Popular titanium end caps

We offer a wide range of titanium end cap designs, including elliptical, dished, hemispherical, torispherical, conical, and standard pipe caps. Each shape meets specific sealing and structural needs under different operating conditions.

Elliptical Head

High structural strength. Ideal for pressure vessels, gas tanks, and heat exchangers.

Butterfly Head

Flatter profile. Suitable for lightweight vessels or applications with aesthetic requirements.

Hemispherical Head

Best pressure distribution. Perfect for high-pressure systems, though with higher manufacturing cost.

Spherical Head

Flat shape. Commonly used for flow guiding, sealing, or low-to-medium pressure enclosures.

Toriconical Head

Allows bottom drainage. Often used in liquid storage, separation equipment, and bottom-discharge tanks.

Pipe Cap

Simple structure. Welded at pipe ends for permanent or temporary closure in piping systems.

Titanium Muffler End Cap

Made from CP1-grade titanium using stamping technology, this end cap is lightweight, heat-resistant, and highly corrosion-resistant—ideal for racing and high-performance exhaust systems.

Contact us now

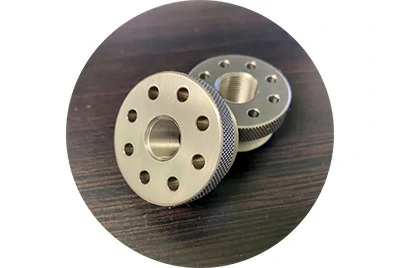

Threaded Titanium End Cap

This product is CNC machined from Grade 5 titanium alloy, specially designed for threaded sealing of D-shaped tubes, offering excellent airtight performance.

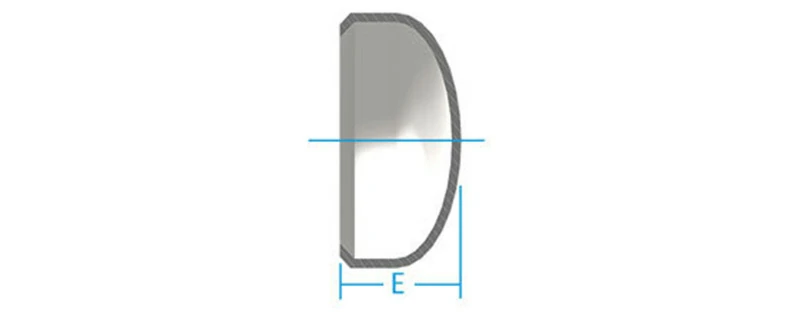

Contact us nowCaps dimensions are listed below for your reference.

| Nom. Pipe Size | Outside Diameter at Bevel (in) | E (in) | Limiting Wall Thickness for Length (in) | Length (in) |

|---|---|---|---|---|

| 1/2" | 0.84 | 1.00 | 0.18 | 1.00 |

| 3/4" | 1.05 | 1.00 | 0.15 | 1.00 |

| 1" | 1.32 | 1.50 | 0.18 | 1.50 |

| 1-1/4" | 1.66 | 1.50 | 0.19 | 1.50 |

| 1-1/2" | 1.90 | 1.50 | 0.20 | 1.50 |

| 2" | 2.38 | 1.50 | 0.22 | 1.75 |

| 2-1/2" | 2.88 | 1.50 | 0.28 | 2.00 |

| 3" | 3.50 | 2.00 | 0.30 | 2.50 |

| 3-1/2" | 4.00 | 2.50 | 0.32 | 3.00 |

| 4" | 4.50 | 2.50 | 0.34 | 3.00 |

| 5" | 5.56 | 3.00 | 0.38 | 3.50 |

| 6" | 6.62 | 3.50 | 0.43 | 4.00 |

| 8" | 8.62 | 4.00 | 0.50 | 5.00 |

| 10" | 10.75 | 5.00 | 0.50 | 6.00 |

| 12" | 12.75 | 6.00 | 0.50 | 7.00 |

| 14" | 14.00 | 6.50 | 0.50 | 7.50 |

| 16" | 16.00 | 7.00 | 0.50 | 8.00 |

| 18" | 18.00 | 8.00 | 0.50 | 9.00 |

| 20" | 20.00 | 9.00 | 0.50 | 10.00 |

| 22" | 22.00 | 10.00 | 0.50 | 10.00 |

| 24" | 24.00 | 10.50 | 0.50 | 12.00 |

| 26" | 26.00 | 10.50 | 26" | 26.00 |

| 28" | 28.00 | 10.50 | ||

| 30" | 30.00 | 10.50 | ||

| 32" | 32.00 | 10.50 | ||

| 34" | 34.00 | 10.50 | ||

| 36" | 36.00 | 10.50 | ||

| 38" | 38.00 | 12.00 | ||

| 40" | 30.00 | 12.00 | ||

| 42" | 42.00 | 12.00 | ||

| 44" | 44.00 | 13.50 | ||

| 46" | 46.00 | 13.50 | ||

| 48" | 48.00 | 13.50 |

The following section provides an overview of available wall thickness options for titanium end caps.

