Titanium Alloy vs Steel: In-Depth Performance Comparison

Updated : Jun. 23, 2025In aerospace, automotive, and chemical sectors, choosing titanium or stainless steel impacts weight, corrosion resistance, strength, and cost—this article shows the data.

Density Difference

Titanium alloy clocks in at 4.51 g/cm³, while 304 stainless steel sits around 7.85 g/cm³, making same-volume parts about 42 % lighter when made of titanium.

Strength and Stiffness

In tensile tests, Ti-6Al-4V reaches an ultimate strength of 920 MPa, versus ~520 MPa for 304 stainless steel.

Titanium's Young's modulus is 116 GPa compared to 200 GPa for steel, giving titanium better vibration damping and steel greater rigidity under load.

Corrosion and High-Temperature Performance

Under a 10 ‰ salt-spray test, titanium corrodes less than 0.01 mm/year, while 304 steel can lose 0.1 mm/year under the same conditions.

Titanium also melts at about 1670 °C, versus 1530 °C for stainless steel—ideal for marine or high-heat environments.

Fatigue and Impact Toughness

Titanium's fine-grain structure delivers exceptional fatigue life under cyclic loads. High-carbon steels absorb more energy in impact tests but tend to show shorter endurance in long-term fatigue

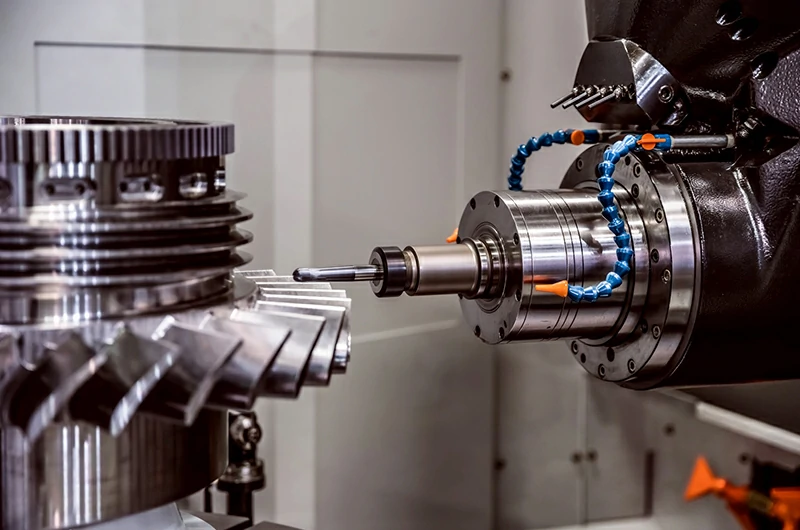

Manufacturing Experience

Cutting titanium runs 30 % slower than stainless steel, and tool life is 50 % shorter, driving machining costs higher. Welding titanium requires high-purity argon and strict temperature control, whereas steel welding is more straightforward and economical.

Unmatched in critical fields like aerospace and marine for its light weight, corrosion resistance, and fatigue life, titanium takes the lead. For standard structural parts, stainless steel's rigidity, low price, and ease of fabrication still win. A hybrid approach—titanium where it counts, steel elsewhere—often delivers the best blend of performance and budget.

For a closer look at the numbers, see our cost analysis article: Why Titanium Costs Up to 30× More Than Steel.