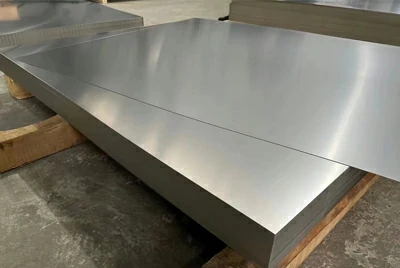

Titanium Plate

Chalco Titanium offers high-quality titanium plates ranging from 0.187″ (4.75 mm) to 4.29″ (109 mm) in thickness, with a maximum width of 95.5″ (2426 mm) and custom-cut lengths available to meet your exact project requirements.

- Thickness: 0.187″ – 4.29″ (4.75 mm – 109 mm)

- Maximum width: 95.5″ (2426 mm)

- Maximum length: Custom-cut available upon request

For easy selection, please note the size distinction:

Titanium sheet typically covers 0.012″ to 0.187″ (0.3–4.75 mm), while titanium plate starts from 0.250″ (6.35 mm) and above.

All Chalco titanium plates strictly conform to ASTM B265 and AMS 4902 standards.

Why choose titanium plate

- Corrosion resistance: Excellent durability against seawater, brine, and chemical media. Grades Gr7 and Gr12 perform even better in chloride-rich environments.

- High strength and light weight: Comparable to steel in strength but only 60% of its weight, ideal for heat exchangers, pressure vessels, and aerospace applications.

- Standards compliance: Produced to ASTM B265 / ASME SB-265, with optional UT (AMS 2631) and NACE MR0175 certifications.

- Grade options: Available in Gr2, Gr5, Gr7, Gr12, with custom sizes, waterjet or saw cutting on request.

Titanium plate specifications

- ASTM B265 / ASME SB-265 – Base standard

- AMS 2631 – Ultrasonic inspection

- AMS 4911 / 4902 / 4907 / 4900 / 4901 / 4919– Aerospace specifications

- MIL-T-9046 / AMS-T-9046 – Military standards

- ASTM F67 / F136 – Medical applications

- NACE MR0175 / ISO 15156 – Corrosion resistance for oil & gas environments

- ISO 9001 / AS9100 / ISO 13485 – Quality management certifications

- EN 10204 3.1 / 3.2 – Mill test report and third-party inspection (SGS / TÜV)

We support UT testing, chemical analysis, mechanical testing, custom cutting, and fabrication by drawing.

Beyond supplying Titanium Plates that meet international standards, we deliver testable, traceable, and machinable one-stop solutions — ensuring customers’ confidence in both quality and delivery.

Common titanium plate alloys

We supply a full range of Titanium Plates from Gr1 to Gr23, covering both industrial and aerospace grades.

Commercially pure titanium series

-

Gr1 Titanium Plate

Features: High purity, very ductile, easy to weld.

Applications: Heat exchangers, chemical, deep-drawn parts.

-

Gr2 Titanium Plate

Features: Common grade, excellent corrosion resistance.

Applications: Heat exchangers, chemical parts, deep drawing.

-

Gr3 Titanium Plate

Features: Stronger than Gr2, still easy to machine and weld.

Applications: Pressure vessels, heat exchangers, chemical reactors.

-

Gr4 Titanium Plate

Features: High strength and toughness.

Applications: Pressure vessels, evaporators, heat exchangers, aerospace parts.

-

2H Titanium Plate

Features: High-strength pressure vessel Titanium Plate.

Applications: Heat exchangers, pressure vessels, tube sheets.

-

7H Titanium Plate

Features: Strong and highly corrosion-resistant.

Applications: Desalination, FGD, chemical vessels, heat exchangers.

Titanium alloys

-

Gr5 (Ti-6Al-4V) Titanium Plate

Features: High strength and heat resistance, most used grade.

Applications: Aircraft parts, pressure shells, racing, armor.

-

Gr23 (Ti-6Al-4V ELI) Titanium Plate

Features: Better ductility and higher toughness.

Applications: Medical implants, aerospace precision parts.

-

Gr7 (Ti-0.2Pd) Titanium Plate

Features: Excellent in acidic and chloride environments.

Applications: Chemical, seawater, desulfurization systems.

-

Gr12 (Ti-0.3Mo-0.8Ni) Titanium Plate

Features: Superior crevice and hot brine resistance.

Applications: Desalination, FGD, petrochemical systems.

-

Gr9 (Ti-3Al-2.5V) Titanium Plate

Features: Lightweight yet strong, ideal for tubing.

Applications: Aircraft hydraulics, sports equipment.

Special and high-temperature alloys (customizable)

-

Ti-6Al-2Sn-4Zr-2Mo (6-2-4-2) Titanium Plate

Features: Excellent high-temperature strength.

Applications: Aircraft engine parts.

-

Ti-6Al-6V-2Sn (6-6-2) Titanium Plate

Features: Very high strength and fatigue resistance.

Applications: Defense, racing, protective structures.

-

Ti-8Al-1Mo-1V (8-1-1) Titanium Plate

Features: Highly stable, ideal for thick plates.

Applications: High-temperature structural parts.

-

Ti-5Al-2.5Sn (Grade 6) Titanium Plate

Features: Early aerospace alloy.

