Titanium Tube Welding Complete Guide

Updated : Oct. 22, 2025Titanium and its alloys are vital in aerospace, chemical, marine, and medical fields, but their welding process remains highly challenging. This guide explores the key challenges of titanium tube welding and provides a complete workflow from preparation to inspection to help you achieve flawless results.

Challenges in Titanium Tube Welding

- Porosity defects: Hydrogen has very low solubility in titanium at low temperatures. During cooling, it precipitates as titanium hydride and expands, forming pores in the weld that significantly reduce fatigue strength.

- Delayed cold cracking: Cracks may appear hours or even longer after welding, usually in the heat-affected zone, caused by hydrogen diffusion, TiH₂ precipitation, and residual stress.

- High-temperature oxidation and discoloration: At welding temperatures above 500–700 °C, titanium readily absorbs oxygen and nitrogen, leading to weld discoloration (silver, gold, blue, gray) and reduced ductility and toughness.

- Heat input and deformation control: Thin-walled titanium tubes may warp or burn through due to excessive heat, while thick-walled tubes can accumulate heat and develop large residual stresses.

- Backside protection complexity: The weld root is highly reactive at elevated temperatures. Insufficient argon purging inside the tube causes root oxidation, compromising sealing and strength.

- Strict cleanliness requirements: Base metal, grooves, filler wire, and fixtures must be free of oil, oxide scale, and dust, as even slight contamination can cause brittle inclusions at high temperature.

Analysis of Common Defect Mechanisms

Porosity

The chief culprit behind porosity in titanium welds is hydrogen. Sources include residual moisture or oil on material surfaces and even impure shielding gas. Hydrogen dissolves in the high-temperature weld pool; as the weld cools, its solubility drops sharply. The supersaturated hydrogen cannot escape in time and becomes trapped in the metal, forming pores.

Delayed Cracking

Even more insidious than porosity is delayed cracking. Hours—or even longer—after welding, hydrogen atoms diffuse from the weld into the heat-affected zone where stresses concentrate. There, they precipitate as titanium hydrides, causing volumetric expansion and high internal stresses that can lead to spontaneous cracking without external load.

Common Titanium Tube Welding Processes

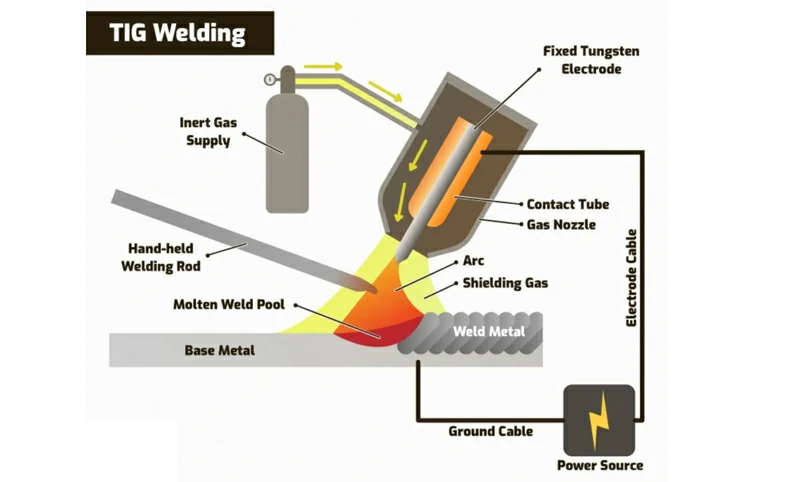

- TIG welding (tungsten inert gas welding): The most common method, using high-purity argon shielding. It produces high-quality welds and is ideal for thin-walled titanium tubes requiring precision and cleanliness.

- PAW welding (plasma arc welding): Offers high energy density, faster welding speed, and good penetration control, suitable for applications demanding efficiency and stability.

- MIG welding (metal inert gas welding): Suitable for thicker sections and mass production. It allows high-speed welding but requires stricter shielding gas control and is harder to manage.

- Electron beam welding (EBW): Features very high energy density, fast welding speed, and a small heat-affected zone. Commonly used in aerospace and other fields requiring extreme precision and strength.

- Laser welding: Enables automation, precise process control, attractive weld appearance, and fast speed. Ideal for complex shapes or high-precision titanium tubes.

- Cladding welding (overlay welding): Involves spraying titanium powder or other metals onto the tube surface and melting it to fuse with the base material. Mainly used for localized reinforcement or repair.

