Titanium Stub Ends

Updated : Jun. 26, 2025Titanium stub ends are corrosion-resistant pipe fittings used with lap joint flanges for easy, weld-free disassembly.

Ideal for chemical, marine, and high-purity systems, we offer Grade 2 and Grade 7 options in MSS Type A, Type B, and ANSI long styles.

Sizes from 1/2" to 8" are in stock, with fast delivery and custom options available.

Titanium stub ends specifications

- ASME B16.9

- MSS-SP-43

- ASME B16.5 / B16.47

- ASTM B363 / ASME SB-363

- ISO 15156 / NACE MR0175, MR0103

Our titanium stub ends comply with ISO 15156, NACE MR0175/MR0103, NORSOK M-650, AMS 2631D Class A, and ISO 5832-2.

We also provide EN 10204 Type 3.1 material certificates, backed by a quality management system certified to AS9100, ISO 9001, and AS9120. Full traceability and global standards are ensured.

Common titanium stub ends alloys

-

Grade 2(UNS R50400)

Commercially pure titanium with a balance of good strength, ductility, and excellent corrosion resistance.

-

Grade 5(Ti-6Al-4V, UNS R56400)

One of the most widely used titanium alloys, offering high strength and excellent heat resistance.

-

Grade 7(Ti-0.2Pd, UNS R52400)

Based on Grade 2 with palladium added for better corrosion resistance in acids and chlorides.

Titanium stub ends product features

- Grade 2 titanium stub ends come with a serrated spiral finish on the end face, in accordance with ASME B16.5. (Other finishes available upon request.)

- Butt-weld titanium fittings are permanently marked by electrochemical etching, meeting ASME B16.9 requirements.

- Dimensional tolerances comply with ASME B16.9 standards.

- Wall thickness meets the ASME B36.19M standards for 10S and 40S schedules.

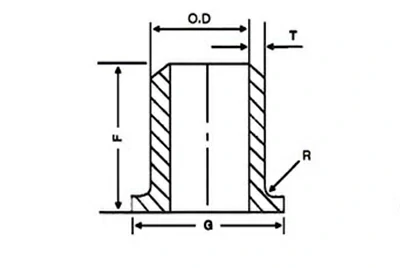

ANSI titanium stub ends

ANSI stub end is a long pattern lap joint stub end made to ASME B16.9 dimensions, ideal for piping systems requiring extended connections or pairing with long neck flanges.

Contact us now

ANSI stub end has a longer sealing surface and a higher neck, making it suitable for heavy-duty connections under high pressure and high temperature.

It is commonly used in pipeline systems with high strength requirements in industries such as petrochemical, chemical, power generation, and shipbuilding.

Manufactured in accordance with ASME B16.9 or ASME B16.28 standards.

Below is a standard ANSI stub end size chart, showing outer diameters and flange contact dimensions for various inch sizes, provided for your selection reference. Quick Quote