Applications: High-temperature parts and structural shells.

Whether you are a chemical equipment manufacturer, aerospace supplier, or project integrator, we can customize the most suitable Titanium Plate solution according to your standards, drawings, and testing requirements.

Popular titanium plate sizes

We commonly supply Titanium Plates ranging from 0.187″ (4.75 mm) to 3.0″ (76 mm), covering the full range from medium-thin to thick plates.

Standard widths include 12″, 24″, 36″, and 48″ (305 mm, 610 mm, 915 mm, 1220 mm), with custom cutting available to meet project needs.

Typical available sizes:

| Thickness (in) | Thickness (mm) | Width (in) | Width (mm) |

|---|---|---|---|

| 0.187" (3/16") | 4.75 mm | 12 / 24 / 36 / 48 | 305 / 610 / 915 / 1220 |

| 0.250" (1/4") | 6.35 mm | 12 / 24 / 36 / 48 | 305 / 610 / 915 / 1220 |

| 0.312" (5/16") | 7.94 mm | 12 / 24 / 36 / 48 | 305 / 610 / 915 / 1220 |

| 0.375" (3/8") | 9.53 mm | 12 / 24 / 36 / 48 | 305 / 610 / 915 / 1220 |

| 0.500" (1/2") | 12.7 mm | 12 / 24 / 36 / 48 | 305 / 610 / 915 / 1220 |

| 0.750" (3/4") | 19.05 mm | 12 / 24 / 36 / 48 | 305 / 610 / 915 / 1220 |

| 1.000" (1") | 25.4 mm | 12 / 24 / 36 / 48 | 305 / 610 / 915 / 1220 |

| 1.500" (1-1/2") | 38.1 mm | 12 / 24 | 305 / 610 |

| 2.000" (2") | 50.8 mm | 12 / 24 | 305 / 610 |

| 3.000" (3") | 76.2 mm | 12 / 24 | 305 / 610 |

Need more sizes? Click the anchor below to jump to the Full Titanium Plate Stock Size Chart at the bottom of the page .

We support custom cutting and special thickness orders.

All sizes can be supplied with ultrasonic testing (UT) and EN 10204 3.1 / 3.2 material certificates and inspection reports.

Want to know the weight and price for these sizes?

You can use our Titanium Weight Calculator !

Quickly calculate the theoretical weight of Titanium Plates by thickness and size, and estimate your project’s total weight (kg) and shipping cost.

We also offer custom quotes and delivery times based on your specific requirements.

Popular titanium plate products

We specialize in solid Titanium Plates, covering the full range from industrial to aerospace grades, and from standard to extra-thick plates.

Click the category anchors below to quickly explore different application types, technical data, and selection guides.

Aerospace titanium plate

The aerospace industry demands exceptional strength, precision, and consistency in materials.

Chalco Titanium supplies AMS-certified Titanium Plates, covering the full range from commercially pure titanium to high-strength alloys. They are widely used in aircraft structures, fuselage skins, engine supports, and high-strength fastener blanks.

-

AMS 4911 Titanium Plate(Ti-6Al-4V)

High strength, light weight, heat resistant, easy to weld and machine. Applications: Skins, frames, engine rings, landing gear, protective parts.

-

AMS 4902 Titanium Plate(Grade 2)

Excellent formability, weldability, low density, strong corrosion resistance. Applications: Hydraulic systems, heat exchangers, fuel tanks, insulation, pipe supports.

For aerospace, defense, and high-reliability structural applications, Titanium Plates with thickness ≥0.25″ (6.35 mm) can undergo ultrasonic testing (UT) per AMS 2631 standards.

Marine titanium plate

Chalco Titanium supplies seawater-resistant Titanium Plates (Gr2 / Gr7 / Gr12 / Gr16) with outstanding chloride corrosion resistance, high strength-to-weight ratio, long service life, and low maintenance — ideal for desalination, desulfurization, and offshore equipment.

Contact us now

- Thickness range: 0.187″ – 3.0″ (4.75 – 76 mm)

- Finish options: Pickled / polished / machined surface

- Testing options: UT (AMS 2631), NACE MR0175 / ISO 15156 compliance

- Documentation: EN 10204 3.1 / 3.2 MTC and full traceability provided

Pressure vessel titanium plate

Chalco Titanium supplies Titanium Plates for ASME VIII pressure vessels and chemical equipment, fully compliant with ASTM B265 / ASME SB-265 standards, and available in H grades (2H / 7H / 16H / 26H).

Contact us now

These "H-grade” plates maintain excellent corrosion resistance while offering higher structural strength and safety margins — ideal for manufacturing heat exchanger shells, pressure tanks, chemical towers, and storage vessels.

We can supply according to drawings:

- Head blanks

- Flange blanks

- Shell or panel plates

Supports waterjet / laser / saw cutting, with controlled rolling direction and sampling positions to ensure uniform mechanical properties for every plate.

Heat exchanger tube-sheet plate blanks

Chalco Titanium uses high-purity Titanium Plates precisely cut and drilled into tube-sheet blanks, widely used in chemical plants, seawater desalination, condensers, and evaporator systems.

In heat exchangers, the tube sheet links the shell and tubes, requiring high strength, corrosion resistance, and machinability.

