High Performance Titanium Wire Mesh

Updated : Aug. 12, 2025Titanium Wire Mesh is precisely woven from Gr1/Gr2 pure titanium or titanium alloy wire, offering excellent corrosion resistance, high-temperature stability, and a superior strength-to-weight ratio. Compared to stainless steel or nickel meshes, titanium mesh provides longer service life and greater safety in harsh environments. It is widely used in seawater filtration, electrolytic electrodes, aerospace components, and chemical reactors where demanding performance is required.

Chalco supplies Titanium Wire Mesh in compliance with ASTM B348 and ASTM B863, with standard mesh sizes from 0.2 to 200 mesh and wire diameters from 0.05 mm to 1.2 mm. Products are available in rolls, sheets, or framed mesh assemblies upon request.Request Sample

Why Choose Titanium Wire Mesh?

Titanium Wire Mesh is highly favored in industries such as aerospace, medical filtration, electrochemistry, battery systems, and seawater desalination, thanks to its unmatched combination of performance and reliability:

-

Exceptional Corrosion Resistance

Exceptional Corrosion Resistance

Titanium naturally forms a dense, stable oxide film in oxidizing environments, providing outstanding resistance to acids, alkalis, and chloride ions. It is ideal for seawater, chloride-rich, and electrolytic environments.

-

High Strength-to-Weight Ratio

High Strength-to-Weight Ratio

With a higher specific strength than most metallic alloys, titanium significantly reduces structural weight while maintaining mechanical integrity—perfect for lightweight aerospace structures and chemical process equipment.

-

Excellent Biocompatibility

Excellent Biocompatibility

Commercially pure titanium is non-toxic and non-reactive to human tissues, making it suitable for medical-grade filters, implantable devices, and laboratory fluid systems requiring ultra-clean performance.

-

Good Electrical & Thermal Conductivity

Good Electrical & Thermal Conductivity

In applications such as current collectors, electrodes, and battery protection layers, titanium mesh ensures efficient electrochemical transmission and thermal dissipation due to its stable conductive and thermal properties.

-

High-Temperature Stability

High-Temperature Stability

Capable of operating continuously below 400°C without structural degradation, Titanium Wire Mesh is ideal for hot gas filtration, combustion systems, and other high-temperature screening tasks.

Technical Specifications of Titanium Wire Mesh

Chalco offers a comprehensive range of Titanium Woven Wire Mesh options to meet the requirements of industrial filtration, laboratory sieving, and electrochemical applications.

Specifications

Available Alloys:Gr1, Gr2, Gr5, Gr7, Gr9, Gr12

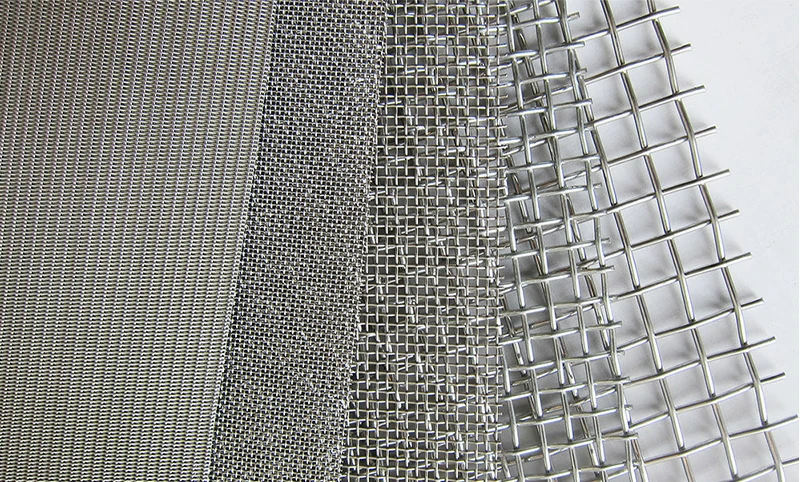

Mesh Count:0.2 mesh – 200 mesh

Wire Diameter:0.05 mm – 1.2 mm

Aperture Size:0.05 mm – 11 mm (based on mesh & wire diameter)

