Laser Cut Titanium

Updated : Jul. 9, 2025Titanium is a metal material known for its high strength, low density and excellent corrosion resistance. It is increasingly used in aerospace, medical equipment, precision industrial equipment and high-end manufacturing fields.

However, titanium is also a very challenging object to process, especially in the cutting process, which faces many technical difficulties. The emergence of laser technology provides an ideal solution for titanium processing, effectively solving the problems that traditional methods cannot overcome.

Challenges of cutting titanium

Titanium has unique physical and chemical properties that present challenges that are difficult to control during processing. First, the thermal conductivity of titanium is very low, only about 1/5 of aluminum and 1/10 of steel. This causes heat to accumulate locally during the cutting process, forming a heat-affected zone. This local heat concentration may cause material performance degradation or even deformation.

Titanium is highly reactive under high temperature conditions, especially with oxygen and nitrogen, to generate brittle TiO₂ and TiN compounds. These compounds adhere to the surface of the cut, affecting subsequent welding or other processing steps, and even reducing the fatigue resistance of the parts.

Titanium has a low elastic modulus and is prone to rebound during mechanical cutting, which results in severe tool wear and a short tool life, leading to high processing costs. These challenges pose a huge obstacle to traditional processing methods such as mechanical milling, drilling or plasma cutting, and efficient alternative processes are urgently needed.

Why is the laser suitable for cutting titanium?

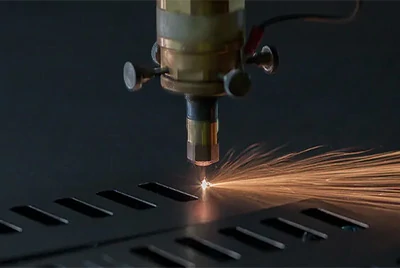

Laser cutting technology is very suitable for solving the problems of heat accumulation and tool wear in titanium processing due to its highly concentrated energy input, extremely fine cutting gap width and non-contact processing characteristics.

Laser can focus most of the energy on a very small area (usually less than 0.3 mm spot), effectively avoiding large-area thermal damage to titanium materials. Through the use of auxiliary inert gases, such as high-purity nitrogen or argon, the titanium material can be prevented from oxidizing in the cutting area and the surface purity of the material can be maintained.

Lasers are particularly suitable for precision cutting of titanium thin plates (0.1–6 mm) and medium and thick plates (6–10 mm), and have shown obvious advantages in the manufacturing of high-end fields such as aerospace engine components, medical implants, and complex mechanical parts.

Different types of laser cutting titanium techniques

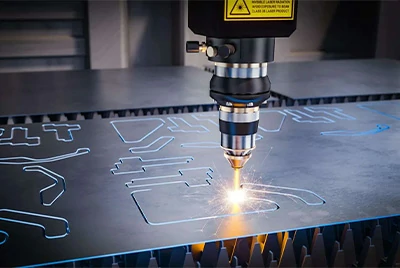

Fiber laser cutting titanium

Fiber laser cutting of titanium is one of the most widely used technologies in the industry. It uses near-infrared lasers with a wavelength of about 1064 nm. It has outstanding advantages, high energy density, and the beam can quickly melt the titanium surface after focusing, forming a narrow and clean cutting seam (usually 0.1-0.3 mm wide). The heat-affected zone is extremely small (usually <0.1 mm), which can effectively avoid thermal deformation and performance degradation of titanium materials.

Fiber laser cutting is fast and precise, and is particularly suitable for fine processing of titanium thin plates (0.1-6 mm) and medium-thick plates (6-12 mm), such as precision aerospace parts, medical equipment, and electronic equipment housings. Low maintenance costs, low energy consumption, and strong operating stability make fiber laser the mainstream choice for titanium processing.

CO2 laser cutting titanium

The wavelength of a CO₂ laser is 10,600 nm, which falls within the far-infrared range. Titanium has a relatively low absorption rate for this wavelength, resulting in slightly lower energy efficiency compared to fiber lasers when cutting titanium. However, CO₂ lasers still play a significant role in processing thick titanium plates due to their stable performance in heavy-duty applications.

CO₂ laser cutting is suitable for industrial processing of titanium thick plates (above 8 mm), especially for environments that do not require extreme processing accuracy but require stability and high power. It is often used for processing titanium structural parts, pipes, containers or large industrial parts. The equipment cost is high and the power consumption is large, but its long-term stability and thick plate processing capabilities are still outstanding.

