Titanium and Titanium Alloy Welded Pipe

Titanium alloy welded tube is a titanium metal tube made of high-purity titanium strip or titanium plate through rolling and automatic welding. Compared with traditional seamless titanium tube, welded titanium tube has higher dimensional consistency, lower production cost, and can be customized in length, wall thickness and material. It is widely used in high-end fields such as chemical corrosion protection, heat exchangers, seawater desalination, medical equipment, aerospace, etc.

Chalcotitanium titanium welded pipe product specification overview

Grade: Gr1, Gr2, Gr5 (Ti-6Al-4V), Gr7, Gr9, Gr12 …

Outer diameter (OD): 6mm – 114mm, custom sizes available

Wall thickness (WT): 0.5mm – 6.0mm, contact us for custom sizes

Length (L): Regular 6 meters, can be customized up to 12 meters. Click to view [full size table]

Tolerance control: outer diameter tolerance ±0.10mm, wall thickness tolerance ±5%;

click to view [Complete tolerance table]

Chalcotitanium titanium welded pipe stock alloys

Chalcotitanium supplies the following popular titanium alloy welded pipe grades all year round, which are widely used in chemical, energy, medical, offshore and other industries. If you have other grades, please contact us for inventory or customized services. We can produce non-standard specifications and special alloy materials on demand.

-

Grade 1 titanium welded tube

Excellent corrosion resistance, good formability, suitable for light load occasions such as chemical industry and seawater treatment.

-

Grade 2 titanium welded tube

With slightly higher strength than GR1 and excellent weldability, it is a widely used grade for welding pipes in heat exchangers, medical, and environmental applications.

-

Grade 7 titanium welded tube

It has extremely strong corrosion resistance in strong acid media (such as hydrochloric acid and sulfuric acid) and is often used in high-corrosion scenarios in the chemical industry.

-

Grade 5 titanium welded tube

It has high strength and good heat resistance, and is suitable for aerospace and high-strength structural parts. Its weldability is slightly worse than other grades but is still controllable.

-

Grade 9 titanium welded tube

It has good weldability and high strength, suitable for piping systems and pressure vessel applications.

-

Grade 12 titanium welded tube

It has excellent corrosion resistance and is particularly suitable for environments containing chloride ions. It is widely used in marine engineering and power plant condensation systems.

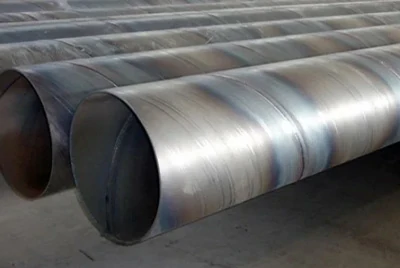

Chalcotitanium titanium welded pipe product type display

Chalcotitanium titanium alloy welded pipe products are divided into the following seven categories according to manufacturing methods and structural forms, fully covering high-end application needs such as industry, chemical industry, medical treatment, energy, aviation, etc. Each type can be customized according to demand in terms of material (such as Gr1, Gr2, Gr5, etc.), specification size, tolerance standard and surface treatment method.

Titanium plate welded pipe

Formed by rolling and welding titanium plates, it is ideal for small to medium batches with high flexibility. Suitable for structural and heat exchange tubes, supporting TIG, PAW, and laser welding.

Outer diameter range: φ10mm–φ200mm

Wall thickness range: 0.5mm–6.0mm

Titanium strip continuous welded pipe

Online-welded from continuous titanium strip for efficient, standardized production. Offers good dimensional consistency and supports annealing and inspection. Used in heat exchangers and fluid systems.

Outer diameter range: φ6mm–φ50mm

Welded rolled pipe

After welding and rolling, the structure is denser, the weld transition is natural, and both dimensional accuracy and mechanical properties are enhanced. Can serve as an alternative to seamless pipes.

Quality assurance: Supports multi-pass cold rolling or hot rolling finishing

Ultra-long girth-welded tube

Suitable for large-diameter or customized structural pipes, manufactured by girth welding multiple sections. Flexible in length and shape, used in heat exchangers, housings, and large structures.

Extra-long size: Up to >6m or customized non-standard parts

Quality assurance: Circumferential weld X-ray inspection available

Titanium alloy round tube

Standard round titanium welded pipes are widely used in pipelines, heat exchangers, and structural parts, meeting ASTM B338, ASME SB861, and other standards.

