Titanium Valve Spring Retainers

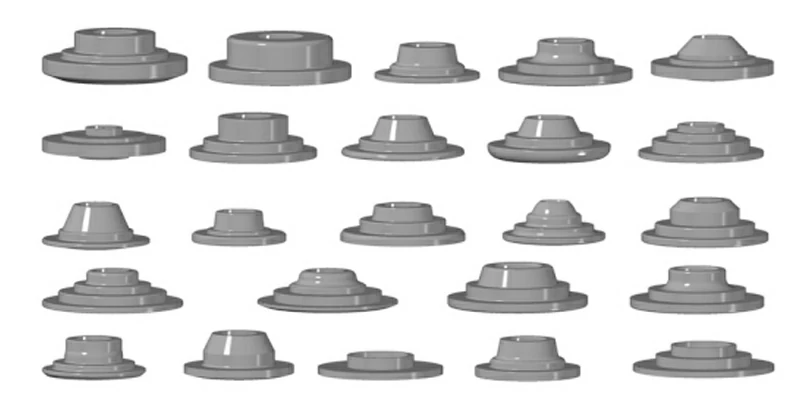

Updated : Nov. 26, 2025Titanium valve spring retainers are core lightweight components in valve train systems, approximately 40-60% lighter than steel products, significantly reducing inertia and valve float. Chalcotitanium offers CNC-precision machined titanium retainers/titanium spring retainers compatible with mainstream engine platforms such as Honda, Toyota, and GM LS, supporting OEM replacement and mass customization to meet the needs of engine manufacturers and tuning shops for lightweight design, high-speed stability, and long-term reliability.

Product Overview

Chalco Titanium has focused on the production of titanium valve spring retainers for over 10 years, using aerospace-grade Ti-6Al-4V titanium alloy and high-precision CNC machining to ensure strict tolerance control and batch consistency.

- Lightweight design: approximately 40–60% lighter than steel products, significantly reducing valve system inertia;

- High strength and durability: It has excellent fatigue resistance, ensuring the stability of the valve system at high speeds;

- Typical specifications: outer diameter 16–22 mm, inner diameter 6–8 mm, thickness 2–3 mm (customizable according to customer requirements).

- Angle selection: Offers designs such as 7° and 10°, compatible with various valve spring structures;

- Applications: Covering engine manufacturing, performance modification, and racing power systems.

Whether for OEM bulk replacements or high-performance powertrain retrofits, Chalco's titanium valve spring retainers provide customers with reliable lightweight solutions, supporting parametric customization and rapid delivery.

Engine-Specific Products: Titanium Valve Spring Retainers

Chalcotitanium offers titanium valve spring retainers compatible with mainstream engine platforms such as Honda, Toyota, and GM LS. Featuring a lightweight design, high-strength titanium alloy materials, and CNC precision machining, these products meet the needs of engine manufacturers and tuning shops for mass OEM replacements and high-performance powertrain applications.

Honda Titanium Retainer Products

Chalco offers the Titanium Retainer, designed specifically for Honda's VTEC series engines such as the B16, K20, F20B, and D16Z6. Its lightweight structure effectively reduces valve system inertia and improves high-speed stability.

Contact us now

- B16 Titanium Retainers: Common outer diameter 16–18 mm, compatible with B-series platforms, supporting high-speed applications.

- K20 Retainers / Titanium Springs: Recommended outer diameter 18–20 mm, can withstand 9000+ rpm, suitable for high-performance engines on the K-series platform.

- F20B / D16Z6 series: OEM replacement and customized versions are available to meet different displacement and application needs.

If you are looking for a high-revving modification solution for your Honda engine, our Honda titanium spring retainer products are a lightweight and reliable choice.

Toyota Titanium Retainer Products

Chalco offers titanium valve spring retainers compatible with Toyota 2JZ, 2JZ-GE, and 2JZ-GTE platforms, particularly suitable for turbocharged and high-load applications.

Contact us now

- 2JZ Titanium Retainers: Outer diameter range 18–22 mm, improving high-speed stability, compatible with 2JZ series platforms.

- 2JZ-GE / 2JZ-GTE Retainers: Differentiated designs for naturally aspirated and turbocharged operation, ensuring reliability at maximum speeds.