Open Area (%) :10% – 85% (varies by weave type)

Mesh Shape:Square, Rectangular

Surface Finish:Degreased, Pickled, Bright Polished

Color Options:Natural Titanium, Black, White, Anodized Blue, Gold, Purple

Standards:ASTM B863, ASTM F67, ASTM F136

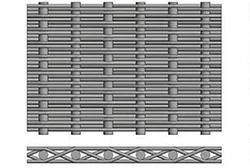

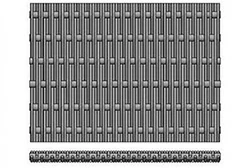

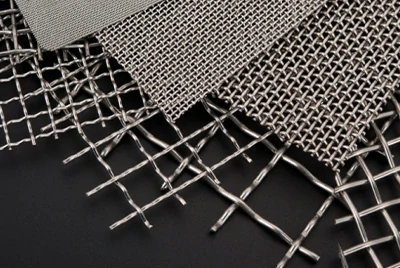

Common Weave Types

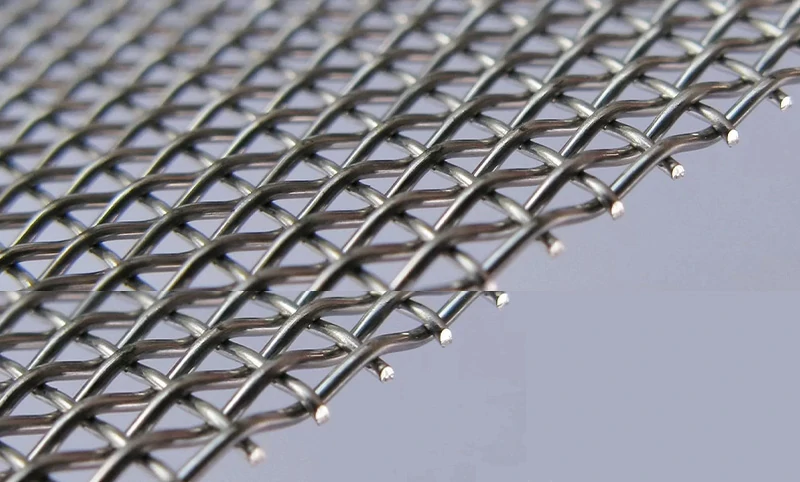

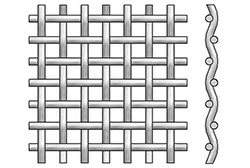

Plain Weave

Most common pattern; warp and weft alternate over and under, creating an even aperture. Suitable for low-to-mid mesh counts.

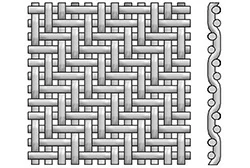

Twill Weave

Each wire passes over two or more cross wires, forming a diagonal pattern with tighter weave and higher strength.