Comparison of Titanium Tube Welding Processes

| Process type | Weld quality | Speed & efficiency | Suitable thickness | Typical applications |

|---|---|---|---|---|

| TIG welding | ⭐⭐⭐⭐⭐ High precision, clean welds | Slow | Thin to medium wall | Chemical pipelines, medical equipment, vacuum systems |

| PAW welding | ⭐⭐⭐⭐ Stable penetration | Moderate to fast | Thin to medium-thick wall | Automated production, heat exchanger tubes |

| MIG welding | ⭐⭐⭐ Quality depends on shielding | Fast | Medium-thick wall | Mass production, industrial piping |

| Electron beam welding (EBW) | ⭐⭐⭐⭐⭐ Extremely precise, very low defect rate | Very fast | Thin to thick wall | Aerospace engines, precision components |

| Laser welding | ⭐⭐⭐⭐ Attractive welds, high controllability | Very fast | Thin wall, complex shapes | Automotive parts, medical implants |

| Cladding welding (overlay) | ⭐⭐⭐ Mainly for reinforcement or repair | Slow | Localized areas | Pipeline repair, wear- or corrosion-resistant overlays |

Preparation Before Welding Titanium Tubes

Pre-weld Cleaning (base metal, filler wire, environment)

Absolute cleanliness is essential. The base material, filler wire, and welding environment must be free from oil, dust, cutting fluids, or human grease...

Oxide Removal (to prevent inclusions)

The oxide layer on titanium has a higher melting point than the base metal...

Joint Fit-up (keep alignment, avoid gaps)

Joint assembly must be highly precise...

Shielding Preparation (high-purity argon, trailing shield, purging)

Titanium readily absorbs oxygen and nitrogen at high temperatures...

Gas Delivery Setup (plastic tubing, flow control)

Shielding gas should be delivered through clean, non-porous plastic hoses...

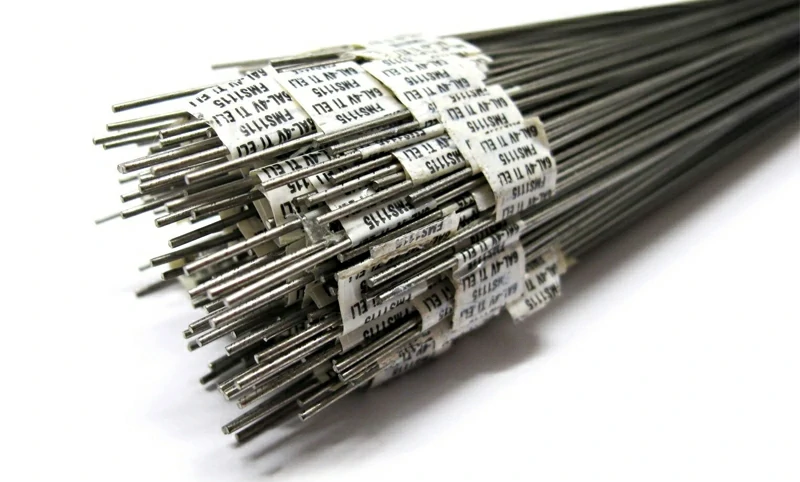

Filler Metal Selection (match with base metal)

For titanium tubes with wall thickness greater than 0.010 in, filler metal is required. Its chemical composition and mechanical properties should closely match the base metal to ensure joint strength and corrosion resistance. In some cases, filler with slightly lower yield strength than the base metal is chosen to improve ductility, but only after strict validation.

Here's a clean English heading for your section:

| Base material | Recommended filler wire |

|---|---|

| Grade 1 (CP-1, commercially pure) | AWS A5.16 ERTi-2 |

| Grade 2 (CP-2) | AWS A5.16 ERTi-2 |

| Grade 5 (Ti-6Al-4V) | AWS A5.16 ERTi-5 |

| Grade 9 (Ti-3Al-2.5V) | AWS A5.16 ERTi-3 / AWS A5.16 ERTi-9 |

| Grade 23 (Ti-6Al-4V ELI, extra-low interstitial) | AWS A5.16 ERTi-23 |

Welding Operation and Key Parameters

Arc Initiation and Start

TIG welding of titanium tubes should use high-frequency non-contact arc initiation to avoid tungsten contamination and inclusions at the start zone. Argon gas must be pre-flowed before striking to ensure the weld area is fully protected by inert gas.

Heat Input and Travel Speed Control

Heat input should be kept within a reasonable range to ensure full penetration without excessive heat that may cause burn-through or embrittlement. Travel speed must remain steady and uniform—too slow may cause oxidation, while too fast can lead to lack of fusion.