| Category | Wall Thickness (Schedule) | Description |

|---|---|---|

| Standard series | SCH 5S, SCH 10S, SCH 20, SCH 30 | Commonly used in low-pressure systems and lightweight structural applications. |

| Medium thickness | SCH 40 (STD), SCH 60, SCH 80 (XS) | Suitable for medium pressure and general industrial environments. |

| Heavy wall series | SCH 100, SCH 120, SCH 140, SCH 160, SCH XXS | Designed for high pressure, high temperature, and heavy-impact conditions. |

Titanium end caps stock list

We offer a wide range of titanium end caps in stock, covering multiple sizes and schedules for fast delivery and reliable supply.

| Size (NPS) | Schedule | Fitting Type | Material | In Stock |

|---|---|---|---|---|

| 3/4" S/10S WELD CAP TI GR 2 | S/10S | WELD CAP | GR 2 | 65 |

| 1" S/10S WELD CAP TI GR 2 | S/10S | WELD CAP | GR 2 | 85 |

| 1-1/2" S/10S WELD CAP TI GR 2 | S/10S | WELD CAP | GR 2 | 26 |

| 2" S/10S WELD CAP TI GR 2 | S/10S | WELD CAP | GR 2 | 48 |

| 3" S/10S WELD CAP TI GR 2 | S/10S | WELD CAP | GR 2 | 16 |

| 4" S/10S WELD CAP TI GR 2 | S/10S | WELD CAP | GR 2 | 85 |

| 6" S/10S WELD CAP TI GR 2 | S/10S | WELD CAP | GR 2 | 54 |

| 8" S/10S WELD CAP TI GR 2 | S/10S | WELD CAP | GR 2 | 86 |

| 3/4" S/40S WELD CAP TI GR 2 | S/40S | WELD CAP | GR 2 | 35 |

| 1" S/40S WELD CAP TI GR 2 | S/40S | WELD CAP | GR 2 | 44 |

| 1-1/2" S/40S WELD CAP TI GR 2 | S/40S | WELD CAP | GR 2 | 25 |

| 2" S/40S WELD CAP TI GR 2 | S/40S | WELD CAP | GR 2 | 18 |

| 3" S/40S WELD CAP TI GR 2 | S/40S | WELD CAP | GR 2 | 65 |

| 4" S/40S WELD CAP TI GR 2 | S/40S | WELD CAP | GR 2 | 7 |

| 6" S/40S WELD CAP TI GR 2 | S/40S | WELD CAP | GR 2 | 514 |

| 8" S/40S WELD CAP TI GR 2 | S/40S | WELD CAP | GR 2 | 58 |

| 3" S/40S WELD CAP TI GR 7 | S/40S | WELD CAP | GR 7 | 68 |

| 4" S/40S WELD CAP TI GR 7 | S/40S | WELD CAP | GR 7 | 74 |

If you can't find the exact titanium end cap you need, we offer fast customization and prompt delivery — contact us now for a tailored solution. Quick Quote

Features of titanium end caps

- Resistant to chloride, seawater, mineral acids, and various chemical media—ideal for harsh environments like chemical plants and marine systems.

- High tensile strength and excellent toughness ensure reliable sealing and protection under high pressure, high temperature, and impact conditions.

- Supports butt welding, cold forming, or threaded connection—easy to install and customize.

- Available in hemispherical, elliptical, dished, and conical shapes to meet diverse pressure and flow control requirements.

- Maintains structural stability under extreme temperatures, preventing pitting, crevice, and thermal corrosion.

With outstanding performance and standard compatibility, titanium end caps are the preferred choice for industrial sealing and anti-corrosion systems.

Contact us for the best model and alloy recommendation tailored to your needs. Quick Quote

Applications of titanium end caps

Titanium end caps are widely used in industrial systems where sealing, corrosion resistance, and strength are critical. They can block the flow of liquids or gases while withstanding both external corrosion and internal media attack. Common applications include:

- Wellhead equipment, pipeline sealing, and high-pressure anti-corrosion systems in oil and gas.

- Acid and alkali-resistant fluid systems and pressure vessel closures in chemical and petrochemical industries.

- Sterile transfer lines and end protection for pure water or steam pipes in pharmaceutical and medical systems.

- Liquid processing tanks and pipeline seals in food and brewing to prevent contamination.

- End seals and anti-corrosion plugs in brine systems for seawater desalination.

- High-temperature exhausts and pressure-sealing closures in aerospace and defense sectors.

- Heat exchangers, steam pipelines, and condensate system closures in power generation and energy equipment.