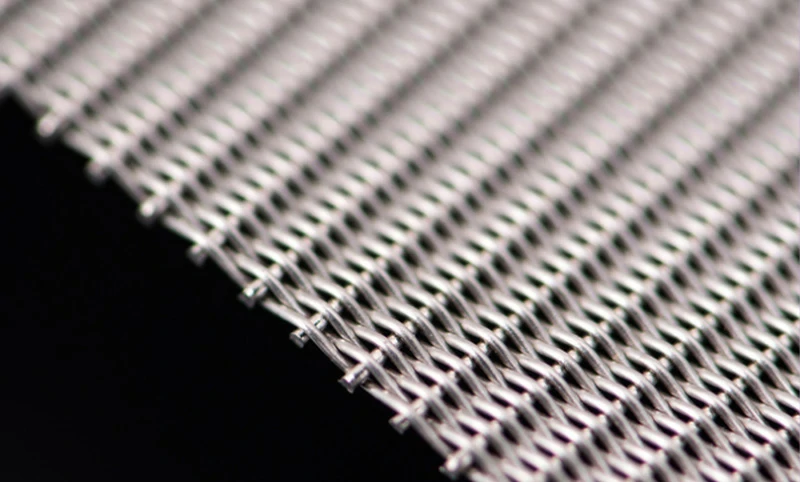

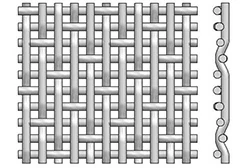

Five-Heddle Weave

Complex pattern with each wire intersecting four or more, forming a flat, dense weave for precision support applications.

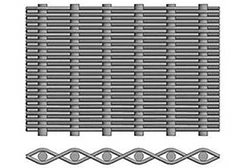

Plain Dutch Weave

Thick warp wires and dense weft wires create fine apertures with high flow rate, ideal for precision filtration.

Twill Dutch Weave

Combines twill and Dutch patterns for superior strength and pressure resistance; suitable for ultra-fine and corrosive media.

Reverse Dutch Weave

Weft wires are thicker than warp wires, creating a tight structure with high permeability; used in high-speed filtration and backflush systems.

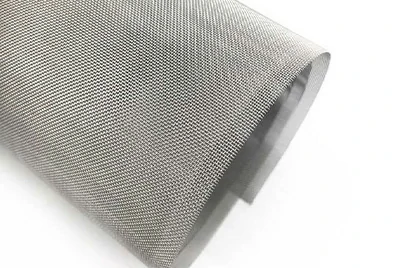

Supply Forms of Titanium Woven Wire Mesh

Chalco supplies Titanium Woven Wire Mesh in two primary forms:

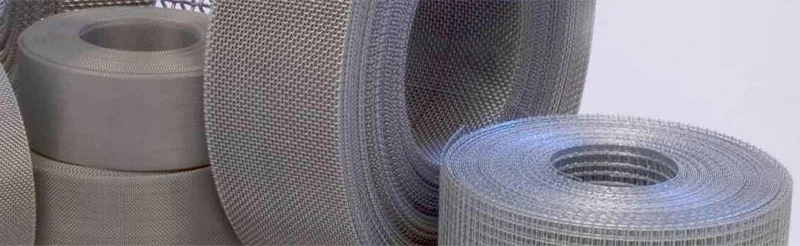

Titanium Woven Wire Mesh - Roll

Mesh: 30 – 200 mesh

Wire Diameter: ≤ 0.4 mm

Standard Width: 1000 / 1200 / 1500 / 2000 mm

Features: Flexible and rollable; suitable for large-area installation

Titanium Woven Wire Mesh - Sheet

Mesh: 2 – 80 mesh

Wire Diameter: ≥ 0.4 mm

Standard Size: 500 × 500 mm, 1000 × 1000 mm

Features: Rigid, customizable in size and edge finish

Note: The thicker the wire, the higher the rigidity—making it unsuitable for roll supply. Conversely, ultra-fine wires may deform easily in sheet form and are better suited for rolls.Get a Quote

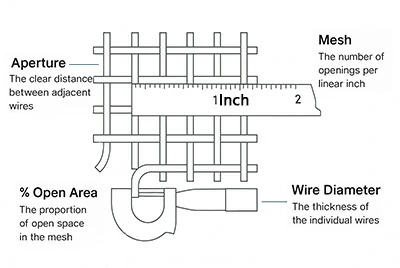

Titanium Wire Mesh – Key Measurement Terms

Mesh: Number of openings per inch; higher mesh means finer filtration

Wire Diameter: Thickness of the titanium wires that form the mesh

Aperture: Actual space between two adjacent wires, determining passage width

% Open Area: Ratio of open area to total mesh area; higher value means better flow