Contact us now

- Uniform structure and dense interior ensure stable mechanical performance.

- Excellent corrosion resistance with available grades Gr2 / Gr7 / Gr12.

- Supports drilling, slotting, chamfering, and sealing surface machining for precise assembly and reliable sealing.

- Thickness 0.5″ – 4.0″ (12 – 100 mm), maximum diameter up to 2500 mm.

Complete or semi-finished blanks can be supplied according to heat exchanger drawings.

Medical titanium plate

-

Ti-6Al-4V (Grade 5) Titanium Plate

Most used medical–aerospace alloy with high strength and good workability. Applications: Surgical tools, supports, plates, joint parts.

-

Ti-6Al-4V ELI (Grade 23) Titanium Plate

Low-interstitial, high-purity alloy for implants like dental roots, bone screws, and fixation plates.

- Nickel- and chromium-free, meeting ISO 10993 biocompatibility standards.

- High strength-to-weight ratio for lighter structures.

- Corrosion resistant and non-rusting, stable in body fluids without ion release.

- Highly formable, suitable for CNC machining, cold forming, and welding.

Titanium clad plate

When you need both corrosion resistance and cost control, Titanium Clad Plate is the ideal solution.

Chalco Titanium uses explosive bonding, hot rolling, or diffusion welding to bond pure titanium or titanium alloy with stainless steel, carbon steel, copper, or nickel — creating an integrated "corrosion-resistant outer + pressure-bearing inner” structure.

Titanium clad steel plate

Titanium clad copper plate

Titanium clad aluminum plate

- Bimetal structure: The titanium layer provides corrosion resistance, while the base metal offers strength and pressure capacity.

- High bonding strength: Explosion or hot bonding ensures interface shear strength ≥130 MPa.

- Heat transfer + corrosion resistance: Titanium resists acids, alkalis, and chlorides, ideal for heat exchangers and immersion service.

- Cost-effective: 50–70% cheaper than solid titanium plates while extending equipment life.

Armor and ballistic titanium plate

Titanium Plates offer high strength-to-weight ratio, excellent impact resistance, and superior energy absorption — weighing only 60% of armor steel.

They are corrosion-resistant, weatherproof, weldable, and machinable, and can be combined with ceramics or aramid fibers for lightweight, high-protection armor systems.

Chalco Titanium supplies armor-grade Titanium Plates meeting MIL, AMS, ASTM standards for military, vehicles, and personal protection.

Contact us now

- Grades: Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI (Grade 23), Ti-6Al-6V-2Sn (6-6-2)

- Thickness: 0.187″–2.0″ (4.75–50 mm), customizable

- Delivery condition: Heat treated / stress relieved / pickled or sandblasted surface

- Testing: UT (AMS 2631), hardness & impact tests, ballistic performance verification

Titanium cathode plate

Chalco Titanium supplies high-quality cathode Titanium Plates meeting ASTM B265 standards, made from industrial pure titanium Grade 1, Grade 2, Grade 7, and Grade 12.

They offer excellent corrosion resistance and conductivity, making them ideal cathode materials for electrolysis, electroplating, electrometallurgy, and chemical industries.

Chalco Titanium has integrated production capabilities from titanium ingot melting to hot rolling, cold rolling, pickling, cutting, and polishing.

Contact us now

Custom cathode titanium plates, titanium cathode frames, and coated titanium electrodes (RuO₂ / IrO₂ / Ta₂O₅ coatings) can be made according to customer drawings.

- Excellent corrosion resistance

- High electrical and thermal conductivity

- Lightweight with high strength

- Long service life, low maintenance

- Stable under long-term operation, ensuring uniform electric field distribution

Looking for near-net shape blanks or plates with specific rolling direction?

Contact Chalco Titanium — we can provide custom cut plates with controlled grain orientation and full traceable documentation (UT, MTC, mechanical test).

Typical applications of titanium plate

- Chemical equipment: Corrosion-resistant reactors, evaporators, and pickling tanks.

- Pressure vessels and storage tanks: For pressurized systems and corrosive media storage.

- Heat exchangers and tube sheets: Ensure high thermal conductivity and corrosion resistance, extending service life.

- Seawater desalination and marine engineering: Resist chloride corrosion and perform well in high-salt, humid environments.

- Power generation and FGD systems: Used in condensers, gas heat exchangers, and desulfurization tower linings.

- Aerospace structures: High strength-to-weight ratio for fuselage, landing gear, and engine parts.

- Medical implants and instruments: Excellent biocompatibility for implants and surgical tools.

- Armor and ballistic systems: Lightweight and strong for better impact resistance in vehicles and protective gear.

- Electrochemical and cathodic protection systems: Serve as anode substrates to prevent steel corrosion.

- Water treatment systems: Corrosion-resistant components for wastewater, electrolysis, and environmental equipment.

- Oil and gas equipment: Long-term stability in sulfur- and chloride-rich conditions.

- Electronics and semiconductor parts: Used in vacuum chambers, sputtering targets, and structural supports.

- Automotive and racing components: Lightweight and strong for exhaust systems and chassis structures.

- Architectural and decorative panels: Oxidized surfaces create multi-color finishes for facades and interiors.

- Sports and leisure equipment: Durable and lightweight for bicycles, rackets, wheelchairs, and camping gear.