Surface treatments: Pickling, polishing, mirror finish available

Titanium alloy square tube / rectangular tube

Formed with special molds for customizable aspect ratios and angles, ideal for frames, supports, and decorative structures with stable performance.

Common specifications: 10×10mm – 100×50mm

Titanium alloy special section tube

Includes oval, D-shaped, flat, hexagonal tubes, etc., for specific shapes or flow performance needs. Used in medical, automotive, and structural design applications.

Mold customization: Supports custom mold development and batch production

Titanium alloy welded pipe for heat exchanger

Welded titanium tubes offer high dimensional accuracy, stable quality, and cost efficiency, making them ideal for heat exchangers. Chalco supplies titanium alloy welded tubes for shell-and-tube, plate, and spiral heat exchangers, meeting diverse industrial requirements.

Chalcotitanium titanium alloy welded pipe production, processing and quality assurance

- Supports multiple processes such as TIG, PAW, laser welding, etc., and automated welding is stable and efficient.

- The pure argon shielded welding process is suitable for wide and thick titanium plates and large diameter welding.

- After welding, cold rolling or hot rolling finishing can be carried out to improve the accuracy and uniformity of the pipe.

- Use controlled atmosphere annealing to prevent oxidation, relieve stress and improve overall stability.

- Provide a variety of surface treatments such as pickling and electrolytic polishing to meet high-cleanliness applications.

- The weld is full and smooth, with a small heat-affected zone, and has excellent strength and appearance consistency.

- The welds can be subjected to non-destructive testing such as X-ray and ultrasonic testing to ensure the safety and reliability of the structure.

As a professional titanium pipe manufacturer and processing supplier, Chalco Titanium provides complete production, finishing, and quality control capabilities to support demanding industrial projects. In addition to welded titanium alloy pipes, we also supply Titanium Thin Wall Tube, Titanium Bend Pipe, Titanium Seamless Pipe and other pipe products for various structural and precision applications. If you have related titanium pipe project requirements, please feel free to contact us for technical support and quotation.

Chalcotitanium titanium alloy welded pipe application cooperation areas

Titanium alloy welded pipes are widely used in many key industries due to their excellent corrosion resistance, light weight, high strength and excellent processing performance. Chalcotitanium is committed to providing high-quality, customized titanium alloy welded pipe solutions for heat exchange, chemical industry, marine engineering, medical and pharmaceutical, new energy and environmental protection, etc., helping customers achieve equipment performance optimization and cost control.

Chalcotitanium welded pipe for heat exchanger manufacturing

Compared with seamless pipes, welded pipes are easier to control in length and wall thickness, are particularly suitable for large-scale, standardized production, and are more cost-effective.

Chalcotitanium offers custom OD/wall thickness combinations with tight tolerances (±0.10mm), annealing and pickling, and full weld inspection reports to ensure heat transfer efficiency and long-term reliability.

Chalcotitanium welded pipe for chemical industry/petrochemical industry

Corrosion-resistant titanium alloys such as Gr7 and Gr12 are often used for conveying corrosive media. Welded pipes can be adapted to larger diameters or special structures by means of splicing/thickening.

Chalcotitanium provides multi-pass welding and thick plate welding capabilities, has a stock of corrosion-resistant alloys such as Gr7/Gr12, supports third-party testing and can customize complex structures according to drawings.

Chalcotitanium welded pipe for seawater desalination and marine engineering

In salt spray, high humidity and high corrosion environments, titanium alloy welded pipes have the advantages of light weight and high strength. At the same time, they can achieve ultra-long structural welding and reduce flange connection points.

Chalcotitanium provides extra-long structural pipes (6m+), butt welding capabilities, anti-oxidation annealing treatment and comprehensive non-destructive testing to meet offshore grade requirements.

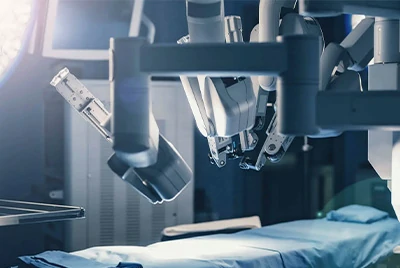

Chalcotitanium welded pipe for medical/pharmaceutical industry

In situations with high cleanliness requirements, welded pipes can achieve smooth inner walls and customized surface treatment to meet the requirements of cleaning processes such as CIP/SIP.