| Nominal Pipe Size INCH | Outside Diameter OD | ANSI G | ANSI F | ANSI R |

|---|---|---|---|---|

| 1/2 | 21.3 | 35 | 76 | 3 |

| 3/4 | 26.7 | 43 | 76 | 3 |

| 1 | 33.4 | 51 | 102 | 3 |

| 1-1/4 | 42.2 | 64 | 102 | 5 |

| 1-1/2 | 48.3 | 73 | 102 | 6 |

| 2 | 60.3 | 92 | 152 | 8 |

| 2-1/2 | 73.0 | 105 | 152 | 8 |

| 3 | 88.9 | 127 | 152 | 10 |

| 3-1/2 | 101.6 | 140 | 152 | 10 |

| 4 | 114.3 | 157 | 152 | 11 |

| 5 | 141.3 | 186 | 203 | 11 |

| 6 | 168.3 | 216 | 203 | 13 |

| 8 | 219.1 | 270 | 203 | 13 |

| 10 | 273 | 324 | 254 | 13 |

| 12 | 323.9 | 381 | 254 | 13 |

| 14 | 355.6 | 413 | 254 | 13 |

| 16 | 406.4 | 470 | 254 | 13 |

| 18 | 457.2 | 533.5 | 254 | 13 |

| 20 | 508 | 584 | 254 | 13 |

| 24 | 609.1 | 692 | 254 | 13 |

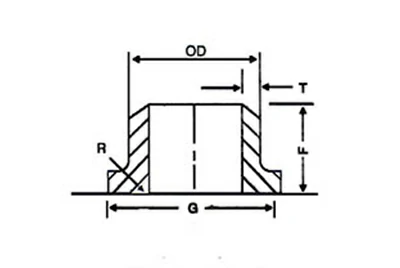

MSS Type A Stub End

MSS type A stub end is a short pattern lap joint stub end, specifically designed to fit tightly with lap joint flanges. It meets the MSS-SP-43 standard.

Contact us now

The flange contact surface is shorter than the ANSI type, with a moderate neck height that ensures a tight fit with lap joint flanges.

It is suitable for medium and low-pressure systems, offering cost-effective and easy installation.

Compliant with MSS-SP-43, it's ideal for corrosion-resistant materials like stainless steel and titanium.

Below is a standard MSS type A stub end size chart to help you select the right size based on pipe diameter. Quick Quote

| Nominal Pipe Size INCH | Outside Diameter OD | F | TYPEA R |

|---|---|---|---|

| 1/2 | 21.3 | 51 | 3 |

| 3/4 | 26.7 | 51 | 3 |

| 1 | 33.4 | 51 | 3 |

| 1-1/4 | 42.2 | 51 | 5 |

| 1-1/2 | 48.3 | 51 | 6 |

| 2 | 60.3 | 64 | 8 |

| 2-1/2 | 73.0 | 64 | 8 |

| 3 | 88.9 | 64 | 10 |

| 3-1/2 | 101.6 | 76 | 10 |

| 4 | 114.3 | 76 | 11 |

| 5 | 141.3 | 76 | 11 |

| 6 | 168.3 | 89 | 13 |

| 8 | 219.1 | 102 | 13 |

| 10 | 273 | 127 | 13 |

| 12 | 323.9 | 152 | 13 |

| 14 | 355.6 | 152 | 13 |

| 16 | 406.4 | 152 | 13 |

| 18 | 457.2 | 152 | 13 |

| 20 | 508 | 152 | 13 |

| 24 | 609.1 | 152 | 13 |

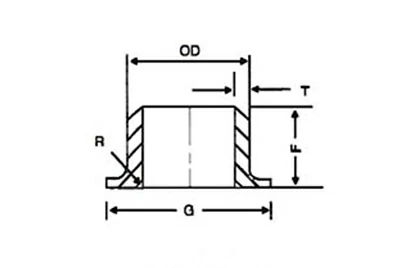

MSS type B stub end

MSS type B stub end fits slip-on flanges, with a flanged face designed to nest inside the flange bore. Complies with MSS-SP-43.

Contact us now

The flange contact surface is shorter than Type A, with a slight step on the back, offering a lighter structure ideal for thin-wall piping.

Best suited for low-pressure or non-critical systems where high structural strength is not required, providing a more cost-effective solution.

Also compliant with MSS-SP-43, it must be used with matching Type B lap joint flanges.

Below is a standard MSS type B stub end size chart for slip-on flange selection reference. Quick Quote