| Mesh | Wire Diameter | Aperture | % Open Area | ||

|---|---|---|---|---|---|

| IN | MM | IN | MM | ||

| 1X1 | 0.08 | 2.03 | 0.92 | 23.37 | 84.6 |

| 2X2 | 0.063 | 1.6 | 0.437 | 11.1 | 76.4 |

| 3X3 | 0.054 | 1.37 | 0.279 | 7.09 | 70.1 |

| 4X4 | 0.063 | 1.6 | 0.187 | 4.75 | 56 |

| 4X4 | 0.047 | 1.19 | 0.203 | 5.16 | 65.9 |

| 5X5 | 0.041 | 1.04 | 0.159 | 4.04 | 63.2 |

| 6X6 | 0.035 | 0.89 | 0.132 | 3.35 | 62.7 |

| 8X8 | 0.028 | 0.71 | 0.097 | 2.46 | 60.2 |

| 10X10 | 0.025 | 0.64 | 0.075 | 1.91 | 56.3 |

| 10X10 | 0.02 | 0.51 | 0.08 | 2.03 | 64 |

| 12X12 | 0.023 | 0.584 | 0.06 | 1.52 | 51.8 |

| 12X12 | 0.02 | 0.508 | 0.063 | 1.6 | 57.2 |

| 14X14 | 0.023 | 0.584 | 0.048 | 1.22 | 45.2 |

| 14X14 | 0.02 | 0.508 | 0.051 | 1.3 | 51 |

| 16X16 | 0.018 | 0.457 | 0.0445 | 1.13 | 50.7 |

| 18X18 | 0.017 | 0.432 | 0.0386 | 0.98 | 48.3 |

| 20X20 | 0.02 | 0.508 | 0.03 | 0.76 | 36 |

| 20X20 | 0.016 | 0.406 | 0.034 | 0.86 | 46.2 |

| 24X24 | 0.014 | 0.356 | 0.0277 | 0.7 | 44.2 |

| 30X30 | 0.013 | 0.33 | 0.0203 | 0.52 | 37.1 |

| 30X30 | 0.012 | 0.305 | 0.0213 | 0.54 | 40.8 |

| 30X30 | 0.009 | 0.229 | 0.0243 | 0.62 | 53.1 |

| 35X35 | 0.011 | 0.279 | 0.0176 | 0.45 | 37.9 |

| 40X40 | 0.01 | 0.254 | 0.015 | 0.38 | 36 |

| 50X50 | 0.009 | 0.229 | 0.011 | 0.28 | 30.3 |

| 50X50 | 0.008 | 0.203 | 0.012 | 0.31 | 36 |

| 60X60 | 0.0075 | 0.191 | 0.0092 | 0.23 | 30.5 |

| 60X60 | 0.007 | 0.178 | 0.0097 | 0.25 | 33.9 |

| 70X70 | 0.0065 | 0.165 | 0.0078 | 0.2 | 29.8 |

| 80X80 | 0.0065 | 0.165 | 0.006 | 0.15 | 23 |

| 80X80 | 0.0055 | 0.14 | 0.007 | 0.18 | 31.4 |

| 90X90 | 0.005 | 0.127 | 0.0061 | 0.16 | 30.1 |

| 100X100 | 0.0045 | 0.114 | 0.0055 | 0.14 | 30.3 |

| 100X100 | 0.004 | 0.102 | 0.006 | 0.15 | 36 |

| 100X100 | 0.0035 | 0.089 | 0.0065 | 0.17 | 42.3 |

| 110X110 | 0.004 | 0.1016 | 0.0051 | 0.1295 | 30.7 |

| 120X120 | 0.0037 | 0.094 | 0.0046 | 0.1168 | 30.7 |

| 150X150 | 0.0026 | 0.066 | 0.0041 | 0.1041 | 37.4 |

| 160X160 | 0.0025 | 0.0635 | 0.0038 | 0.0965 | 36.4 |

| 180X180 | 0.0023 | 0.0584 | 0.0033 | 0.0838 | 34.7 |

| 200X200 | 0.0021 | 0.0533 | 0.0029 | 0.0737 | 33.6 |

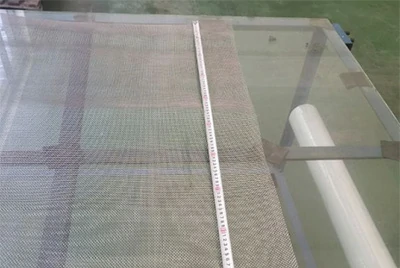

Image Gallery of Titanium Wire Mesh

Typical Applications of Titanium Wire Mesh by Industry

Titanium Wire Mesh is widely used in high-demand and high-value industries due to its exceptional corrosion resistance, lightweight yet high strength, excellent conductivity, and biocompatibility. Below are key industries and representative applications:

Chemical & Petrochemical Industry

Aggressive media such as strong acids, alkalis, and chlorinated compounds quickly degrade traditional metal meshes. Titanium Wire Mesh, with its self-passivating oxide layer, maintains structural integrity and filtration precision even under high temperature and pressure.