Our Toyota titanium retainer products are the preferred choice for 2JZ series engines in racing and high-performance modifications.

GM LS Titanium Retainer Products

For American high-displacement V8 platforms, Chalco offers LS1 and LS3 Titanium Retainers, which ensure high strength and durability with a lightweight design.

Contact us now

- LS1 Titanium Retainers: Used in LS1 series V8 engines to reduce inertial load and improve valve system response.

- LS3 Titanium Retainers: Compatible with the LS3 platform, specifically developed for high-horsepower and high-speed operating conditions.

Choose our GM LS titanium retainer products to keep your V8 engine stable and reliable even at high RPMs and high horsepower.

Other Titanium Retainer Products (Engines & Powersports)

In addition to mainstream automotive engine platforms, Chalco also provides customized titanium retainer products for motorboats, motorcycles, and special power systems (such as Sea-Doo, Yamaha, Nissan TB48, and Mercedes-Benz M111) to meet the lightweight requirements of diverse power systems.

Sea-Doo 2024+ 4-TEC Titanium Alloy Valve Holder

Metallized titanium valve spring retainer

Nissan TB48 engine titanium alloy retainer

Oxidized colored titanium valve spring retainer

Sea-doo Titanium Alloy Fixing Kit

Seadoo Titanium Alloy Holding Kit

Whether it's automotive powertrain modifications, motorboat power systems, or special engine applications, Chalco's custom titanium valve spring retainer products offer OEM/ODM customized lightweight solutions, supporting both bulk supply and rapid delivery.

Chalco Titanium Retainer Manufacturing & Processing Capabilities

Chalco Titanium has a complete manufacturing and testing system to ensure that the product achieves the best performance balance between lightweight and high strength, meeting the mass application needs of engine manufacturers and modification shops.

Premium Materials: All materials are made of aerospace-grade Ti-6Al-4V (Grade 5 Titanium), and high-end alloys such as Ti-17 can be provided on demand to meet the application requirements of extreme high-speed engines.

CNC Precision Machining: Through five-axis CNC machining and high-precision tooling fixtures, tolerances such as outer diameter, inner diameter, and angle are strictly controlled to ensure batch consistency and stable installation of products.

Testing & Certifications: We provide test reports for hardness, fatigue resistance, dimensional accuracy, etc. Our production system complies with standards such as ISO9001 / IATF16949, and we can also provide RoHS / REACH environmental compliance certificates upon customer request.

OEM / ODM Customization: We support customized designs based on valve and spring parameters provided by customers, and can provide small-batch rapid prototyping and large-batch mass production delivery.

Surface Treatment Options: Optional processes such as nitriding and PVD coating can be used to improve surface hardness and wear resistance, and a variety of appearance treatments are available to meet different customers' performance and marking needs.

Whether it's OEM bulk replacement parts or high-performance engine retrofitting and powertrain projects, Chalco can provide an integrated solution from material selection to precision machining, surface treatment, and inspection and delivery, ensuring batch consistency and compliance with international standards.

Cooperation Fields of Titanium Valve Spring Retainers

Chalco Titanium valve spring retainers are widely used in various industries and powertrain sectors. We provide mass production and customized solutions for engine OEMs, tuning shops, racing teams, and users of specialized powertrain systems.

Engine OEMs and Tier 1 suppliers

provide volume products compliant with ISO/IATF standards for OEM replacements and engine platform upgrades, ensuring consistency and long-term reliability.

Performance tuning shops and racing teams

provide titanium alloy retainers adapted for high-revving, high-boost conditions, supporting high-strength materials such as Ti-6Al-4V / Ti-17 to meet the requirements of extreme racing environments.

Specialized power systems

are applied to diverse platforms such as motorboats, motorcycles, special vehicles, and industrial power units, supporting small-batch prototyping and large-scale mass production to meet customized needs.

By collaborating with diverse customer groups, Chalco is able to provide high-volume titanium retainer solutions that meet international standards, and supports global delivery and technical support.

By collaborating with diverse customer groups, Chalco is able to provide high-volume titanium retainer solutions that meet international standards, and supports global delivery and technical support.