Titanium Clad Copper

Updated : Oct. 23, 2025We supply a full range of titanium clad bar, plate, tube, and wire with cladding thickness of 1.0–3.0 mm (customized thicker options available). End sealing, slot machining, and long busbar customization are also supported.

All products undergo dimensional inspection, cladding thickness measurement, and necessary UT/NDT testing before delivery. EN 10204 3.1 certificates are provided with each shipment.

Why choose titanium clad copper

- Copper core ensures excellent conductivity, reducing power loss and hot spots

- Titanium layer resists acids, alkalis, and chlorides, remaining stable even at liquid surfaces and spray zones.

- Fewer replacements and less downtime make the overall TCO more cost-effective than pure copper, stainless steel, or pure titanium.

- Available in round, square, rectangular, or custom cross-sections; cladding thickness, end sealing, slotting, and drilling can be processed on request.

- Inspection and certificates provided (such as UT, shear/peel strength, cladding-thickness map, EN 10204 3.1) for easy verification and traceability.

You don't have to choose between conductivity and corrosion resistance. Titanium clad copper guarantees performance, uptime, and lifetime cost savings.

Send us your drawings, and we will provide selection advice and a quotation the same day, along with a free sample to help you verify and place orders quickly.

Popular titanium clad copper products

We supply a full range of titanium clad copper products, including plate, bar, tube, wire, as well as cathode plates, conductive beams, and customized parts. Click the anchors below to quickly find the specifications you need.

- Cladding (titanium layer): Ti Gr1 / Gr2

- Core (copper): C11000 (ETP) / C10200 (OFHC)

- Clad process: explosive bonding / roll bonding

- Cladding thickness: 0.6–3.0 mm (typical 1.0–2.5 mm, customizable)

- Length: up to 12 m

- Medium/temperature: suitable for chlorides, acids, alkalis, and sea water

- MOQ/lead time: sample pieces and small-batch trials supported; expedited delivery available

Tell us your specifications and application needs (such as shape, size, or working environment), and we will quickly match the right solution, provide a detailed quotation, and offer sample support.

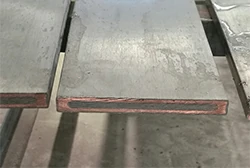

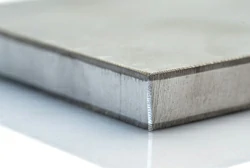

Titanium clad copper plate

Titanium clad copper plate is a bimetallic or multilayer composite plate manufactured by explosive bonding or roll bonding.

Contact us now

It uses high-conductivity copper (C11000 ETP / C10200 OFHC, >99% IACS, 58 MS/m) as the core, covered with titanium, combining the excellent conductivity of copper with the corrosion resistance of titanium.

- Titanium cladding thickness: 0.6 – 20.0 mm

- Copper core thickness: ≤100 mm

- Maximum single plate width: 2000 mm

- Maximum single plate length: 4000 mm

- Standards: ASTM B898, ASTM B432, GB/T 13238, QXB 1506-94, NB/T 47002, EN 13445-2

In addition to the common titanium–copper double-layer structure, we also offer three-layer composites and multilayer composites with stainless steel or nickel alloys, suitable for pressure vessels, electrochemical, and electrolytic equipment under complex conditions.

Three-layer composite

Three-layer composite

Three-layer composite

Titanium clad copper plate provides corrosion resistance, high conductivity, and strong bonding without delamination. We can produce wide, long, and heavy plates to fully meet the demanding requirements of pressure vessels, electrolytic cells, and large-scale equipment.

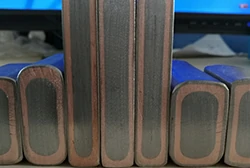

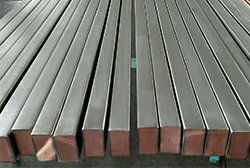

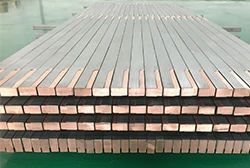

Titanium clad copper bar

Titanium clad copper bar is a conductive component designed for electroplating, SX-EW, chlor-alkali, and water treatment in highly corrosive environments.

Contact us now

It uses a high-conductivity copper core to ensure stable current distribution and low voltage drop, covered with a titanium layer that provides long-term corrosion resistance in acids, alkalis, chlorides, and seawater.

Formed by explosive bonding or roll bonding, it achieves metallurgical bonding with high strength, resisting delamination under thermal cycles, bending, and welding.

- Nearly 100% IACS conductivity reduces energy loss and voltage drop.