Chalcotitanium provides internal and external pickling and polishing, low roughness control, seamless weld treatment and full process traceability material report to meet high cleanliness applications.

Chalcotitanium welded pipe for new energy/environmental protection equipment

It is suitable for high-strength and corrosion-resistant requirements in hydrogen energy equipment, waste gas treatment, heat recovery systems, etc. The welding structure is flexible and can press special-shaped or composite sections.

Chalcotitanium provides customization of special-shaped sections, composite welded structures, weld consistency control and rapid delivery support to meet the diverse needs of new energy and environmental protection equipment.

Chalcotitanium titanium alloy welded pipe stock dimensions and tolerances

| Titanium Welded Pipe | ASME B36.10 | Schedule 40 & 80 Data Sheets | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Pipe Size | Outer Dimension | Sch40 | Sch80 | ||||||||||||

| Wall Thickness | Inside Diameter | Weight | Wall Thickness | Inside Diameter | Weight | ||||||||||

| in | mm | in | mm | in | mm | in | mm | lbs/ft | kg/m | in | mm | in | mm | lbs/ft | kg/m |

| 1/8″ | 6 | 0.41 | 10.29 | 0.07 | 1.73 | 0.27 | 6.83 | 0.14 | 0.21 | 0.10 | 2.41 | 0.22 | 5.46 | 0.18 | 0.27 |

| 1/4″ | 8 | 0.54 | 13.72 | 0.09 | 2.24 | 0.36 | 9.25 | 0.24 | 0.36 | 0.12 | 3.02 | 0.30 | 7.67 | 0.31 | 0.46 |

| 3/8″ | 10 | 0.68 | 17.15 | 0.09 | 2.31 | 0.49 | 12.52 | 0.33 | 0.49 | 0.13 | 3.20 | 0.42 | 10.74 | 0.43 | 0.63 |

| 1/2″ | 15 | 0.84 | 21.34 | 0.11 | 2.77 | 0.62 | 15.80 | 0.49 | 0.73 | 0.15 | 3.73 | 0.55 | 13.87 | 0.63 | 0.93 |

| 3/4″ | 20 | 1.05 | 26.67 | 0.11 | 2.87 | 0.82 | 20.93 | 0.65 | 0.97 | 0.15 | 3.91 | 0.74 | 18.85 | 0.85 | 1.26 |

| 1″ | 25 | 1.32 | 33.40 | 0.13 | 3.38 | 1.05 | 26.65 | 0.97 | 1.44 | 0.18 | 4.55 | 0.96 | 24.31 | 1.25 | 1.86 |

| 1-1/4″ | 32 | 1.66 | 42.16 | 0.14 | 3.56 | 1.38 | 35.05 | 1.31 | 1.95 | 0.19 | 4.85 | 1.28 | 32.46 | 1.72 | 2.57 |

| 1-1/2″ | 40 | 1.90 | 48.26 | 0.15 | 3.68 | 1.61 | 40.89 | 1.56 | 2.33 | 0.20 | 5.08 | 1.50 | 38.10 | 2.09 | 3.11 |

| 2″ | 50 | 2.38 | 60.33 | 0.15 | 3.91 | 2.07 | 52.50 | 2.10 | 3.13 | 0.22 | 5.54 | 1.94 | 49.25 | 2.89 | 4.30 |

| 2-1/2″ | 65 | 2.88 | 73.03 | 0.20 | 5.16 | 2.47 | 62.71 | 3.33 | 4.96 | 0.28 | 7.01 | 2.32 | 59.00 | 4.41 | 6.56 |

| 3″ | 80 | 3.50 | 88.90 | 0.22 | 5.49 | 3.07 | 77.93 | 4.36 | 6.49 | 0.30 | 7.62 | 2.90 | 73.66 | 5.90 | 8.78 |

| 3-1/2″ | 90 | 4.00 | 101.60 | 0.23 | 5.74 | 3.55 | 90.12 | 5.24 | 7.80 | 0.32 | 8.08 | 3.36 | 85.45 | 7.20 | 10.71 |

| 4″ | 100 | 4.50 | 114.30 | 0.24 | 6.02 | 4.03 | 102.26 | 6.21 | 9.24 | 0.34 | 8.56 | 3.83 | 97.18 | 8.62 | 12.83 |

