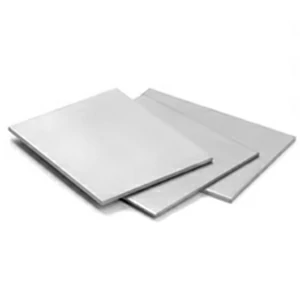

Titanium Sheet

Titanium Sheet generally refers to titanium materials with a thickness of about 0.5–4.75 mm. It features low density, high strength-to-weight ratio, and excellent corrosion resistance. It remains stable in chloride media, acidic or alkaline environments, and seawater, while also offering good formability and weldability. This makes it an ideal choice for chemical linings, heat exchanger plates, marine engineering, industrial sheet metal, and medical equipment.

As a professional titanium sheet supplier, Chalco strictly follows ASTM/ASME B265 standards, with regular stock of Grade 1, Grade 2, Grade 5, and Grade 12. We support 4×8 ft titanium sheet cut-to-size, supply both coil and flat sheet, and offer surface finishes such as pickled and polished. Fabrication services include laser cutting, waterjet cutting, bending, and TIG welding, enabling fast and reliable delivery.

Titanium Sheet vs Plate: How to Distinguish and Select

Titanium Sheet and Titanium Plate are both covered under ASTM/ASME B265. The standard itself does not strictly separate them by thickness, but the industry generally uses around 3/16″ (≈4.75 mm) as the dividing line.

-

Sheet (Thin Plate) Thickness usually ranges 0.5-4.75 mm. Supplied in coils or cut-to-size sheets, with tighter flatness and thickness tolerances. Suitable for stamping, bending, and large-panel assembly. Commonly used for heat exchanger plates, chemical linings, and industrial sheet metal. Recommended when lightweight design, precision stamping, or small bending radius is required.

-

Plate (Thick Plate) Thickness above ≈4.75 mm, with higher strength, suitable for machining or load-bearing components. Often supplied with UT inspection, and commonly used in flanges, structural parts, or pressure vessels. Recommended when load capacity, post-weld machining, or strict inspection levels are needed.

Chalco offers a full range of Titanium Sheet & Plate, covering Grade 1, Grade 2, Grade 5, and Grade 12, and can switch supply forms according to customer needs to ensure the best balance of performance and cost.

For more details on thick plates, please visit Titanium Plate Page.

Titanium Sheet Specification

Alloy Grade: Gr1, Gr2, Gr3, Gr4 (commercially pure titanium); Gr5 (Ti-6Al-4V), Gr23 (Ti-6Al-4V ELI); Gr7 (Ti-0.15Pd), Gr11, Gr12 (Ti-0.3Mo-0.8Ni); Gr9 (Ti-3Al-2.5V), etc.

Thickness Range: 0.3 mm – 4.75 mm; for thicker sizes, see Titanium Plate

Sizes: Conventional sizes: 1000 × 2000 mm, 1220 × 2440 mm; Maximum sizes: 2400 × 6000 mm; Cut-to-size compatible

Tolerance: Thickness tolerance: ±0.1 - 0.25 mm, width tolerance: ≤3 mm

Delivery Form: Coil, Flat Sheet, Cut-to-Size

Processing Technique: Hot Rolled, Cold Rolled Rolled, annealed, and surface finished

Surface Finish: Pickling, brightening, polishing, sandblasting, and anodizing

Production Standards: ASTM B265 / ASME SB-265; AMS 4901 / 4902 / 4911; ASTM F67 (CP Ti), ASTM F136 (Ti-6Al-4V ELI); DIN 17860, etc.

Documents & Packing: EN 10204 3.1 material certification; export seaworthy packaging (moisture-proof/scratch-proof/edge protection), support third-party inspection

After confirming dimensions and tolerances, the next step is to select the titanium sheet alloy grade. Different grades directly impact corrosion resistance, formability, and strength: Grade 2 (general purpose formability/corrosion resistance), Grade 5 (high-strength Ti-6Al-4V), Grade 7/11 (palladium-containing, pitting/crevice corrosion resistance), and Grade 12 (suitable for welding and chemical media).

Titanium Sheet Grades Selection

Grade 2 Titanium Sheet

Features: The most widely used commercially pure titanium, offering a balance of strength and corrosion resistance, with excellent formability and weldability.

Typical Applications: Chemical equipment, marine vessels, heat exchanger plates, pipelines.