Nd:YAG laser cutting titanium

Nd:YAG lasers also have a wavelength of about 1064 nm, but usually output energy in pulses, and are traditional solid-state laser devices. Although their energy density and cutting efficiency are not as good as modern fiber lasers, they have been widely used in the micro-machining and fine processing of titanium materials in the past few decades.

The advantage of Nd:YAG laser is its high pulse energy, which is suitable for micro-hole cutting, precision welding and medical implant manufacturing of precision titanium parts. In recent years, with the development of fiber laser technology, Nd:YAG laser has been gradually replaced, but it still maintains a certain application value in specific medical precision parts or special scenarios.

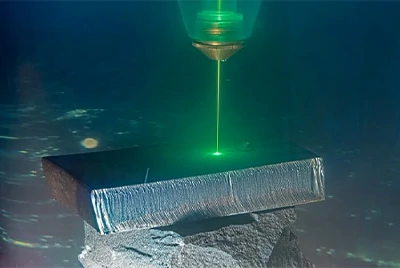

Green laser cutting titanium

The wavelength of green laser is about 532 nm. Titanium has a higher absorption efficiency for lasers of this wavelength, which can achieve a smaller heat-affected zone and higher processing accuracy than infrared lasers. It is particularly suitable for precision cutting and micro-processing of thin titanium sheets.

Green laser has demonstrated its outstanding advantages in the precision cutting of consumer electronic shells, the production of microelectronic components, and the manufacturing of minimally invasive medical devices. It can effectively avoid the formation of oxides, improve the quality of the processed surface, and meet the stringent surface accuracy and quality standards.

Disc laser cut titanium

Disk laser is a new type of solid-state laser with a wavelength of about 1030 nm, which is close to the characteristics of fiber laser, but its power expansion capability is stronger and can easily reach high-power output of several kilowatts. Disk laser has high stability and excellent beam quality, which is especially suitable for industrial-scale processing of thicker titanium plates and large-sized titanium parts.

In the manufacture of large aerospace components, heavy equipment parts, and titanium parts for the automotive industry, disc lasers have shown significant advantages because they can quickly and stably achieve efficient cutting with industrial-grade precision, and have relatively low operating costs and easy maintenance.

Ultrafast laser cutting of titanium

Ultrafast laser technology mainly refers to picosecond (10 ⁻ ¹² seconds) and femtosecond (10 ⁻ ¹ ⁵ seconds) lasers, with wavelengths usually at 1030 nm or green wavelengths at 515 nm. Its biggest advantage is "cold processing". Due to the extremely short pulse duration, the material is vaporized and removed before significant heat conduction occurs, with almost no heat-affected zone and edge melting.

Therefore, ultrafast lasers are particularly suitable for scenarios that are heat-sensitive or have extremely high requirements for precision and surface quality. For example, medical device stents, titanium micro-hole processing, precision electronic components, etc. Although this technology is relatively expensive, it provides unparalleled precision and quality for high-end manufacturing.

Key benefits of laser cutting titanium

Laser cutting technology has significant advantages over traditional machining or plasma cutting. First, laser cutting does not require direct contact with the material, and does not cause tool wear and mechanical stress.

Laser cutting has extremely high precision and controllability. The cutting seam width can be controlled between 0.1-0.3 mm, and the heat-affected zone is usually less than 0.1 mm.

Laser processing can flexibly realize the processing of complex geometries without the need for molds or special tools, saving upfront costs and shortening product development cycles.

In addition, laser cutting can be seamlessly integrated with automated CNC systems and CAD design software to achieve efficient batch processing and small-batch customization, reduce production costs, and increase market response speed.

Typical defects of laser cutting

Oxidation and surface discoloration

Titanium reacts easily with oxygen in the air at high temperatures to form an oxide film, which causes the surface color to darken and produce a "dark change" phenomenon. This not only affects the appearance, but may also change the surface properties.

To prevent oxidation, it is recommended to arrange a double layer of high-purity nitrogen curtain before and after the laser cutting area to form an effective oxygen barrier. At the same time, combined with a high-speed cooling strategy, the temperature around the cut can be quickly reduced, which can greatly inhibit the occurrence of oxidation reactions.

Dross and burrs

After cutting, slag adheres to the edge of the cut or forms burrs, which is an important problem affecting precision and secondary processing. Its causes are mostly related to insufficient auxiliary gas flow rate, unstable gas pressure or focus drift.

The slag removal effect can be enhanced by finely controlling the pressure and flow ratio of the cutting gas, especially ensuring a stable distance between the nozzle and the material. Controlling the focus position to avoid drift can also reduce bottom dross and top edge burrs.