| 5″ | 125 | 5.56 | 141.30 | 0.26 | 6.55 | 5.05 | 128.19 | 8.41 | 12.52 | 0.38 | 9.53 | 4.81 | 122.25 | 11.96 | 17.79 |

| 6″ | 150 | 6.63 | 168.28 | 0.28 | 7.11 | 6.07 | 154.05 | 10.92 | 16.24 | 0.43 | 10.97 | 5.76 | 146.33 | 16.44 | 24.46 |

| 8″ | 200 | 8.63 | 219.08 | 0.32 | 8.18 | 7.98 | 202.72 | 16.43 | 24.45 | 0.50 | 12.70 | 7.63 | 193.68 | 24.96 | 37.15 |

| 10″ | 250 | 10.75 | 273.05 | 0.37 | 9.27 | 10.02 | 254.51 | 23.29 | 34.66 | 0.59 | 15.09 | 9.56 | 242.88 | 37.01 | 55.07 |

| 12″ | 300 | 12.75 | 323.85 | 0.41 | 10.31 | 11.94 | 303.23 | 30.80 | 45.82 | 0.69 | 17.48 | 11.37 | 288.90 | 50.93 | 75.78 |

| 14″ | 350 | 14.00 | 355.60 | 0.44 | 11.13 | 13.12 | 333.35 | 36.42 | 54.19 | 0.75 | 19.05 | 12.50 | 317.50 | 61.07 | 90.87 |

| 16″ | 400 | 16.00 | 406.40 | 0.50 | 12.70 | 15.00 | 381.00 | 47.62 | 70.86 | 0.84 | 21.44 | 14.31 | 363.53 | 78.52 | 116.83 |

| 18″ | 450 | 18.00 | 457.20 | 0.56 | 14.28 | 16.88 | 428.65 | 60.22 | 89.61 | 0.94 | 23.83 | 16.12 | 409.55 | 98.25 | 146.19 |

| 20″ | 500 | 20.00 | 508.00 | 0.59 | 15.09 | 18.81 | 477.83 | 70.72 | 105.23 | 1.03 | 26.19 | 17.94 | 455.63 | 120.18 | 178.82 |

| 24″ | 600 | 24.00 | 609.60 | 0.69 | 17.48 | 22.62 | 574.65 | 98.42 | 146.45 | 1.22 | 30.96 | 21.56 | 547.68 | 170.51 | 253.72 |

| Titanium Welded Pipe | ASME B36.19 | 5-S & 10-S Data Sheets | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Pipe Size | O.D. | 5-S | 10-S | ||||||||||||

| Wall Thickness | Inside Diameter | Weight | Wall Thickness | Inside Diameter | Weight | ||||||||||

| in | mm | in | mm | in | mm | in | mm | lbs/ft | kg/m | in | mm | in | mm | lbs/ft | kg/m |

| 1/8″ | 6 | 0.41 | 10.29 | x | x | x | x | x | x | 0.05 | 1.25 | 0.31 | 7.80 | 0.11 | 0.16 |

| 1/4″ | 8 | 0.54 | 13.72 | x | x | x | x | x | x | 0.07 | 1.65 | 0.41 | 10.41 | 0.19 | 0.28 |

| 3/8″ | 10 | 0.68 | 17.15 | x | x | x | x | x | x | 0.07 | 1.65 | 0.55 | 13.84 | 0.24 | 0.36 |

| 1/2″ | 15 | 0.84 | 21.34 | 0.07 | 1.65 | 0.71 | 18.03 | 0.31 | 0.46 | 0.08 | 2.11 | 0.67 | 17.12 | 0.39 | 0.57 |

| 3/4″ | 20 | 1.05 | 26.67 | 0.07 | 1.65 | 0.92 | 23.37 | 0.39 | 0.59 | 0.08 | 2.11 | 0.88 | 22.45 | 0.49 | 0.73 |

| 1″ | 25 | 1.32 | 33.40 | 0.07 | 1.65 | 1.19 | 30.10 | 0.50 | 0.74 | 0.11 | 2.77 | 1.10 | 27.86 | 0.81 | 1.20 |