Standards: ASTM B265 · ASME SB-265 · ASTM F67 · AMS 4902

Grade 5 Ti Sheet (Ti-6Al-4V)

Features: The most common titanium alloy, combining high strength and lightweight with fatigue resistance and good weldability.

Typical Applications: Aerospace, energy equipment, marine engineering, sporting goods.

Standards: ASTM B265 · AMS 4911 · ASTM F1472

-

Grade 1 Titanium Sheet

Features: Softest and most ductile CP titanium, excellent weldability and corrosion resistance, high formability

Applications: Chemical linings, heat exchangers, medical instruments

Standards: ASTM B265 · ASTM F67

-

Grade 3 Titanium Sheet

Features: Stronger than Gr2 with slightly reduced ductility, good corrosion resistance

Applications: Pressure vessels, industrial structures, aerospace components

Standards: ASTM B265 · ASTM F67 · AMS 4900

-

Grade 4 Titanium Sheet

Features: Strongest CP titanium with excellent corrosion resistance

Applications: Aerospace parts, medical implants, high-strength components

Standards: ASTM B265 · ASTM F67 · AMS 4901

-

Grade 23 Titanium Sheet (Ti-6Al-4V ELI)

Features: Higher toughness and superior biocompatibility, low interstitial alloy

Applications: Medical implants, orthopedic devices, aerospace applications

Standards: ASTM B265 · ASTM F136

-

Grade 7 Titanium Sheet (Ti-0.15Pd)

Features: Palladium-alloyed, excellent resistance to pitting and crevice corrosion

Applications: Desalination, chemical equipment, chloride-rich environments

Standards: ASTM B265 · ASME SB-265

-

Grade 9 Titanium Sheet (Ti-3Al-2.5V)

Features: Medium strength, better formability and weldability than Gr5

Applications: Aerospace hydraulic tubing, bicycles, sports equipment

Standards: ASTM B265 · ASME SB-265

-

Grade 11 Titanium Sheet (Ti-0.15Pd)

Features: Similar to Gr7 but with greater ductility for complex forming

Applications: Chemical plants, environmental equipment, seawater systems

Standards: ASTM B265 · ASME SB-265

-

Grade 12 Titanium Sheet (Ti-0.3Mo-0.8Ni)

Features: Mo and Ni alloyed, combining strength, corrosion resistance, and weldability

Applications: Chemical pipelines, heat exchangers, pump and valve systems

Standards: ASTM B265 · ASME SB-265

Standards & Compliance

All Titanium Sheets supplied by Chalco are manufactured and inspected strictly in accordance with international standards. Each order comes with compliance documentation and traceability to meet the requirements of engineering audits and global procurement.

- General Standards: ASTM B265 / ASME SB-265 (Titanium and Titanium Alloy Sheet, Strip & Plate). Applicable to Grade 1/2/3/4/5/7/9/11/12/23, covering chemical composition, mechanical properties, dimensions, and appearance.

- Aerospace / Project Standards: AMS 4900/4901/4902 (CP Titanium Sheet), AMS 4911 (Ti-6Al-4V), AMS 4907 (Ti-6Al-4V ELI). Designed for aerospace, offshore, and other high-reliability project tenders and acceptance.

- Medical Standards: ASTM F67 (Commercially Pure Titanium, Surgical Implant), ASTM F136 (Ti-6Al-4V ELI), ASTM F1472 (Ti-6Al-4V). Suitable for medical devices and implant-grade applications.

- Documentation: EN 10204 3.1 MTC supplied with all shipments. Optional third-party inspections and higher-level certification (e.g. 3.2) available to meet regulatory and customer system requirements.

- Tolerances & Flatness: Strictly controlled according to ASTM/ASME B265 for thickness tolerance, dimensional accuracy, and flatness. For stamping or sealing surfaces, enhanced flatness or visual controls can be specified in inquiries.

- Traceability & Identification: Each batch is fully traceable with heat numbers and batch codes. Complete process records are maintained to support compliance audits and long-term maintenance.

Ordering Tip: When submitting an inquiry, please specify the required standard (e.g. ASTM B265 or AMS 4911), grade, thickness/size, and surface finish. We will provide matching datasheets (chemical composition and mechanical properties) along with MTC 3.1 for engineering review.