Contact us now

Recommended Product

| Alloy | Mesh | Weave Type | Wire Diameter (mm) | % Open Area | Supply Form |

|---|---|---|---|---|---|

| Gr2 | 40–80 | Plain | 0.30 | 45% | Sheet + Edged Frame |

Desalination & Water Treatment

The combined presence of chloride ions and biofouling organisms in seawater leads to rapid corrosion of stainless steel. Commercially pure titanium mesh forms a stable passivation film in salt-spray environments, significantly extending the service life of pre-filtration units and reverse osmosis (RO) systems.

Contact us now

Recommended Product

| Alloy | Mesh | Weave Type | Wire Diameter (mm) | % Open Area | Supply Form |

|---|---|---|---|---|---|

| Gr1 | 60 - 100 | Twill | 0.15–0.25 | 50 % | Roll (10–30 m) |

Electrolysis / Battery & Current Collector

Applications like chlor-alkali electrolysis, hydrogen generation, and fuel cells require high current density and strong coating adhesion. Heavy-gauge titanium mesh with Platinum/MMO coating is commonly used as titanium mesh electrodes, ensuring long-term stability in harsh electrochemical environments.

Contact us now

Recommended Product

| Alloy | Mesh | Weave Type | Wire Diameter (mm) | % Open Area | Supply Form |

|---|---|---|---|---|---|

| Gr1 | 10 - 30 | Crimped / Mat | ≥ 0.50 | 30 % | Sheet + Edged / Spot-Welded |

Medical & Pharmaceutical

Medical filtration environments are highly sensitive to metal ion release and biocompatibility. Precision-woven ASTM F67 Gr1 titanium mesh with Dutch weave ensures ultra-fine filtration in sterile environments without triggering adverse biological responses or implant rejection.

Contact us now

Recommended Product

| Alloy | Mesh | Weave Type | Wire Diameter (mm) | % Open Area | Supply Form |

|---|---|---|---|---|---|

| Gr1 | 120 - 200 | Plain Dutch | 0.05 | 20 % | Roll or Small Sheet |

Semiconductor & Cleanroom Electronics

Cleanrooms require anti-static, EMI-shielding, and non-shedding materials. Fine titanium wire mesh provides stable conductivity without particle generation, ideal for airflow diffusers, cleanroom panels, and protective shielding in precision electronics.

Contact us now

Recommended Product

| Alloy | Mesh | Weave Type | Wire Diameter (mm) | % Open Area | Supply Form |

|---|---|---|---|---|---|

| Gr2 | 80 | Plain + Crimped | 0.12 | 35 % | Roll (Width 1.5 m) |

Aerospace & High-Temp Environments

Balancing lightweight with corrosion and thermal resistance is crucial. Ti-6Al-4V woven mesh with five-heddle structure maintains high specific strength up to 400 °C, suitable for hot gas flow diffusers, structural reinforcement, or lightweight EMI barriers.