- Titanium layer resists strong corrosion, extends service life, and reduces downtime and maintenance.

- Metallurgical bonding withstands heat and load without delamination.

- Supports drilling, slotting, bending; titanium end-caps or weld seals prevent copper exposure.

- Standard: GB/T 12769

Available in multiple shapes with different cladding thickness and custom lengths to meet project needs.

| Shape | Size range | Typical application |

|---|---|---|

| Round bar | Ø6–78 mm | Cathode hanger, conductive link |

| Square bar | 20–40 mm | Structure / fixture |

| Flat bus bar | Thickness 6–30 mm, Width 20–150 mm | Bus bar / hanger bar |

Round Bar

Flat Bar

Square Bar

Flat Bar

Flat Bar

Custom Shapes

Titanium clad copper bars are widely used in electroplating lines, electrolytic plants, in combination with MMO/DSA anodes, and in any electrochemical environment requiring low voltage drop and high corrosion resistance.

Simply tell us your product dimensions and application needs, and our engineers will provide you with an accurate quotation and lead time right away.

Titanium clad copper tube

Titanium clad copper tube is a metallurgically bonded pipe with a high-conductivity copper core inside and a titanium cladding outside.

Contact us now

Titanium clad copper tube is a metallurgically bonded pipe with a high-conductivity copper core inside and a titanium cladding outside.

| Cladding | Ti Gr1/Gr2 |

|---|---|

| Copper core | C11000/C10200 |

| Cladding thickness | Typically 1.0–2.5 mm (customizable 0.6–4.0 mm) |

| Length | As per drawing (single long tubes available) |

| Ends | plain / threaded / bevel / titanium sealed ends / flare / flange |

| Processes | explosive bonding / roll bonding + drawing / forming |

- Copper core provides nearly 100% IACS conductivity, ensuring low voltage drop in pipelines and electrode supports.

- Titanium layer remains stable in chlorides, acids, alkalis, and seawater over the long term.

- Explosive bonding or roll bonding creates metallurgical bonding with high strength, resisting delamination.

- Weldable and machinable; titanium end-caps or weld seals prevent copper exposure in wet zones.

- Straight tubes, coils, U-bends, perforated or slotted tubes, and tubes with joints or flanges can be customized according to drawings.

Titanium clad copper tubes are widely used in electrolytic and electrochemical equipment as conductive or fluid pipelines, MMO/DSA electrode frameworks and outlet tubes, and in chlor-alkali and water treatment systems near liquid surfaces.

They perform excellently wherever low voltage drop and high corrosion resistance are required.

Just provide the basic parameters or drawings, and we will handle the rest. Our engineering team will confirm the best solution and deliver a fast quotation.

Titanium clad copper wire

Titanium clad copper wire uses a high-conductivity copper core covered with industrial pure titanium through metallurgical bonding, with the surface further coated with mixed metal oxides.

Contact us now

It combines low resistance with strong corrosion resistance, making it suitable for impressed current cathodic protection in highly corrosive media.

| Diameter | 1.5 mm(0.06") / 3.0 mm(0.12") |

|---|---|

| Supply form | straight, reel, pre-cut, or pre-bent |

| Applicable media | soil, mud, fresh water, brackish water, seawater |

- Cladding (titanium layer): Ti Gr1 / Gr2

- Core (copper): C10200 (OFHC) / C11000 (ETP)

- MMO coating: IrO₂ / Ta₂O₅ / RuO₂, customizable based on medium and load requirements

- TCC composite process: hot extrusion, hot extrusion + drawing, explosive bonding, explosive rolling

- OFHC copper core provides high conductivity, reducing cable resistance and potential gradient.

- Titanium substrate resists chlorine, acids, and alkalis, while the MMO coating remains stable in low pH and saline water.

- Service life can be significantly extended by increasing coating load or lowering operating current density.

- Suitable for direct burial in fine sand or carbon backfill, immersion in fresh water, brackish water, or seawater; can be wrapped on pipelines (continuous close CP), arranged in deep well strings, piggybacked under tank bottoms, or suspended in rings along tank walls.

- The wire can be connected, capped, and hot-pressed or welded to feeder cables, ensuring easy on-site installation.

Titanium clad copper cathode plate

Titanium clad copper cathode plates are designed for cathode backplates, current distribution plates, and electrode frames in highly corrosive electrochemical environments.

Contact us now

Titanium clad copper cathode plates are designed for cathode backplates, current distribution plates, and electrode frames in highly corrosive electrochemical environments.

The copper core provides low voltage drop and uniform current paths, while the titanium layer offers long-term resistance to chlorides, acids, alkalis, and seawater.

