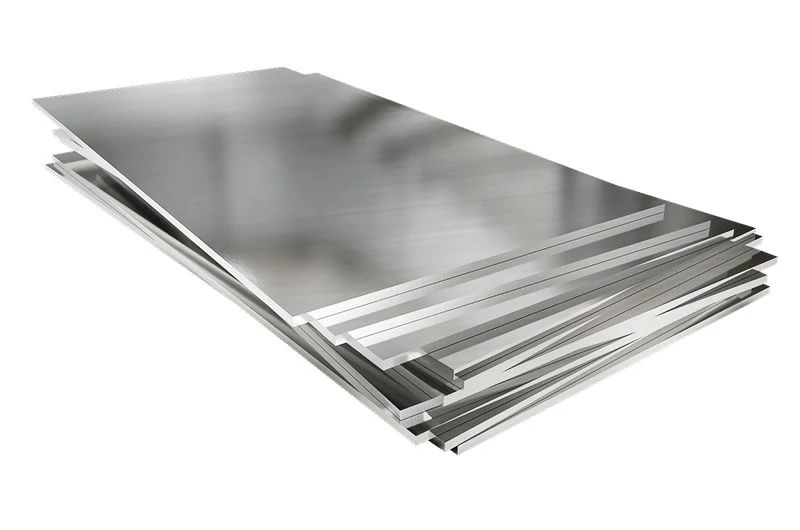

Grade 1 Titanium Sheet Plate

Standards & Specifications

| Application | Code / Version | Material / Product |

|---|---|---|

| General Plate | ASTM B265, ASME SB265 | CP Titanium |

| Pressure Equipment | ASME BPVC Sec IID (Table 1A) | Design Data |

| Welding | AWS D1.6 / ISO 15614‑5 | Welding Qualification |

| Medical Use | ISO 5832‑2 | Implantable Titanium |

| Corrosion Eval. | NACE MR0103 | H₂S Service |

Design Note: When the sheet acts as both shell and pressure boundary, allowable stress may limit thickness reduction. Consider using high-strength Grade 1H or upgrading to Grade 2/3.

Chemistry & Strength Mechanism

| Element | Fe | O | C | N | H | Ti |

|---|---|---|---|---|---|---|

| Max wt% | 0.20 | 0.18 | 0.08 | 0.03 | 0.015 | Balance |

Mechanical & Physical Properties (Annealed)

| Property | Value | Notes |

|---|---|---|

| Tensile Strength (UTS) | ≥ 240 MPa (≈ 35 ksi) | Baseline for design |

| Yield Strength (Rp0.2) | 170–310 MPa | Can increase with cold work |

| Elongation (A) | 24% | Ideal for deep drawing/spinning |

| Hardness | ~70 HB | Softest among titanium grades |

| Density | 4.51 g/cm³ | ~60% of steel |

| Thermal Conductivity | 16 W/m·K | Moderate |

| Melting Point | 1668 °C | Suitable for high-temp service |

Stock Snapshot

Full stock list available for download

| Thickness (mm) | Width (mm) | Length (mm) | Process | Finish | Edge |

|---|---|---|---|---|---|

| 0.64 | 1125 | 2145 | Cold Rolled | Bright | Q |

| 1.0 | 1000 | 2000 | Cold Rolled | Bright | Q |

| 1.0 | 1220 | 2440 | Cold Rolled | Bright | Q |

| 2.0 | 1250 | 6000 | Cold Rolled | Pickled | Q |

| 3.0 | 1500 | 6000 | Hot Rolled | Pickled | M |

| 5.0 | 1500 | 6000 | Hot Rolled | Pickled | M |

| 10.0 | 1800 | 8000 | Hot Rolled | Pickled | M |

| 20.0 | 2000 | 6000 | Hot Rolled | Pickled | M |

- 48 h dispatch for stock items.

- Custom rolling for non-standard thickness: 10–15 days.

Failure Modes & Mitigation

| Failure Mode | Trigger Conditions | Recommended Strategy |

|---|---|---|

| Crevice Corrosion | > 80 °C + tight gaps + Cl⁻ | Use Grade 7/16 (TiPd) or optimize design |

| Hydrogen Embrittlement | Improper pickling control | Rinse with high-pressure DI water; keep H < 0.5 ppm |

| Cold Cracking | Deep drawing with residual stress | Neutral soap lubrication + annealing |

| Galvanic Corrosion | Contact with carbon steel / CuNi | Use insulation, coatings, or sacrificial anodes |

| Abrasive Scratching | Sand particles > 10 m/s | Limit solids or upgrade to Grade 2 |

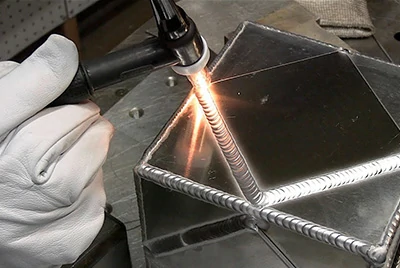

Forming & Welding Window

- Min. bend radius: 1×t for 90° air bends

- Deep drawing limit: IFD ≈ 0.85

- Welding: GTAW with back shielding < 50 ppm O₂; interpass temp < 150 °C

- Annealing: 700–785 °C for 30 min in inert atmosphere. Cooling rate has minor effect on grain size.

Typical Applications & Design Notes

Seawater Heat Exchangers (Tube/ Baffle Plates)

Use ASME IID values for S; above 120 °C, prefer Grade 2.

Chemical Liners / Storage Tanks

Often explosion-bonded with Grade 1 cladding on Q345R / SA516 base.

Cladding Base for Explosion Bonding

Grade 1 ensures metallurgical bonding due to high purity and softness.

Medical Mesh / Cranial Plates

0.5–1.0 mm, requires BA finish & 100% PMI test.

Spun Skins / Honeycomb Panels

Draw ratio up to 2.1; intermediate stress relief at 750 °C during spinning.

Processing & Secondary Services

| Service | Specification | Lead Time |

|---|---|---|

| Waterjet / Laser Cutting | ≤ 25 mm | 24 h |

| Bending & Deep Drawing | R ≥ t × 1 | 2–3 d |

| Machining | CNC milling, drilling, tapping | 3–5 d |

| Surface Treatment | Pickling, sandblasting, BA, #4 | 2 d |

| Testing | UT, ET, PMI, Hardness | 1 d |

FAQ

Q1: What's the difference between Grade 1 and TA1?

They are equivalent materials with different standard codes.

Q2: Can 0.5 mm sheet be rolled into a φ300 mm cylinder?

Yes, bend radius ≥ 0.5t with neutral lubrication.

Q3: Is it safe to use in seawater at 90 °C?

Prefer Grade 7, or keep crevices < 0.15 mm and apply in-line chlorination.