Case study: titanium end caps for high-pressure anti-corrosion sealing in oil and gas systems

A major oil and gas equipment manufacturer in the Middle East required wellhead components and pipeline accessories for field development.

The working conditions included high pressure, high salinity, and H₂S corrosion. The end caps needed to meet strict standards for strength and extreme corrosion resistance.

- Maintained 25 MPa pressure long-term with no deformation or leakage

- Operated for 18 months in high-sulfur environments without signs of corrosion

- Seamlessly integrated with the customer's existing ASME B16.9 fitting system

Client feedback:

"These titanium end caps perform reliably under high temperature, high pressure, and high salinity. They are our go-to solution for sealing natural gas wellheads."

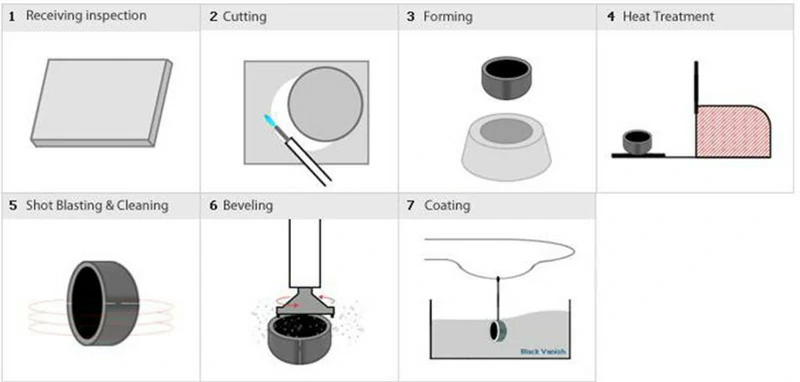

Titanium end caps manufacturing process

We produce seamless titanium end caps using cold forming technology to ensure precise dimensions, stable structure, and excellent weldability. The main steps include:

- Incoming inspection: Verify titanium grade and dimensions to meet required standards.

- Cutting: Slice raw materials into specified round blanks.

- Cold forming: Shape the end caps via spinning or die pressing.

- Heat treatment: Anneal to relieve stress and enhance strength and toughness.

- Sandblasting: Remove oxide layers and improve surface cleanliness.

- Beveling: Prepare weld grooves for tight, secure joints.

- Surface treatment: Optional pickling, passivation, or protective coating application.

Why choose our titanium pipe caps

In highly corrosive, high-temperature, or high-pressure environments, standard end caps are prone to corrosion and leakage. Our titanium end caps, made from Grade 2 and Grade 5 titanium, offer superior corrosion and pressure resistance.

- We offer a full size range from 1/8" to 3", compatible with SCH 10S / 40S wall thickness. Threaded and butt-weld options are available, with custom sizes upon request.

- Ready-to-ship inventory, low MOQ support, and fast delivery. All products comply with ASTM B363 and ASME B16.9 international standards.

- Precision-machined weld bevels ensure seamless integration with titanium piping systems, preventing leaks and corrosion for long-term reliability.

Matching titanium fittings for a one-stop solution

We don't just supply titanium end caps—we also offer a full range of titanium pipe fittings to complete your system.

Titanium Flanges

Titanium Transition Reducer

Titanium Tees

Titanium Elbows

Titanium Pipe Plugs

Titanium coupling

Our one-stop sourcing service helps prevent galvanic corrosion, welding incompatibility, and system failure caused by mixing different materials. This ensures greater system stability and long-term durability.

Contact us for a complete titanium piping solution and a matching quotation! Quick Quote

Frequently asked questions (FAQ)

What is an end cap?

An end cap is a pipe closure fitting installed at the end of a pipe or vessel. It seals the opening to prevent media leakage or contamination.

Titanium end caps offer outstanding corrosion resistance, making them ideal for demanding environments.

What types of titanium end caps are available?

We provide a variety of titanium end cap designs, including hemispherical, elliptical, conical, dished, flat, and threaded types—each suited for different pressure and structural needs.

How do I determine the right end cap size?

You'll need to select based on the pipe's nominal size (NPS), wall thickness (SCH), and connection type (welded or threaded).

We offer technical support and drawings to ensure a perfect fit. Quick Quote

Can titanium end caps be welded? How is the weldability?

Yes. Titanium end caps, especially those made of Grade 2 or Grade 5, offer excellent weldability. After beveling, they form seamless, strong, and corrosion-resistant joints with titanium pipes.

Can titanium exhaust pipes be bent?

Yes. Grade 2 and Grade 5 titanium pipes have good ductility and heat resistance, and can be cold- or hot-bent using proper equipment—ideal for custom exhaust systems.

Are titanium pipes safe?

Absolutely. Titanium pipes are strong, corrosion-resistant, and non-toxic. They are widely used in chemical, pharmaceutical, and food industries as a safe and reliable material choice.