Titanium Cable Material

Compared to stainless steel cables, titanium cable offers superior biocompatibility, low magnetic response, and excellent corrosion resistance, making it MRI/CT compatible and reducing postoperative risks.

Chalco Titanium, a leading titanium cable manufacturer, controls the entire production chain from ingot melting to multi-strand cable formation. We supply ASTM F136 / ASTM B863 compliant titanium cables, supporting:

- Custom structures & diameters (1.0 / 1.3 / 1.7 mm standard, other sizes available)

- Clean-level processing & OEM collaboration (including material certificates, batch traceability, and cleanliness reports)

- Fast delivery & global support (small-batch testing, samples ready in as fast as 2 weeks)

Why Choose Titanium Cable Instead of Stainless Steel?

In orthopedic fixation systems, material performance directly impacts surgical safety and postoperative recovery. Compared to traditional stainless steel cables, titanium orthopedic cable provides the following advantages:

- Superior Biocompatibility – Titanium is highly inert in the human body, releasing no harmful ions, reducing the risk of inflammation or allergic reactions.

- Excellent Corrosion Resistance – Maintains long-term stability in blood and body fluids, unlike stainless steel, which is prone to pitting or stress corrosion.

- Non-Magnetic Performance – Titanium causes minimal interference during MRI and CT scans, unlike stainless steel, which creates artifacts and compromises imaging accuracy.

- High Flexibility & Fatigue Life – Multi-strand titanium braided cable endures dynamic loads in tension band wiring and spinal fixation without premature failure.

- Lightweight Advantage – Titanium weighs only about 56% of stainless steel for the same diameter, reducing overall implant weight.

Titanium Cable Specifications & Supply Options

Titanium cable material is widely used in orthopedic fixation systems for its high flexibility, biocompatibility, and corrosion resistance, making it the preferred choice for medical device OEMs. Chalco Titanium offers multiple cable structures, diameters, and processing options to meet the demands of cerclage, tension band wiring, and other surgical applications, while supporting OEM customization and clean processing.

Basic Specifications

- Alloy Grades: Grade 5 (Ti-6Al-4V, TC4) / Grade 23 (Ti-6Al-4V ELI)

- Standard Diameters: 1.0 mm / 1.3 mm / 1.7 mm (±0.05 mm)

- Stranding Structures: 1×3 / 1×7 / 1×19 / 7×7 / 7×19 / 7×7×7

- Cut-to-Length Options: 400 mm / 500 mm / 520 mm / 600 mm or custom length

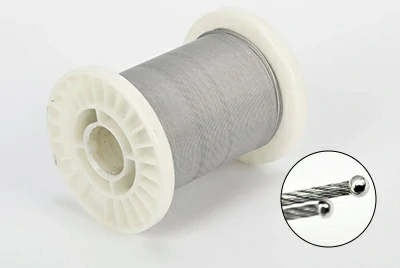

- Supply Forms: Spool, cut-to-length, semi-finished stranded cables

- Clean-Level Processing: Hot alkaline cleaning, ultrasonic cleaning, alcohol rinse; cleanliness report available; OEM sterilization support

- Packaging: Vacuum-sealed + double sterile bag, export-grade protective box

Typical Mechanical Properties

| Diameter (mm) | Tensile Strength (N) | Application Note |

|---|---|---|

| 1.0 | ≥450 | For minimally invasive cerclage |

| 1.3 | ≥760 | Spinal fixation, higher load |

| 1.7 | ≥1300 | High-strength tension band |

*Values may vary slightly based on structure, heat treatment, and strand count; custom specifications available upon request.

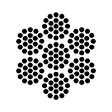

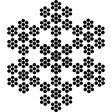

Stranding Structure Overview

| Sample |

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Structure | 1×3 | 1×7 | 1×19 | 7×7 | 7×19 | 7×7×7 |

| Typical Strands | 3 | 7 | 19 | 49 | 133 | 343 |

| Flexibility | ★ | ★★ | ★★★ | ★★★ | ★★★★★ | ★★★★★ |

| Diameter Range | 0.08-0.71 | 0.08-0.91 | 0.15-1.27 | 0.18-1.19 | 0.23-1.19 | 0.69-2.01 |

| Common Ortho Spec | - | - | 1.3 | 1.0 | 1.0 | 1.7 |

*Flexibility Trend: Higher strand count = greater flexibility, suitable for complex anatomical fixation. Complex structures enhance fatigue resistance but require higher stranding precision and cleanliness.

Orthopedic Titanium Cable System & Common Forms

- Cable: Multi-strand titanium cable

- Needle: Straight / Curved / Detachable

- Crimp: Locking mechanism for secure fixation

- Tensioner & Crimping Tools: For tension adjustment and final locking

Note: The above items represent downstream OEM components. Chalco Titanium only supplies high-purity titanium cable material, with OEM technical support and full material certification.

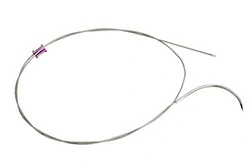

Common Titanium Cable Forms

Straight Needle Cable

Pre-assembled with a straight needle for linear passage; commonly used for tension band wiring and patella fracture fixation.

Curved Needle Cable

Equipped with a curved needle for anatomical conformity; widely applied in patella, acetabulum, or sternal fixation.

Cable Only (No Needle)

Pure titanium stranded cable supplied for OEM customers to assemble with needles and crimps; ideal for batch production.

Disclaimer: The forms listed above are for reference only. Final products must be manufactured and registered by certified medical device companies.