Explosive bonding or roll bonding creates metallurgical bonding with high strength, preventing delamination and supporting large sizes and complex perforations.

- Wide, long, and heavy plates available, reducing joints and hot spots.

- Supports drilling, slotting, beveling, stud welding, and titanium edge sealing to prevent copper exposure.

- UT, shear/peel tests, cladding-thickness maps, and EN 10204 3.1 certificates are provided.

- Standard: ASTM B898 (clad plate)

| Cladding(Ti) | 0.6–4.0 mm |

|---|---|

| Copper core | ≥8 mm |

| Maximum width | 3600 mm |

| Maximum length | 16000 mm |

| Forms | Flat plate, ribbed plate, window/slot plate, welded frame plate |

Cathode Plate

Cathode Plate

Cathode Plate

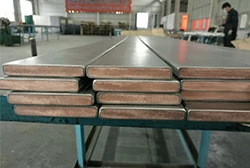

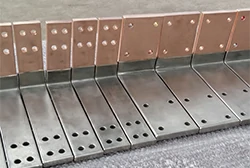

Titanium clad copper conductive beam

Titanium clad copper conductive beam carries high current without overheating, with titanium cladding for long-term corrosion resistance.

Contact us now

The two metals are firmly bonded together through special processes (explosive bonding or roll bonding), allowing the beam to bear loads and operate reliably for many years in humid and corrosive environments.

| Thickness | 10–30 mm |

|---|---|

| Width | 50–150 mm |

| Titanium cladding thickness | 1.0–3.0 mm |

| Core material | Cu C11000/C10200 |

| Length | Single piece ≤ 9–12 m |

| Processing | drilling, slotting, beveling; titanium end-caps / weld seals; polished contact surfaces |

- High-current long-distance power supply reduces hot spots.

- Stable in liquid, spray, and splash zones, with less downtime and better TCO.

- Meets deflection and straightness requirements for span and fixture loads.

- Titanium end-caps or seals in wet zones; holes, slots, and contact surfaces processed as required.

- Compatible with Ti-to-Ti clamps/shoes, insulating sleeves, lifting points, and lugs for easy on-site installation and maintenance.

Conductive Beam

Conductive Beam

Conductive Beam

Titanium clad copper customized parts

In addition to standard titanium clad copper bars, tubes, plates, and wires, we also manufacture customized parts based on customer drawings and operating conditions.

- Diverse shapes: flat strips, special profiles, welded assemblies, perforated/slotted parts, bent sections, flanges, and end pieces.

- Processing methods: CNC precision machining, drilling, slotting, bending, welding (Ti-to-Ti / Cu-to-Cu), titanium end sealing, and surface treatment.

- Size range: from small contact pieces to large bus beams up to 9–12 m; thickness, width, and cladding thickness can all be customized.

Customized titanium clad copper

Customized titanium clad copper

Customized titanium clad copper

Customized titanium clad copper

Customized titanium clad copper

Customized titanium clad copper

Upload your drawings or requirements, and we will immediately prepare a fast quotation plus free samples to help you move your project forward faster.

Titanium clad copper performance table

Under typical explosive bonding parameters, the titanium–copper interface reaches strength levels of about σₜ ≈ 250 MPa (tensile), σf ≈ 230 MPa (shear), and σbt ≈ 196 MPa (bending interface).

After subsequent heat treatment at 550–650 ℃, the shear strength remains in the range of 147–203 MPa.

Whether in high-current electrolytic cells or in applications with frequent thermal cycling and installation, titanium clad copper maintains stable performance without delamination or failure, ensuring long-term reliable operation of equipment.

Table 1. Technological parameters and bonding strength of explosive welding Titanium Clad Copper plate

| Cladding material | Base material | h₀ / mm | Wg / (g·cm⁻²) | σₜ / MPa | σf / MPa | σbt / MPa | ||

|---|---|---|---|---|---|---|---|---|

| Metal | δ₁ / mm | Metal | δ₂ / mm | |||||

| Copper | 2.5×710×710 | Titanium | 10×700×700 | 4 | 1.4 | 250 | 230 | 196 |

Table 2. Technological parameters and shear strength of explosive welding of Titanium Clad Copper plate

| Cladding material | Base material | h₀ / mm | Wg / (g·cm⁻²) | σt / MPa | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Metal δ₁ / mm | Metal δ₂ / mm | - | - | 1 | 2 | 3 | 4 | 5 | 6 | Average | ||

| Titanium | 3 | Copper | 6 | 5 | 1.4 | 215 | 191 | 208 | 209 | 202 | 195 | 203 |

| Titanium | 3 | Copper | 6 | 5 | 1.4 | 193 | 198 | 194 | 181 | 135 | 121 | 170 |

| Titanium | 3 | Copper | 6 | 5 | 1.4 | 144 | 150 | 142 | 147 | 157 | 137 | 147 |

Do you need test plans and acceptance standards for your project?