Contact us now

Recommended Product

| Alloy | Mesh | Weave Type | Wire Diameter (mm) | % Open Area | Supply Form |

|---|---|---|---|---|---|

| Gr5 (Ti-6Al-4V) | 20 - 60 | Five-heddle | 0.40 | 35 % | Sheet (Custom Size) |

Need tailored specifications or a quotation sample?

Click the button below to connect with our technical engineers — we’ll provide a custom solution within 24 hours.Engineering Consultation

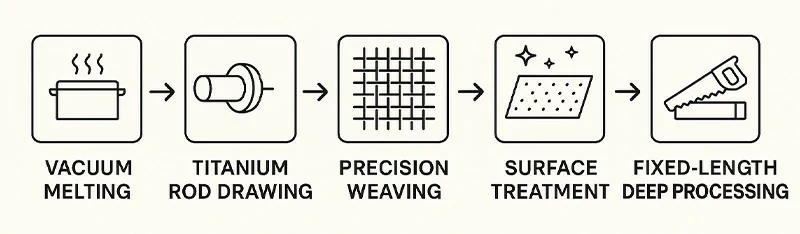

From Wire to Mesh: Chalco's Integrated Production Capabilities

Complete Supply Chain · In-House Controlled

From vacuum melting → titanium rod drawing → precision weaving → surface finishing → custom cutting, Chalco completes the entire titanium mesh production in-house. This ensures tight quality control, short lead times, and avoids typical delays or inconsistencies from outsourcing.

- Annual capacity > 500,000 m² (3 automated weaving lines + 1 edge-welding line)

- Maximum width up to 2 meters, roll length up to 30 meters — one of the few suppliers capable of mass-producing ultra-wide titanium mesh

Full Range of Specifications · Large Inventory

- Mesh Count: 0.2 mesh – 200 mesh (fully covered)

- Alloy Grades: Gr1, Gr2, Gr5, Gr7, Gr9, Gr12 (standard inventory available)

- Supply Forms: rolls, sheets, framed mesh — standardized semi-finished stock for fast delivery

- Sampling Lead Time: as fast as 2 weeks

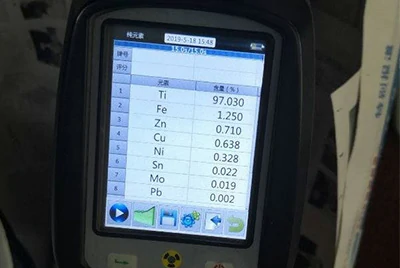

Quality System · Dual Industry Certification

Fully certified by ISO 9001 & AS9100 quality management systems

Each batch delivered with:

- Chemical composition spectrometry

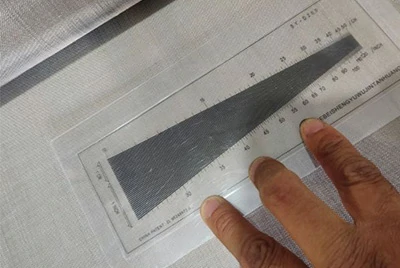

- Tensile testing report

- Aperture & wire diameter verification report

Medical / aerospace orders can include ASTM F67 / F136 compliance upon request

Surface Treatment Capabilities

| Process | Purpose & Notes |

|---|---|

| Edge Welding / Spot Welding | Anti-scratch, improves edge strength |

| Laser / Water Jet Cutting | High-precision ±0.2 mm shaping |

| Platinum / MMO Coating | For electrode use, adhesion > 8 N/cm |

| Electro-polishing / Anodizing | Suitable for medical & cleanroom applications |

Deep Processing & Custom Solutions

To meet diverse application needs, Chalco also provides ready-to-use fabricated mesh components and custom-assembled structures. From filter discs to complex frames, our deep processing capabilities help you accelerate product integration and meet final application demands efficiently.

Beyond standard products, Chalco also supports custom drawings, functional development, and precision prototyping. Combined with rapid delivery and global logistics capabilities, we ensure seamless project execution from design to deployment.