| 1-1/4″ | 32 | 1.66 | 42.16 | 0.07 | 1.65 | 1.53 | 38.86 | 0.64 | 0.95 | 0.11 | 2.77 | 1.44 | 36.63 | 1.04 | 1.55 |

| 1-1/2″ | 40 | 1.90 | 48.26 | 0.07 | 1.65 | 1.77 | 44.96 | 0.73 | 1.09 | 0.11 | 2.77 | 1.68 | 42.72 | 1.20 | 1.79 |

| 2″ | 50 | 2.38 | 60.33 | 0.07 | 1.65 | 2.25 | 57.02 | 0.92 | 1.37 | 0.11 | 2.77 | 2.16 | 54.79 | 1.52 | 2.26 |

| 2-1/2″ | 65 | 2.88 | 73.03 | 0.08 | 2.11 | 2.71 | 68.81 | 1.74 | 2.59 | 0.12 | 3.05 | 2.64 | 66.93 | 2.03 | 3.02 |

| 3″ | 80 | 3.50 | 88.90 | 0.08 | 2.11 | 3.33 | 84.68 | 1.74 | 2.59 | 0.12 | 3.05 | 3.26 | 82.80 | 2.49 | 3.71 |

| 3-1/2″ | 90 | 4.00 | 101.60 | 0.08 | 2.11 | 3.83 | 97.38 | 2.00 | 2.97 | 0.12 | 3.05 | 3.76 | 95.50 | 2.86 | 4.26 |

| 4″ | 100 | 4.50 | 114.30 | 0.08 | 2.11 | 4.33 | 110.08 | 2.25 | 3.35 | 0.12 | 3.05 | 4.26 | 108.20 | 3.23 | 4.81 |

| 5″ | 125 | 5.56 | 141.30 | 0.11 | 2.77 | 5.35 | 135.76 | 3.65 | 5.44 | 0.13 | 3.40 | 5.30 | 134.49 | 4.47 | 6.65 |

| 6″ | 150 | 6.63 | 168.28 | 0.11 | 2.77 | 6.41 | 162.74 | 4.36 | 6.49 | 0.13 | 3.40 | 6.36 | 161.47 | 5.35 | 7.95 |

| 8″ | 200 | 8.63 | 219.08 | 0.11 | 2.77 | 8.41 | 213.54 | 4.36 | 6.49 | 0.15 | 3.76 | 8.33 | 211.56 | 7.71 | 11.47 |

| 10″ | 250 | 10.75 | 273.05 | 0.13 | 3.40 | 10.48 | 266.24 | 8.74 | 13.01 | 0.17 | 4.19 | 10.42 | 264.67 | 10.73 | 15.97 |

| 12″ | 300 | 12.75 | 323.85 | 0.16 | 3.96 | 12.44 | 315.93 | 12.07 | 17.97 | 0.18 | 4.57 | 12.39 | 314.71 | 13.90 | 20.69 |

| 14″ | 350 | 14.00 | 355.60 | 0.16 | 3.96 | 13.69 | 347.68 | 13.27 | 19.75 | *0.188 | 4.78 | 13.62 | 346.05 | 15.96 | 23.74 |

| 16″ | 400 | 16.00 | 406.40 | 0.17 | 4.19 | 15.67 | 398.02 | 16.06 | 23.89 | *0.188 | 4.78 | 15.62 | 396.85 | 18.27 | 27.18 |

| 18″ | 450 | 18.00 | 457.20 | 0.17 | 4.19 | 17.67 | 448.82 | 18.08 | 26.91 | *0.188 | 4.78 | 17.62 | 447.65 | 20.58 | 30.62 |

| 20″ | 500 | 20.00 | 508.00 | 0.19 | 4.78 | 19.62 | 498.45 | 22.89 | 34.06 | *0.218 | 4.78 | 19.62 | 498.45 | 26.50 | 39.43 |

| 24″ | 600 | 24.00 | 609.60 | 0.22 | 5.54 | 23.56 | 598.53 | 31.86 | 47.41 | *0.250 | 6.35 | 23.62 | 600.05 | 36.49 | 54.29 |

| Titanium Welded Pipe | ASME B36.19 | 40-S & 80-S Data Sheets | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Pipe Size | O.D. | 40-S | 80-S | ||||||||||||

| Wall Thickness | Inside Diameter | Weight | Wall Thickness | Inside Diameter | Weight | ||||||||||