Provide drawings and operating parameters, and we will deliver selection advice, performance commitments, inspection lists, and sample pieces for verification.

Customer success cases

Plating line retrofit

In a plating production line, we replaced heavily corroded copper components with titanium clad copper conductive beams and bus bars.

Result: downtime was reduced by about 40–60%, current distribution became more stable, and coating thickness was more uniform.

SX-EW electrolytic plant (long-span bus bars)

In an SX-EW copper plant, the customer adopted our titanium clad copper bus bars to replace the traditional stainless steel solution.

Result: voltage drop decreased by about 30–50% (under equal cross-section and current conditions), insulation repairs in wet areas were significantly reduced, and operating temperature rise was lower.

Water treatment electrochemical reactor (with MMO/DSA)

In an electrochemical water treatment system, we supplied titanium clad copper connectors with titanium end-cap design.

Result: copper exposure and corrosion were completely eliminated, annual maintenance was limited to visual checks and voltage inspections, and overall maintenance costs dropped significantly.

Note: actual improvement varies depending on the original system condition, cross-section design, current, and environment. The above data comes from real project experience, and detailed test records can be provided for bidding or technical discussions.

How is titanium clad copper made?

Explosive bonding

Explosives are placed between copper and titanium. A controlled explosion generates a high-speed shock wave, forcing the two metals to collide in the solid state and form a wavy metallurgical interface.

- High interfacial bonding strength (typical shear strength ≥150 MPa).

- Suitable for large-size and thick billets.

- Resistant to delamination with good thermal cycle performance.

Typical applications: large bus bars, conductive beams, back plates, and other thick-section components.

Roll bonding (hot rolling / cold rolling)

Titanium and copper are stacked together and repeatedly rolled at high or room temperature. Through plastic deformation and diffusion, a metallurgical bond is formed.

- Uniform interface, suitable for large panel production.

- High production efficiency with relatively low cost.

Typical applications: plates, flat bars, and strips, suitable for electrolytic cell cathode plates and PCB plating bus bars.

Combined process: explosive + rolling

Large billets are first bonded by explosive welding, then reduced to the required thickness through hot rolling or groove rolling.

- Combines the high bonding strength of explosive welding with improved surface quality from rolling.

- Suitable for wide plates and thick flat bars.

Typical applications: thick plates, flat bars, and large bus bars produced to standards such as ASTM B898 or GB/T 12769.

Hot extrusion + drawing

Titanium–copper composite billets are heated and extruded through a die to form bars, tubes, or wires. They are then cold-drawn or drawn with a floating mandrel to improve dimensional accuracy and surface quality.

- Good surface finish and high dimensional precision.

- Better bending performance than single extrusion.

- Suitable for mass production and one of the mainstream methods in the market.

Typical applications: bars, wires, and tubes, especially for plating fixtures, hangers, and electrode wires.

Processing and services

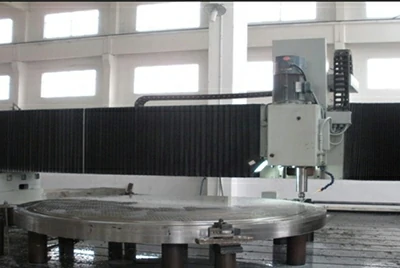

We have extensive experience in manufacturing stainless steel, titanium, nickel, steel, and copper composites.

With deep knowledge of various application scenarios, we can quickly match the right solution to ensure project success.

- Cutting / leveling / straightening: guarantee dimensions and straightness, meeting the installation requirements of long bus bars and conductive beams in electrolytic cells.

- Machining / drilling / slotting: use special tools and proper feeds to avoid tearing the titanium layer; all machining is preferably done before end sealing.

- End-sealing: after machining, ends are weld-sealed or capped with titanium to fully isolate the copper core and prevent copper exposure in wet zones.

- Provide Ti-to-Ti welding (preferred in wet zones/liquid surfaces) and Cu-to-Cu connections arranged in dry areas, ensuring long service life and low contact resistance.

Just send us your drawings or application parameters, and we will provide integrated processing, welding, and inspection services—ready to use upon delivery with no secondary treatment required.