Common Orthopedic Applications of Titanium Cable

Titanium orthopedic cable is widely used in fracture repair and fixation systems. With high flexibility, corrosion resistance, and low magnetic response, it supports a variety of surgical techniques. Below are typical applications:

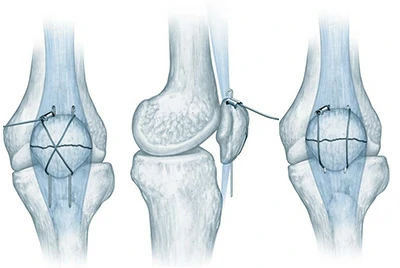

Patella Cerclage (Knee Cap Fracture Fixation)

Used for tension band wiring in patella fractures. The multi-strand titanium cable design provides superior flexibility, reducing intraoperative breakage risk and minimizing imaging artifacts.

Hip & Trochanter Reconstruction

Ideal for acetabular and greater trochanter fracture reconstruction. Lightweight titanium cables reduce implant burden while offering excellent biocompatibility.

Spinal Tension Band Fixation

Provides additional stabilization in spinal surgery. Titanium's low magnetic property ensures MRI/CT compatibility for accurate postoperative imaging.

Sternal & Rib Cerclage

Applied in sternal reconstruction or rib fracture wiring. Titanium braided cable resists corrosion and fatigue, enduring cyclic respiratory loads.

Revision Surgery & Bone Augmentation

Used in failed fixation revisions or bone defect reinforcement. High fatigue strength and flexibility lower the risk of secondary surgeries.

Manufacturing & Quality Assurance

Chalco Titanium is more than a titanium wire trader—we are a full-chain manufacturer. From vacuum melting of titanium ingots to multi-strand cable stranding and clean cut-to-length processing, every step is controlled in-house to ensure consistency, traceability, and compliance.

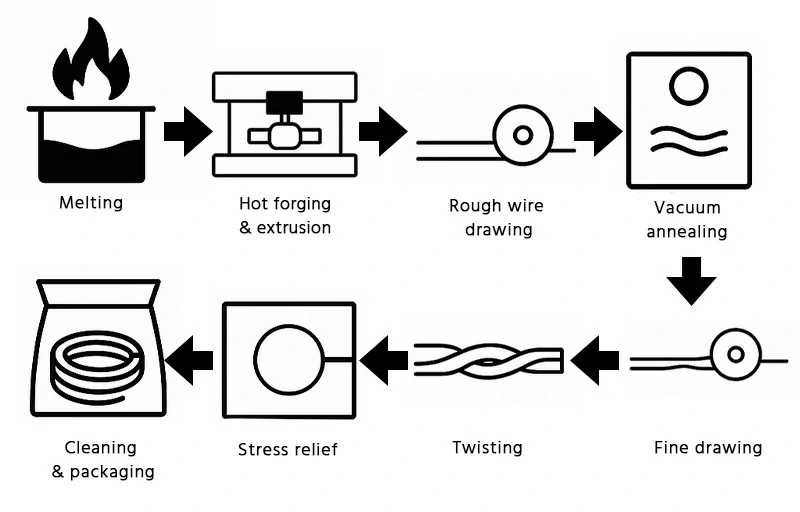

Full-Process Control: From Melt to Finished Cable

Process Steps: Melting → Hot Forging & Extrusion → Primary Drawing → Vacuum Annealing → Precision Drawing → Stranding → Stress Relief → Clean Finish & Packaging

Key Quality Control Points:

- Chemical Composition Analysis (ASTM F136 / ASTM B863 standards)

- Diameter Tolerance Control (±0.05 mm)

- Surface Cleanliness Testing

- Residual Torque & Tensile Testing

Quality System & Documentation Support

- Certifications: ISO 9001 / AS9100

- Supplied Documents: MTC (Material Test Certificate), Batch Traceability, Cleanliness Report

- Third-Party Testing: SGS / BV reports upon request

- OEM Support: Full compliance documentation for regulatory approval

Packaging & Global Delivery

- Cleanroom Packaging: Vacuum-sealed + double sterile bags

- Export Protection: Impact-resistant outer box, air and sea freight ready

- Delivery Commitment: Standard specs in stock + custom orders ready in as fast as 2 weeks

FAQ

Which international standards do your titanium cables comply with?

Chalco Titanium cables are manufactured from medical-grade titanium, fully compliant with ASTM F136 (Ti-6Al-4V ELI implant material) and aligned with ASTM B863 (titanium wire) and ISO 5832 series standards. Production is certified under ISO 9001 / AS9100, and we provide MTC (Material Test Certificate), batch traceability, and cleanliness reports.

Can you customize the length, structure, or clean-level processing?

Yes. We offer multiple stranding structures, including 1×7, 7×7, and 7×19, with diameters from 0.08–2.0 mm. Options include spool supply, cut-to-length segments, and clean-level processing (ultrasonic cleaning, alcohol rinse), with full documentation.

Are titanium cables MRI/CT compatible?

Yes. Titanium's low magnetic response ensures no interference with MRI or CT imaging, making it ideal for orthopedic cerclage and spinal fixation applications.

What is the minimum order quantity? Can you provide samples?

Standard MOQ is 10 m. We support small-batch testing, with sample delivery in as fast as 2 weeks, enabling faster product validation and registration.

How are the cables packaged and what is the delivery time?

All titanium cables are vacuum-sealed and double sterile-packed, with export-grade protective cartons. Standard sizes are in stock, and custom orders can ship in 2–4 weeks worldwide.