| in | mm | in | mm | in | mm | in | mm | lbs/ft | kg/m | in | mm | in | mm | lbs/ft | kg/m |

| 1/8″ | 6 | 0.41 | 10.29 | 0.07 | 1.73 | 0.27 | 6.83 | 0.14 | 0.21 | 0.10 | 2.41 | 0.22 | 5.46 | 0.18 | 0.27 |

| 1/4″ | 8 | 0.54 | 13.72 | 0.09 | 2.24 | 0.36 | 9.25 | 0.24 | 0.36 | 0.12 | 3.02 | 0.30 | 7.67 | 0.31 | 0.46 |

| 3/8″ | 10 | 0.68 | 17.15 | 0.09 | 2.31 | 0.49 | 12.52 | 0.33 | 0.49 | 0.13 | 3.20 | 0.42 | 10.74 | 0.43 | 0.63 |

| 1/2″ | 15 | 0.84 | 21.34 | 0.11 | 2.77 | 0.62 | 15.80 | 0.49 | 0.73 | 0.15 | 3.73 | 0.55 | 13.87 | 0.63 | 0.93 |

| 3/4″ | 20 | 1.05 | 26.67 | 0.11 | 2.87 | 0.82 | 20.93 | 0.65 | 0.97 | 0.15 | 3.91 | 0.74 | 18.85 | 0.85 | 1.26 |

| 1″ | 25 | 1.32 | 33.40 | 0.13 | 3.38 | 1.05 | 26.65 | 0.97 | 1.44 | 0.18 | 4.55 | 0.96 | 24.31 | 1.25 | 1.86 |

| 1-1/4″ | 32 | 1.66 | 42.16 | 0.14 | 3.56 | 1.38 | 35.05 | 1.31 | 1.95 | 0.19 | 4.85 | 1.28 | 32.46 | 1.72 | 2.57 |

| 1-1/2″ | 40 | 1.90 | 48.26 | 0.15 | 3.68 | 1.61 | 40.89 | 1.56 | 2.33 | 0.20 | 5.08 | 1.50 | 38.10 | 2.09 | 3.11 |

| 2″ | 50 | 2.38 | 60.33 | 0.15 | 3.91 | 2.07 | 52.50 | 2.10 | 3.13 | 0.22 | 5.54 | 1.94 | 49.25 | 2.89 | 4.30 |

| 2-1/2″ | 65 | 2.88 | 73.03 | 0.20 | 5.16 | 2.47 | 62.71 | 3.33 | 4.96 | 0.28 | 7.01 | 2.32 | 59.00 | 4.41 | 6.56 |

| 3″ | 80 | 3.50 | 88.90 | 0.22 | 5.49 | 3.07 | 77.93 | 4.36 | 6.49 | 0.30 | 7.62 | 2.90 | 73.66 | 5.90 | 8.78 |

| 3-1/2″ | 90 | 4.00 | 101.60 | 0.23 | 5.74 | 3.55 | 90.12 | 5.24 | 7.80 | 0.32 | 8.08 | 3.36 | 85.45 | 7.20 | 10.71 |

| 4″ | 100 | 4.50 | 114.30 | 0.24 | 6.02 | 4.03 | 102.26 | 6.21 | 9.24 | 0.34 | 8.56 | 3.83 | 97.18 | 8.62 | 12.83 |

| 5″ | 125 | 5.56 | 141.30 | 0.26 | 6.55 | 5.05 | 128.19 | 8.41 | 12.52 | 0.38 | 9.53 | 4.81 | 122.25 | 11.96 | 17.79 |

| 6″ | 150 | 6.63 | 168.28 | 0.28 | 7.11 | 6.07 | 154.05 | 10.92 | 16.24 | 0.43 | 10.97 | 5.76 | 146.33 | 16.44 | 24.46 |

| 8″ | 200 | 8.63 | 219.08 | 0.32 | 8.18 | 7.98 | 202.72 | 16.43 | 24.45 | 0.50 | 12.70 | 7.63 | 193.68 | 24.96 | 37.15 |

| 10″ | 250 | 10.75 | 273.05 | 0.37 | 9.27 | 10.02 | 254.51 | 23.29 | 34.66 | *0.500 | 12.70 | 9.75 | 247.65 | 31.49 | 46.86 |