Titanium plate surface finishes

Titanium Plates can be supplied with various surface treatments, including polishing, pickling, brushing, sandblasting, mill finish, or coating, depending on the application.

Chalco Titanium offers multiple surface and edge-processing options, giving customers flexibility to match project requirements.

-

Pickled Titanium Plate

Features: Acid pickling removes oxides and impurities, leaving a clean, uniform silver-gray surface.

Applications: Chemical equipment, heat exchangers, pressure vessels, and welded structures.

-

Sandblasted Titanium Plate

Features: Fine sandblasting creates a matte surface finish.

Applications: Marine structures, aerospace components, decorative or pre-coating surfaces.

-

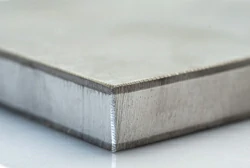

Ground / Polished Titanium Plate

Features: Mechanically ground or mirror-polished for smooth or high-gloss surfaces.

Applications: Medical instruments, precision parts, instrument housings, and premium equipment covers.

-

Machined-Edge Titanium Plate

Features: Edges are milled, chamfered, or deburred for precision fit.

Applications: Mechanical parts, aerospace components, installation panels.

-

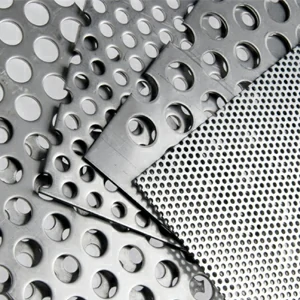

Perforated Titanium Plate

Features: Made from solid titanium plate through precision punching or laser cutting.

Applications: Filters, heat dissipation systems, acoustic and protection panels.

-

Anodized Titanium Plate

Features: Forms a titanium oxide film through controlled anodizing.

Applications: Architectural decoration, art installations, electronic housings.

Whether you need industrial pickled plates, aerospace sandblasted plates, precision-polished plates, or custom perforated and anodized finishes, Chalco Titanium can manufacture to your drawings and deliver to standard.

Standard supply is annealed and pickled, with customizable surface precision and finish upon request.

Titanium plate manufacturing processes

Hot rolling

Heated titanium billets are repeatedly rolled at high temperatures to achieve uniform thickness and dense structure.

Hot-rolled Titanium Plates have excellent ductility and formability with balanced strength and toughness — ideal for pressure vessels and chemical equipment.

Cold rolling

Precision rolling below the recrystallization temperature produces smoother surfaces and more accurate dimensions.

Cold-rolled Titanium Plates offer higher strength and hardness, suitable for aerospace, electronics, and precision component manufacturing.

Forging

High-temperature deformation refines grains and ensures a uniform internal structure.

Forged Titanium Plates deliver superior strength and reliability, commonly used in aerospace parts, flanges, and pressure shells.

Casting

Molten titanium is poured into molds and cooled to form complex or thick-walled parts.

Cast Titanium Plates are more cost-effective and mainly used for non-pressure structures or decorative applications.

Our services — why choose Chalco Titanium

From custom cutting to global delivery, we provide not just Titanium Plates but also confidence, efficiency, and expertise.

Custom cutting and machining

Precise cutting according to customer drawings with waterjet, sawing, or edge planing options.

All cuts maintain tight tolerances and clean edges, reducing your post-processing costs.

Competitive pricing and bulk discounts

We use reinforced moisture-proof packaging and recyclable wooden crates to prevent impact, moisture, and scratches — ensuring safe transport while supporting sustainability.

Fast shipping and global delivery

With multiple warehouses nationwide, standard sizes can be shipped within 48 hours.

We support DDP / DDU / CIF / FOB trade terms for reliable worldwide delivery.

Urgent orders can request expedited production and priority shipping.

Flexible payment and settlement options

We support T/T, L/C, PayPal, and credit card payments to meet the purchasing needs of customers worldwide.

Customer first, full support

From quotation to delivery, every step is traceable, and our professional team is available 24/7 to respond to your project needs.

We value every trust and deliver on our promise of reliable delivery and stable quality.

Choosing Chalco Titanium means more than buying Titanium Plates — it’s choosing a long-term partner who understands metals, values deadlines, and ensures quality.

Quality assurance and inspection

Chalco Titanium strictly follows ASTM B265 / AMS 4911 / AMS 2631 and other international standards.

Every process — from melting and rolling to flaw detection and testing — is fully traceable.

We provide complete MTC certificates, UT inspection reports, and COO certificates, giving customers full confidence in every purchase.

Ultrasonic Testing

Performance Testing

Visual Inspection

| Inspection item | Standard | Description |

|---|---|---|

| Ultrasonic testing (UT) | AMS 2631 A1–A3 | Detects inclusions, laminations, and porosity; applicable for plates ≥0.25″ thick. |

| Chemical composition analysis | ASTM E539 / E1409 | Tested by ICP-OES / XRF spectrometry to ensure precise composition. |

| Mechanical testing | ASTM E8 / E23 | Tensile, bending, and impact tests to verify strength and ductility. |

| Dimensional and visual inspection | ASTM B265 / EN 485 | Checks flatness, thickness, tolerance, and surface quality. |

| Certification documents | EN 10204 3.1 / 3.2 | Provides full documentation: MTC, COO, packing list, UT report, etc. |

We believe a reliable Titanium Plate is defined not just by its composition, but by complete traceability, testing, and certification throughout production.