Push Welding and Dip Feeding Technique

The push welding method is recommended to keep the shielding gas fully covering the weld pool. Use an intermittent "dip feeding” technique, adding filler wire in short intervals while moving, to avoid prolonged immersion of the wire in the weld pool that could introduce contamination.

Molten Pool Dwell Time and Bubble Release

A slightly longer dwell time should be maintained to allow hydrogen bubbles to escape and reduce porosity. However, excessive dwell can overheat the pool and increase gas absorption.

Shielding and Post-flow

After welding, maintain argon post-flow for ≥20–25 seconds to keep the weld protected until it cools below 400 °C. Back purging is equally critical—ensure at least 10 complete purges before striking the arc to prevent root oxidation.

Post-weld Treatment and Quality Inspection

Post-flow Gas Management

After welding, argon post-flow should be maintained for 20–25 seconds until the weld cools to around 400 °C (800 °F), at which point titanium no longer reacts with oxygen. Some specifications require continued protection until below 150 °C (500 °F); the exact time should follow the process requirements.

Pickling, Rinsing, and Drying

Light oxide scale may remain on the surface after welding. It should be removed by pickling with a hydrofluoric acid + nitric acid solution, then rinsed thoroughly with pure water and fully dried to avoid residual corrosive agents.

Weld Color and Quality Evaluation

One notable advantage of titanium alloys is that the weld color after welding directly reflects the effectiveness of shielding. Weld color not only indicates whether gas protection was sufficient but also reveals the thickness of the oxide film, making it an important criterion for assessing weld quality.

| Weld color | Quality conclusion | Notes |

|---|---|---|

| Bright silver | Acceptable | Clean surface, no oxidation, good protection |

| Silver | Acceptable | Shielding gas fully effective, weld quality qualified |

| Light straw | Acceptable | Slight oxidation, still within allowable range |

| Dark straw | Acceptable | Mild oxidation, acceptable |

| Bronze | Acceptable | Thin oxide layer, does not affect weld performance |

| Brown | Acceptable | Protection basically effective, still qualified |

| Purple | Not acceptable | Indicates insufficient shielding, discoloration must be removed and weld repaired |

| Dark blue | Not acceptable | Protection failed, severe oxidation present |

| Light blue | Not acceptable | Serious oxidation, weld not qualified |

| Green | Not acceptable | Obvious oxidation, mechanical properties reduced |

| Gray | Not acceptable | Severe high-temperature oxidation, weld scrapped |

| White | Not acceptable | Surface severely contaminated or oxidized, weld scrapped |

Additional Notes

- All discoloration must be removed before continuing welding.

- The removal area should cover the weld and up to 0.03 in (≈0.76 mm) into the heat-affected zone (HAZ).

- Purple, blue, and green discoloration will result in weld rejection if additional welding is required.

- Blue and green discoloration may be acceptable on completed welds but must be removed before further processing.

Nondestructive Testing (PT/RT/UT)

In addition to visual color evaluation, nondestructive testing and laboratory inspections are required for comprehensive weld quality assessment:

- PT (penetrant testing): Detects surface micro-cracks and porosity.

- Hardness testing: Evaluates whether the weld area has hardened due to oxidation or hydrogen embrittlement.

- RT (radiographic testing) and UT (ultrasonic testing): Identify internal defects.

- Destructive testing: Used under critical conditions to verify weld strength and toughness.

Pressure and Leakage Testing

For pressure-bearing titanium tubes, hydrostatic or pneumatic tests should be conducted after welding to verify weld tightness. If necessary, helium mass spectrometry leak detection should also be performed to ensure there are no hidden leaks.

Titanium Tube Welding FAQ

What is the best method for welding titanium tubes?

Gas Tungsten Arc Welding (TIG/GTAW) is widely recognized as the best method, offering unmatched precision and cleanliness control.

How can titanium weld discoloration be prevented?

The key is perfect inert gas shielding. Ensure high argon purity and use primary shielding, a trailing shield, and internal argon purging simultaneously.

Why does porosity occur in titanium welds?

The main cause is hydrogen contamination. The base metal, filler wire, and work environment must be absolutely clean and dry, with high-purity argon gas used.

Is preheating required for titanium tube welding?

For thin-walled tubes under 3 mm, preheating is usually unnecessary. For thick-walled tubes, moderate preheating helps reduce welding stress.

Chalco Titanium Product Offering

We not only have deep expertise in the complexities of titanium tube welding, but also supply high-quality titanium welded pipes and seamless pipes, fully compliant with ASTM B338 and ASTM B862 standards.

If you face challenges in titanium tube applications or welding, or need to source high-standard titanium tube products, contact our technical experts today for professional solutions.