Titanium Sheet Surface Finish

Titanium Sheets can be supplied with different surface conditions depending on processing steps. Chalco offers the following common finishes:

- Mill Finish: As-rolled condition with natural texture, suitable for further machining or processing.

- Pickled: Oxide layer removed by acid pickling, providing a clean surface ideal for welding and corrosion resistance. This is the most common delivery condition.

- Bright: Cold-rolled and finished for improved flatness, suitable for formed and appearance-sensitive parts.

- Polished: Smooth and shiny surface, often used for medical devices, decorative parts, and precision components requiring high aesthetics.

These finishes meet the needs of industrial, anti-corrosion, medical, and decorative applications.

Titanium Sheet Fabrication Capabilities

In addition to standard supply, Chalco provides advanced fabrication services to support fast transition from sheet to finished parts:

- Bending: CNC-controlled bending for housings, enclosures, and structural components.

- Punching: Customized hole shapes, sizes, and patterns for ventilation, filtration, or heat dissipation.

- Laser & Waterjet Cutting: High-precision cutting with clean edges, suitable for complex parts.

- Welding: TIG/MIG welding services for equipment assembly and modular manufacturing.

These fabrication processes ensure reliable solutions for chemical equipment, heat exchangers, aerospace structures, and precision instruments.

Titanium Sheet Secondary Products

Beyond standard flat sheets, Chalco also provides a range of value-added titanium sheet products that take advantage of titanium’s light weight and corrosion resistance. Through perforation and forming processes, these products are widely used in filtration, heat dissipation, electrochemical systems, and structural reinforcement.

Titanium Disc

Produced by stamping or cutting from titanium sheets or coils, discs can be customized in both diameter and thickness. With excellent corrosion resistance and formability, they are commonly used in cookware, tableware, medical instruments, and pressure vessel end caps. Customers can choose from grades such as Grade 2 and Grade 5, depending on the application.

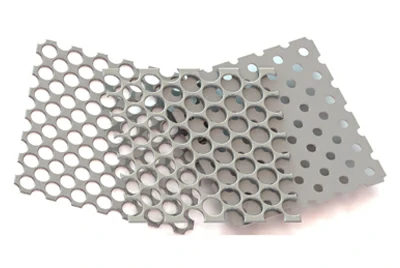

Perforated Titanium Sheet

Designed with customized hole types and sizes, perforated sheets maintain titanium’s inherent light weight and corrosion resistance while adding enhanced ventilation, filtration, and heat dissipation. They are widely applied in chemical filters, ventilation systems, noise reduction panels, and protective or decorative components.

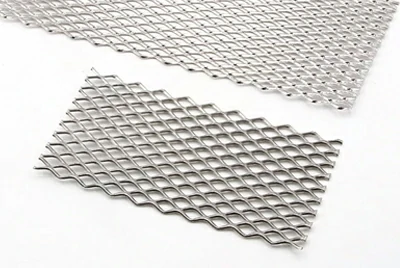

Titanium Mesh Sheet

Manufactured by expanding or weaving processes, titanium mesh combines low weight, high strength, and conductivity. It is extensively used in electrodes, water treatment filtration, battery systems, and reinforcement structures, and is suitable for long-term operation in highly corrosive environments.

Chalco not only offers titanium sheets in a wide range of sizes and finishes but also supplies perforated sheets, mesh sheets, and discs, helping customers reduce downstream processing costs and shorten delivery times. For special requirements, please contact us for custom solutions and sample support.

Titanium Sheet Applications by Industry

Chemical & Desalination

Titanium Sheets are widely used in chemical processing and seawater desalination thanks to their superior corrosion resistance and long-term stability, making them an ideal replacement for stainless steel.

Application Parts: Heat exchanger plates, pressure vessel linings, condenser plates

Grades: Gr2, Gr7

Aerospace

For aerospace, materials must combine light weight with high strength. Titanium Sheets provide excellent strength-to-weight ratio, fatigue resistance, and heat tolerance.

Application Parts: Aircraft skins, support plates, fuel system components

Grades: Gr5, Gr9

Medical & Pharmaceutical

Features: With proven biocompatibility and non-toxicity, Titanium Sheets are widely applied in medical and pharmaceutical equipment as well as implantable devices.

Application Parts: Surgical instruments, medical implants, pharmaceutical equipment linings

Grades: Gr1, Gr2, Gr23 ELI

Energy & Power

Features: In energy and power systems, Titanium Sheets are often used as electrodes or corrosion-resistant structures to ensure long-term stable performance.