Microcracks and thermal stress cracks

High thermal gradients during laser cutting can easily introduce microcracks at the edge of the material, especially in thick plates or high-strength titanium alloys. The use of ultrafast lasers can effectively reduce heat input and inhibit crack formation. At the same time, the use of low-power multiple scans and return path strategies can also peel off the material layer by layer, reduce one-time thermal shock, and improve the overall cutting quality and edge integrity.

Industry applications

Laser cutting has been widely used in aerospace manufacturing for the processing of complex curved surfaces of titanium alloy honeycomb structure skins and engine heat shields. Such structures require extremely high dimensional accuracy and edge cleanliness, which are difficult to meet with traditional mechanical processing. Laser technology achieves precise cutting through non-contact, high-focused energy, effectively ensuring assembly accuracy and overall strength.

In the medical device industry, titanium vascular stents and orthopedic implants are mostly made of thin-walled microtubes, which have extremely high requirements for size and shape control. Ultrashort pulse laser cutting technology can complete burr-free processing of titanium microtubes below 0.5 mm without generating heat-affected zones, and is one of the current mainstream high-end solutions.

In the field of high-end consumer electronics, titanium has become an important material for high-end mobile phone cases and customized watches due to its light weight, toughness and anti-fingerprint performance. Laser cutting technology is used for fine grooving, LOGO engraving and special-shaped processing, which not only meets the visual aesthetics, but also ensures the subsequent assembly accuracy.

Laser cutting vs waterjet cutting

In titanium processing, laser cutting and water jet cutting are two common and efficient process options. Each has its own advantages in cutting accuracy, thermal impact, cost control, etc., and is suitable for different application requirements.

| Comparison dimensions | Laser cutting | Waterjet cutting |

|---|---|---|

| Cutting principle | Light beam heating to evaporate or melt titanium; usually inert gas to prevent oxidation | High-pressure water jet mixed with abrasive cuts by physical erosion without heating |

| Heat affected zone (HAZ) | There is a heat-affected zone and the edges may oxidize, deform or harden | No thermal impact, very suitable for maintaining the original properties of titanium |

| Slit width & accuracy | Narrow incision (0.1–0.3 mm), high precision (±0.005″ ≈0.13 mm) | The incision is wide (≈0.5–1 mm), slightly lower accuracy (±0.005″–0.01″) |

| Cutting speed | Fast speed for thin plates, up to 20–70 in/min | Slower, more obvious on thick plates, but can cut multiple layers at the same time |

| Material thickness applicable | Best for <12 mm (most models); performance decreases when thicker | Can cut thicker metals (up to tens of millimeters) without heat treatment |

| Material adaptability | Best for titanium and most metals, reflective materials will affect efficiency | Suitable for almost all materials, including titanium, ceramics, glass, composites |

| Post-processing requirements | Smooth edges, usually no or minimal deburring required | The cut edges are small and the finished product can be used directly or with minimal processing |

| Equipment and operating costs | The equipment cost is relatively low, but the operation consumes a lot of energy and requires gas. | High equipment cost (especially high pressure system), maintenance parts are easy to wear |

Can Charco help you?

Chalco's titanium products

Chalco focuses on the research and development and supply of titanium materials. Its products include titanium plates, titanium bars, titanium tubes, titanium foils, titanium forgings and various customized titanium profiles with complete specifications and stable performance. Its materials are widely used in key fields such as aerospace, marine engineering, electronic manufacturing, and chemical equipment that require extremely high corrosion resistance and high specific strength.

Processing and supporting services provided by Chalco

In addition to providing high-quality titanium products, Chalco also has a complete titanium material deep processing capability, covering a variety of high-precision processing methods such as laser cutting, water jet cutting, wire cutting, etc. The company is equipped with multi-power laser equipment (500W-6000W), high-pressure water cutting system and high-frequency wire cutting machine tools, which can meet the stable cutting requirements from 0.3mm ultra-thin titanium foil to 30mm thick titanium plate, taking into account both precision and efficiency.

In terms of customized services, Chalco supports cutting according to drawings, special-shaped processing, batch layout optimization, and provides one-stop surface treatment processes such as deburring, anodizing, sandblasting, and mechanical polishing to comprehensively improve the performance and appearance quality of parts. At the same time, it is equipped with advanced dimensional detection and non-destructive testing (ultrasonic, penetration) systems to verify the quality of each workpiece before leaving the factory.

For high-demand fields such as medical devices and aviation parts, Chalco has established exclusive process flow that complies with ISO 13485 and AS9100 international quality systems to ensure batch stability, material traceability and high consistency. Whether it is single-piece rapid prototyping or batch delivery, efficient response and short-cycle delivery can be achieved, saving production time and quality costs for customers.