For project-specific testing standards or report templates, please contact us for details.

Frequently asked questions (FAQ)

How long do titanium plates last in the body?

Titanium plates are designed to last a lifetime. They are biocompatible and non-corrosive, meaning they can remain safely in the body permanently unless a later medical procedure requires removal.

What are titanium plates used for?

Titanium plates are widely used to repair and support fractured bones in the skull, jaw, arm, and wrist.

Outside the medical field, titanium plates are used in aerospace, marine, and industrial applications where high strength and corrosion resistance are critical.

What are the risks of titanium bone plates?

Titanium is extremely safe and well-tolerated by the human body. In rare cases, patients may experience mild irritation, allergic reactions, or discomfort in cold temperatures, but these are uncommon.

How much does titanium plate surgery cost?

The cost varies depending on the procedure and location. On average, titanium plate implant surgery ranges from USD 3,000 – 10,000, including hospital and implant fees.

Titanium plates for sale / titanium plate supplier

Chalco Titanium supplies titanium plates in Grades 1–23, fully certified to ASTM B265 / AMS 4902, with optional ultrasonic testing (AMS 2631) and EN 10204 3.1/3.2 MTC certificates.

Why is titanium used for armor protection?

Titanium combines high strength with 40% less weight than steel, making it ideal for lightweight ballistic protection in vehicles and defense systems.

Available titanium plate stock sizes

Chalco Titanium offers a wide range of Titanium Plates in stock, with thicknesses from 5.0–40 mm, widths up to 2550 mm, and lengths up to 10900 mm.

Custom cutting is available to meet your specific application needs.

| Material | Thickness (mm) | Width (mm) | Length (mm) | Process | Surface |

|---|---|---|---|---|---|

| Gr2 | 5.0 | 1660 | 2120 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1660 | 5007 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1660 | 5643 | Hot Rolling | Bright |

| Gr1 | 5.0 | 1000 | 6000 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1000 | 3810 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1000 | 2000 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1000 | 3000 | Hot Rolling | Pickled |

| Gr1 | 5.0 | 1000 | 2720 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1766 | 700 | Hot Rolling | Black |

| Gr2 | 5.0 | 2060 | 5260 | Hot Rolling | Black |

| Gr2 | 5.0 | 2010 | 1940 | Hot Rolling | Black |

| Gr2 | 5.0 | 2100 | 4260 | Hot Rolling | Black |

| Gr2 | 5.0 | 2120 | 2930 | Hot Rolling | Black |

| Gr2 | 5.0 | 2160 | 6600 | Hot Rolling | Black |

| Gr2 | 5.0 | 2210 | 1950 | Hot Rolling | Black |

| Gr2 | 5.0 | 2210 | 5710 | Hot Rolling | Black |

| Gr2 | 5.0 | 2220 | 5900 | Hot Rolling | Black |

| Gr2 | 5.0 | 2250 | 8200 | Hot Rolling | Black |

| Gr2 | 5.0 | 2330 | 7880 | Hot Rolling | Black |

| Gr2 | 5.0 | 2230 | 8350 | Hot Rolling | Black |

| Gr2 | 5.0 | 2400 | 6810 | Hot Rolling | Black |

| Gr2 | 5.0 | 2460 | 5920 | Hot Rolling | Black |

| Gr2 | 5.0 | 2530 | 3000 | Hot Rolling | Black |

| Gr2 | 5.0 | 2550 | 6050 | Hot Rolling | Black |

| Gr12 | 5.0 | 900 | 2170 | Hot Rolling | Black |

| Gr1 | 5.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1500 | 4085 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 5.0 | 1470 | 1840 | Hot Rolling | Pickled |

| Gr1 | 5.5 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 5.5 | 1410 | 2060 | Hot Rolling | Black |

| Gr2 | 5.5 | 1310 | 2040 | Hot Rolling | Black |

| Gr1 | 5.5 | 1500 | 4180 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1800 | 3600 | Hot Rolling | Pickled |

| TC4 | 6.0 | 1650 | 6000 | Hot Rolling | Ground |

| Gr2 | 6.0 | 1000 | 4090 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1500 | 5540 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1250 | 6000 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1200 | 6000 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 980 | 6000 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1000 | 6000 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1000 | 4295 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1000 | 1420 | Hot Rolling | Black |

| Gr2 | 6.0 | 1400 | 1650 | Hot Rolling | Black |

| Gr2 | 6.0 | 940 | 1600 | Hot Rolling | Black |

| Gr12 | 6.0 | 1500 | 2290 | Hot Rolling | Black |

| Gr12 | 6.0 | 1500 | 2026 | Hot Rolling | Black |

| Gr1 | 6.0 | 2100 | 2350 | Hot Rolling | Black |

| Gr12 | 6.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr12 | 6.0 | 1500 | 3000 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1800 | 6000 | Hot Rolling | Black |