Packaging & Global Logistics

- Rolls: Moisture-proof paper + Stretch wrap + Plywood box

- Sheets: EPE pad + Vacuum sealed bag + Fumigated wooden crate

- Logistics: Long-term partners with DHL / FedEx for 5-day express, ocean shipping with FCA / CIF terms, one-click customs clearance

Chalco's vertically integrated mesh production and agile delivery allow us to support the full project lifecycle — from pilot testing to large-scale OEM.

Get a quoteQuick Quote

FAQs

What are the key advantages of titanium wire mesh compared to stainless steel mesh in real applications?

Titanium wire mesh offers superior corrosion resistance, strength-to-weight ratio, and biocompatibility. It significantly outperforms stainless steel in harsh environments such as seawater, chlorine, and acid/alkaline solutions. Titanium is also lightweight and non-magnetic, making it ideal for aerospace, medical, and other high-spec industries.

Is titanium mesh suitable for extreme environments like seawater or high temperatures?

Yes. Titanium naturally forms a stable passivation layer, allowing it to maintain integrity in oxidizing or mildly reducing media, even under prolonged exposure to salt spray, chlorides, acids, and alkalis. It is recommended for long-term use up to 400 °C, and short-term exposure up to 600 °C, ideal for heat exchangers, current collectors, and marine components.

What are the common weave types of titanium wire mesh? How do they differ in use?

Typical weaves include plain weave, twill weave, Dutch weave (plain/twill), five-heddle, and crimped:

- Plain weave: for general filtration

- Dutch weave: for high-precision filtration (e.g. pharmaceutical)

- Five-heddle: more flexible, suited for wrapping or high fatigue resistance

Each weave affects filtration accuracy, mechanical strength, and flexibility — selection should be based on specific operating conditions.

How to calculate the % open area of titanium mesh?

For plain weave, the approximate formula is:

%OA ≈ [A / (A + D)]² × 100%

Where A = aperture, D = wire diameter. For more complex weaves (twill, Dutch), due to varied strand arrangements, we recommend using Chalco’s online open area calculator or contacting our technical team for accurate guidance.

How does % open area affect mesh performance?

% Open Area directly influences flow rate and pressure drop:

- High %OA: better permeability, lower pressure loss — ideal for fluid filtration

- Low %OA: higher structural support and uniform current distribution — ideal for electrode substrates

Designers must balance strength vs. permeability based on application.

Can you supply electrode-grade titanium mesh with platinum/MMO coatings? What about coating adhesion?

Yes. Chalco supplies MMO coated titanium mesh — including platinum, ruthenium, or iridium-based mixed metal oxide (MMO) coatings — designed for electrolysis, water treatment, chlor-alkali production, and fuel cells. Our electrode-grade titanium mesh ensures long-term stability, uniform current distribution, and coating adhesion exceeding 8 N/cm. ASTM D3359 peel test reports are available on request.

Is titanium mesh easy to weld, form, or integrate with other components?

Commercially pure titanium wires are TIG or spot-weldable under inert gas shielding; heat input must be controlled to avoid grain coarsening. Titanium is more formable than stainless steel — it can be bent, edged, rolled, and paired with stainless steel frames or electrode holders with ease.

Which standards do you comply with? Can you provide ASTM F67 or AMS 4911 certification?

Yes. Our titanium mesh is made from material compliant with ASTM B348, ASTM B265, ASTM F67 (medical grade), and AMS 4911 (aerospace). We provide chemical analysis, mechanical reports, and third-party inspection if required. For pharmaceutical or aerospace use, we offer custom production with on-demand testing.

How do you ensure batch-to-batch consistency? Is full traceability supported?

Chalco enforces barcode & heat number tracking throughout the process. Each mesh batch includes tensile testing, spectral analysis, aperture verification, and roll-width inspection records. Full traceability from raw titanium to woven mesh is ensured. We also support SGS, BV, TUV third-party inspections.