Quality control & testing

- We strictly follow international and national standards (GB/T, ASTM, etc.) to ensure titanium clad copper products meet requirements for conductivity, corrosion resistance, and structural strength. Main tests include:

- Bending test: 90° bending per GB/T 232 and ASTM E190, verifying no delamination or cracking.

- Metallographic analysis: optical microscope per GB/T 6394 and ASTM E112, checking interface bonding quality and grain size.

- Cupping test: per GB/T 4156, evaluating material ductility.

- Chemical analysis: O/N/H analysis per GB/T 4698 and ASTM E1409/E1447, ensuring raw material purity.

- UT testing: per GB/T 12969.2, 100% inspection of interface delamination and internal defects.

- Dimensional check: optical measuring instruments for precise control of dimensional tolerances.

- Leak test: per ASTM B338, ensuring no leakage defects in tubes.

- Mechanical test: universal testing machine per GB/T 228 and ASTM E8, measuring tensile strength and elongation.

- Hardness test: Vickers hardness per GB/T 4340 and ASTM E384.

We are equipped with advanced titanium clad copper production and testing facilities, covering the entire process from billet preparation and precision machining to final inspection.

We provide full production with integrated testing, machining, and quality control, delivering titanium clad copper parts that are certified, ready to use, and built for long-term reliability.

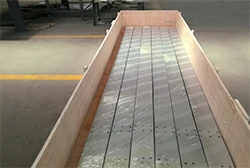

Packaging, transportation & flexible payment

- All product ends are protected against impact and scratches, with full-length anti-moisture film (VCI rust-proof film) wrapping, plus wooden box fixation to ensure safe transport without damage.

- Wooden boxes are marked with orientation and lifting signs to support safe storage and installation.

- Small batches or short samples can be delivered quickly for on-site ΔV, thermal imaging, and corrosion resistance verification.

- Large orders can be delivered in batches according to factory planning, reducing one-time inventory pressure and ensuring continuous project supply.

- Complete factory records are provided, including size, material, cladding thickness inspection sheets, EN 10204 3.1 certificates, and NDT reports (if required).

- Installation and maintenance guides are included for direct use by the customer.

We support multiple international trade payment methods (T/T, L/C, etc.) and can arrange flexible terms based on the customer's country and project requirements.

Titanium clad copper price & cost

Want to know the titanium clad price and titanium clad cost?

We offer factory-direct titanium clad copper plate, bar, tube, and wire with customizable specifications, supporting both project sampling and mass production.

If you are looking for a reliable supplier of titanium clad for sale, you can contact us directly today.

Simply upload your drawings or provide key parameters (shape, size, cladding thickness, rated current, medium, and temperature), and we can offer a same-day budgetary quotation and send a free sample segment for on-site conductivity and corrosion resistance verification.

Whether for small-batch testing or large-scale projects, we provide both standard and expedited lead times, along with complete quality documentation (EN 10204 3.1, UT/mechanical reports, etc.) and secure packaging and transportation solutions.

Related products – clad metals solutions

Explore more clad metal solutions—besides copper-aluminum composite, we also supply titanium clad copper, copper clad steel, aluminum clad steel and other tailored combinations to match your industry needs.

Copper Clad Steel

Copper Clad Aluminum

Aluminum Clad Steel

Titanium Clad Aluminum

Titanium Clad Nickel

Titanium Clad Steel

Click to view our clad product page, featuring all titanium clad materials.

FAQ – titanium clad copper

What's the difference between copper and copper clad?

Pure copper has excellent conductivity but poor corrosion resistance. Titanium clad copper keeps the conductivity of the copper core while the titanium cladding provides long-term protection in corrosive environments.

Is copper titanium cookware safe?

Our products are industrial-grade titanium clad copper, used in electroplating, SX-EW, and water treatment—not cookware.

For cookware, "titanium copper” usually refers to a different consumer-grade process.

What is a titanium clad?

Titanium clad copper is a bimetal composite: high-conductivity copper (C11000 / C10200) inside, titanium Grade 1 or 2 outside.

They are metallurgically bonded by explosive welding or roll bonding.

How do I choose the right cladding thickness?

Most plating and SX-EW lines use 1.0–2.5 mm. For continuous immersion or strong oxidizing conditions, we recommend thicker cladding.

We'll size it precisely based on your current density and bath chemistry.

Can you ensure no exposed copper at cut edges or holes?

Yes. We provide titanium end-caps, weld seals, and edge protection solutions.

How can I compare with pure copper in terms of cost?

Focus on ΔV/energy use, maintenance stops, and service life. We provide a TCO calculator and one-page evaluation templates.