| Gr1 | 6.0 | 1810 | 3270 | Hot Rolling | Black |

| Gr1 | 6.0 | 1850 | 6260 | Hot Rolling | Black |

| Gr1 | 6.0 | 1850 | 2420 | Hot Rolling | Black |

| Gr2 | 6.0 | 1980 | 2140 | Hot Rolling | Black |

| Gr1 | 6.0 | 1910 | 6130 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1920 | 4720 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 2030 | 1130 | Hot Rolling | Black |

| Gr2 | 6.0 | 2020 | 1150 | Hot Rolling | Black |

| Gr2 | 6.0 | 2040 | 1145 | Hot Rolling | Black |

| Gr1 | 6.0 | 2510 | 2510 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1790 | 7000 | Hot Rolling | Black |

| Gr2 | 6.0 | 1810 | 5010 | Hot Rolling | Black |

| Gr2 | 6.0 | 1810 | 2040 | Hot Rolling | Black |

| Gr2 | 6.0 | 1820 | 4660 | Hot Rolling | Black |

| Gr2 | 6.0 | 1820 | 6810 | Hot Rolling | Black |

| Gr2 | 6.0 | 1820 | 3110 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6590 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 7300 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6200 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6040 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6100 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6100 | Hot Rolling | Black |

| Gr2 | 6.0 | 1980 | 2020 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6100 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6020 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6550 | Hot Rolling | Black |

| Gr2 | 6.0 | 1830 | 6230 | Hot Rolling | Black |

| Gr2 | 6.0 | 1835 | 6140 | Hot Rolling | Black |

| Gr2 | 6.0 | 1840 | 1730 | Hot Rolling | Black |

| Gr2 | 6.0 | 1840 | 6270 | Hot Rolling | Black |

| Gr2 | 6.0 | 1840 | 6110 | Hot Rolling | Black |

| Gr2 | 6.0 | 1840 | 6070 | Hot Rolling | Black |

| Gr2 | 6.0 | 1840 | 6010 | Hot Rolling | Black |

| Gr2 | 6.0 | 1840 | 6450 | Hot Rolling | Black |

| Gr2 | 6.0 | 1840 | 2910 | Hot Rolling | Black |

| Gr2 | 6.0 | 1840 | 6000 | Hot Rolling | Black |

| Gr2 | 6.0 | 1850 | 4830 | Hot Rolling | Black |

| Gr2 | 6.0 | 1850 | 6230 | Hot Rolling | Black |

| Gr2 | 6.0 | 1850 | 6000 | Hot Rolling | Black |

| Gr2 | 6.0 | 1850 | 6100 | Hot Rolling | Black |

| Gr2 | 6.0 | 1850 | 6010 | Hot Rolling | Black |

| Gr2 | 6.0 | 1850 | 5950 | Hot Rolling | Black |

| Gr2 | 6.0 | 1850 | 6300 | Hot Rolling | Black |

| Gr2 | 6.0 | 1860 | 6200 | Hot Rolling | Black |

| Gr2 | 6.0 | 1870 | 6290 | Hot Rolling | Black |

| Gr2 | 6.0 | 1860 | 6100 | Hot Rolling | Black |

| Gr2 | 6.0 | 1860 | 6370 | Hot Rolling | Black |

| Gr2 | 6.0 | 1870 | 6100 | Hot Rolling | Black |

| Gr2 | 6.0 | 1880 | 1830 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1880 | 6100 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1880 | 6350 | Hot Rolling | Black |

| Gr2 | 6.0 | 1890 | 6200 | Hot Rolling | Black |

| Gr2 | 6.0 | 1910 | 5990 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1920 | 6360 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1920 | 6200 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1920 | 6000 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 2010 | 4239 | Hot Rolling | Black |

| Gr2 | 6.0 | 2070 | 6940 | Hot Rolling | Black |

| Gr2 | 6.0 | 2070 | 3980 | Hot Rolling | Black |

| Gr2 | 6.0 | 2030 | 3060 | Hot Rolling | Black |

| Gr2 | 6.0 | 2090 | 4920 | Hot Rolling | Black |

| Gr2 | 6.0 | 2100 | 4700 | Hot Rolling | Black |

| Gr2 | 6.0 | 2100 | 4610 | Hot Rolling | Black |

| Gr2 | 6.0 | 2100 | 6740 | Hot Rolling | Black |

| Gr2 | 6.0 | 2120 | 4480 | Hot Rolling | Black |

| Gr12 | 6.0 | 2070 | 6870 | Hot Rolling | Black |

| Gr12 | 6.0 | 2050 | 5450 | Hot Rolling | Black |

| Gr1 | 6.0 | 1500 | 4270 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1500 | 2990 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1500 | 2840 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1500 | 3000 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1500 | 2675 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1250 | 3470 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1500 | 2290 | Hot Rolling | Pickled |

| Gr1 | 6.0 | 1500 | 3010 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1500 | 1500 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 820 | 980 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 810 | 1000 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1410 | 1500 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1500 | 1680 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1110 | 2040 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1115 | 1515 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 970 | 1500 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 970 | 1500 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1500 | 1550 | Hot Rolling | Pickled |