| Nominal Pipe Size INCH | Outside Diameter OD | F | TYPEB R |

|---|---|---|---|

| 1/2 | 21.3 | 51 | 0.8 |

| 3/4 | 26.7 | 51 | 0.8 |

| 1 | 33.4 | 51 | 0.8 |

| 1-1/4 | 42.2 | 51 | 0.8 |

| 1-1/2 | 48.3 | 51 | 0.8 |

| 2 | 60.3 | 64 | 0.8 |

| 2-1/2 | 73.0 | 64 | 0.8 |

| 3 | 88.9 | 64 | 0.8 |

| 3-1/2 | 101.6 | 76 | 0.8 |

| 4 | 114.3 | 76 | 1.6 |

| 5 | 141.3 | 76 | 1.6 |

| 6 | 168.3 | 89 | 1.6 |

| 8 | 219.1 | 102 | 1.6 |

| 10 | 273 | 127 | 1.6 |

| 12 | 323.9 | 152 | 1.6 |

| 14 | 355.6 | 152 | 1.6 |

| 16 | 406.4 | 152 | 1.6 |

| 18 | 457.2 | 152 | 1.6 |

| 20 | 508 | 152 | 1.6 |

| 24 | 609.1 | 152 | 1.6 |

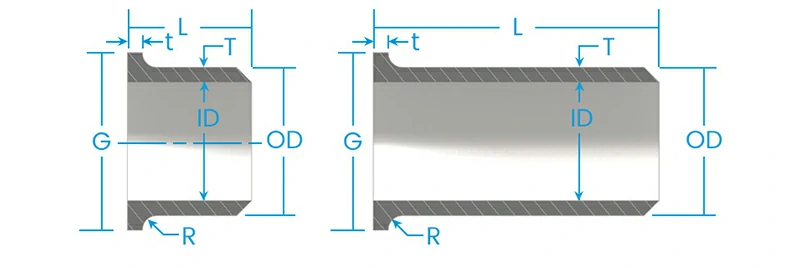

Titanium stub ends S10 and S40 standard size chart

Our titanium pipe fittings comply with ASME B36.19M standards for 10S and 40S wall thickness, ensuring each product is strong and reliable.

| NOM. PIPE SIZE | S10 INSIDE DIA. | S10 WALL THICKNESS | S10 LAP THICKNESS | S40 INSIDE DIA. | S40 WALL THICKNESS | S40 LAP THICKNESS |

|---|---|---|---|---|---|---|

| 1/2 | 0.674 | 0.083 | 0.083 | 0.622 | 0.109 | 0.109 |

| 3/4 | 0.884 | 0.109 | 0.109 | 0.824 | 0.113 | 0.113 |

| 1 | 1.097 | 0.109 | 0.109 | 1.049 | 0.133 | 0.133 |

| 1-1/4 | 1.442 | 0.109 | 0.109 | 1.380 | 0.140 | 0.140 |

| 1-1/2 | 1.682 | 0.109 | 0.109 | 1.610 | 0.145 | 0.145 |

| 2 | 2.157 | 0.109 | 0.109 | 2.067 | 0.154 | 0.154 |

| 2-1/2 | 2.635 | 0.120 | 0.120 | 2.469 | 0.203 | 0.203 |

| 3 | 3.260 | 0.120 | 0.120 | 3.068 | 0.216 | 0.216 |

| 3-1/2 | 3.760 | 0.120 | 0.120 | 3.548 | 0.226 | 0.226 |

| 4 | 4.260 | 0.120 | 0.120 | 4.026 | 0.237 | 0.237 |

| 5 | 5.295 | 0.134 | 0.134 | 5.047 | 0.258 | 0.258 |

| 6 | 6.357 | 0.134 | 0.134 | 6.065 | 0.280 | 0.280 |

| 8 | 8.329 | 0.148 | 0.148 | 7.981 | 0.322 | 0.322 |

| 10 | 10.420 | 0.165 | 0.165 | 10.020 | 0.365 | 0.365 |

| 12 | 12.390 | 0.180 | 0.180 | 12.000 | 0.375 | 0.375 |

| 14 | 13.624 | 0.188 | 0.188 | 13.250 | 0.375 | 0.375 |

| 16 | 15.624 | 0.188 | 0.188 | 15.250 | 0.375 | 0.375 |

| 18 | 17.624 | 0.188 | 0.188 | 17.250 | 0.375 | 0.375 |

| 20 | 19.564 | 0.218 | 0.218 | 19.250 | 0.375 | 0.375 |

| 24 | 23.500 | 0.375 | 0.375 | 23.250 | 0.375 | 0.375 |

Applications of titanium stub ends

Titanium stub ends, used with standard lap joint flanges, enable seamless and corrosion-resistant connections. They maintain system sealing while greatly improving maintenance efficiency and service life.

Corrosive fluid pipelines

Ideal for transporting acids, seawater, and chloride-based media, commonly used in chemical, metallurgical, and environmental industries.