| 12″ | 300 | 12.75 | 323.85 | 0.38 | 9.53 | 12.00 | 304.80 | 28.52 | 42.43 | *0.500 | 12.70 | 11.75 | 298.45 | 37.64 | 56.01 |

| 14″ | 350 | 14.00 | 355.60 | *0.375 | 9.53 | 13.25 | 336.55 | 31.40 | 46.72 | *0.500 | 12.70 | 13.00 | 330.20 | 41.48 | 61.72 |

| 16″ | 400 | 16.00 | 406.40 | *0.375 | 9.53 | 15.25 | 387.35 | 36.01 | 53.58 | *0.500 | 12.70 | 15.00 | 381.00 | 47.62 | 70.86 |

| 18″ | 450 | 18.00 | 457.20 | *0.375 | 9.53 | 17.25 | 438.15 | 40.61 | 60.43 | *0.500 | 12.70 | 17.00 | 431.80 | 53.77 | 80.01 |

| 20″ | 500 | 20.00 | 508.00 | *0.375 | 9.53 | 19.25 | 488.95 | 45.22 | 67.29 | *0.500 | 12.70 | 19.00 | 482.60 | 59.91 | 89.15 |

| twenty four" | 600 | 24.00 | 609.60 | *0.375 | 9.53 | 23.25 | 590.55 | 54.44 | 81.01 | *0.500 | 12.70 | 23.00 | 584.20 | 72.20 | 107.44 |

| Titanium alloy welded pipe size tolerance table (conventional control range) | ||

|---|---|---|

| project | Tolerance range | illustrate |

| Outside diameter tolerance | ±0.10 mm ~ ±0.20 mm | According to the size of the tube, the small tube is more precise |

| Wall thickness tolerance | ±5% ~ ±10% | Normally controlled within ±5%, special requirements can be negotiated |

| Length tolerance | ±2.0 mm ~ ±5.0 mm | Cut to length, support special length customization |

| Weld height | < 0.3 mm (outer wall) | Can do internal and external weld grinding and polishing |

| Ellipticity | ≤ 1% of outer diameter | Ensure uniform molding and easy assembly |

| Straightness | ≤1 mm / 1000 mm | Suitable for pipes with high requirements for engineering assembly precision |

Titanium Welded Pipe Product Selection Guide

1. Welded pipe vs seamless pipe: How to choose?

| Project | Welded titanium tube | Seamless titanium tube |

|---|---|---|

| Manufacturing method | Plate/strip welding | Piercing + hot extrusion + cold rolling |

| Dimensional accuracy | High, especially suitable for customized needs | medium |

| Producible length | Can produce extra-long tubes (customized) | Generally shorter |

| cost | More cost-effective | High cost, especially for large diameters |

| Application adaptability | Heat exchangers, structural parts, food and medical, etc. | High voltage equipment, aerospace, etc. |

| Is there a weld? | Yes (controllable and detectable) | none |

If you are concerned about dimensional accuracy, cost efficiency, and the application pressure requirements are not extreme, welded titanium tubes are more preferred.

Click to read details [ Differences between titanium alloy welded pipes and seamless pipes]

2. How to evaluate whether the price of titanium welded pipe is reasonable?

The price of titanium welded pipes is determined by alloy grade, size, additional processes and order quantity. For example, alloys such as Gr5 and Gr7 are more expensive, and custom pipes, annealing or non-destructive testing will also increase the unit price. Note: Low-priced products may not be annealed or use recycled materials. It is recommended to verify the quality control process and material source.

3. How to choose a reliable titanium welded pipe supplier?

Priority is given to manufacturers with integrated welding, annealing and testing capabilities. We support customized special-shaped tubes and long tube sections, issue complete quality assurance documents, have rich export experience, and can respond quickly to various needs. It is recommended to first test the process stability with a sample or a small batch.

4. Confirm welding quality and inspection standards?

The welds should be subjected to X-ray or ultrasonic nondestructive testing, and airtightness/water pressure testing should be performed if necessary. All our products can be annealed, and post-processing such as weld cleaning and pickling is provided, and material reports and test data are attached to ensure reliability.

5. Do you need a custom shape or length?

We can produce square tubes, rectangular tubes, oval tubes and other special-shaped cross-section tubes, supporting welding of super-long structures, composite structures and customized sizes. Welcome to provide drawings, we will quickly evaluate the feasibility and assist in proofing.