| Gr2 | 6.0 | 1330 | 1400 | Hot Rolling | Pickled |

| Gr2 | 7.0 | 2030 | 7290 | Hot Rolling | Black |

| Gr2 | 7.0 | 1800 | 7280 | Hot Rolling | Black |

| Gr2 | 7.0 | 1216 | 2990 | Hot Rolling | Pickled |

| Gr2 | 7.0 | 1220 | 2780 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1577 | 2000 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 2000 | 2620 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 2000 | 6000 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1500 | 6000 | Hot Rolling | Bright |

| Gr1 | 8.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1500 | 2510 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1500 | 2820 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1010 | 3810 | Hot Rolling | Pickled |

| Gr1 | 8.0 | 960 | 1310 | Hot Rolling | Black |

| Gr12 | 8.0 | 745 | 1500 | Hot Rolling | Pickled |

| Gr12 | 8.0 | 1610 | 2000 | Hot Rolling | Black |

| Gr2 | 8.0 | 1500 | 3220 | Hot Rolling | Pickled |

| Gr12 | 8.0 | 1500 | 1800 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1376 | 1580 | Hot Rolling | Black |

| Gr2 | 8.0 | 1400 | 1500 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1500 | 980 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1500 | 900 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1500 | 760 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1500 | 790 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1240 | 2930 | Hot Rolling | Black |

| Gr2 | 8.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 1220 | 2040 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 790 | 1500 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 730 | 1440 | Hot Rolling | Pickled |

| Gr1 | 8.0 | 1500 | 2130 | Hot Rolling | Pickled |

| Gr1 | 8.0 | 1500 | 2570 | Hot Rolling | Pickled |

| Gr12 | 8.0 | 850 | 920 | Hot Rolling | Pickled |

| Gr12 | 8.0 | 1500 | 2170 | Hot Rolling | Pickled |

| Gr12 | 8.0 | 810 | 820 | Hot Rolling | Pickled |

| Gr12 | 8.0 | 840 | 2110 | Hot Rolling | Black |

| Gr12 | 8.0 | 1540 | 5660 | Hot Rolling | Black |

| Gr12 | 8.0 | 1900 | 2830 | Hot Rolling | Black |

| Gr12 | 8.0 | 2060 | 1850 | Hot Rolling | Black |

| Gr2 | 8.0 | 2000 | 2990 | Hot Rolling | Pickled |

| Gr1 | 8.0 | 2100 | 5340 | Hot Rolling | Black |

| Gr1 | 8.0 | 735 | 1500 | Hot Rolling | Pickled |

| Gr2 | 8.0 | 830 | 1500 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 2000 | 2270 | Hot Rolling | Pickled |

| TC4 | 10.0 | 2010 | 2520 | Hot Rolling | Ground |

| Gr2 | 10.0 | 2000 | 1390 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 2000 | 2020 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 2000 | 1995 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 2000 | 6000 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 2000 | 2980 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1500 | 6810 | Hot Rolling | Pickled |

| Gr1 | 10.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 830 | 3735 | Hot Rolling | Pickled |

| Gr1 | 10.0 | 1500 | 3800 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1000 | 1910 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1500 | 6330 | Hot Rolling | Pickled |

| Gr12 | 10.0 | 1200 | 6000 | Hot Rolling | Pickled |

| Gr12 | 10.0 | 1200 | 3950 | Hot Rolling | Pickled |

| Gr1 | 10.0 | 800 | 2380 | Hot Rolling | Black |

| Gr12 | 10.0 | 1600 | 2150 | Hot Rolling | Black |

| Gr12 | 10.0 | 870 | 4000 | Hot Rolling | Black |

| Gr2 | 10.0 | 1400 | 2730 | Hot Rolling | Black |

| Gr2 | 10.0 | 1520 | 3085 | Hot Rolling | Pickled |

| Gr1 | 10.0 | 1120 | 1220 | Hot Rolling | Black |

| Gr2 | 10.0 | 1500 | 1520 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1500 | 1890 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1500 | 2990 | Hot Rolling | Pickled |

| Gr12 | 10.0 | 1200 | 1690 | Hot Rolling | Pickled |

| Gr12 | 10.0 | 746 | 1650 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 830 | 3735 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1500 | 3800 | Hot Rolling | Pickled |

| Gr12 | 10.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr12 | 10.0 | 1500 | 4020 | Hot Rolling | Pickled |

| Gr12 | 10.0 | 2020 | 4300 | Hot Rolling | Black |

| Gr12 | 10.0 | 2020 | 1000 | Hot Rolling | Black |

| Gr12 | 10.0 | 2110 | 6350 | Hot Rolling | Black |

| Gr12 | 10.0 | 2110 | 5010 | Hot Rolling | Black |

| Gr12 | 10.0 | 1220 | 2645 | Hot Rolling | Black |

| Gr12 | 10.0 | 1200 | 1500 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 850 | 1180 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1500 | 2490 | Hot Rolling | Pickled |

| Gr2 | 10.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 11.0 | 1870 | 2080 | Hot Rolling | Pickled |

| Gr1 | 12.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1050 | 6000 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1550 | 3190 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 3785 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 6330 | Hot Rolling | Pickled |