Contact us now

Precision process piping systems

Used in industries like pharmaceuticals and biotechnology where high cleanliness and easy disassembly for cleaning are essential.

Contact us nowHigh-purity fluid systems

Designed for ultrapure water and high-purity gas pipelines in the semiconductor and electronics industries.

Contact us now

Removable connection systems

Ideal for areas requiring regular maintenance, such as heat exchangers and pressure vessels.

Contact us nowWe offer customized titanium stub ends solutions tailored to your specific application needs, including size, material, and type. Quick Quote

Features of titanium stub ends

- Titanium offers excellent corrosion resistance against a wide range of acids, alkalis, and salts.

- The stub end and lap joint flange design allows easy assembly and disassembly without repeated welding.

- Titanium has only 60% the density of stainless steel while maintaining high strength.

- Its surface is smooth and stable, releasing no metallic impurities.

- Titanium retains strength and stability even at high temperatures.

- Grade 2 and Grade 7 titanium stub ends have good weldability.

Connection method and usage of titanium stub ends

Titanium stub ends are typically used with lap joint flanges to form a detachable, corrosion-resistant, and easy-to-maintain piping connection.

One end is butt-welded to the titanium pipe

The stub end is butt-welded to the titanium pipe for strong, corrosion-resistant joints.

Contact us now

Flanged end is clamped with lap joint flange

The flanged face mates with the inner side of the lap joint flange, secured by bolts for a reliable seal and easy disassembly.

Contact us nowWhy Choose Chalco as Your Titanium Stub Ends Supplier

- Comprehensive Product Range & Customization: We offer a full range of ANSI and MSS Type A/B stub ends. Standard sizes are in stock, and we support custom dimensions, materials, and connection types based on your drawings.

- Quality Certification & International Standards: All products come with EN 10204 3.1 material certificates and meet ASME, ASTM, ISO, NACE, and NORSOK standards. Our manufacturing system is certified to AS9100, ISO 9001, and AS9120, ensuring reliable quality and traceability.

- Global Supply Experience: With years of titanium export experience, we serve clients across North America, the Middle East, Europe, Southeast Asia, India, Japan, South America, and more. We understand regional standards and customs procedures to ensure smooth delivery.

- Technical Support & Fast Delivery: Our engineers provide fast, accurate guidance to help you choose the right type and grade, reducing trial-and-error costs. In-stock items ship within 3–5 days, while custom orders have clear lead times. Fast delivery via DHL, UPS, or sea freight is available to keep your projects on schedule.

- Full Range Titanium Pipe Fitting Products Supply: In addition to stub ends, Chalco supplies a full range of titanium pipe fittings and related products, including titanium couplings, titanium transition reducers, titanium tees, titanium caps, and titanium plugs, providing a complete piping solution.

- Contact & Support: Get a quote, technical data, or samples today. Our professional, efficient, and dependable service is ready to support your success, making Chalco your trusted partner for titanium pipe fittings.

Contact us now for a quote, technical data, or samples. Let our professional, efficient, and dependable service support your success. We're ready to be your trusted partner for titanium pipe fittings. Quick Quote

Titanium stub ends frequently asked questions (FAQ)

What applications are titanium stub ends suitable for?

They are ideal for piping systems with strong corrosion, frequent disassembly, or high cleanliness requirements. Commonly used in chemical processing, pharmaceuticals, seawater systems, electronics, and oil & gas industries.

How to choose between Type A, Type B, or ANSI stub ends?

- Type A is most commonly used with standard lap joint flanges.

- Type B is suitable for systems where slip-on flanges are used as lap joint flanges.

- ANSI long pattern stub ends are used when longer connections or pairing with long neck flanges is needed.

We recommend selecting based on flange type and piping design. Or simply contact us — we'll help you choose the best solution for your project. Quick Quote

Can titanium stub ends be customized to drawings or non-standard sizes?

Yes. We support custom production based on your drawings, special specifications (size, flange thickness, length), or specified titanium grades.

Do titanium stub ends have a long service life?

Yes. Compared to stainless steel and other materials, titanium offers superior corrosion resistance and fatigue strength, resulting in a longer service life and significantly reduced maintenance and replacement costs.