Application Parts: Electrode plates, battery casings, fuel cell components

Grades: Gr2, Gr7

Architecture & Decoration

Features: For architecture, aesthetics and durability are essential. With its unique metallic texture and surface finishing options, Titanium Sheet is increasingly used in high-end building facades and artistic installations.

Application Parts: Curtain wall panels, façades, art installations

Grades: Gr2, Gr5

Manufacturing & Supply Advantages

Chalco provides integrated capabilities from raw material to final delivery, covering both coil and flat sheet supply. We support shearing, laser cutting, waterjet cutting, CNC bending, and TIG/MIG welding, with detailed process sheets and sample validation for complex profiles. Prototyping cycles are short, and bulk deliveries remain stable.

For quality and traceability, we implement three-level inspections (incoming, in-process, and outgoing) with barcode tracking for each batch. Key dimensions and surface conditions are fully recorded. All shipments come with EN 10204 3.1 certificates, and optional third-party inspections or on-site acceptance can be arranged. For pressure-bearing or critical components, UT testing ranges and levels can be agreed in advance.

Packaging & Logistics: We use moisture-proof, anti-scratch edge protection, and seaworthy anti-salt spray packaging. Export shipments include customs clearance and certificate of origin documents. With years of experience serving clients in Europe, North America, Japan, the Middle East, and Latin America, we ensure smooth international logistics.

Our Key Supply Advantages:

- Standards Compliance: Production according to ASTM/ASME B265; projects can follow AMS 4900/4901/4902/4911, and medical routes such as ASTM F67/F136.

- Inventory & Fast Response: Regular stock in 0.5–4.0 mm thickness and 4×8 ft sheet sizes; cut-to-size services enable faster delivery.

- Engineering Support: Expert advice on bending radius, welding protection, cutting methods, and flatness control, reducing production risk.

Pricing & Procurement Guide

The price of Titanium Sheets is influenced by multiple factors, including:

- Grade: (e.g., Gr2, Gr5)

- Thickness and dimensions:

- Surface condition: (Pickled / Bright / Polished)

- Processing requirements: (Cutting / Bending / Welding)

- Order quantity and delivery schedule:

We support pricing per piece or per kilogram. To optimize cost planning, we recommend using our <Weight Calculator│/tool/weight/>; to estimate weight and shipping costs.

How We Quote:

Please provide the following details in your inquiry to receive a fast and accurate quotation (within 48 hours):

- Grade: (e.g., Gr2, Gr5)

- Thickness, dimensions, and quantity:

- Surface condition: (Pickled / Bright / Polished)

- Target standard: (e.g., ASTM B265 / AMS 4911)

- Processing requirements: (Cutting, Bending, Welding, etc.)

- Delivery time and destination:

FAQ

What is the difference between Titanium Sheet and Titanium Plate?

The main difference lies in thickness. Materials with a thickness ≤4.75 mm are commonly classified as Titanium Sheet, while thicker materials are considered Titanium Plate. Sheets are widely used for stamping, heat exchangers, and formed parts, while plates are used in structural components and pressure vessels.

Which international standards do your Titanium Sheets meet?

All Titanium Sheets comply with ASTM B265 / ASME SB-265. Depending on project needs, we can supply according to AMS 4900 / AMS 4911 / DIN / EN standards. For medical applications, ASTM F67 / ASTM F136 are available. Each shipment is supplied with an EN 10204 3.1/3.2 MTC certificate.

How is the price of Titanium Sheet calculated?

Pricing depends on the grade (e.g., Gr2, Gr5), thickness, size, surface finish, processing method, and order quantity. We offer pricing per piece or per kilogram. To plan costs, use our <Weight Calculator│/tool/weight/> to estimate weight and then submit your full specifications. A formal quotation will be provided within 48 hours.

Do you provide cutting, bending, or welding services?

Yes. Chalco offers shearing, laser/waterjet cutting, CNC bending, and TIG/MIG welding. For complex parts, we can provide process sheets and sample validation to minimize mass production risks.

What is the typical lead time? Do you provide export packaging?

Standard sizes are available for immediate delivery after order confirmation. Customized sizes, depending on complexity, usually take 2–4 weeks. All exports are packaged with moisture-proof, anti-salt spray, and anti-shock protection, including customs clearance and certificate of origin, ensuring safe international shipping.