| Gr1 | 12.0 | 1500 | 7000 | Hot Rolling | Pickled |

| Gr12 | 12.0 | 1500 | 1996 | Hot Rolling | Black |

| Gr12 | 12.0 | 1520 | 1886 | Hot Rolling | Black |

| Gr12 | 12.0 | 1610 | 3900 | Hot Rolling | Black |

| Gr12 | 12.0 | 1500 | 4000 | Hot Rolling | Pickled |

| Gr1 | 12.0 | 1520 | 2386 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 2700 | Hot Rolling | Pickled |

| Gr12 | 12.0 | 1500 | 1500 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 1680 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 1980 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 2000 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 3000 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 2000 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 970 | 2000 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1500 | 1800 | Hot Rolling | Pickled |

| Gr2 | 12.0 | 1650 | 9350 | Hot Rolling | Black |

| Gr12 | 12.0 | 1080 | 1150 | Hot Rolling | Black |

| Gr12 | 12.0 | 850 | 1140 | Hot Rolling | Black |

| Gr12 | 12.0 | 330 | 1580 | Hot Rolling | Black |

| Gr12 | 12.0 | 1510 | 6000 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 1750 | 3660 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 1500 | 6960 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 1500 | 2020 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 910 | 1450 | Hot Rolling | Black |

| Gr2 | 14.0 | 1500 | 2736 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 1500 | 2300 | Hot Rolling | Black |

| Gr2 | 14.0 | 1500 | 2480 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 1500 | 3000 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 1500 | 2000 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 865 | 870 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 1500 | 6000 | Hot Rolling | 抛光 |

| Gr2 | 14.0 | 1500 | 5000 | Hot Rolling | 抛光 |

| Gr2 | 14.0 | 1500 | 5000 | Hot Rolling | Pickled |

| Gr2 | 14.0 | 2220 | 4390 | Hot Rolling | Black |

| Gr2 | 14.0 | 2570 | 7750 | Hot Rolling | Black |

| Gr2 | 15.0 | 2000 | 6000 | Hot Rolling | Pickled |

| Gr2 | 15.0 | 1010 | 1865 | Hot Rolling | Black |

| Gr1 | 15.0 | 848 | 1010 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 2000 | 6000 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1810 | 3468 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 2000 | 1800 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 2000 | 2000 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1500 | 3000 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 820 | 3370 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1500 | 5600 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1400 | 5100 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1250 | 6000 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1400 | 3590 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1500 | 3700 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 1500 | 2470 | Hot Rolling | Pickled |

| Gr2 | 16.0 | 900 | 1500 | Hot Rolling | Pickled |

| Gr1 | 16.0 | 2030 | 5300 | Hot Rolling | Black |

| Gr2 | 16.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 18.0 | 2000 | 3600 | Hot Rolling | Pickled |

| Gr2 | 18.0 | 2000 | 6000 | Hot Rolling | Pickled |

| Gr2 | 18.0 | 2000 | 4500 | Hot Rolling | Pickled |

| Gr2 | 18.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 18.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr1 | 18.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr1 | 18.0 | 1520 | 1930 | Hot Rolling | Black |

| Gr2 | 18.0 | 2519 | 2850 | Hot Rolling | Pickled |

| Gr2 | 18.0 | 970 | 6000 | Hot Rolling | Pickled |

| Gr2 | 18.0 | 2182 | 2500 | Hot Rolling | Pickled |

| Gr2 | 20.0 | 2000 | 6000 | Hot Rolling | Pickled |

| Gr2 | 20.0 | 1500 | 3000 | Hot Rolling | Pickled |

| Gr2 | 20.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 20.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr1 | 20.0 | 1010 | 1370 | Hot Rolling | Black |

| Gr2 | 20.0 | 2180 | 10900 | Hot Rolling | Black |

| Gr1 | 20.0 | 2080 | 8800 | Hot Rolling | Black |

| Gr2 | 22.0 | 2090 | 6100 | Hot Rolling | Black |

| Gr2 | 25.0 | 1500 | 4000 | Hot Rolling | Pickled |

| Gr2 | 25.0 | 1500 | 6180 | Hot Rolling | Pickled |

| Gr2 | 25.0 | 1500 | 5875 | Hot Rolling | Pickled |

| Gr1 | 25.0 | 1660 | 1660 | Hot Rolling | Pickled |

| Gr2 | 25.0 | 500 | 3600 | Hot Rolling | Pickled |

| Gr2 | 25.0 | 2070 | 6150 | Hot Rolling | Black |

| Gr1 | 25.0 | 1680 | 5000 | Hot Rolling | Black |

| Gr2 | 28.0 | 1860 | 4810 | Hot Rolling | Pickled |

| Gr2 | 30.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 30.0 | 610 | 670 | Hot Rolling | Black |

| Gr2 | 30.0 | 1110 | 1130 | Hot Rolling | Pickled |

| Gr2 | 30.0 | 1500 | 1840 | Hot Rolling | Pickled |

| Gr2 | 30.0 | 1500 | 2600 | Hot Rolling | Pickled |

| Gr2 | 32.0 | 900 | 1800 | Hot Rolling | Black |

| Gr2 | 33.0 | 1610 | 1980 | Hot Rolling | Black |

| Gr2 | 33.0 | 2340 | 1600 | Hot Rolling | Black |

| Gr2 | 40.0 | 1500 | 6000 | Hot Rolling | Pickled |

| Gr2 | 40.0 | 1500 | 2740 | Hot Rolling | Pickled |